A continuous production method and production device of nano-zinc phosphate antirust pigment

A technology of anti-rust pigments and production methods, applied in anti-corrosion coatings, inorganic pigment treatment, chemical instruments and methods, etc., can solve the problems of high cost, no industrialized production equipment, and no industrialized production, and achieve low production costs. The effect of product quality and product stability, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

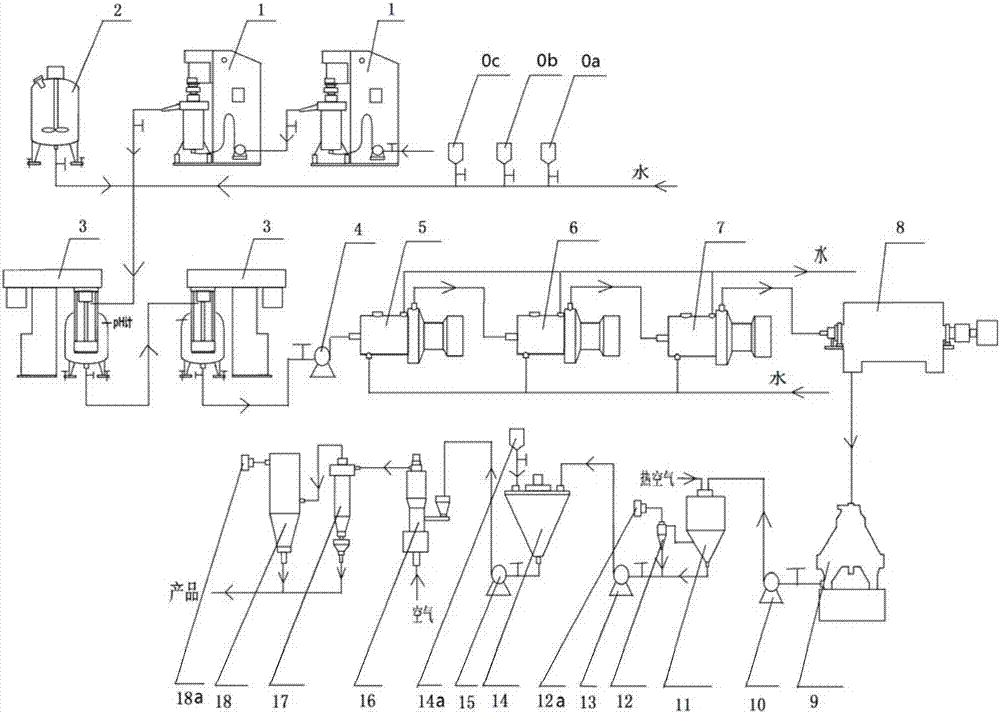

[0044] A continuous production method of nano-zinc phosphate antirust pigment, comprising the following steps:

[0045] (1) Dispersion: Weigh 99.7% zinc oxide by indirect method, and prepare zinc oxide solution with water at a weight ratio of 1:9; take 10,000 parts of zinc oxide solution, 11 parts of dispersant, and add them to the vertical sand mill at the same time , grinding zinc oxide to D98≦1 μm to obtain a zinc oxide dispersion; the dispersant 1 is commercially available Silok-7455;

[0046] (2) Acid preparation: add industrial phosphoric acid and deionized water into the dilution tank, stir, and prepare a phosphoric acid solution with a concentration of 10%;

[0047] (3) Add 2 parts of CTAB, 3 parts of Span-40, 1300 parts of deionized water, 30 parts of cyclohexylamine, and 15 parts of copolymer of acrylic acid and butyl acrylate into the reaction kettle continuously and uniformly. The zinc dispersion liquid and the phosphoric acid solution are continuously and uniform...

Embodiment 2

[0055] A continuous production method of nano-zinc phosphate antirust pigment, comprising the following steps:

[0056] (1) Dispersion: Weigh 99.7% zinc oxide by indirect method, and prepare zinc oxide solution with water at a weight ratio of 4:6; take 10,000 parts of zinc oxide solution and 18 parts of dispersant, and add them to the vertical sand mill at the same time , grinding zinc oxide to D98≦1 μm to obtain a zinc oxide dispersion; the dispersant 1 is commercially available Momentive 3013 dispersant;

[0057] (2) Acid preparation: add industrial phosphoric acid and deionized water into the dilution tank, stir, and prepare a phosphoric acid solution with a concentration of 30%;

[0058] (3) Add 20 parts of Tween, 10 parts of Pingpingjia, 1900 parts of deionized water, 50 parts of onion film, and 50 parts of copolymer of acrylic acid and butyl acrylate into the reaction kettle continuously and uniformly. The dispersion liquid and the phosphoric acid solution are continuou...

Embodiment 3

[0066] A continuous production method of nano-zinc phosphate antirust pigment, comprising the following steps:

[0067] (1) Dispersion: Weigh 99.7% zinc oxide by indirect method, and prepare zinc oxide solution with water at a weight ratio of 2:7; take 10,000 parts of zinc oxide solution and 15 parts of dispersant, and add them to the vertical sand mill at the same time , grinding zinc oxide to D98≦1 μm to obtain a zinc oxide dispersion; the dispersant 1 is commercially available Momentive 4065 dispersant;

[0068] (2) Acid preparation: add industrial phosphoric acid and deionized water into the dilution tank, stir, and prepare a phosphoric acid solution with a concentration of 20%;

[0069] (3) Add 5 parts of sodium dodecylbenzenesulfonate, 10 parts of sodium dodecyl sulfate, 1600 parts of deionized water, 40 parts of PEG-200040 parts, and 25 parts of copolymer of acrylic acid and butyl acrylate to the reaction Add the zinc oxide dispersion and phosphoric acid solution to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com