Environment-friendly hydraulic support antifreeze fluid and preparation method thereof

A hydraulic support, antifreeze technology, applied in the petroleum industry, lubricating compositions and other directions, can solve the problems of easy skin cancer, poor anti-rust effect, and no published patent documents have been found, and achieves good anti-rust and lubricating effects. Long rust time, easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

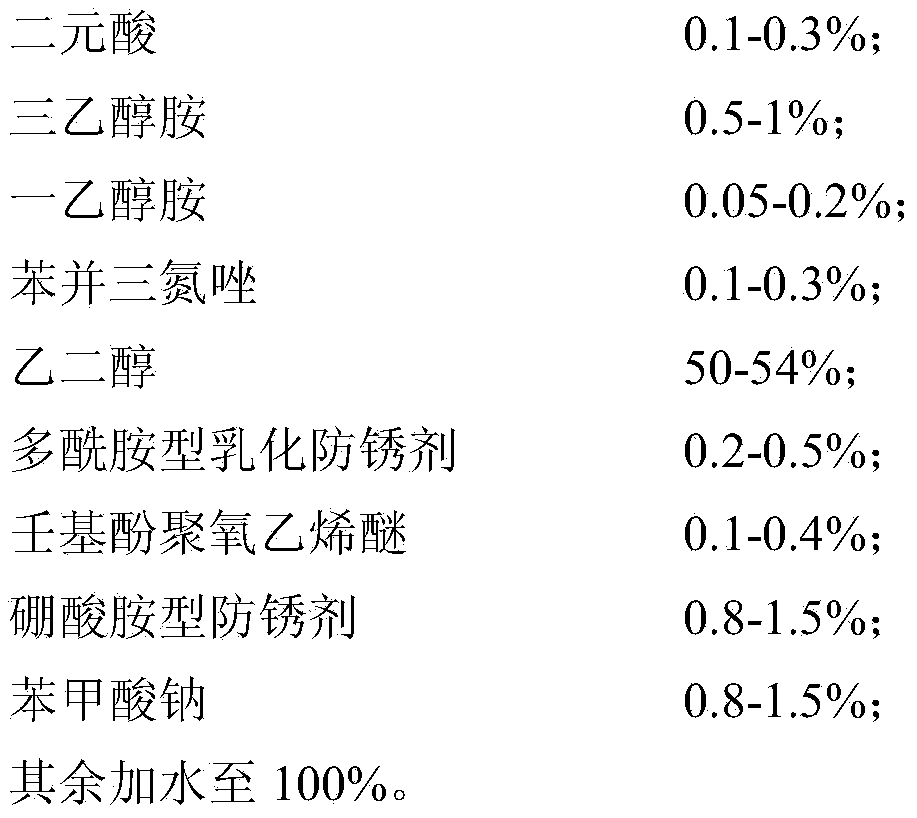

[0020] An environment-friendly hydraulic support antifreeze, its composition and weight percentage are respectively (taking 1000g hydraulic support antifreeze as an example):

[0021]

[0022] A preparation method of environment-friendly hydraulic support antifreeze, the steps are as follows:

[0023] ⑴Add appropriate amount of water to reactor A, heat up to 35-50°C, add the reaction amount of dibasic acid to mix, then add the reaction amount of triethanolamine and monoethanolamine and stir, keep the reaction temperature at 40-42°C for 3.5-5 Hour, finally add the benzotriazole of reaction amount and fully stir, form mixed solution a;

[0024] (2) Add the remaining water in step (1) to the reaction kettle B, start stirring at room temperature, then add ethylene glycol, and stir for 10 minutes until the ethylene glycol and water are completely miscible;

[0025] (3) Add polyamide-type emulsifying antirust agent, nonylphenol polyoxyethylene ether, and mixed solution a to reac...

Embodiment 2

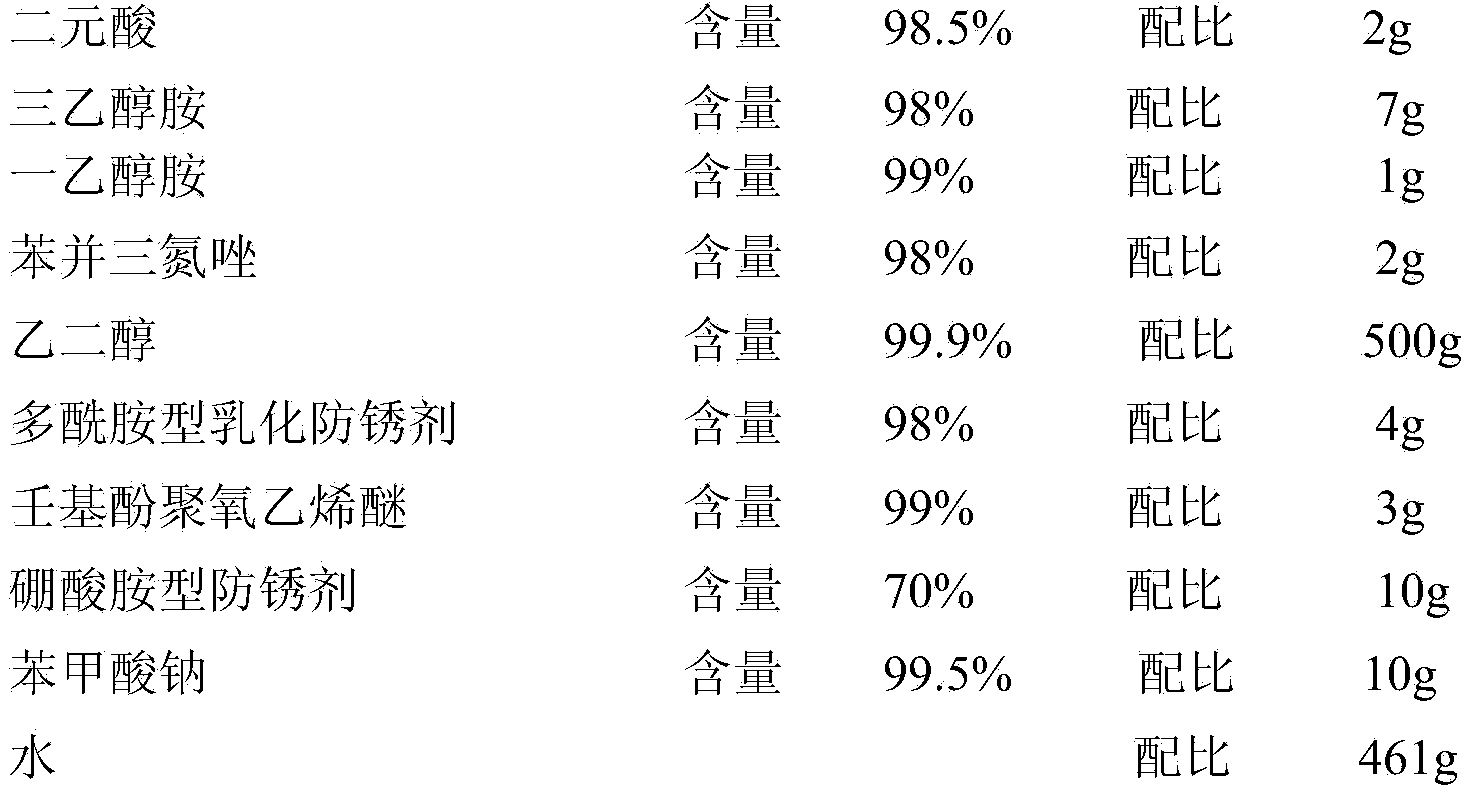

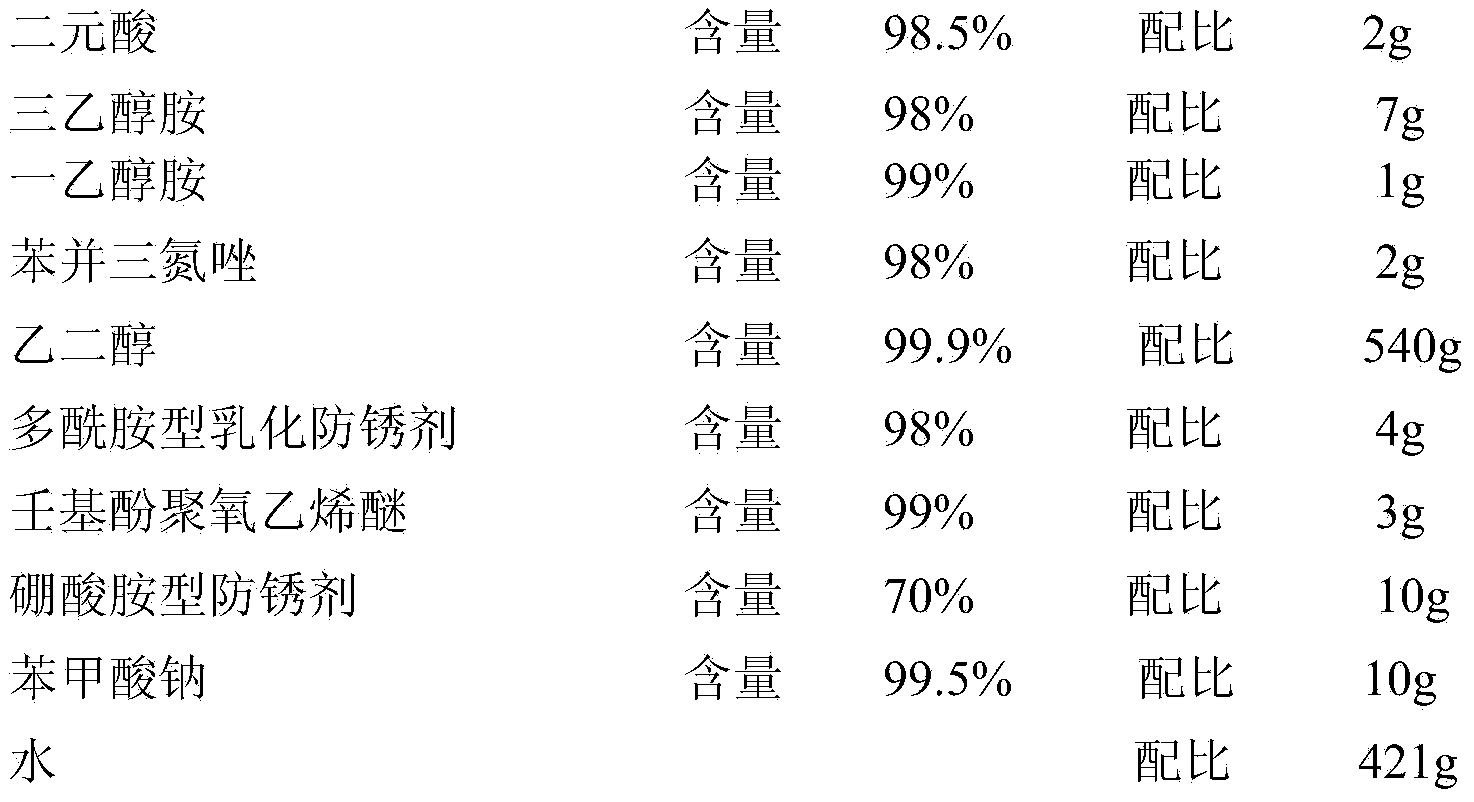

[0028] An environment-friendly hydraulic support antifreeze, its composition and weight percentage are respectively (taking 1000g hydraulic support antifreeze as an example):

[0029]

[0030] The steps of its preparation method are the same as in Example 1.

[0031] Mechanism of action of the present invention:

[0032] First, organic acid reacts with triethanolamine and monoethanolamine to form a water-based rust inhibitor. The added boric acid amine rust inhibitor provides a stable pH value and plays a synergistic role in rust prevention with the rust inhibitor body. Boric acid amine The anti-rust agent and sodium benzoate make the hydraulic support antifreeze not corrupt during storage and use and inhibit the growth of bacteria. Adding polyamide emulsified anti-rust agent to the hydraulic support antifreeze can not only prevent rust, but also provide lubrication for the antifreeze. Through the above mechanism of action, the anti-rust and lubricating effects can be opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com