Method for preparing gel polymer lithium ion battery

A technology of lithium-ion batteries and gel polymers, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of complex extraction process of plasticizers, decreased battery yield, and easy micro-short circuit, etc. Ion conduction, cost reduction, effect of increasing irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

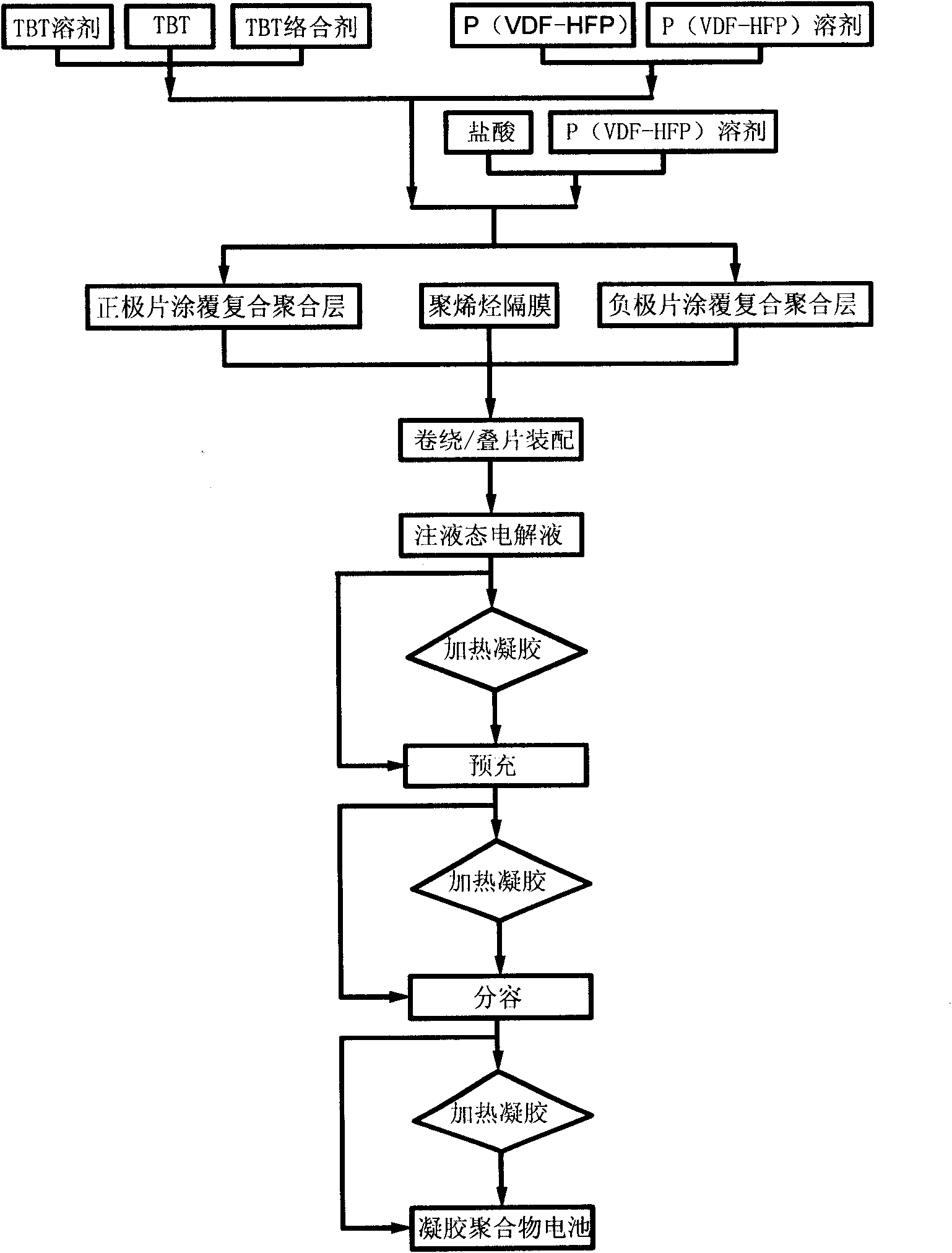

[0046] Prepare a kind of gel polymer lithium-ion battery, its preparation process is as follows figure 1 As shown, the materials and components are as follows:

[0047] Cathode, LiCoO 2 : Acetylene carbon black conductive agent: PVDF binder (mass ratio) = 96: 1.6: 2.4; the positive current collector is aluminum foil.

[0048] Negative electrode, 96% artificial graphite: SBR binder: sodium carboxymethyl cellulose (mass ratio) = 96: 2.5: 1.5; negative electrode current collector is copper foil.

[0049] Separator, 39.5% porosity polyolefin separator, thickness 12 μm.

[0050] Liquid electrolyte, EC: DEC: PC (mass ratio) = 1: 1: 0.2, LiFP 6 = 1M.

[0051] P(VDF-HFP) solution, P(VDF-HFP):acetone (mass ratio)=1:13.

[0052] TBT precursor solution (taking the amount of P(VDF-HFP) as 1), TBT:AcAc:n-butanol (mass ratio)=0.34:0.1:4.

[0053] Catalyst (TBT amount is 1), HCl: H 2 O: acetone (mass ratio) = 0.1:2:10.

[0054] Prepare liquid electrolyte, P(VDF-HFP) solution, TBT pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com