3D Glass light-sensitive black ink composition and preparation method thereof

A technology of ink composition and black ink, applied in the direction of ink, application, household utensils, etc., can solve the problems of weak performance, lack of ink enhancement performance, unsolved adhesion and simultaneous abnormal deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of carboxyl-containing acrylic resin

[0042] Mix methacrylic acid, methyl methacrylate, isobornyl methacrylate, and benyl methacrylate in proportion, stir and heat, add a certain percentage of catalyst azobisisobutylcyanide to the reaction substrate, and control the methacrylic acid , methyl methacrylate, isobornyl methacrylate, and benyl methacrylate are in a ratio of 2:2-3:2-3:1-2, and the catalyst accounts for 1% by weight of the raw material. Adjust the reaction temperature and adjust The ratio of four kinds of raw materials, respectively obtain acid value at 50-200KOH / g, weight-average molecular weight is product acrylic resin A, B, C, D, at 4000-8000, expands the ratio range of four kinds of raw materials simultaneously, makes A The weight ratio of acrylic acid, methyl methacrylate, isobornyl methacrylate, and benyl methacrylate is outside the ratio range of 2:2-3:2-3:1-2, and acrylic resin E, F, G and H. The specific acid value and we...

Embodiment 2

[0046] Embodiment 2: the selection of the thixotropic agent containing silicon dioxide

[0047] The method for measuring silicon content in the thixotropic agent is the molybdenum blue photometric method or gravimetric method, and other methods known in the art can also be used.

[0048] The DBP absorption value of the thixotropic agent is measured according to the method of DIN53601, and the product whose DBP absorption value of the thixotropic agent is 150-250g / 100m1 is selected.

[0049] Select products that meet the requirements of the thixotropic agent according to the above method. The representative products that meet the requirements are matting powder OK412 from Degussa, BYK-405 from BYK, and OK500 from Degussa.

[0050] At the same time, a comparative test is carried out with products that do not meet the requirements. The representative product that does not meet the requirements chooses Grace matting powder RAD2105.

[0051] The silicon content and DBP absorption ...

Embodiment 3

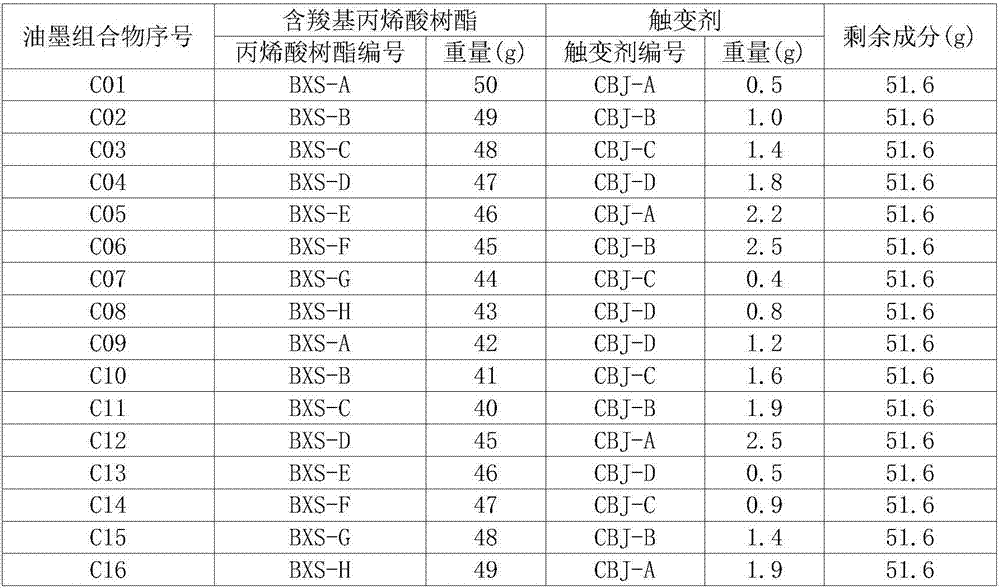

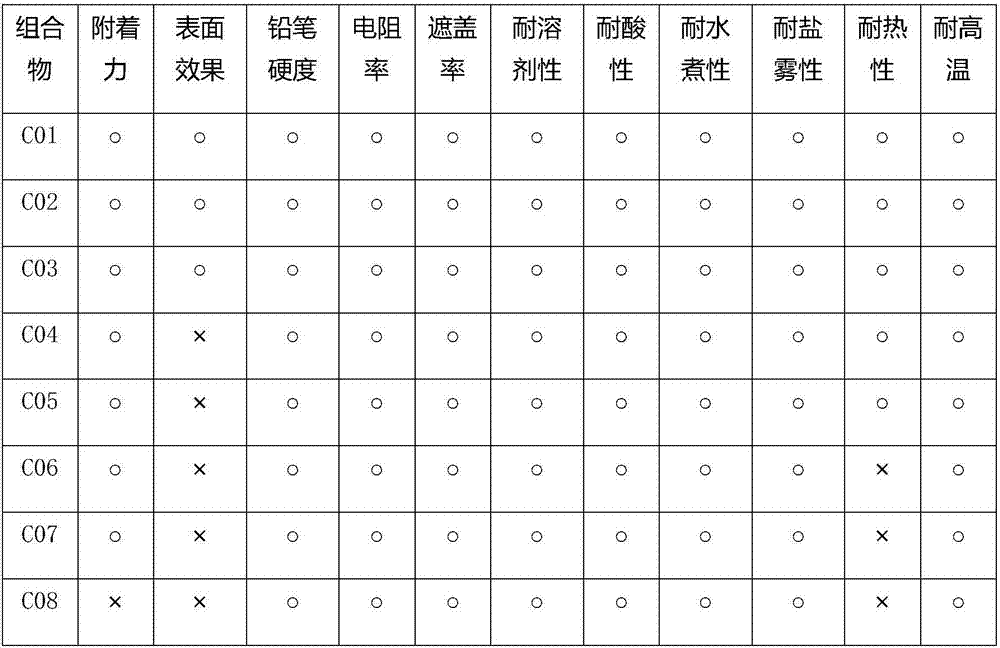

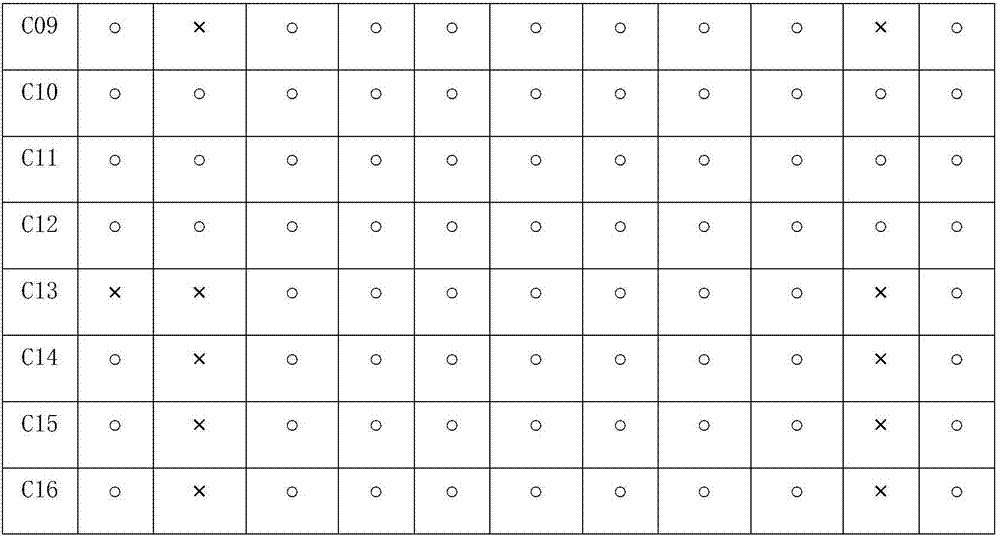

[0054] Embodiment 3: the preparation of black photosensitive ink composition

[0055]Select different carboxyl-containing acrylic resins in embodiment 1 and the thixotropic agent in embodiment 2 respectively, and 10g epoxy resin (purchased from Kunshan Nanya Electronics Company's E51), 12g black pigment (Germany Degussa company's E51) SPECIALBLACK 4), 3g dispersant (BYK-163 of German BYK chemical company), 4.2g photoinitiator (Irgacure-907 of 4g German BASF company and DAROCUR-ITX of 0.2g German BASF company), 13g inorganic filler (Guangxi Osmanthus brand ultra-fine talcum powder), 0.5g defoamer (Japanese Shin-Etsu Chemical's silicone defoamer KM-73), 0.3g leveling agent (Germany BYK-333), 0.6g adhesion promotion (OFS-6040 from Dow Corning, U.S.A.) and 8g organic solvent (propylene glycol methyl ether acetate from Shanghai Sinopharm Group), dispersed at high speed with a disperser (U400\80-220 high-speed disperser) for 10 minutes, and then grinded with three rolls Machine (S-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com