Preparation method for sustained-release type volatile rust preventive paper

A gas-phase anti-rust paper and a gas-phase anti-rust agent technology, which are applied in the preparation field of slow-release gas-phase anti-rust paper, can solve the problems such as the limitation of gas-phase anti-rust agents, and can increase the anti-rust time, improve the heat resistance and the specific surface area. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

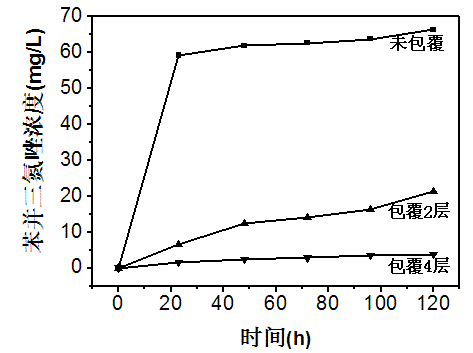

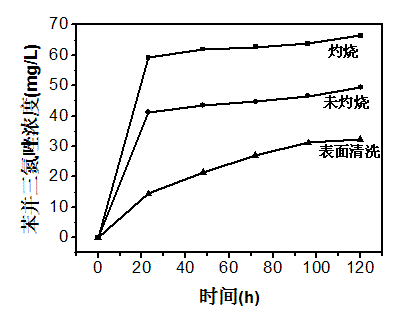

[0030] Place 1000g of 10% ethanol aqueous solution in a suction filter flask, add 35g of benzotriazole, stir to completely dissolve the benzotriazole, 120g of halloysite nanotubes (after burning at 400°C for 2 hours) ), stirring to make the halloysite nanotubes fully contact with the solution. Connect the vacuum pump with the suction filter bottle, vacuum for a certain period of time (such as 10min), keep the sealed system for 20min, release the vacuum, repeat the above operation 4 times, and centrifuge to obtain surface adsorption and the cavity is loaded with vapor phase rust inhibitor (benzene And triazole) halloysite nanotubes.

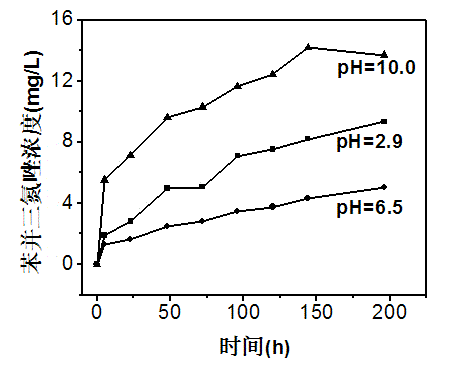

[0031] Prepare 4mg / ml polyacrylamine hydrochloride and polystyrene sodium sulfonate separately for use. 100g of halloysite nanotubes separated by centrifugation were dispersed in 1000ml of polyacrylamine hydrochloride under stirring, and the solid and liquid were separated by centrifugation after 15 minutes; the same amount of sodium polystyrene sul...

Embodiment 2

[0035] Place 1000g of 10% ethanol aqueous solution in a suction filter flask, add 35g of benzotriazole, stir to completely dissolve the benzotriazole, 120g of halloysite nanotubes (after burning at 400°C for 2 hours) ), stirring to make the halloysite nanotubes fully contact with the solution. Connect the vacuum pump with the suction filter bottle, vacuum for a certain period of time (such as 10min), keep the sealed system for 20min, release the vacuum, repeat the above operation 4 times, and centrifuge to obtain surface adsorption and the cavity is loaded with vapor phase rust inhibitor (benzene And triazole) halloysite nanotubes.

[0036] Prepare 4mg / ml polyacrylamine hydrochloride and polystyrene sodium sulfonate separately for use. 100g of halloysite nanotubes separated by centrifugation were dispersed in 1000ml of polyacrylamine hydrochloride under stirring, and the solid and liquid were separated by centrifugation after 15 minutes; the same amount of sodium polystyrene sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com