Water-based heavy-duty single-component primer, as well as preparation method and application thereof

A heavy-duty anti-corrosion, single-component technology, applied in the field of chemical coatings, can solve the problems of long time consumption and high cost that do not belong to the conversion film anti-rust, so as to save the pre-treatment steps of the base material, prolong the anti-rust time, and increase the cost. The effect of closure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

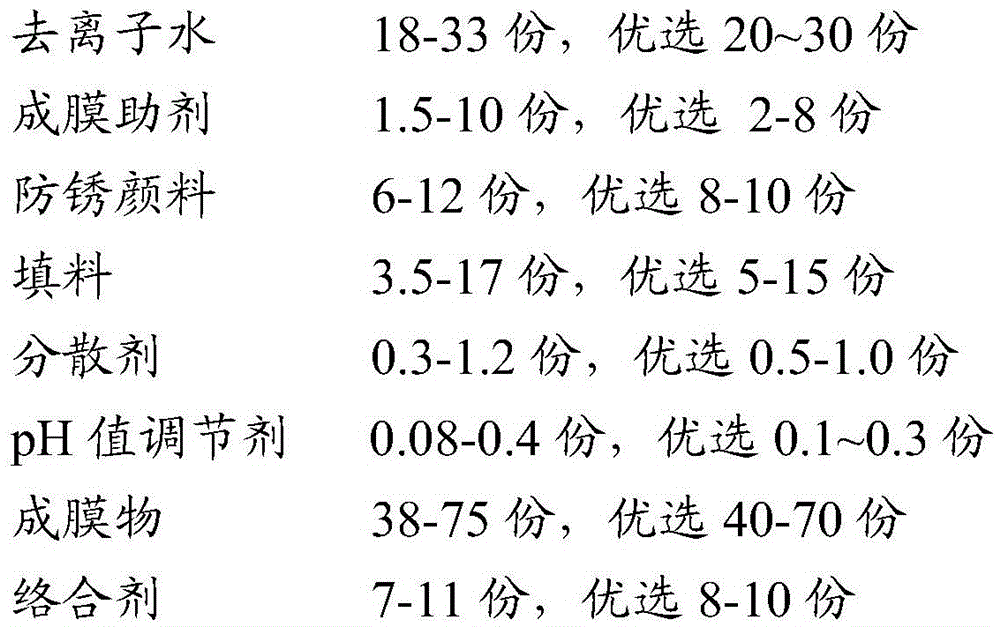

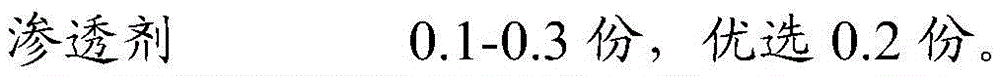

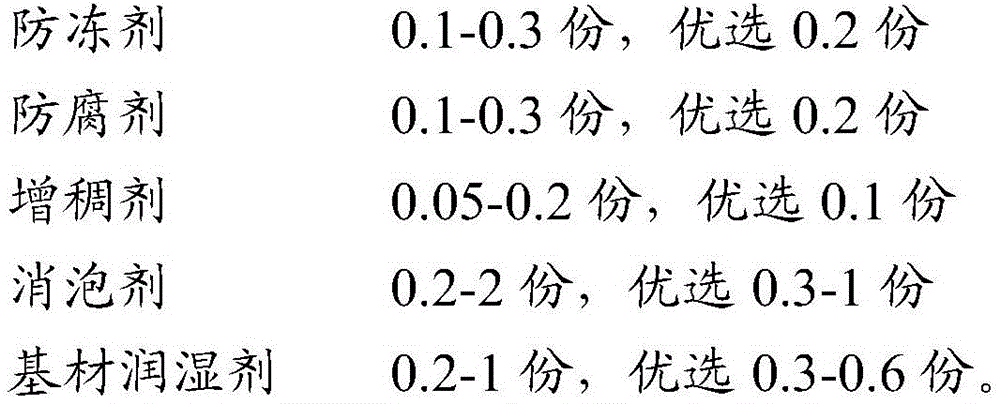

Method used

Image

Examples

Embodiment 1

[0050] At room temperature, 20 parts by mass of deionized water, 0.2 parts of tert-butanol, 2 parts of propylene glycol methyl ether, 0.2 parts of propylene glycol, 0.2 parts of DF-60, 0.1 parts of bentonite, 8 parts of SZP-391, 5 1 part of talcum powder, 0.3 part of Rhodia DN-642, 7 parts of tannic acid, and 0.5 part of Hemings FX600 were added into a stainless steel tank under stirring, and the stirring speed was 1200 rpm. Then stir at a speed of 2500 rpm for half an hour, then use a grinder to grind the material to a fineness of less than 30 microns, and filter the obtained slurry to obtain a filtrate for future use. Take 40 parts of water-based polyurethane resin, add the above-mentioned filtered slurry, 0.3 part of Hemings 165F and 0.1 part of Hemings MA-95 to the water-based polyurethane resin under stirring, wherein the stirring speed is 800 rpm, and Adjust the pH value to 7-9 and adjust the viscosity to KU (25° C.) ≥ 20GB / T9269-2009, then filter and pack the slurry to ...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, except that the content of the added components is different. In this example, 30 parts of deionized water, 0.2 parts of tert-butanol, 8 parts of propylene glycol methyl ether, 0.2 parts of propylene glycol, 0.2 parts of DF-60, 0.1 part of bentonite, 10 parts of SZP-391, and 15 parts of talcum powder were used , 1 part of Rhodia DN-642, 1 part of Hemings FX600, 70 parts of waterborne polyurethane resin, 11 parts of tannic acid, 0.6 parts of Hemings 165F and 0.3 parts of Hemings MA-95. Table 2 lists the performance data of the primer of this example.

[0055] Table 2

[0056]

Embodiment 3

[0058] This embodiment is basically the same as Embodiment 1, except that the content of the added components is different. In this example, 15 parts of deionized water, 0.2 parts of tert-butanol, 4.5 parts of propylene glycol methyl ether, 0.2 parts of propylene glycol, 0.2 parts of DF-60, 0.1 parts of bentonite, 9 parts of SZP-391, and 10 parts of talcum powder were used , 0.5 parts of Rhodia DN-642, 0.75 parts of Hemings FX600, 55 parts of waterborne polyurethane resin, 8 parts of tannic acid, 0.45 parts of Hemings 165F and 0.2 parts of Hemings MA-95. Table 3 lists the performance data of the primer of this example.

[0059] table 3

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com