Preparation method of multifunctional antirust oil and multifunctional antirust oil

A multi-functional anti-rust oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of increased consumption of anti-rust oil, poor anti-rust effect, short anti-rust cycle, etc., to achieve long anti-rust time and high performance Variety, the effect of reducing process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

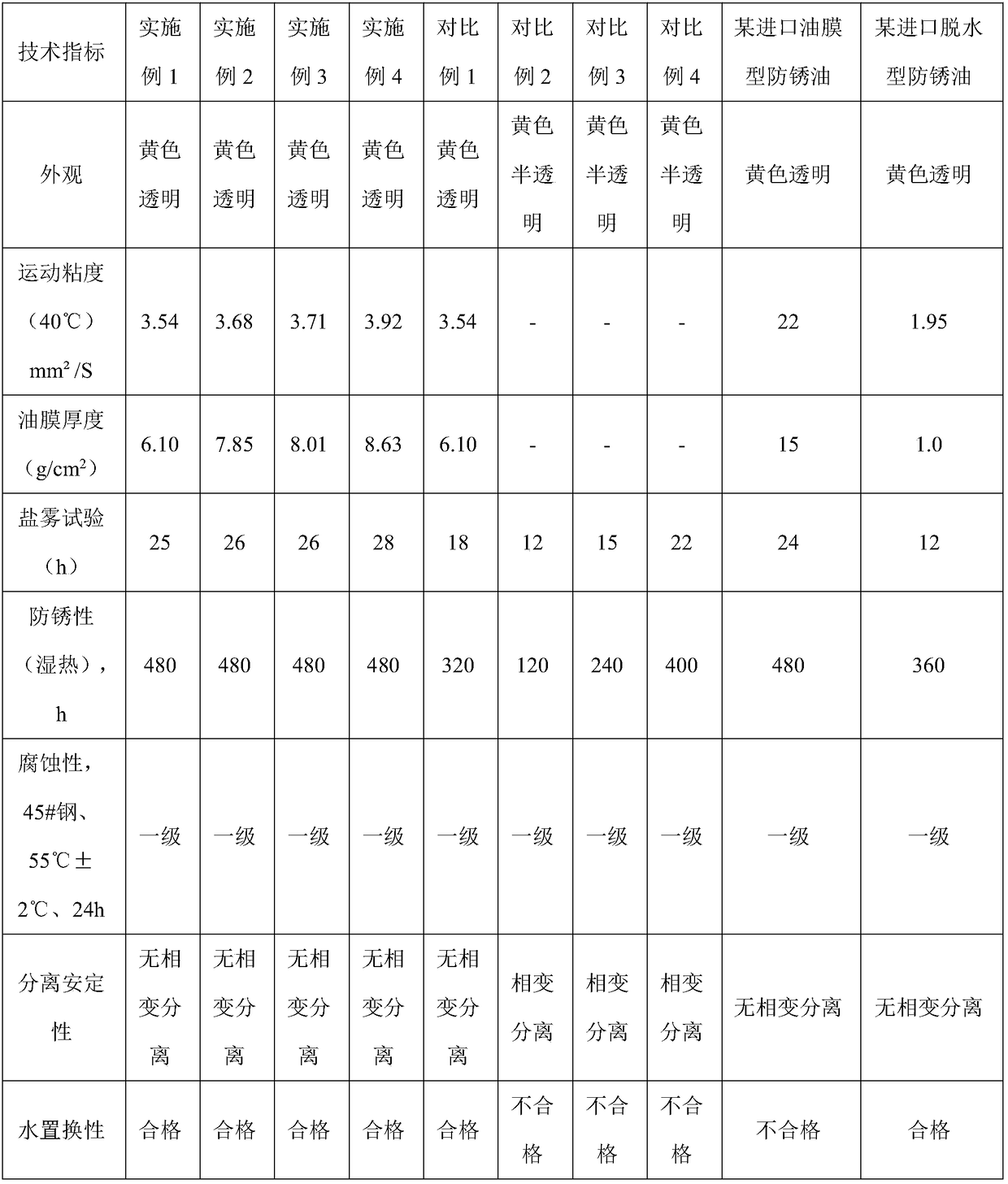

Examples

Embodiment 1

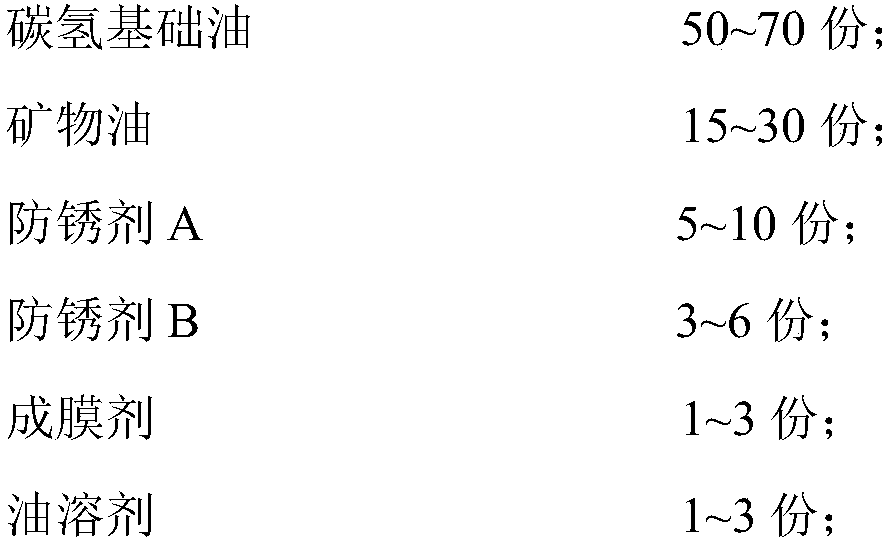

[0041] Take raw materials according to Table 1;

[0042] Add antirust agent A and film forming agent together by weight into a container filled with mineral oil, heat and control the temperature at 95°C, stir at 400rpm for 25min until completely dissolved, cool to 30°C, and then add oil solvent , antirust agent B and hydrocarbon base oil were added to the container, and stirred at 400 rpm for 20 minutes to prepare a multifunctional antirust oil.

Embodiment 2

[0044] Take raw materials according to Table 1;

[0045] Add antirust agent A and film forming agent into a container containing mineral oil by weight, heat and control the temperature at 91°C, stir at 500rpm for 20min until completely dissolved, cool to 33°C, and then add oil solvent , antirust agent B and hydrocarbon base oil were added to the container, and stirred at 320 rpm for 25 minutes to prepare a multifunctional antirust oil.

Embodiment 3

[0047] Take raw materials according to Table 1;

[0048] Add antirust agent A and film forming agent together into a container containing mineral oil by weight, heat and control the temperature at 98°C, stir at 300rpm for 25min until completely dissolved, cool to 40°C, and then add oil solvent , antirust agent B and hydrocarbon base oil were added to the container, and stirred at 300 rpm for 30 minutes to prepare a multifunctional antirust oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com