1670-dtex/2-PEN impregnation tire fabric used for taking radial tire cap ply and making method thereof

A technology for radial tires and dipped cord fabrics, which can be used in textiles, fabrics, textiles, and papermaking. It can solve the problems of insufficient dimensional stability of nylon and achieve excellent performance, simple manufacturing process, and small dry heat shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

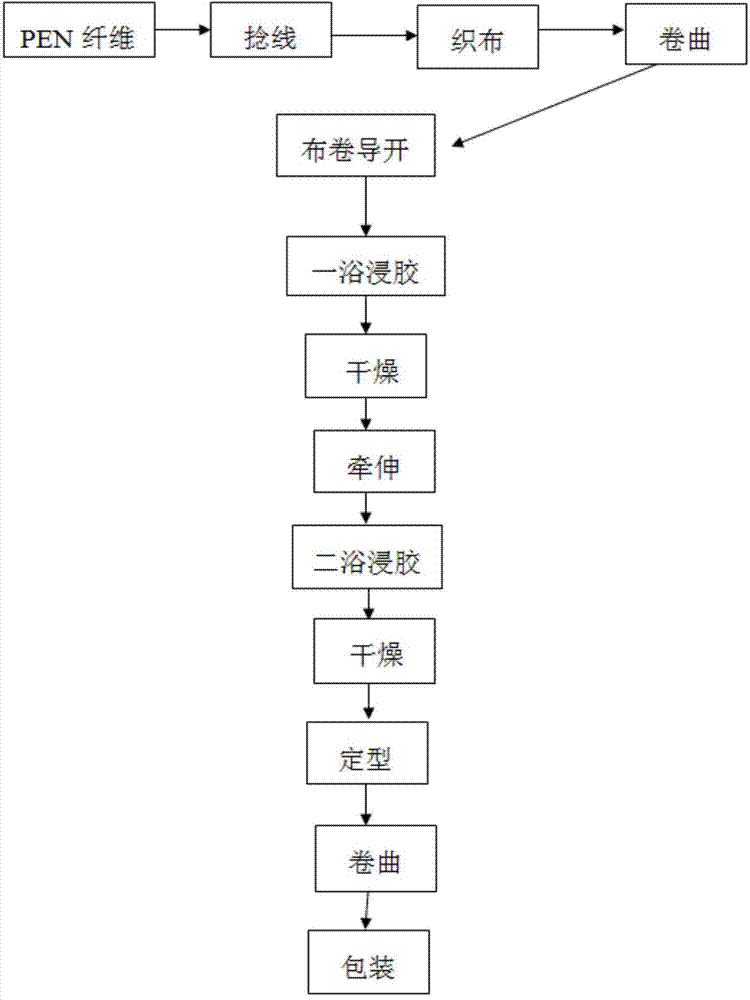

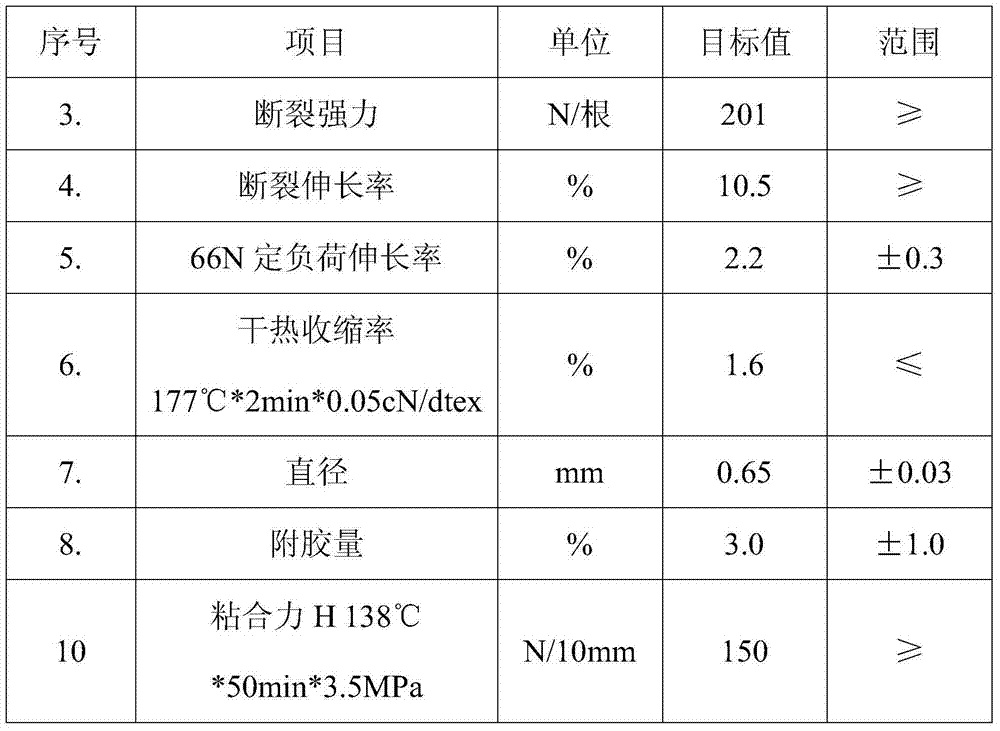

Embodiment 1

[0031] A preparation method for 1670dtex / 2PEN dipped cord fabric for passenger radial tire cap plies, specifically implemented according to the following steps: Twisting the 1670dtex PEN fiber into 1670dtex / 2 white of 2-strand structure on a direct twister The twist of the blank thread reaches the requirement of 360 twists / m; the twisted blank thread is woven on the air-jet loom according to the required density, width and length, at a speed of 700 rpm; double-bath dipping The process is to carry out one-bath dipping treatment on the fabric, the one-bath dipping solution is mainly blocked isocyanate and epoxy resin, the solid content is 3.87%, the drying temperature is 165°C, the tension is 1000daN (1aN=10N), and the drawing temperature is 245°C , tension 2500daN; two-bath dipping treatment for the fabric, the second-bath dipping liquid is mainly RFL, the solid content is 24.1%, the drying temperature is 165°C, the tension is 100daN, the setting temperature is 245°C, the tensio...

Embodiment 2

[0033] A preparation method for 1670dtex / 2PEN dipped cord fabric for passenger radial tire cap plies, specifically implemented according to the following steps: Twisting the 1670dtex PEN fiber into 1670dtex / 2 white of 2-strand structure on a direct twister The twist of the blank thread reaches the requirement of 400 twists / m; the twisted blank thread is woven on the air-jet loom according to the required density, width and length, at a speed of 700 rpm; double-bath dipping process, the fabric is subjected to one-bath dipping treatment, the one-bath dipping solution is mainly blocked isocyanate and epoxy resin, the solid content is 3.87%, the drying temperature is 155°C, the tension is 1500daN, the drawing temperature is 235°C, and the tension is 3000daN; The woven fabric is subjected to two-bath dipping treatment, the second-bath dipping solution is mainly RFL, the solid content is 24.1%, the drying temperature is 155°C, the tension is 1500daN, the setting temperature is 235°C,...

Embodiment 3

[0035] A preparation method for 1670dtex / 2PEN dipped cord fabric for passenger radial tire cap plies, specifically implemented according to the following steps: Twisting the 1670dtex PEN fiber into 1670dtex / 2 white of 2-strand structure on a direct twister The twist of the blank thread reaches the requirement of 380 twists / m; the twisted blank thread is woven on the air-jet loom according to the required density, width and length, at a speed of 700 rpm; double-bath dipping process, the fabric is subjected to one-bath dipping treatment, the one-bath dipping solution is mainly blocked isocyanate and epoxy resin, the solid content is 3.87%, the drying temperature is 160°C, the tension is 1200daN, the drawing temperature is 240°C, and the tension is 2800daN; The woven fabric is subjected to two-bath dipping treatment, the second-bath dipping solution is mainly RFL, the solid content is 24.1%, the drying temperature is 160°C, the tension is 1200daN, the setting temperature is 240°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com