Patents

Literature

165results about How to "Anti-rust for a long time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antirust oil and preparation method thereof

The invention provides antirust oil, which comprises the following components in percentage by weight: 75 to 87.5 percent of base oil, 1 to 3 percent of complex ester, 4 to 10 percent of barium petroleum sulfonate, 2 to 6 percent of barium dinonyl sulfonate, 0.5 to 1.5 percent of dodecylene succinic acid, 0.3 to 0.8 percent of benzotriazole and 3 to 6 percent of di-n-butyl phthalate, wherein the complex ester is obtained by reacting raw materials comprising polyalcohol and dicarboxylic acid. The antirust oil provided by the invention has the advantages of oil-film antirust oil and soft-film antirust oil and long antirust time. A workpiece coated with the antirust oil can be directly put into use without being cleaned or being provided with an additional lubricating additive. The antirust oil can be applied to long-term rusting protection of metal workpieces, such as internal surface rusting protection of engines, gearboxes and pumps.

Owner:KASONG SCI & TECH

Antirust and preparation method and application thereof

ActiveCN107163844AAnti-rust for a long timeImprove anti-rust effectWax coatingsAnti-corrosive paintsSolventChemistry

The invention discloses an antirust and a preparation method and an application thereof. The antirust comprises corrosion inhibitor, film-forming agent, dispersant, synergist with active groups on the surface, and solvent; the weight ratio of the corrosion inhibitor, the film-forming agent, the dispersant and the synergist with the active groups on the surface is 1:0.005 to 0.5:0.002 to 0.4:0.001 to 0.3, and the weight ratio of the solvent to the corrosion inhibitor is 100:0.01 to 50. Modifier is added into the antirust disclosed by the invention to carry out surface modification treatment on the synergist, so that the surface of the synergist is grafted with the active functional groups, such as -OH and -NH3, consequently, the binding force between the antirust and a base material is enhanced, the antirust time is prolonged, and thereby the antirust effect is enhanced. The antirust disclosed by the invention is basically applicable to the surfaces of various iron-based, aluminium-based and copper-based materials, moreover, brushed, sprayed or immersed base materials have excellent corrosion resistance, durability and high adhesive force; the process of the preparation method is mature, the production cost is low, the production process is green and harmless, and therefore the preparation method is suitable for popularization and application on a large scale.

Owner:上海特德拉化工有限公司

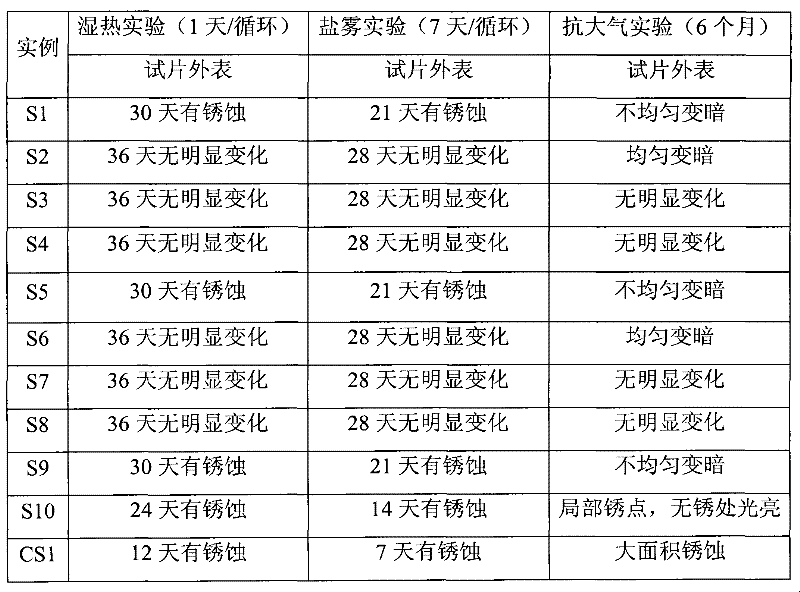

Rust preventive oil and preparation method thereof

The invention provides a rust preventive oil. The rust preventive oil comprises a composite antirust agent and base oil. The composite antirust agent is a mixture of a rare earth-beta-dione complex and at least one of barium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate, barium dinonylnaphthalene sulfonate, barium heavy alkyl benzene sulfonate, non-barium heavy alkyl benzene sulfonates, a lanolin magnesium soap, a lanolin aluminum soap, aluminium stearate, a oxidized petroleum ester barium soap and zinc naphthenate. The invention also provides a preparation method of the rust preventive oil. The preparation method comprises putting the base oil into a reaction vessel, adding the composite antirust agent into the base oil, stirring the mixture with heating to dehydrating the mixture, and then filtering to obtain the rust preventive oil. The rust preventive oil prepared by the invention can keep a rust-preventing effect for a long time in three environments of a temperature and humidity experiment, a salt spray experiment and an atmospheric corrosion resistance experiment, and thus can satisfy needs.

Owner:BYD CO LTD

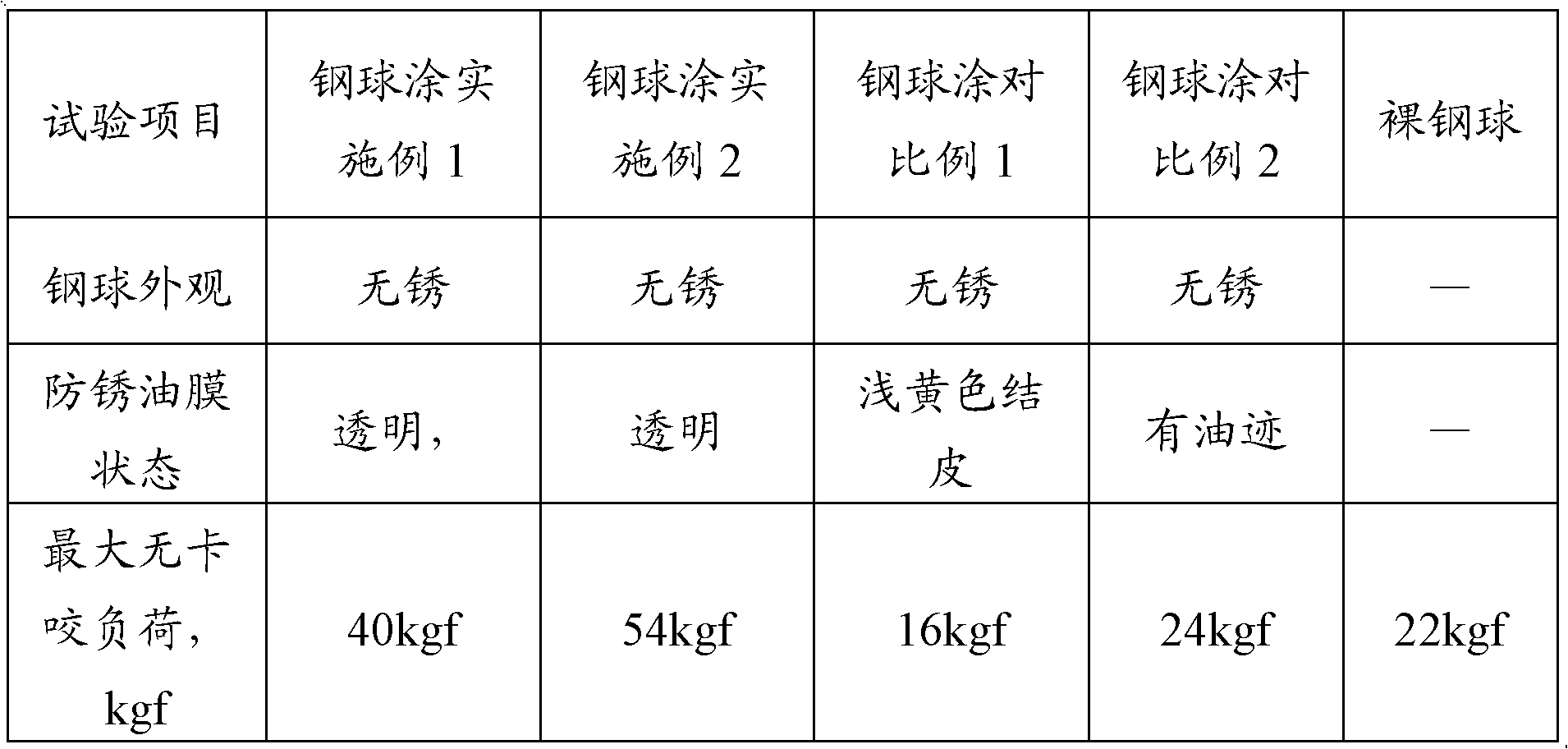

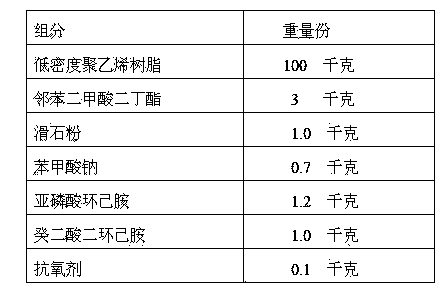

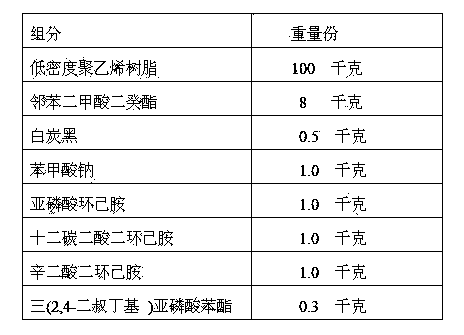

Vapor phase antirust blown polyethylene film and making method thereof

The invention discloses a vapor phase antirust blown polyethylene film and a making method thereof. The vapor phase antirust blown polyethylene film comprises low density polyethylene resin, a plasticizer, an auxiliary filler, sodium benzoate, cyclohexylamine phosphate, amine salt of aliphatic dibasic acid, and an antioxidant. Polyethylene materials comprising vapor phase antirust agents are utilized to make the vapor phase antirust blown polyethylene film through a blowing production process in order to realize convenient production and vapor phase antirust effects. The vapor phase antirust agents adopted in the invention are different from traditional nitrite vapor phase antirust agents, are in favor of realizing environmental protection and benefiting the health of human bodies. The film made in the invention has the advantages of composite structure, obstruction of the outward penetration of the vapor phase antirust agents, antirust effect increase and antirust time prolongation.

Owner:YANTAI HENGDIKE ENERGY TECH

Method for preparing release-type metal vapour-phase rust preventative

The invention relates to a method for preparing environment-friendly release-type metal vapour-phase rust preventative. By means of the effect that cyclodextrin can well include and slowly release the medicament, the medicament includes the active ingredients in vapour-phase rust preventative in cavity of beta-cyclodextrin or a derivative of the beta-cyclodextrin. The mass ratio of the used beta-cyclodextrin or the derivative of the beta-cyclodextrin to the metal vapour-phase rust preventative is 1-2:1. The product can be made into powder, liquid or tablets, directly used for metal rust prevention and particularly used for manufacturing of anti-rust papers and plastic anti-rust films. The product has the following advantages that: 1, the product is safe, environment-friendly and convenient; 2, the product has long-acting and slow-release effect and the rust protection time can be greatly prolonged; and 3, the product can improve the stability and the heat-bearing capacity for the rust preventative and is particularly suitable for the process for manufacturing the anti-rust papers and the plastic anti-rust films.

Owner:XIANYANG DEBANG CHEM ENG TECH

Water-based antirust agent and preparation method thereof

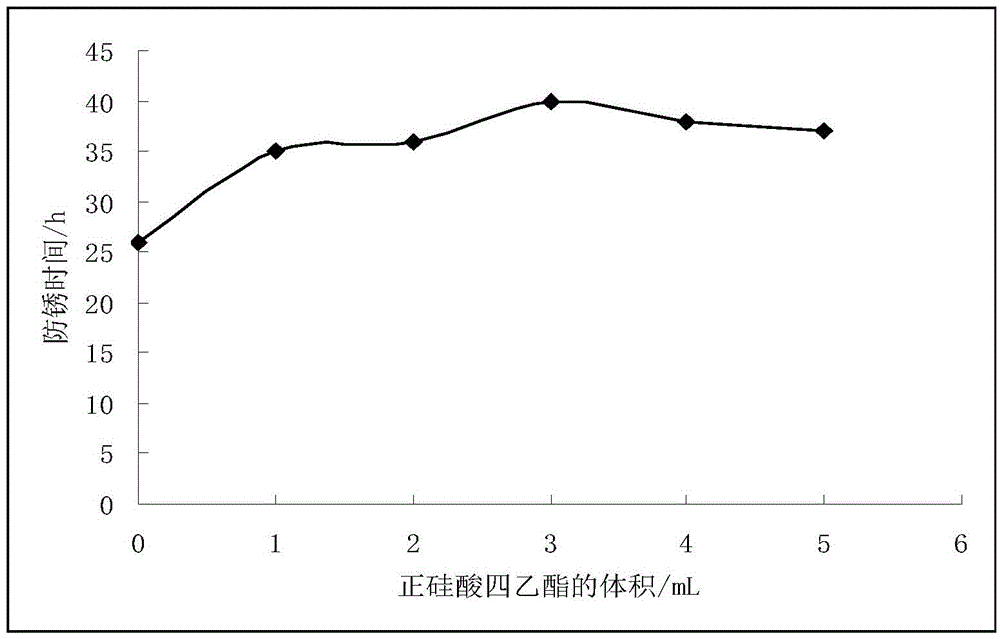

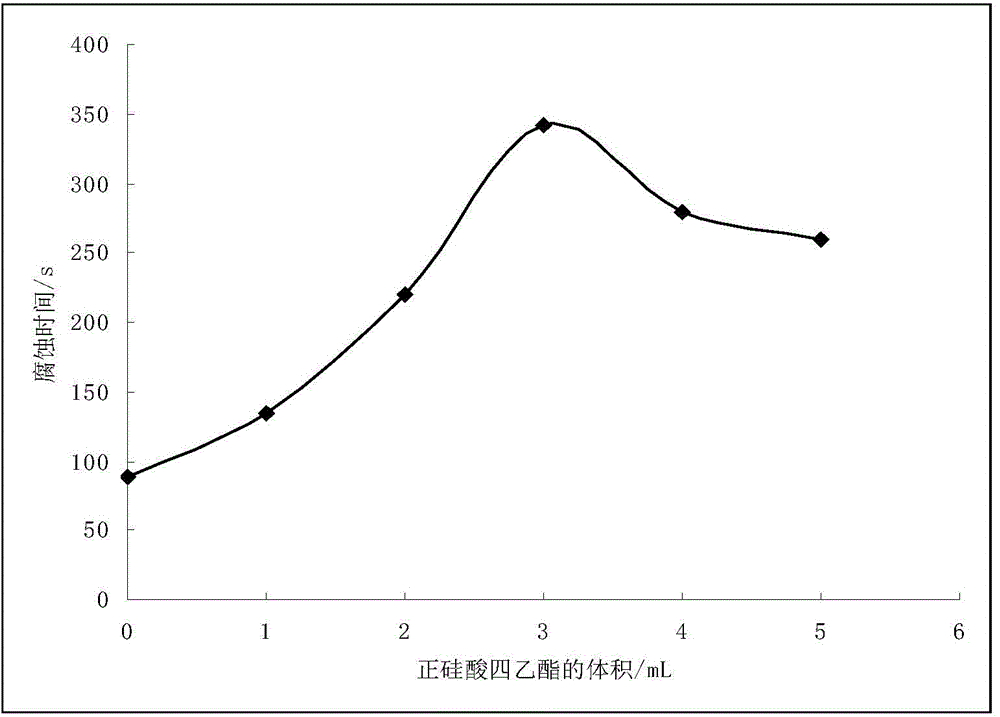

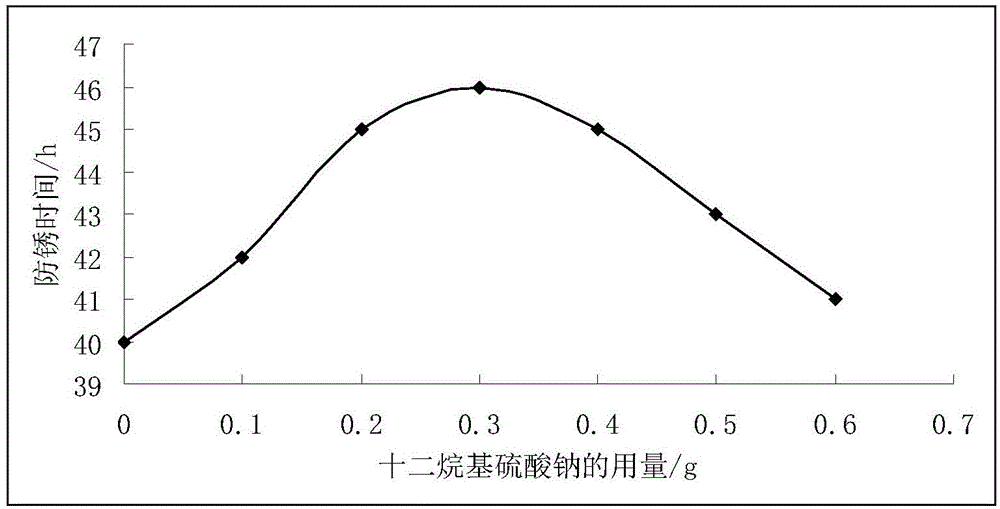

The invention discloses a water-based antirust agent and a preparation method thereof. The water-based antirust agent is prepared from silicate, organic alkali, boric acid and / or boric acid ester, a complexing agent, tungstate, orthosilicate ester and a surface active agent. The raw material source is wide, the preparation method is simple, the production cost is low, the rust-proof effect is good, and the effect duration is long.

Owner:河南索顿新材料有限公司

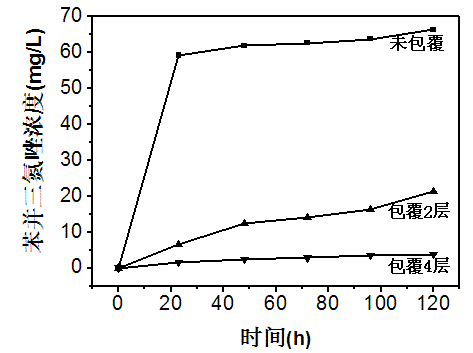

Preparation method for sustained-release type volatile rust preventive paper

InactiveCN104005304ASmall particle sizeReduce releaseSurface covering paperPaper coatingPolyelectrolyteHalloysite

The invention relates to a preparation method for sustained-release type volatile rust preventive paper. According to the invention, a halloysite nanotube of a hollow structure is used as a carrier, a volatile antirust agent is adhered on the surface of the carrier and loaded in the cavity of the carrier in virtue of strong adsorption ability of surfaces of the particles of the halloysite nanotube and the cavity structure, and a polyelectrolyte is used for coating, thereby obtaining a halloysite nanotube-volatile antirust agent compound; the halloysite nanotube-volatile antirust agent compound is compounded with a polymer emulsion, modified starch and the like, an obtained compound coats the surface of paper, and drying and press polish are carried out so as to obtain the volatile rust preventive paper with a sustained-release function. Since the volatile antirust agent is adhered on the surface of the halloysite nanotube and loaded in the cavity of the halloysite nanotube and coated by the polyelectrolyte, the release of the volatile antirust agent is controlled, so antirust time of the rust preventive paper is greatly increased; heat capacity of the volatile antirust agent is improved, so loss of the volatile antirust agent during preparation of the rust preventive paper is greatly reduced.

Owner:SOUTH CHINA UNIV OF TECH

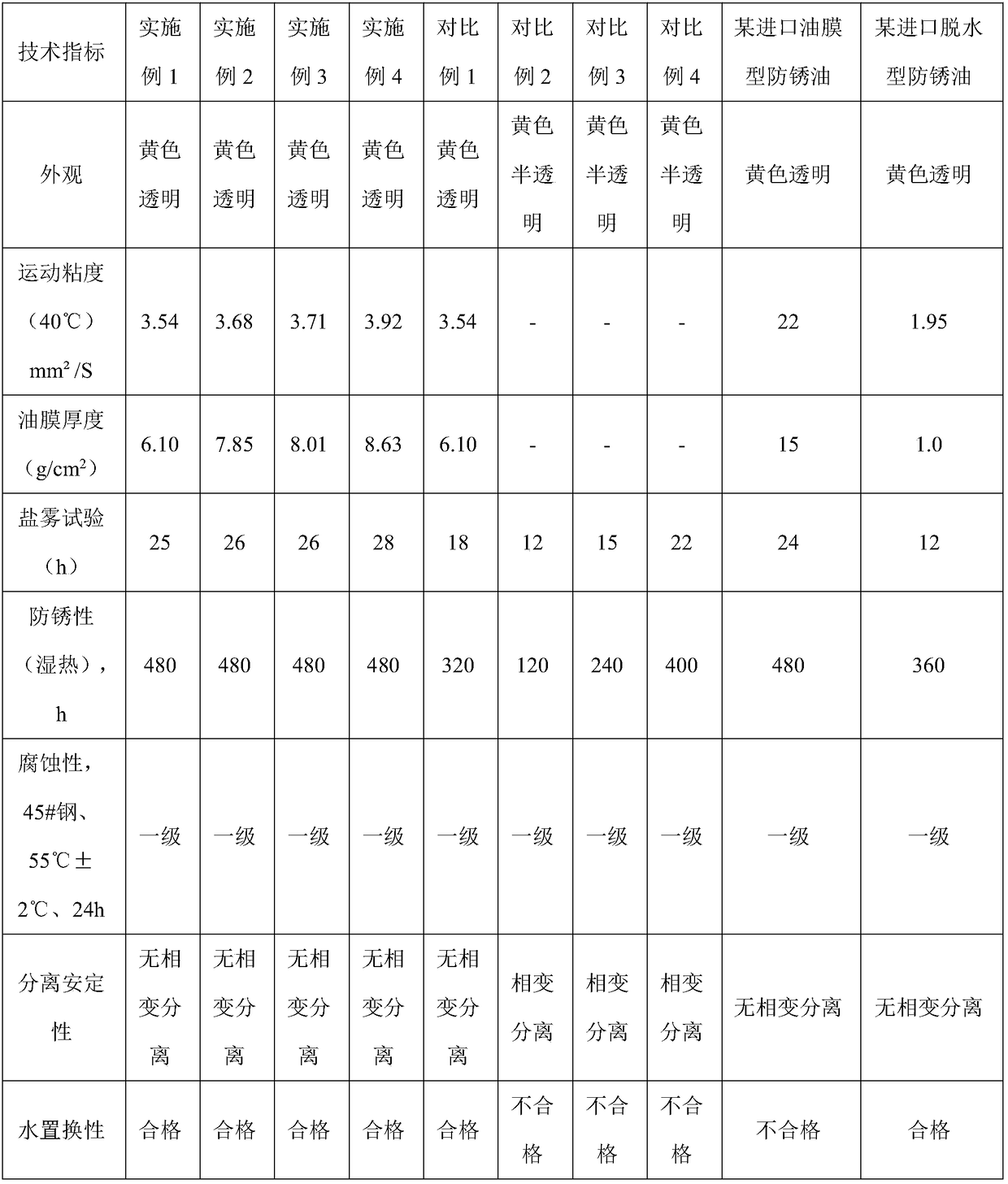

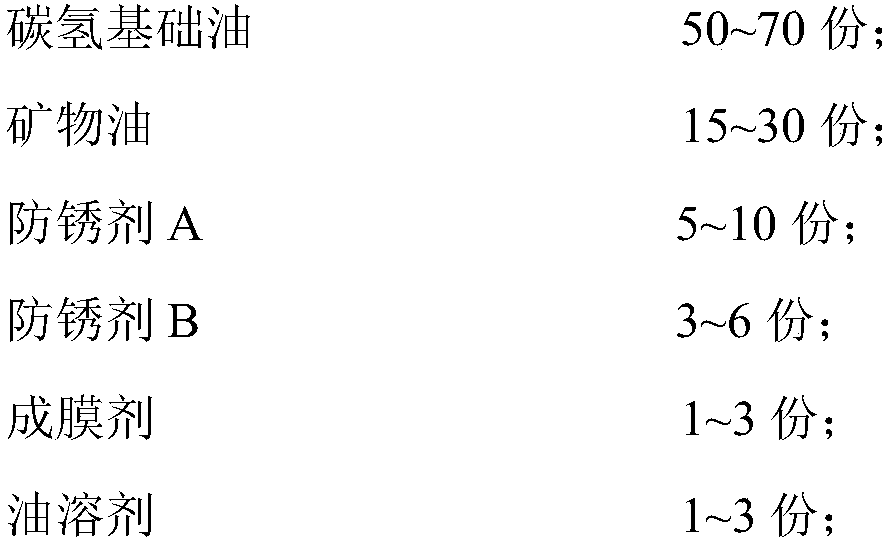

Preparation method of multifunctional antirust oil and multifunctional antirust oil

The invention discloses a preparation method of multifunctional antirust oil and multifunctional antirust oil. The preparation method of the multifunctional antirust oil comprises the following steps:S10, providing base oil, mineral oil, a film forming agent, an oil solvent, a rust inhibitor A and a rust inhibitor B, dissolving the rust inhibitor A and the film forming agent in mineral oil to prepare a mixture; S20, dispersing the oil solvent, the rust inhibitor B and the base oil in the mixture to prepare the multifunctional antirust oil, wherein the rust inhibitor A is any one or a mixtureof at least two of barium petroleum sulfonate, calcium petroleum sulfonate, sodium petroleum sulfonate and barium dinonylnaphthalenesulfonate, and the rust inhibitor B is any one or a mixture of at least two of dodecenylsuccinic acid, dodecenylsuccinate, antirust agent T-703 and zinc naphthenate. The raw materials are added in a specific adding sequence, the rust inhibitor A and the rust inhibitorB are added in two steps, and the multifunctional antirust oil with suitable viscosity, oil film thickness, rust resistance, anti-corrosion property, separation stability and water replacement property is prepared.

Owner:广州兴产新材料科技有限公司

Metal antirust inhibitor and preparing method thereof

The invention provides metal antirust inhibitor and a preparing method thereof. The antirust inhibitor comprises sodium silicate, sodium polyacrylate, mercaptobenzothiazole, benzotriazole, sodium tripolyphosphate, hexamethylenetetramine, imidazoline, alkyl amino alcohol, furfural, polyphosphates, cholamine, sodium borate and ethyl alcohol. The preparing method includes the steps that firstly the sodium silicate, the sodium polyacrylate, the mercaptobenzothiazole, the benzotriazole, the sodium tripolyphosphate, the hexamethylenetetramine, the imidazoline, the alkyl amino alcohol, the furfural, the cholamine and the ethyl alcohol are mixed and heated to be 50 DEG C-60 DEG C, and then the polyphosphates and the sodium borate are added; and the mixture is continuously heated to be 85 DEG C-90 DEG C, heat preservation is conducted on the mixture for 2-3 hours, and then the metal antirust inhibitor is obtained after being cooled naturally. The antirust inhibitor is good in compatibility with all materials, and the antirust time is long and can reach 4-6 hours; and adaptability to copper and aluminum is good, and slow-release rust resistance is achieved while a membrane is formed on the surface of metal, so that the antirust time is prolonged.

Owner:杨洋

Metal antirust agent

InactiveCN102977717AGood compatibilityAnti-rust for a long timeAnti-corrosive paintsWaxPOLYETHYLENE WAX

The invention discloses a metal antirust agent. The metal antirust agent is prepared from the following raw materials, by weight, 2-5 parts of urea, 5-8 parts of liquefied paraffin, 3-5 parts of tri(2-ethylhexyl)acetocitrate, 4-6 parts of acrylic acid, 0.2-0.3 parts of zinc powder, 3-5 parts of epoxy cottonseed oil, 2-3 parts of xylene, 3-5 parts of polyethylene wax, 0.2-0.3 parts of potassium persulphate, 0.3-0.5 parts of borax, 1-2 parts of polyisobutylene, 1-2 parts of 2-aminoethylheptadecenylimidazoline, 1-2 parts of benzotriazol, 0.5-1.5 parts of N-phenyl-2-naphthylamine, 0.6-1.2 parts of zinc dialkyl dithiophosphate, 1.2-1.7 parts of polyvinyl alcohol, 0.8-1.2 parts of polyethylene glycol, 1.2-1.8 parts of propylene glycol, 1.8-2.3 parts of polyoxyethylene octylphenol ether and 100-110 parts of water. The antirust time of the metal antirust agent is long and can reach 4-6 months, and the metal antirust agent can well adapt to copper and aluminum and can form a film on the metal surface when sustained release rust prevention is carried out, so the antirust time of the metal antirust agent is prolonged.

Owner:储勇明

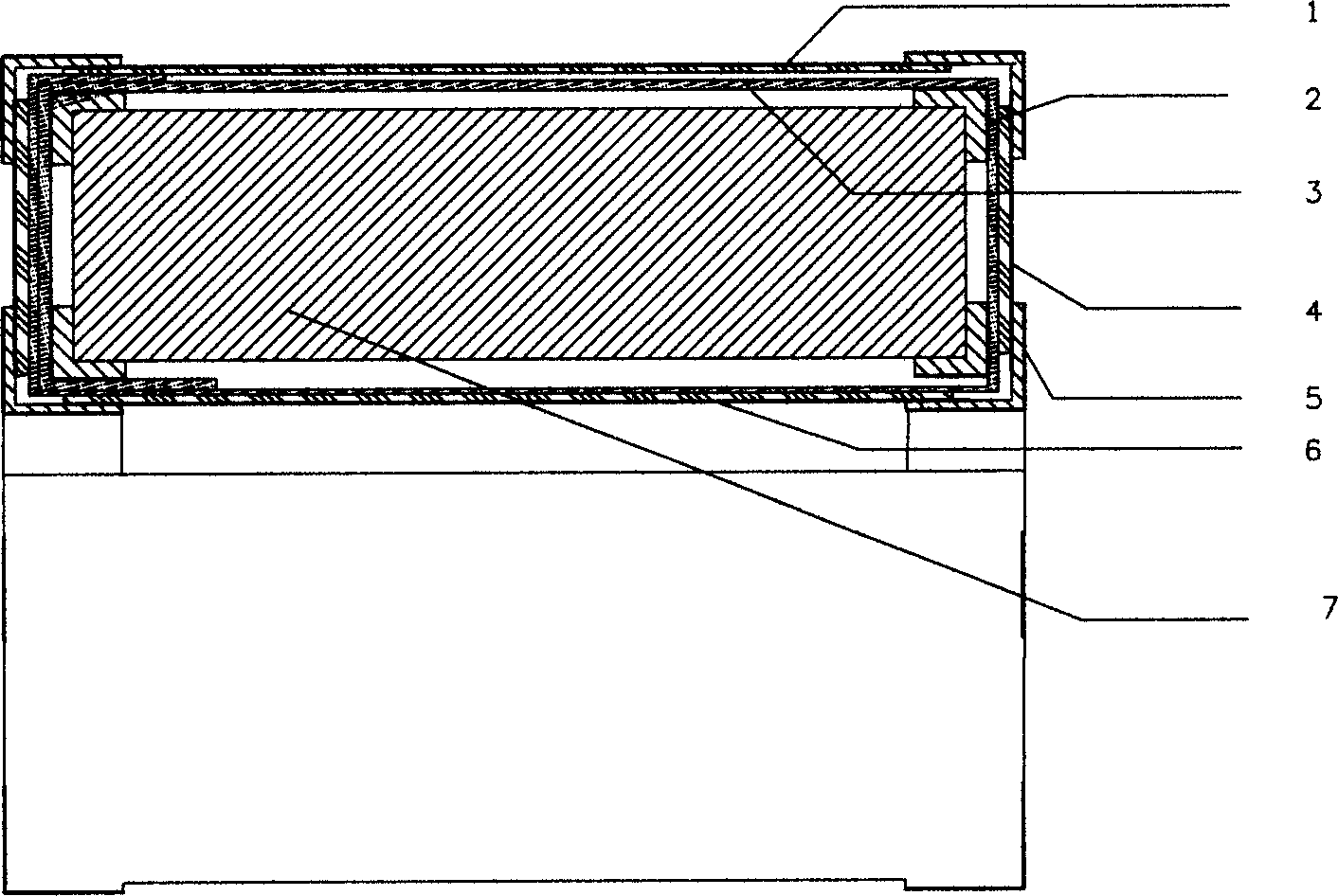

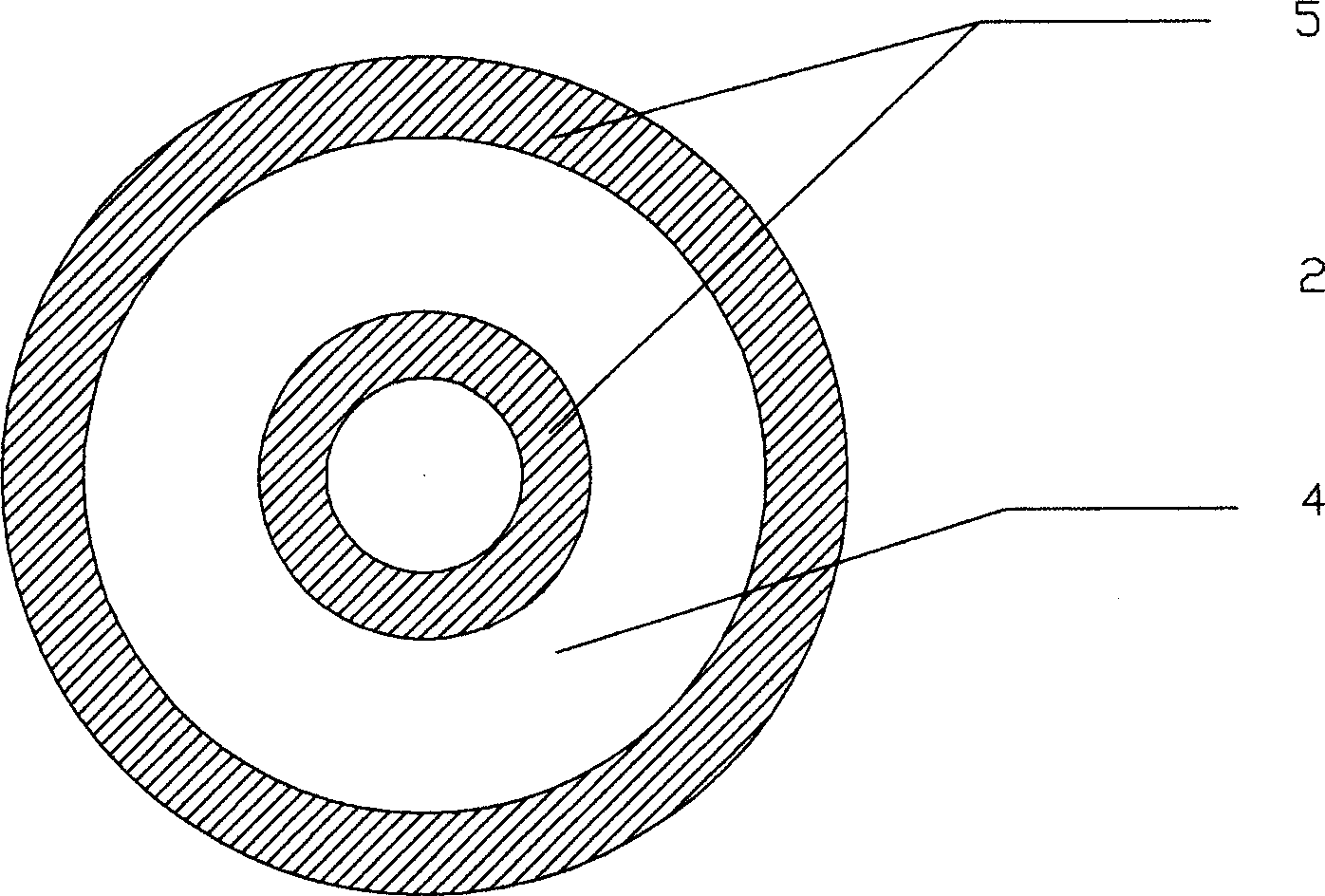

Packaging material for roll material and its packaging method

InactiveCN1380229AExcellent anti-rustImprove waterproof performancePaper article packagingFlexible coversFiberEngineering

The present invention relates to a packaging material for coiled material and its packaging method. It uses industrial composite packaging film, protection plate, end protection plate and metal protective corner as packaging material, and is characterized by that the industrial packaging film is formed from three layers of water-proofing layer, reinforcing layer and rust-proofing layer through the process of co-extrusion, its protection plate and end protection plate adopt the composite fibre packaging plate with water-proofing property. Said invention also provides the use method of these packaging material, and its packaging effect is good and solves the problem of resisting rust for coiled material.

Owner:鞍山市煜辉包装材料有限公司

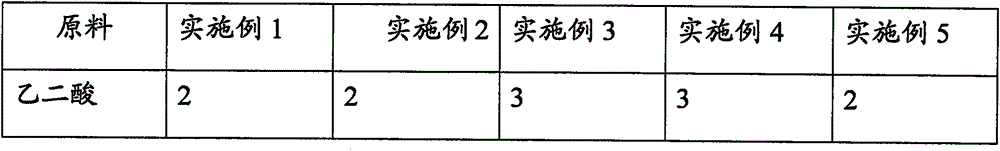

Water-soluble antirust agent

The invention provides a water-soluble antirust agent. The water-soluble antirust agent is prepared from fatty acid, specific amine, an additive, ethyl alcohol and water. The mass ratio of the fatty acid to the alcohol amine to the additive to the ethyl alcohol to the water is (2-3):(1-15):(5-10):(10-15):(80-100). The fatty acid is selected from one or more of oxalic acid, valeric acid, naphthenic acid, citric acid, benzoic acid, lauric acid, adipic acid, oleic acid and sebacic acid, the apecific amine is selected from one or more of octanoic acid dicyclohexylamine, triethanolamine, diethanol amine and ethanol amine, and the additive is an antioxidant. The antirust valid period of the water-soluble antirust agent is long and can reach 3-6 months; an antirust film is thin and is only tens of microns thick, a follow-up process cannot be influenced even though the antirust film is not removed, and the film can be removed with warm water due to the good film removability of the water-soluble antirust agent; and the water-soluble antirust agent is low in production cost, free of foreign smells and beneficial to environmental protection.

Owner:彭国泉

Multifunctional phosphating solution, and preparation method and application thereof

InactiveCN103397324AHigh hardnessStrong impact resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a multifunctional phosphating solution and a preparation method and application thereof. The multifunctional phosphating solution comprises liquid A and liquid B and is characterized in that a ratio of the liquid A to the liquid B in the multifunctional phosphating solution is 1: 0.1-1. The liquid A comprises the following substances, by mass, 26 to 48 parts of diammonium phosphate, 0.9 to 12 parts of phosphoric acid with a concentration of 85%, 0.8 to 1.8 parts of metal powder, 0.6 to 1.4 parts of animal glue, 0.4 to 10 parts of calcined gypsum powder and 0.3 to 0.8 part of alum, with the balance being water. The liquid B comprises the following substances, by mass, 20 to 46 parts of zinc dihydrogen phosphate, 38 to 55 parts of zinc nitrate, 2 to 3.8 parts of sodium fluoride, 2 to 4 parts of zinc oxide and 2 to 6 parts of phosphoric acid with a concentration of 85%, with the balance being water. The multifunctional phosphating solution provided by the invention is composed of the liquid A and the liquid B, can realize removal of oil and rust at the same time and has the efficacy of rust protection, heat insulation, high temperature resistance, heat preservation, flame retardation, noise abatement, shock prevention, isolation, pollution cleaning and resistance to fire. The multifunctional phosphating solution has the following beneficial effects: a fast rust removal speed, great thickness of a formed film, long antirust time, etc.

Owner:李春清

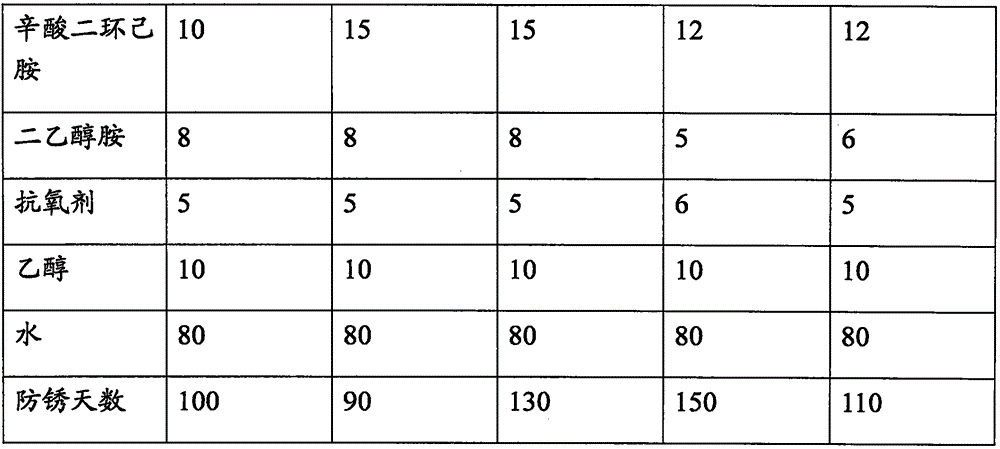

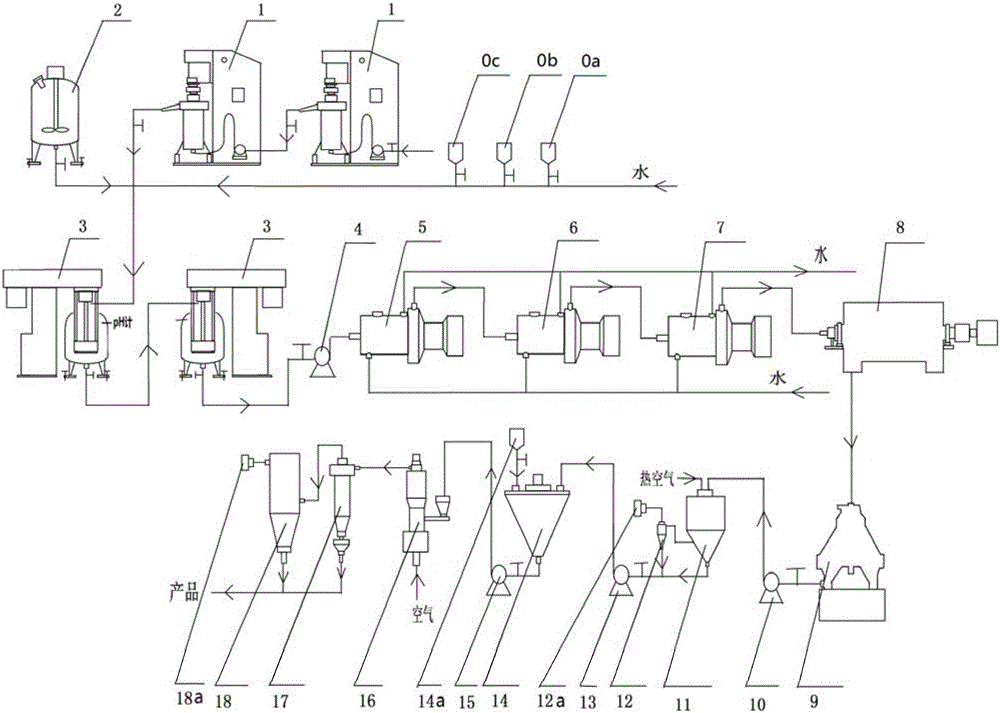

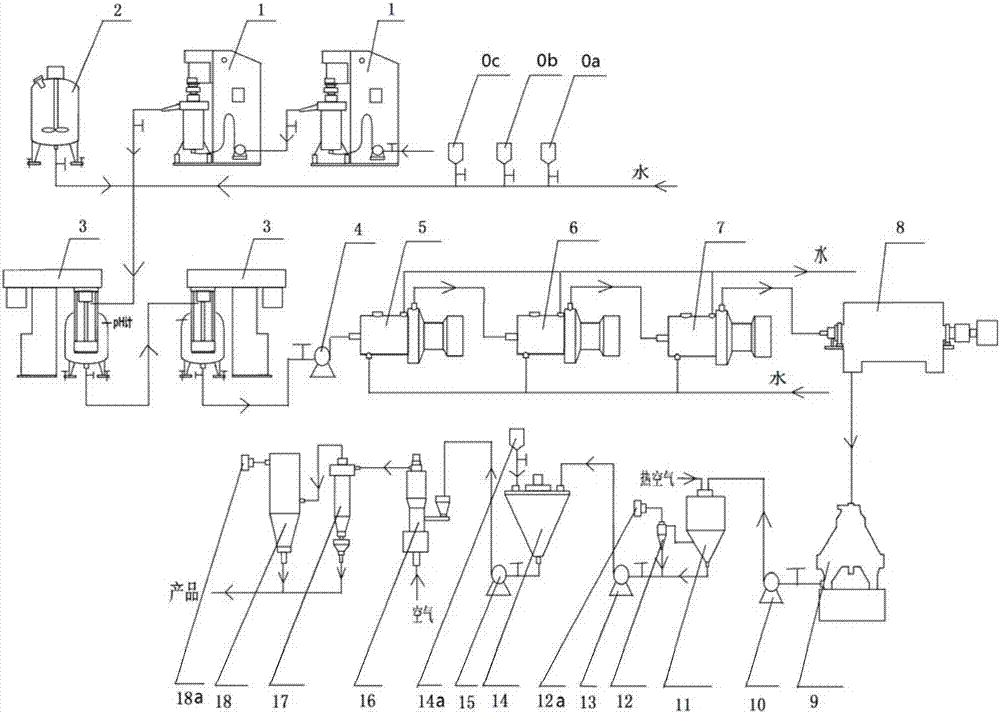

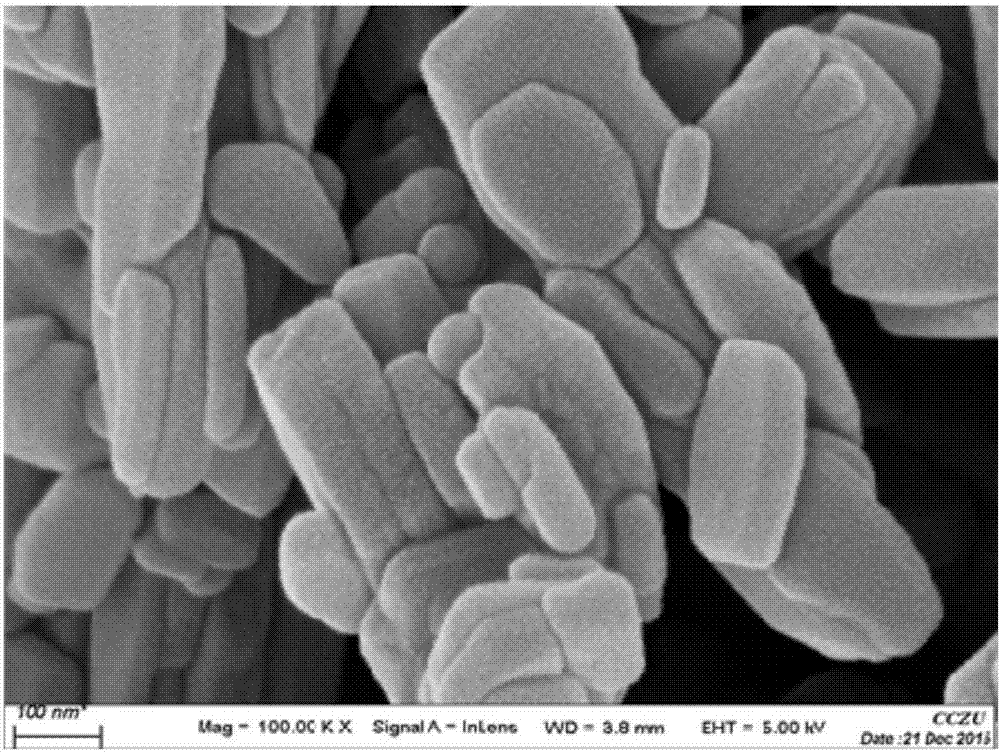

Nanometer zinc phosphate antirust pigment continuous production method and device

InactiveCN105694570AGood uniformityIncrease productivityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsAutomatic controlPhosphoric acid

The invention provides a nanometer zinc phosphate antirust pigment continuous production method and device. Zinc oxide and phosphoric acid are used as raw materials, under the synergistic effect of multiple auxiliaries such as a template agent and a dispersing agent, the contact reaction surface between zinc oxide and phosphoric acid is continuously updated by means of three-level serial grinding, particle shape and size control is conducted, and nanometer zinc phosphate antirust pigments with a uniform particle size are obtained by means of dehydration, spray drying, modification and smashing. Full-automatic control is adopted, production is convenient and fast, the obtained nanometer zinc phosphate antirust pigments are uniform in particle size and stable in product quality, and the antirust performance is improved by 20% compared with existing imported zinc phosphate.

Owner:GUANGXI UNIV FOR NATITIES

Rust-proof corrosion inhibitor and preparing method thereof

The invention provides a rust-proof corrosion inhibitor and the preparing method thereof. The rust-proof corrosion inhibitor comprises sodium silicate, sodium polyacrylate, mercaptobenzothiazole, benzotriazole, sodium tripolyphosphate, hexamethylenetetramine, imidazoline, mercaptobenzothiazole, alkane amido alcohol, furfural, polyphosphates, ethanol amine, sodium borate and ethyl alcohol. The preparing method comprises the steps of heating sodium silicate, sodium polyacrylate, mercaptobenzothiazole, benzotriazole, sodium tripolyphosphate, hexamethylenetetramine, imidazoline, mercaptobenzothiazole, alkane amido alcohol, furfural, ethanol amine and ethyl alcohol mixed liquor to 50-60 DEG C firstly, then adding polyphosphates and sodium borate, continuing to heating to 85-90 DEG C, conducting heat preservation for 2-3 h, and then obtaining the rust-proof corrosion inhibitor after cooling. The rust-proof corrosion inhibitor can be well compatible with variable materials, rust-proof time is long and can be as long as 4-6 months, adaptability to the copper material and the aluminum material is high, and rust-proof time is prolonged due to the fact that a film can be formed on the surface of metal while corrosion inhibition and rust resistance are realized.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

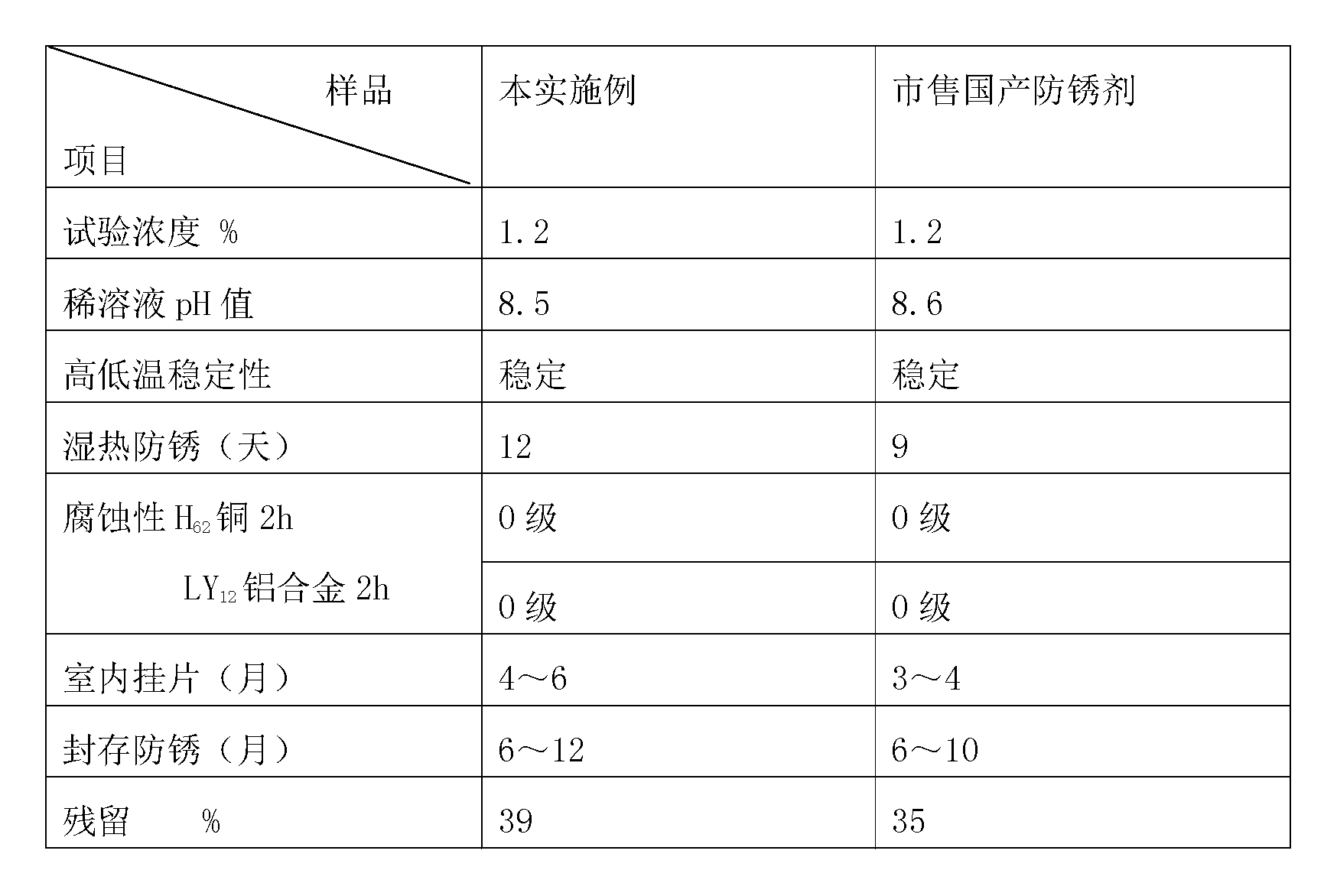

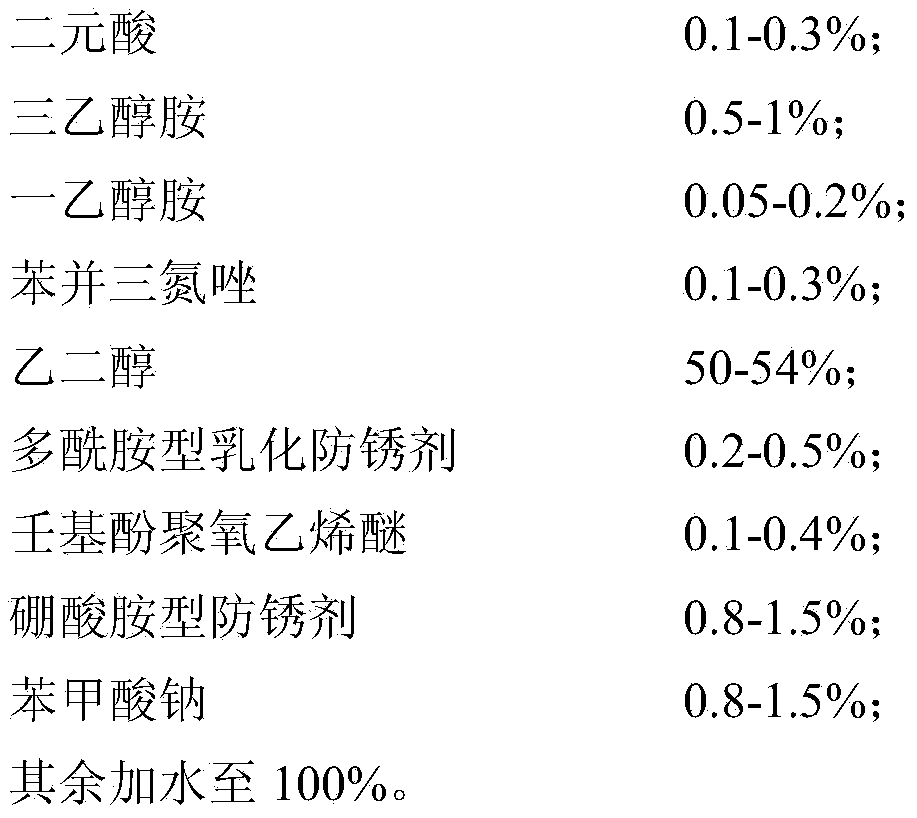

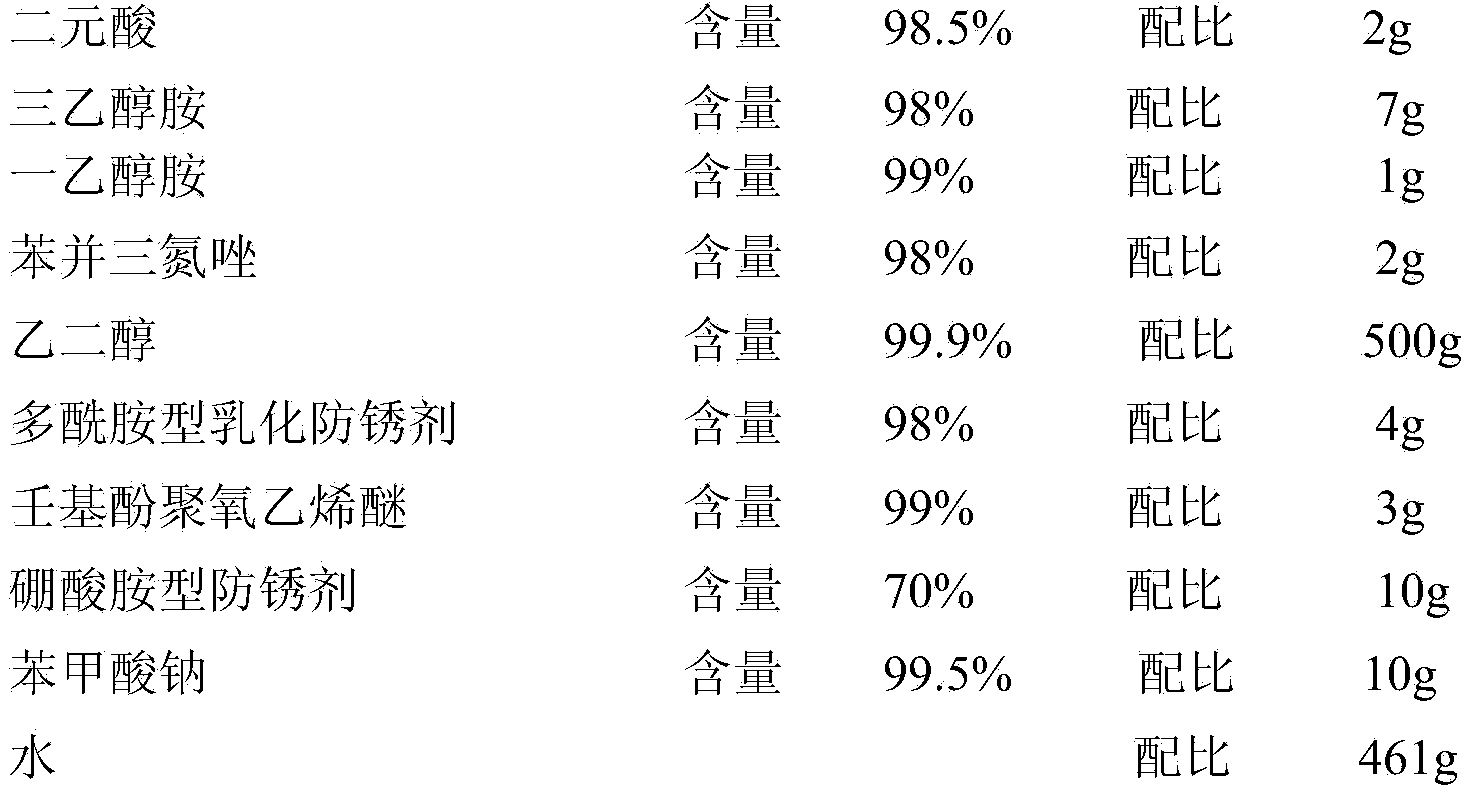

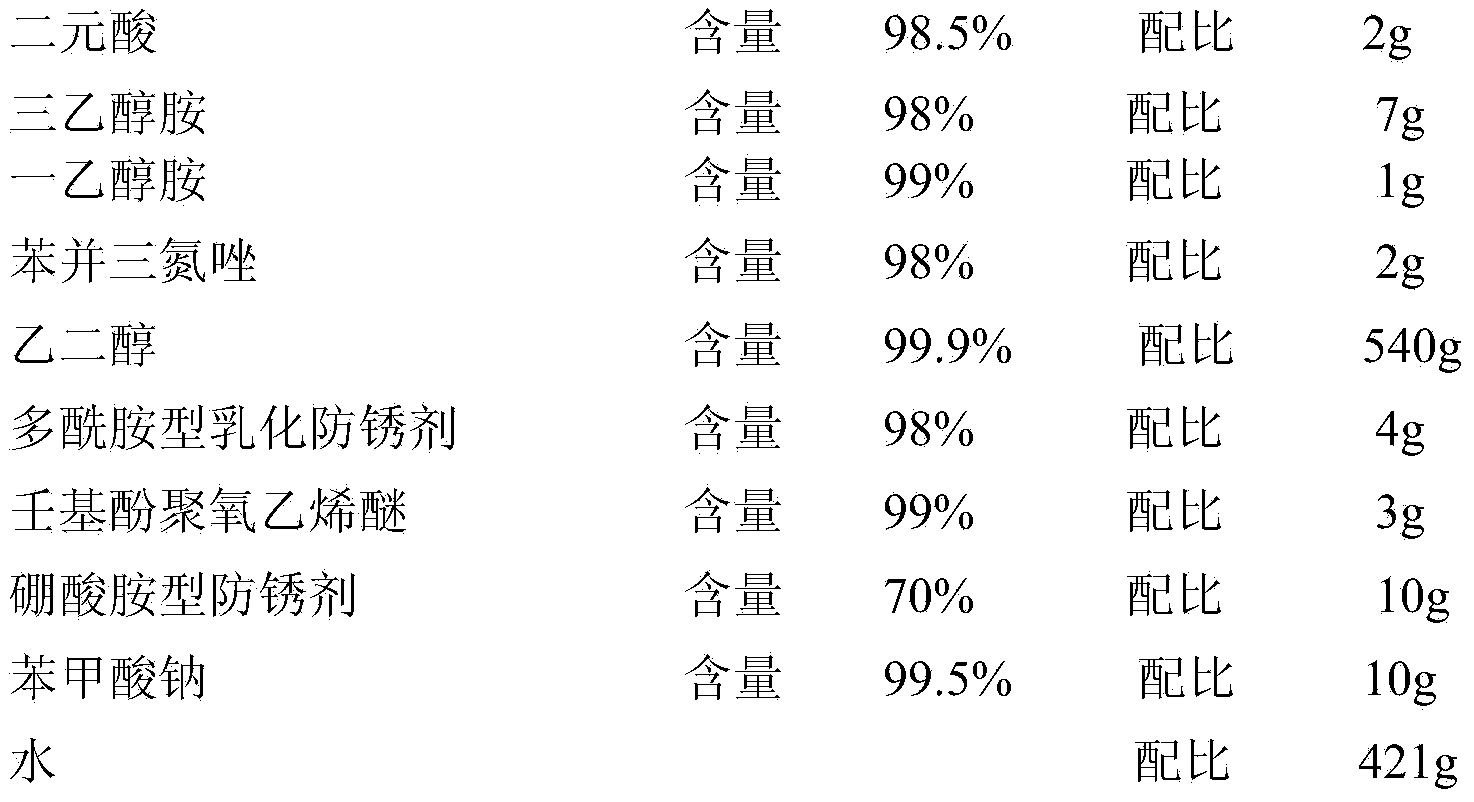

Environment-friendly hydraulic support antifreeze fluid and preparation method thereof

ActiveCN103666738AAnti-rust for a long timeExcellent anti-rustLubricant compositionEmulsionPhenyl Ethers

The invention relates to an environment-friendly hydraulic support antifreeze fluid and a preparation method thereof. The fluid is composed of the following components in percentage by weight: 0.1 to 0.3% of diacid, 0.5 to 1% of triethanolamine, 0.05 to 0.2% of ethanolamine, 0.1 to 0.3% of benzotriazol, 50 to 54% of glycol, 0.2 to 0.5% of polyamide type emulsion antirust agent, 0.1 to 0.4% of polyoxyethylene nonyl phenyl ether, 0.8 to 1.5% of ammonium borate type antirust agent, 0.8 to 1.5% of sodium benzoate, and the balance being water. The action mechanism of the antifreeze fluid is simple and scientific. Through the synergetic effect between each component, optimum antirust, lubricating and antifreeze effects are abtained. The ammonium borate type antirust agent and the sodium benzoate both have an antiseptic function, and thus can effectively prevent the hydraulic support from corrosion during the storage or work process. The ratio of glycol to water can be adjusted so as to obtain various antifreeze liquids applied in different low temperatures.

Owner:华阳新兴科技(天津)集团有限公司

A continuous production method and production device of nano-zinc phosphate antirust pigment

InactiveCN105694570BImprove uniformityMinimize impact on product qualityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsThree levelAutomatic control

The invention provides a nanometer zinc phosphate antirust pigment continuous production method and device. Zinc oxide and phosphoric acid are used as raw materials, under the synergistic effect of multiple auxiliaries such as a template agent and a dispersing agent, the contact reaction surface between zinc oxide and phosphoric acid is continuously updated by means of three-level serial grinding, particle shape and size control is conducted, and nanometer zinc phosphate antirust pigments with a uniform particle size are obtained by means of dehydration, spray drying, modification and smashing. Full-automatic control is adopted, production is convenient and fast, the obtained nanometer zinc phosphate antirust pigments are uniform in particle size and stable in product quality, and the antirust performance is improved by 20% compared with existing imported zinc phosphate.

Owner:GUANGXI UNIV FOR NATITIES

Antirust agent and preparation method thereof

The invention discloses an antirust agent and a preparation method thereof. The antirust agent is mainly prepared from ammonium gluconate, dodecenylsuccinic acid, sodium nitrite, carrageenin, petroleum calcium sulfonate, ammonium molybdate, acetic acid, hydroxypropyl methyl cellulose, urea, glutamic acid, oxidized petrolatum barium soap, poloxamer, terpinyl acetate, nano titanium dioxide, China wood oil and a modified auxiliary agent. The antirust agent disclosed by the invention adopting ammonium gluconate and terpinyl acetate as main components is good in antirust effect, and also has the effects of resisting sun and sterilizing by matching with nano titanium dioxide, and the modified auxiliary agent improves the overall performance of the antirust performance, so that the antirust agent can achieve an antirust effect normally under the influence of moisture and temperature, and is long in antirust time and small in environmental pollution.

Owner:NANTONG YONGYU ANTI RUST MATERIALS CO LTD

Rust-proof and corrosion-resistant coating for turning lathe

InactiveCN104861754AAnti-rust for a long timeImprove corrosion resistanceAnti-corrosive paintsEpoxyDiboride

The invention discloses a rust-proof and corrosion-resistant coating for a turning lathe. The coating comprises the following components in parts by weight: 30-50 parts of a silicon epoxy resin polymer, 4-10 parts of barium petroleum sulfonate, 7-14 parts of aluminum tripolyphosphate, 1-5 parts of nano zinc oxide, 2-6 parts of copper chromium iron black, 3-9 parts of acrylonitrile, 5-12 parts of amino resin, 2-8 parts of sodium fluosilicate, 6-10 parts of vanadium diboride and 8-14 parts of xylene. The mechanical rust-proof coating provided by the invention is long in rust-proof time and good in corrosion resistance, rust-proof oil does not need to be cleaned before coating, additional coating additives do not need to be added, and the coating can be used for long-term seal storage and rust prevention of metal mechanical workpieces.

Owner:王俐帧

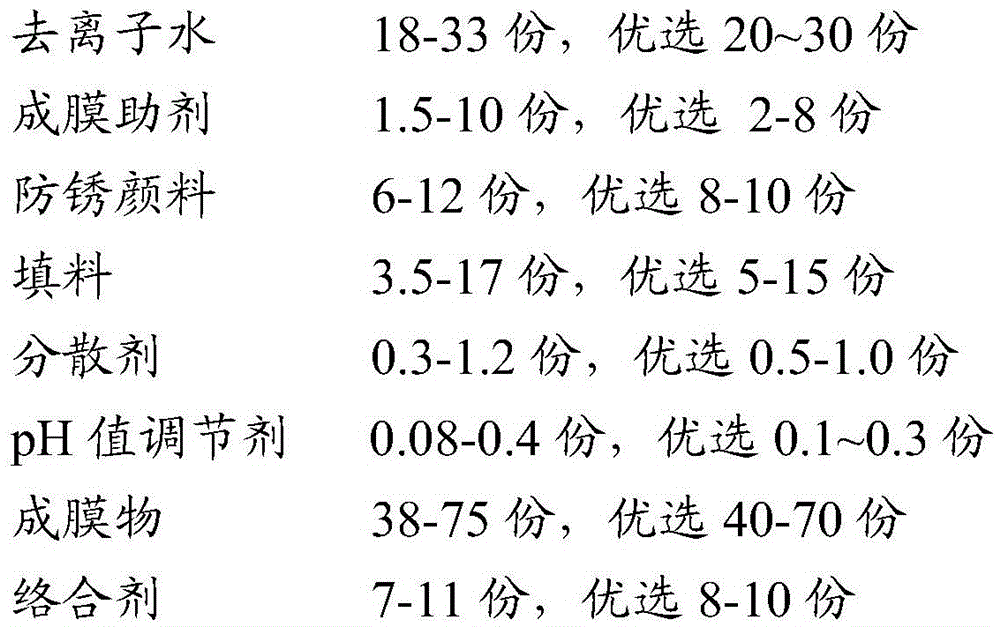

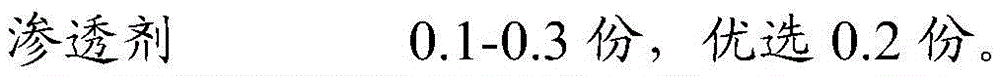

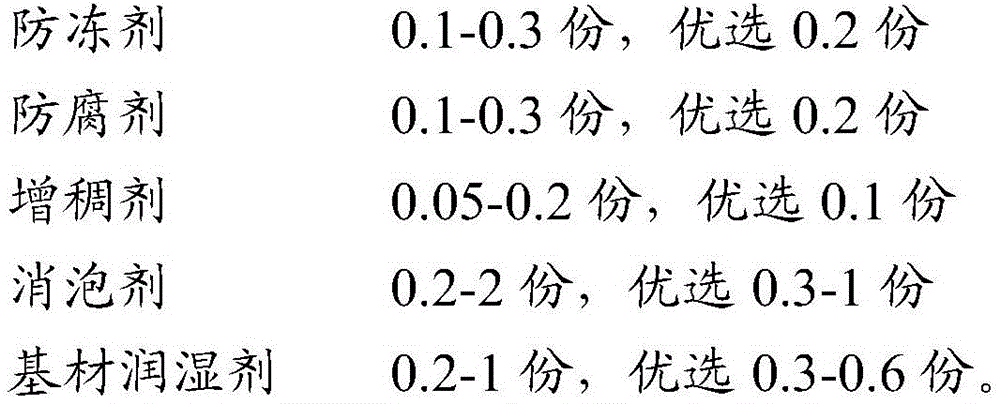

Water-based heavy-duty single-component primer, as well as preparation method and application thereof

InactiveCN106811040AIncreased sealing performanceAnti-rust for a long timeAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryHeavy duty

The invention relates to a water-based heavy-duty single-component primer, which is prepared from the following components in parts by mass: 18 to 33, preferably 20 to 30, parts of de-ionized water, 1.5 to 10, preferably 2 to 8, parts of a coalescing agent, 6 to 12, preferably 8 to 10, parts of an anti-rust pigment, 3.5 to 17, preferably 5 to 15, parts of filler, 0.3 to 1.2, preferably 0.5 to 1.0, part of a dispersant, 0.08 to 0.4, preferably 0.1 to 0.3, part of a pH regulator, 38 to 75, preferably 40 to 70, parts of a film former, 7 to 11, preferably 8 to 10, parts of a complexing agent and 0.1 to 0.3, preferably 0.2, part of a penetrant. The invention also provides a preparation method and application of the water-based heavy-duty single-component primer.

Owner:杨卫兵

Spring rust cleaning liquid and rust cleaning process

InactiveCN104060282ANo corrosionAvoid harmMetallic material coating processesPhosphoric acidBinding force

The invention relates to rust cleaning liquid used for cleaning rust on the surface of a spring and a process adopting the dust cleaning liquid to clean rust for the spring. The spring rust cleaning liquid consists of the following components in percentage by weight: 25%-45% of phosphoric acid, 5%-10% of ethyoxyl alkyl sodium sulfate, 30%-50% of acetone, 8%-15% of catechol and the balance of deionized water. The spring rust cleaning liquid is utilized to carry out rust cleaning on the spring, so that greasy dirt and a rust layer on the surface of the spring can be removed at the same time, a phosphating film also can be generated on the spring surface, and therefore, the process is simplified; the process is free of environmental pollution, free of any harm on operation staff, low in cost, high in rust-cleaning speed, free of corrosion on spring, long in rust-preventing time, and capable of strengthening binding force between the metal surface and the paint.

Owner:ANHUI HONGQIAO METAL MFG

Long-acting water-based metal rust preventing agent

InactiveCN105907308AReduce the cost of rust preventionLow costWax coatingsAnti-corrosive paintsWater basedGas phase

The invention discloses a long-acting water-based metal rust preventing agent. The long-acting water-based metal rust preventing agent is prepared from, by weight, 2-10 parts of pentaerythritol tetraoleate, 5-10 parts of propylene glycol, 3-10 parts of petroleum-resin-modified paraffin emulsion, 1-2 parts of potassium oleate, 2-4 parts of sodium citrate, 0.5-1 part of lignin sulfonate, 2-6 parts of gas-phase titanium dioxide, 1-3 parts of sodium cocoate, 1-2 parts of polyvinylpyrrolidone, 1-2 parts of a modifying agent, 1-2 parts of other auxiliaries and 30-50 parts of water. Accordingly, an efficient long-acting environment-friendly water-based metal rust preventing agent product is obtained through the reasonable raw material proportion, the long-acting water-based metal rust preventing agent is suitable for rust preventing of cast iron, steel materials and multiple kinds of alloy steel, and the rust preventing cost in the metal processing, storing and transporting process is reduced; a film can be formed on the surface of metal while the long-acting water-based metal rust preventing agent is slowly released to prevent rust, therefore, the rust preventing time is prolonged, and decomposition and deterioration of metal processing liquid are inhibited; the long-acting water-based metal rust preventing agent is safe to use, environmentally friendly, simple in preparation method, low in cost and suitable for massive production.

Owner:SUZHOU HONGKE METAL PROD CO LTD

Metal antirust agent containing modified thiadiazole

The invention discloses a metal antirust agent containing modified thiadiazole. The raw materials of the metal antirust agent includes styrene-acrylic emulsion, polyethylene glycol dimethacrylate, polyaniline, polymaleic anhydride, amino acid, benzotriazole, benzimidazole, modified thiadiazole, ricinoleic acid, tololeic acid diethanolamide, sodium molybdate, zirconic acid zinc, propargyl alcohol,cerium nitrate, graphene oxide, triethanolamine, silane coupling agent, potassium hydroxide, natural corrosion inhibitor, ethanol and water. The metal antirust agent containing the modified thiadiazole has good antirust effect and long antirust time.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

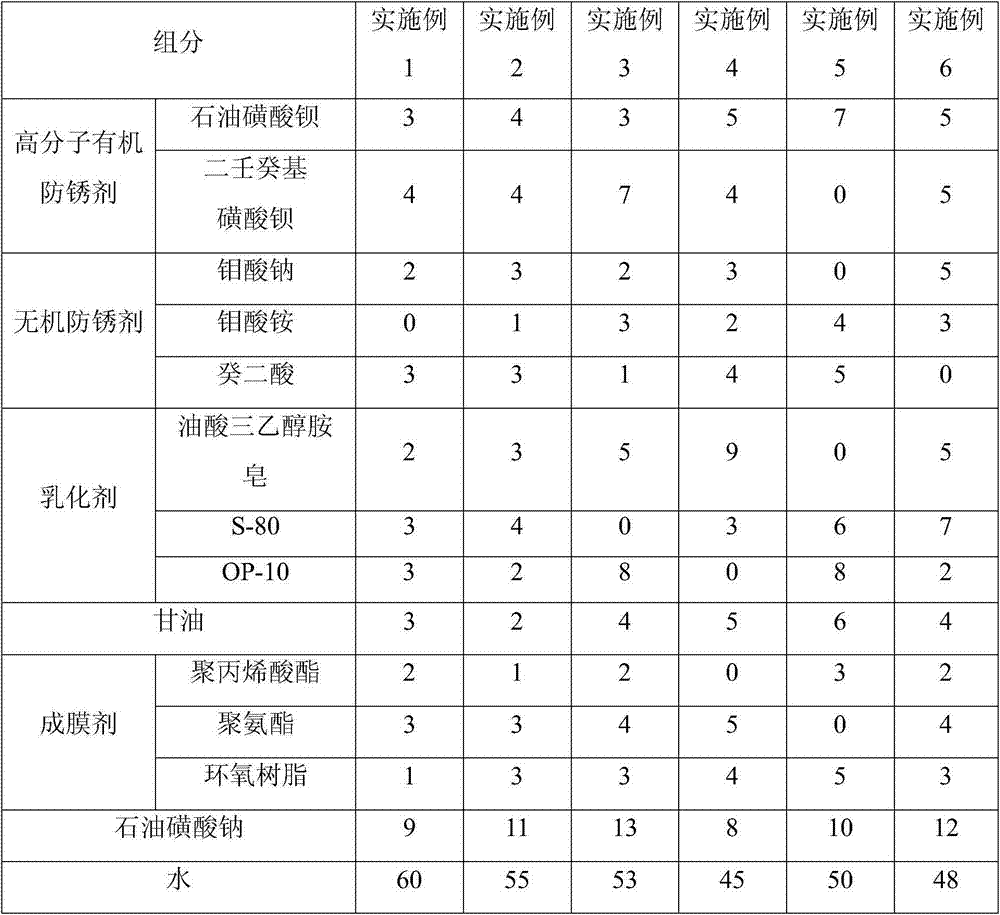

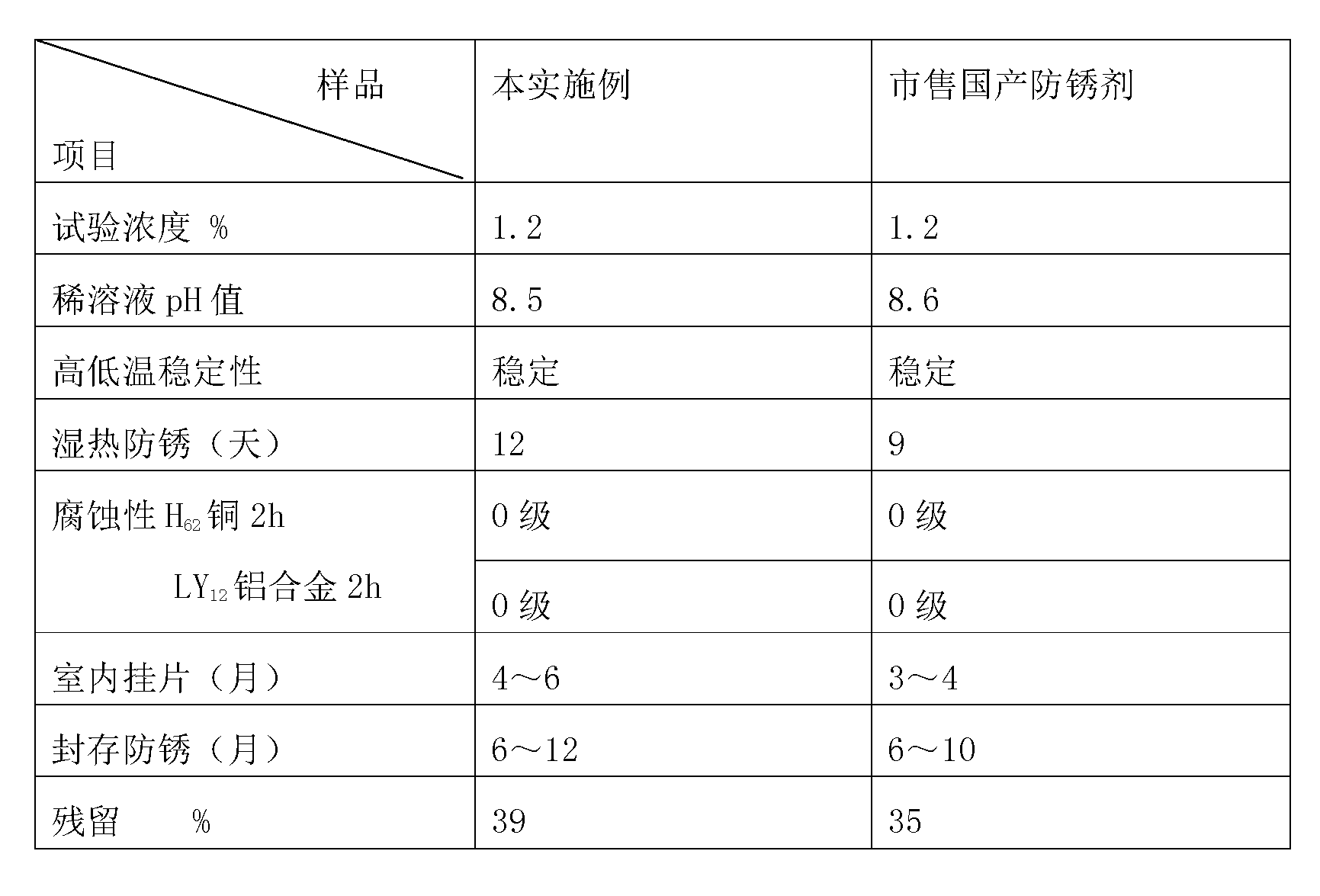

Water soluble rust inhibitor and preparation method thereof

The invention discloses a water soluble rust inhibitor, comprising the following components in parts by weight: 6-10 parts of macromolecule organic rust inhibitor, 3-10 parts of inorganic rust inhibitor, 8-15 parts of emulsifier, 2-6 parts of glycerinum, 5-10 parts of film-forming agent, 8-15 parts of petroleum sodium sulfonate and 40-60 parts of water. According to the water soluble rust inhibitor disclosed by the invention, a substance which can be dissolved into water at normal temperature and can form a film when meeting with black metal and organic and inorganic antirust components which have good anti-rust performance and can be combined with the film-forming agent are selected, so that an antirust protection film which is not dissolved into cold water is combined and formed by bridging action of the emulsifier, and the water soluble rust inhibitor is long in antirust time, thin and compact in formed film, convenient for film removal, and good in environmental protection property, can save a lot of cleaning materials and labor charges, and does not cause pollution to the environment.

Owner:刘晓萍

Water-based antirusting agent for iron casting

InactiveCN104988483ANo pollution in the processAvoid harmMetallic material coating processesEthylenediamineWater based

The invention discloses a water-based antirusting agent for iron casting. The water-based antirusting agent comprises, by mass, 15-20 parts of benzotriazole, 5-8 parts of glycerol, 2-3 parts of fatty alcohol-polyoxyethylene ether, 4-5 parts of diethanol amine, 2-3 parts of ethyl maltol, 3-5 parts of a hydroxyethyl cellulose, 6-8 parts of amino silicon oil, 3-5 parts of bis(hexamethylenetriaminepenta(methylenephosphonic acid)), 2-3 parts of bis(Hexamethylene triamine penta (methylene phosphonic acid)) , 2-3 parts of potassium fluoborate, 3-4 parts of potassium fluosilicate, 2-3 parts of ammonium bifluoride, 3-4 parts of potassium fluoride, 5-6 parts of lauryl sodium sulfate, 3-5 parts of ferric sodium edelate, 2-4 parts of sodium tripolyphosphate, 3-5 parts of isothiazolinone and 100-150 parts of deionized water. Dust cannot be attached to the water-based antirusting agent for iron casting, the surface of cast iron is quiet clean, pollution to the environment is avoided, harms on an operator are avoided, waste water is easily treated, the antirusting time is long, the antirusting time can be one year at least under the natural drying ventilation condition, the water-based antirusting agent is not combustible, and the safety is high.

Owner:谢伟杰

Antirust paint for machinery

InactiveCN107163841AStrong adhesionAnti-rust for a long timeFireproof paintsAnti-corrosive paintsWeather resistancePerlite

The invention provides antirust paint for machinery. The antirust paint comprises, by weight, 4-6 parts of 1-hydroxybenzotriazole, 5-7 parts of amino silicon oil, 10-12 parts of ethyl acetate, 3-5 parts of glycerol, 1-3 parts of potassium tripolyphosphate, 3-5 parts of cobalt-manganese rare earth, 2-4 parts of diisopropanol amine, 3-5 parts of ethylenediamine tetraacetic acid, 8-10 parts of ethanol, 4-6 parts of expanded perlite powder, 3-5 parts of flash-rust-preventing agent, 2-4 parts of sodium hydroxide, 4-6 parts of olive oil, 1-3 parts of borax, 1-4 parts of aluminum powder and the balance deionized water. The antirust paint has the advantages that the antirust paint is high in adhesive force, long in antirust time, good in stability and capable of well protecting metal; the weather resistance and chemical stability of the antirust paint are enhanced by the use of the modified amino silicon oil; by adding the components such as the expanded perlite powder and the borax, the wear resistance of the antirust paint is increased, and the service life of the antirust paint is prolonged.

Owner:合肥轻风飏电气科技有限责任公司

Gas-phase slow-release antirust oil

Disclosed gas-phase slow-release antirust oil is composed of the following raw materials in parts by weight: 2-4 parts of dicyclohexylammonium nitrite, 0.1-0.2 part of hydroxy oximido acid, 3-5 parts of lanolin, 3-5 parts of hydrogenated castor oil, 1-3 parts of urotropine, 1-2 parts of coconut diethanolamide, 1-2 parts of calcium ricinolate, 1-2 parts of dibutyl phthalate, 0.2-0.5 part of allylthiourea, 0.4-1 part of zinc dialkyl dithiophosphate, 60-70 parts of 250sn base oil, 1-2 parts of mannitol, 4-6 parts of antirust agent T706, and 3-5 parts of film-forming machine oil. The added film-forming machine oil pentaerythrityl oleate possesses excellent lubricity and good surface film-forming property, and is capable of obviously improving the film-forming effect of a finished product and reducing film-forming temperature after being blended with 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate) for modification; and the added rare earth lanthanum ion is capable of reacting with OH<-> generated in an oxygen-absorption corrosion process on a metal base material surface so as to generate an indissoluble complex, helps to alleviate corrosion electrode reaction and gives play to extremely good slow release effect.

Owner:ANHUI RONGDA VALVE

Preparation method of metal antirust agent containing 1-hydroxybenzotriazol

InactiveCN102977720AImprove adaptabilityGood compatibilityAnti-corrosive paintsEpoxyDimethyl benzene

The invention discloses a preparation method of a metal antirust agent containing 1-hydroxybenzotriazol. The preparation method comprises the following steps: adding 5-8 parts by weight of liquefied paraffin, 2.2-4.4 parts by weight of tri(2-ethylhexyl)acetocitrate, 3.5-5 parts by weight of acrylic acid, 4-6 parts by weight of epoxy linseed oil, 2-3 parts by weight of xylene and 3-5 parts by weight of polyethylene wax to a reaction kettle, heating to 105-115DEG C, stirring, and adding 3-6 parts by weight of urea, 0.2-0.3 parts by weight of potassium persulphate, 0.3-0.5 parts by weight of borax and 0.2-0.3 parts by weight of zinc powder. The metal antirust agent has a good compatibility with a plurality of materials, and has a long antirust time, and the epoxy linseed oil has no toxic side effects, so the antirust time of the metal antirust agent can reach 4-6 months, and the metal antirust time has a good adaptability to copper and aluminum materials and can form a film on the metal surface when the sustained release rust prevention is simultaneously carried out, thereby the antirust time of the metal antirust agent is prolonged.

Owner:赵立辉 +2

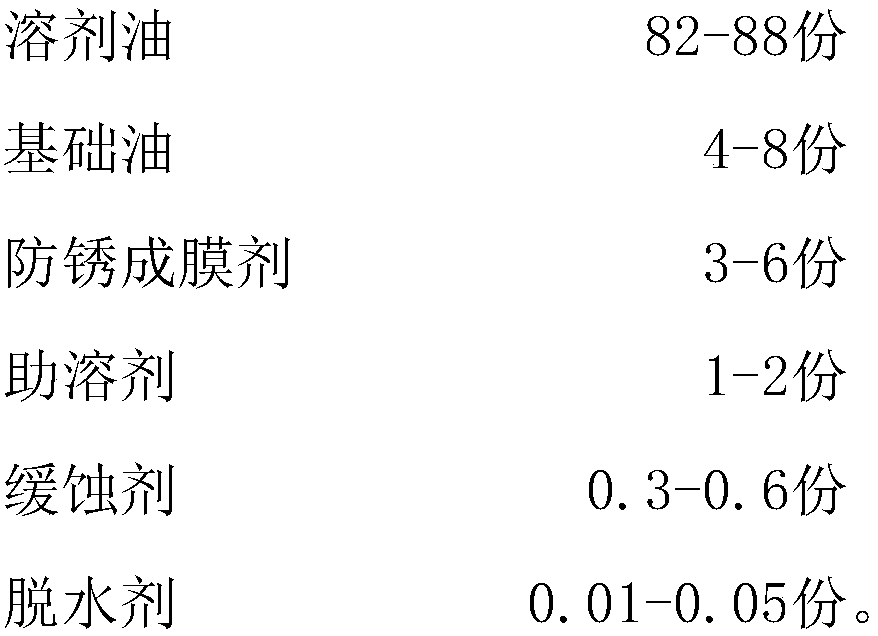

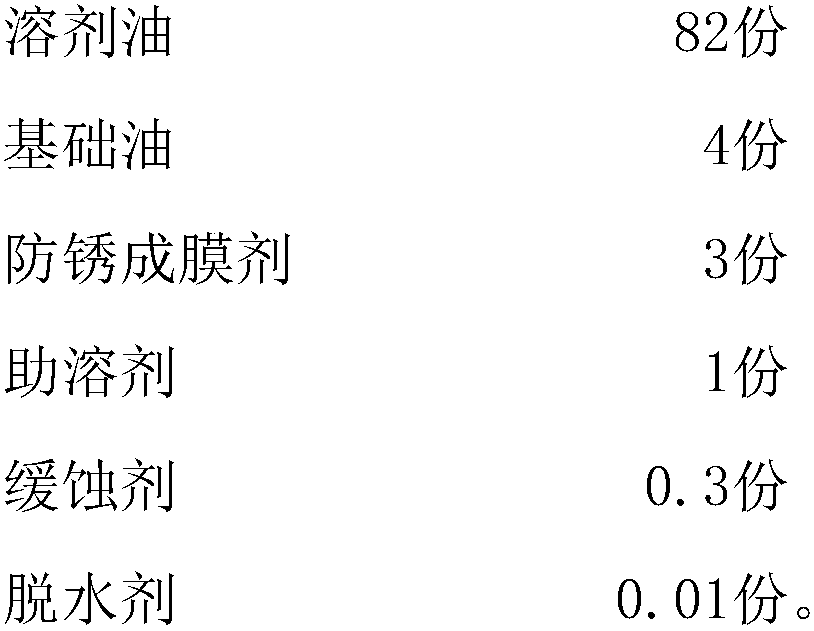

Antirust oil for copper materials and preparation method and application thereof

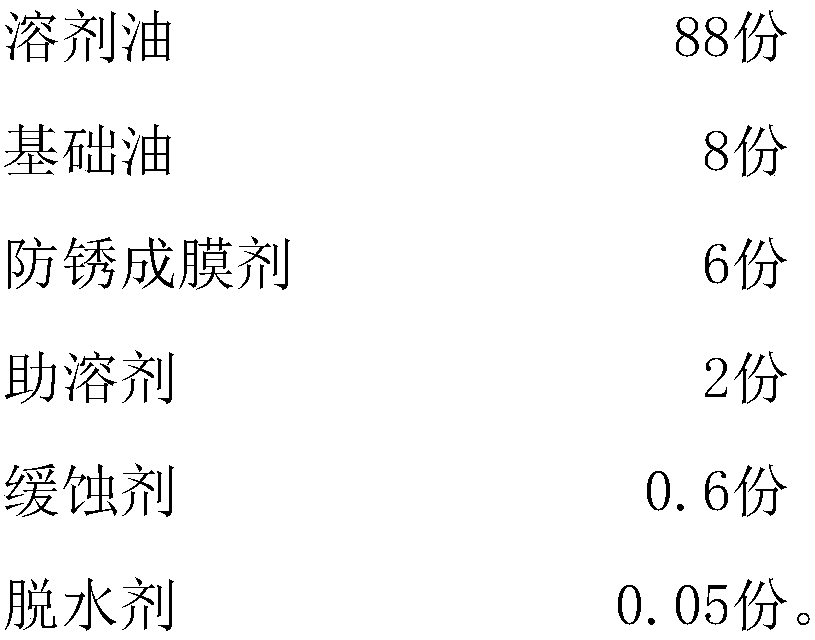

ActiveCN109022109AEasy to useImprove rust resistanceLubricant compositionSalt spray testOxidation resistant

The invention relates to the technical field of antirust technology for copper materials, specifically to antirust oil for copper materials and a preparation method and application thereof. The antirust oil for copper materials comprises the following raw materials (by weight): 82-88 parts of solvent naphtha, 4-8 parts of base oil, 3-6 parts of an antirust film forming agent, 1-2 parts of a cosolvent, 0.3-0.6 part of a corrosion inhibitor, and 0.01-0.05 part of a dehydrant. The invention has the following beneficial effects: the antirust oil for copper materials contains no barium antirust agent, phthalate or toxic compounds such as aromatic hydrocarbons, etc., is environmentally-friendly, is safe to use, has thin oil film, and has excellent oxidation resistance and good antirust effect. The preparation method has simple process and is convenient for industrial production. The application method of the antirust oil for copper materials is simple. Treated copper materials can meet higher salt spray test requirements and indoor storage requirements.

Owner:Dongguan Kaimeng Chemical Co Ltd

Aqueous antirust agent for steel and preparation method thereof

The invention discloses an aqueous antirust agent for steel and a preparation method thereof. The antirust agent is obtained by firstly adding acrylamide, diethanolamine, acetyl tri-2-ethylhexyl citrate, sodium polyacrylate, dimethicone, polyethylene wax and deionized water into a stainless steel reaction kettle according to a weight ratio, heating to 110+ / -5 DEG C, starting to stir, adding sodium molybdate, sodium dihydrogen phosphate and a surfactant, heating to 165-175 DEG C at a speed of 20-25 DEG C / h, reacting for 2-3 h, stopping heating, and finally adding hydroxypropyl methyl cellulose, ferrocene and a thickening agent into the stainless steel reaction kettle, and mixing uniformly for dissolving, so as to obtain the antirust agent. The antirust agent has extremely good antirust effect on steel surfaces and has the antirust time up to 6-8 months. The antirust agent is odorless, free of pollution, low in manufacture cost, convenient for construction and simple in manufacture technology, also does not contain substances harmful to human body, is nontoxic and harmless to human body, and has good environment protection effect.

Owner:WUXI EPIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com