Metal antirust agent

A metal rust inhibitor, stainless steel technology, used in anti-corrosion coatings, coatings, etc., can solve the problem of poor rust-proof performance of rust-proof agents, and achieve extended rust-proof time, good compatibility, and long rust-proof time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

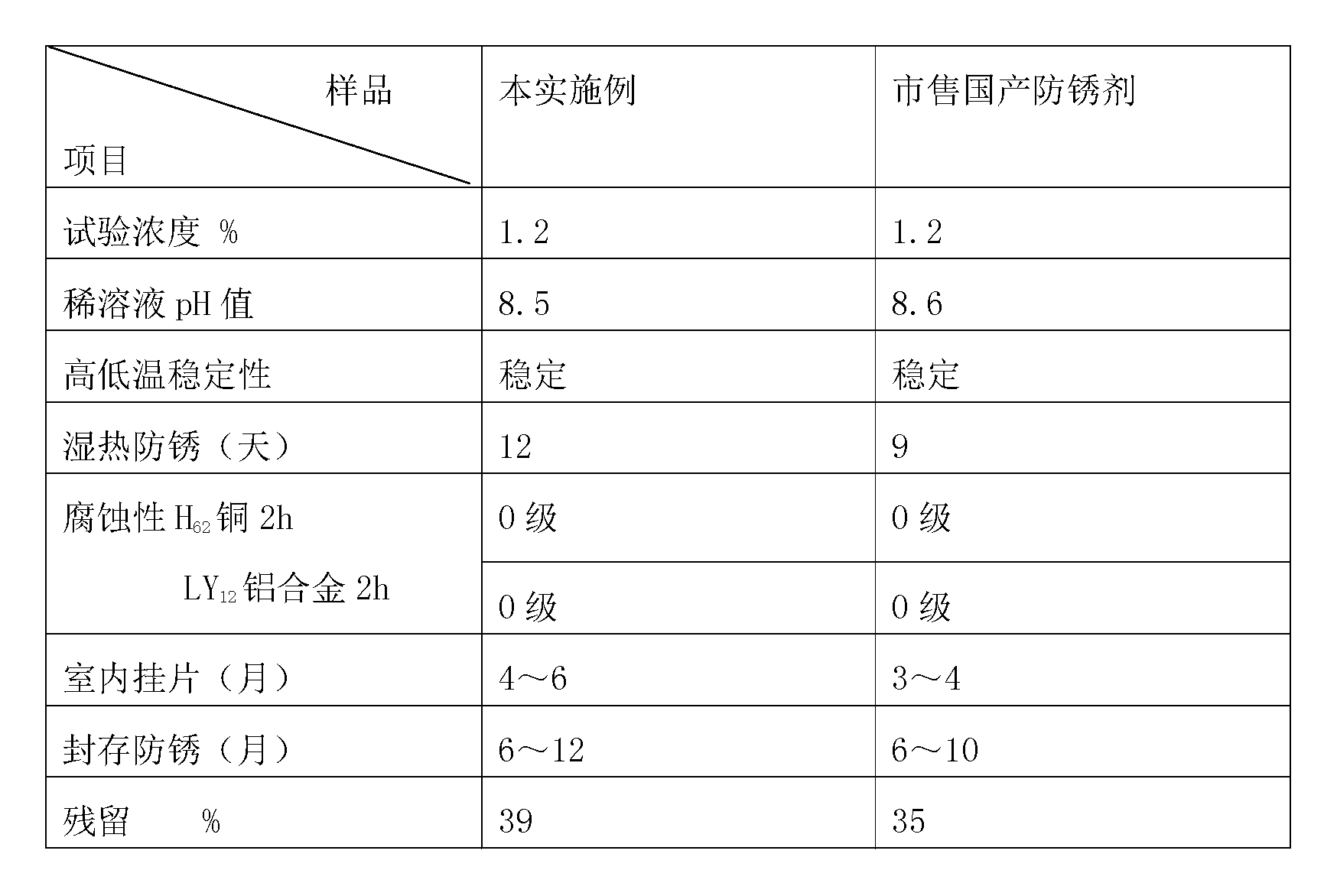

Examples

Embodiment Construction

[0012] A kind of metal antirust agent, it is made by the raw material of following parts by weight (kg): urea 5, liquefied paraffin 8, acetyl citrate tris (2-ethylhexyl) ester 5, acrylic acid 6, zinc powder 0.3, Epoxy cottonseed oil 5, xylene 3, polyethylene wax 5, potassium persulfate 0.3, borax 0.5, polyisobutylene 2, 2-aminoethylheptadecenyl imidazoline 2, benzotriazole 2, N-benzene Base-2-naphthylamine 1.5, zinc dialkyl dithiophosphate 1.2, polyvinyl alcohol 1.7, polyethylene glycol 1.2, propylene glycol 1.3, octylphenol polyoxyethylene ether 2.1, water 100.

[0013] Described a kind of metal antirust agent, preparation method comprises the following steps:

[0014] (1) Add liquefied paraffin, acetyl tris(2-ethylhexyl) citrate, acrylic acid, epoxy cottonseed oil, xylene and polyethylene wax into the stainless steel reactor by weight, raise the temperature to 110°C, start stirring and press Add urea, potassium persulfate, borax, zinc powder in parts by weight;

[0015] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com