High-strength low-extension polyester staple fiber preparation method

A polyester staple fiber, high-strength and low-elongation technology, applied in the field of polyester production technology, can solve the problem that the breaking strength and other qualities of polyester staple fibers cannot meet the requirements of high-strength and low-elongation fibers, and achieve low elongation at break and a wide range of production deniers , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

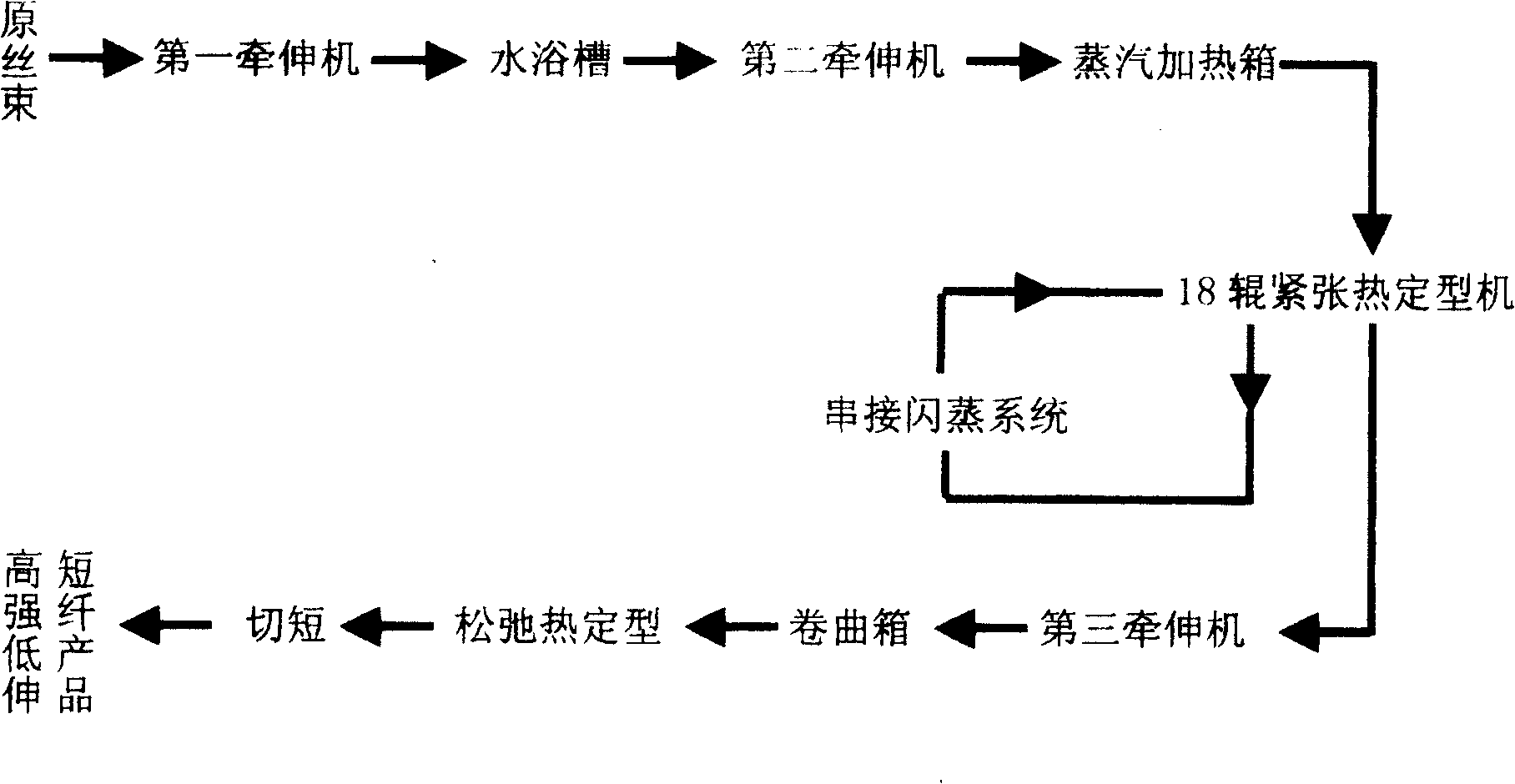

Method used

Image

Examples

Embodiment 1

[0023] The original tow with a specification of 1.33dtex / 3780f, a breaking strength CV value of ≤12%, and a breaking elongation CV value of ≤11% is passed through the first drafting machine, a water bath at a temperature of 70°C, and a second drafting machine. Drafting, the drafting ratio is 1:3.04; after entering the steam heating box with a temperature of 110°C, the 18-roll tension heat setting machine with a roller surface temperature of 217°C is used for secondary drafting, and the drafting ratio is 1:1.16; then enter the second stage The remaining drawing is performed by three drawing machines, and the drawing ratio is 1:0.998; the silk after being crimped by a crimping box with a crimping temperature of 90°C is cooled to below 75°C by a relaxation heat setting machine, and is cut after being evenly dried. The performance of the produced product is good, and the physical indexes of the obtained silk are shown in Table 1.

Embodiment 2

[0025] The original tow with a specification of 1.50dtex / 3780f, a breaking strength CV value ≤ 12%, and a breaking elongation CV value ≤ 11% are passed through the first drafting machine, a water bath at a temperature of 72°C, and a second drafting machine. Drafting, drafting ratio 1: 3.02; after entering the steam heating box with a temperature of 115°C, pass through an 18-roller tension heat setting machine with a roller surface temperature of 210°C for secondary drafting, with a drafting ratio of 1: 1.14; then enter the second The remaining drawing is performed by three drawing machines, and the drawing ratio is 1:0.998; the silk after being crimped by a crimping box with a crimping temperature of 90°C is cooled to below 75°C by a relaxation heat setting machine, and is cut after being evenly dried. The performance of the produced product is good, and the physical indexes of the obtained silk are shown in Table 1.

example 3

[0027] The original tow with a specification of 1.56dtex / 4250f, a breaking strength CV value ≤ 12%, and a breaking elongation CV value ≤ 11% are passed through the first drafting machine, a water bath at a temperature of 75°C, and a second drafting machine. Drafting, drafting ratio 1: 3.0; after entering the steam heating box with a temperature of 117°C, pass through an 18-roll tension heat setting machine with a roller surface temperature of 210°C for secondary drafting, with a drafting ratio of 1: 1.18; then enter the second stage The remaining drawing is carried out by three drawing machines, and the drawing ratio is 1:0.995; after being crimped by a crimping box with a crimping temperature of 95°C, the silk is cooled to below 75°C by a relaxation heat setting machine, and is cut after being uniformly dried. The performance of the produced product is good, and the physical indexes of the obtained silk are shown in Table 1.

[0028] Table 1 The polyester staple fiber finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com