Ultra-high molecular weight polyethylene fiber filtering cloth

A polyethylene fiber, ultra-high molecular weight technology, used in filtration and separation, membrane filters, separation methods, etc., can solve the problems of wear resistance, acid and alkali resistance, impact resistance and short service life, and improve acid resistance. The effect of alkaline performance, high precision and strong load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

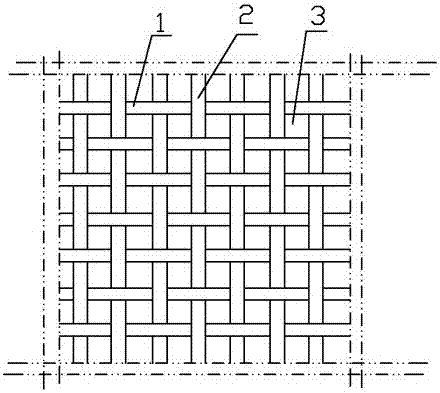

[0015] Refer to attached figure 1 Make the invention. The ultra-high molecular weight polyethylene fiber filter cloth is characterized in that: the ultra-high molecular weight polyethylene fiber warp 1 and the ultra-high molecular weight polyethylene fiber weft 2 are interwoven by a plain weave method, and the adjacent ultra-high molecular weight polyethylene fiber Between the warp 1 and the ultra-high molecular weight polyethylene fiber weft 2 is a filter hole 3 .

[0016] The warp 1 of the ultra-high molecular weight polyethylene fiber and the weft 2 of the ultra-high molecular weight polyethylene fiber can also be made by twill weaving.

[0017] The ultra-high molecular weight polyethylene fiber warp 1 and the ultra-high molecular weight polyethylene fiber weft 2 are made of ultra-high molecular weight polyethylene with a number average molecular weight of 1 million-500 and a strength of 10-50 g / d. Molecular weight polyethylene fibers.

[0018] The ultra-high molecular w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com