Method for preparing high-modulus super low shrinkage industrial yarn using pyromellitic dianhydride

A pyromellitic acid, ultra-low shrinkage technology, applied in the field of industrial textiles, can solve the problem of equipment and technology relying on imports, and achieve the effects of low thermal shrinkage, fast condensation rate, and improved unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

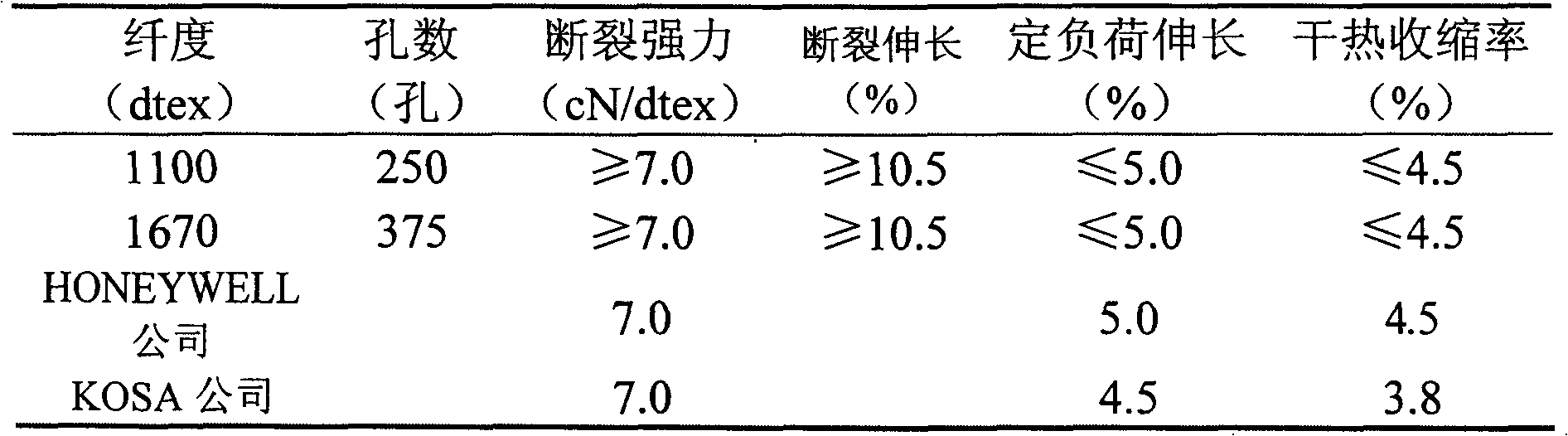

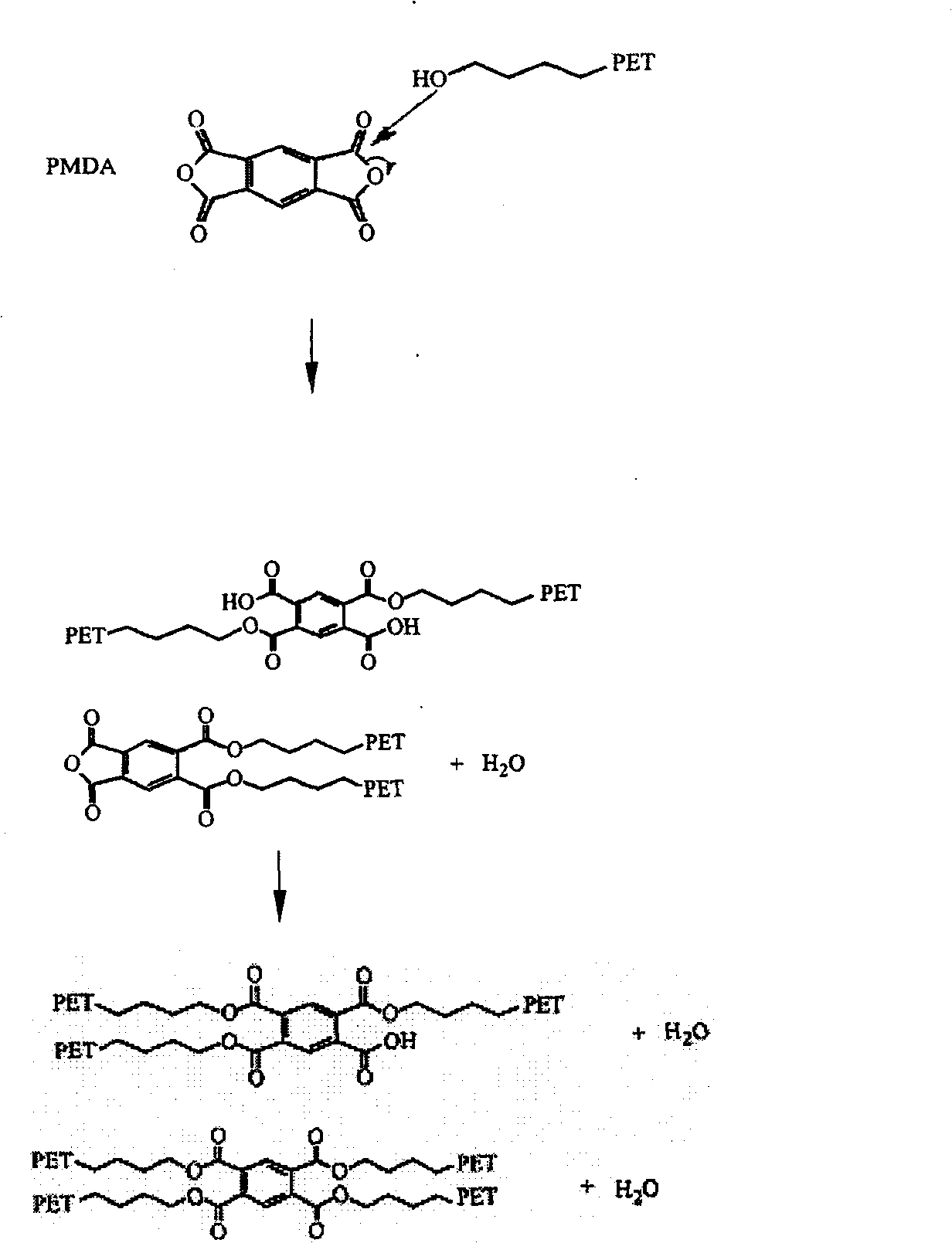

[0009] The following examples will further describe the present invention in detail: ordinary PET is pre-crystallized and dried at 120° C. to 130° C. for 6 hours, and sent to a screw extruder. At the same time, a chain extender PDMA is added with a mass fraction of 0.2%. Set the outlet pressure of the screw extruder to 15 MPa, heat through five heating zones, and control the heating temperature of each zone of the screw extrusion to 250°C, 260°C, 270°C, 280°C, and 300°C to gradually soften and melt the polyester. Finally, the melt temperature was controlled at 300°C. The above temperature accuracy is controlled within ±1°C. After the melt is filtered by the RL-472 melt filter, it enters the spinning box through the melt pipeline, and the temperature of the biphenyl boiler is controlled to keep the box temperature at 300±1°C. Carry out spinning and oiling, the spinning speed is 800m / min, adjust the speed of the metering pump according to the winding speed and the specification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com