Water-soluble antirust agent

A kind of anti-rust agent, water-soluble technology, applied in the field of water-soluble anti-rust agent, can solve the problems of high cost, large consumption of oil and raw materials, serious environmental pollution, etc., achieve good wear resistance and anti-rust performance, and long effective period of anti-rust , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

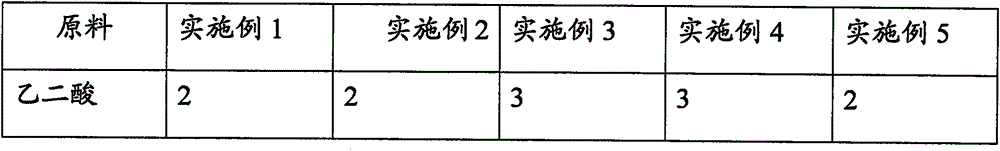

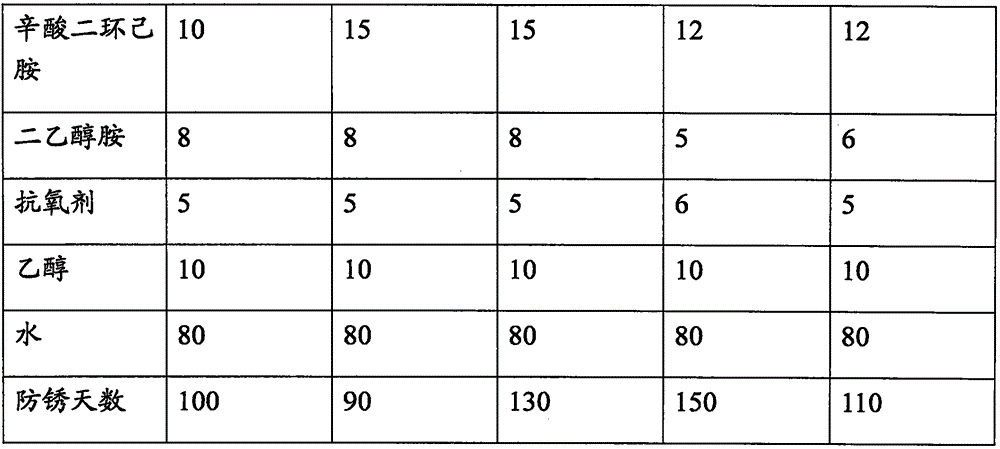

Embodiment 1

[0019] S1. Mix oxalic acid, dicyclohexylamine octanoate, diethanolamine, and antioxidant with a small amount of water in a ratio of 2:10:8:5, and heat to 100 degrees to complete the reaction, to obtain a transparent mixed solution A;

[0020] S2. Add ethanol after cooling the mixed liquid A obtained in S1, adjust the pH to 8-9, continue to add ethanol to mix and stir at a stirring speed of 80 rpm for 2 hours, so that the components in S1 are fully dissolved, and a mixed solution is obtained. Liquid B;

[0021] S3. Adding a surfactant to the mixed solution B obtained in S2, and reacting for 2 hours, then adding water to obtain an aqueous solution of a rust inhibitor.

Embodiment 2

[0023] S1. Mix oxalic acid, dicyclohexylamine caprylate, diethanolamine, and antioxidant with a small amount of water in a ratio of 2:15:8:5, and heat to 100 degrees to complete the reaction, and obtain a transparent mixed solution A;

[0024] S2. Add ethanol after cooling the mixed liquid A obtained in S1, adjust the pH to 8-9, continue to add ethanol to mix and stir at a stirring speed of 80 rpm for 2 hours, so that the components in S1 are fully dissolved, and a mixed solution is obtained. Liquid B;

[0025] S3. Adding a surfactant to the mixed solution B obtained in S2, and reacting for 2 hours, then adding water to obtain an aqueous solution of a rust inhibitor.

Embodiment 3

[0027] S1. Mix oxalic acid, dicyclohexylamine octanoate, diethanolamine, and antioxidant with a small amount of water in a ratio of 3:15:8:5, and heat to 90-110 degrees to complete the reaction to obtain a transparent mixed solution A;

[0028] S2. Add ethanol after cooling the mixed liquid A obtained in S1, adjust the pH to 8-9, continue to add ethanol to mix and stir at a stirring speed of 80 rpm for 2 hours, so that the components in S1 are fully dissolved, and a mixed solution is obtained. Liquid B;

[0029] S3. Adding a surfactant to the mixed solution B obtained in S2, and reacting for 2 hours, then adding water to obtain an aqueous solution of a rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com