A kind of antirust oil for copper material, its preparation method and its application

A technology of anti-rust oil and copper materials, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as difficulty in meeting salt spray test requirements and indoor storage requirements, affecting electrical conduction and welding, and affecting aesthetics, etc., to achieve extended metal anti-corrosion Rust time, enhanced anti-rust performance, simple application method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

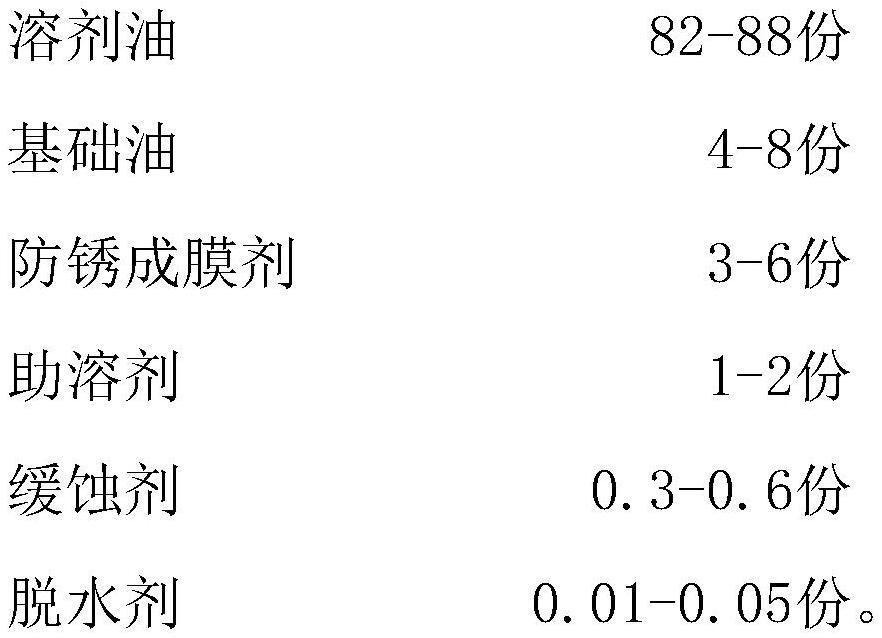

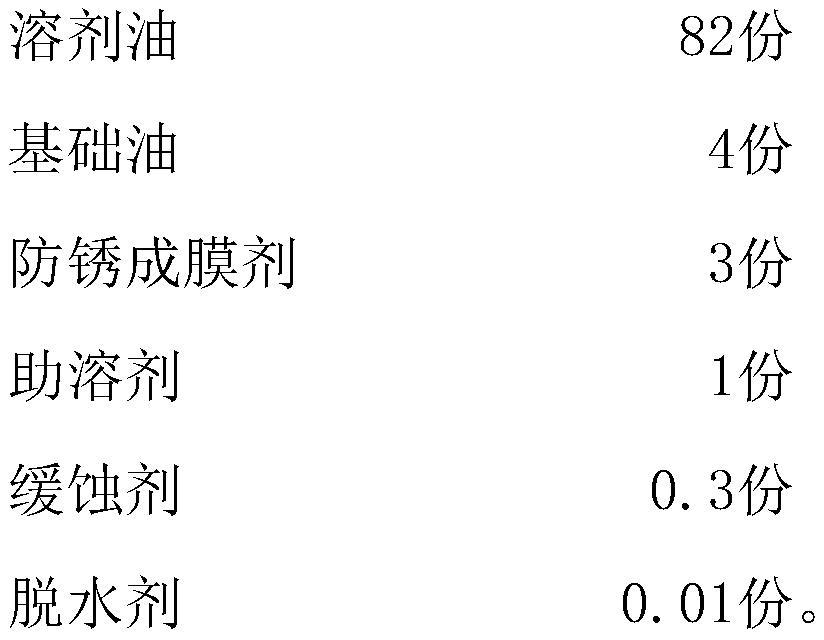

[0038]A copper material anti-rust oil, including raw materials having the following weights:

[0039]

[0040]The solvent oil is D40.

[0041]The base oil is a white oil.

[0042]The anti-rust film membrane is an oleate diethanolamide.

[0043]The solvent is anhydrous ethanol.

[0044]The corrosion inhibitor is 1-phenyl-5 mercaptozole.

[0045]Preferably, the dehydrating agent is isobutanol.

[0046]The preparation method of the copper antust oil, including the following steps:

[0047](1) Add the corrosion inhibitor to the solvent, at a certain temperature, stir for a certain period of time to obtain a solution A;

[0048](2) Add the anti-rust film film to the solution A, at a certain temperature, stirring reaction for a certain time to obtain a complexamine servant, that is, a solution B;

[0049](3) Sequentially add the base oil and solution B in the solvate oil, at a certain temperature, stir for a certain period of time to obtain a solution C;

[0050](4) Add the dehydrating agent to the solution C, stirring at a...

Embodiment 2

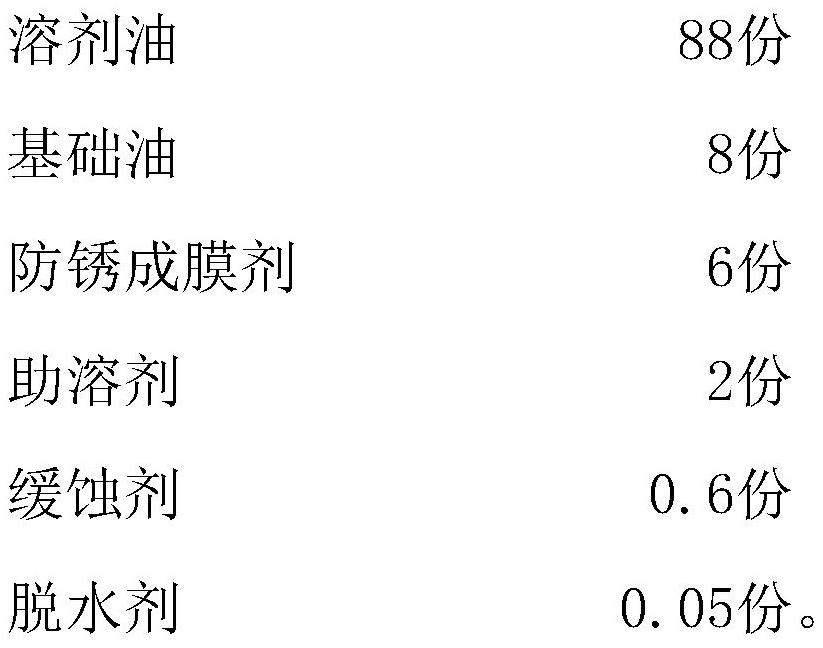

[0054]A copper material anti-rust oil, including raw materials having the following weights:

[0055]

[0056]The solvent oil D60.

[0057]The base oil is silicone oil.

[0058]The anti-rust film membrane is a sorbitol oil.

[0059]The solvent is ethylene glycol butyl ether.

[0060]The corrosion inhibitor is 1-phenyl-5 mercaptozole.

[0061]The dehydrating agent is a monutyl ether.

[0062]The copper has a method of preparing a rust-proof oil, including the following steps:

[0063](1) Add the corrosion inhibitor to the solvent, at a certain temperature, stir for a certain period of time to obtain a solution A;

[0064](2) Add the anti-rust film film to the solution A, at a certain temperature, stirring reaction for a certain time to obtain a complexamine servant, that is, a solution B;

[0065](3) Sequentially add the base oil and solution B in the solvate oil, at a certain temperature, stir for a certain period of time to obtain a solution C;

[0066](4) Add the dehydrating agent to the solution C, stirring at a ce...

Embodiment 3

[0070]A copper material anti-rust oil, including raw materials having the following weights:

[0071]

[0072]

[0073]The solvent oil is a dexive hydrocarbon solvent oil, and the aromatic hydrocarbon solvent oil is D80.

[0074]The base oil is 3 ointments.

[0075]The anti-rust film film is an alkylphenol amino resin.

[0076]The solvent is ethylene glycol.

[0077]The corrosion inhibitor is 1-phenyl-5 mercaptozole.

[0078]The dehydrating agent is a fatty alcohol polyoxyethylene ether.

[0079]The copper has a method of preparing a rust-proof oil, including the following steps:

[0080](1) Add the corrosion inhibitor to the solvent, at a certain temperature, stir for a certain period of time to obtain a solution A;

[0081](2) Add the anti-rust film film to the solution A, at a certain temperature, stirring reaction for a certain time to obtain a complexamine servant, that is, a solution B;

[0082](3) Sequentially add the base oil and solution B in the solvate oil, at a certain temperature, stir for a certain perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com