Method and apparatus for manufacturing polymer composite piezoelectric material having boron nitride nanotubes dispersed therein, and polymer composite piezoelectric material manufactured by the method

A boron nitride nanotube, piezoelectric material technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, nanotechnology, etc. It consumes a lot of time and cost, and the piezoelectricity of composite materials is not very effective, so as to achieve high-voltage electric coefficient and improve piezoelectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

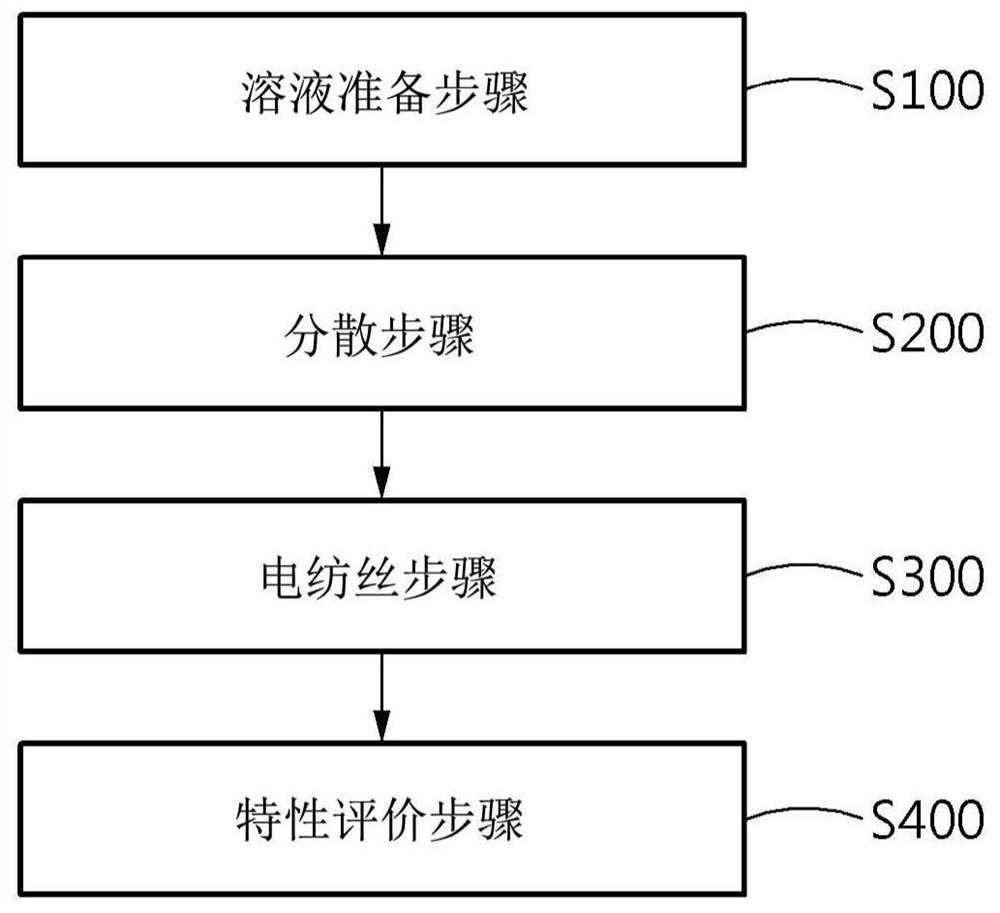

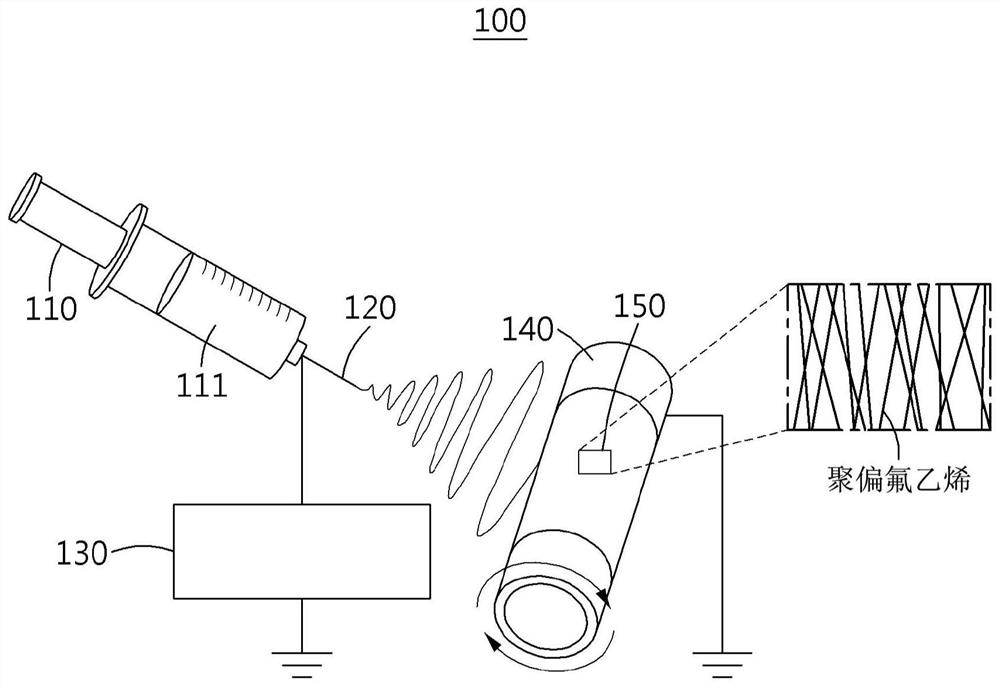

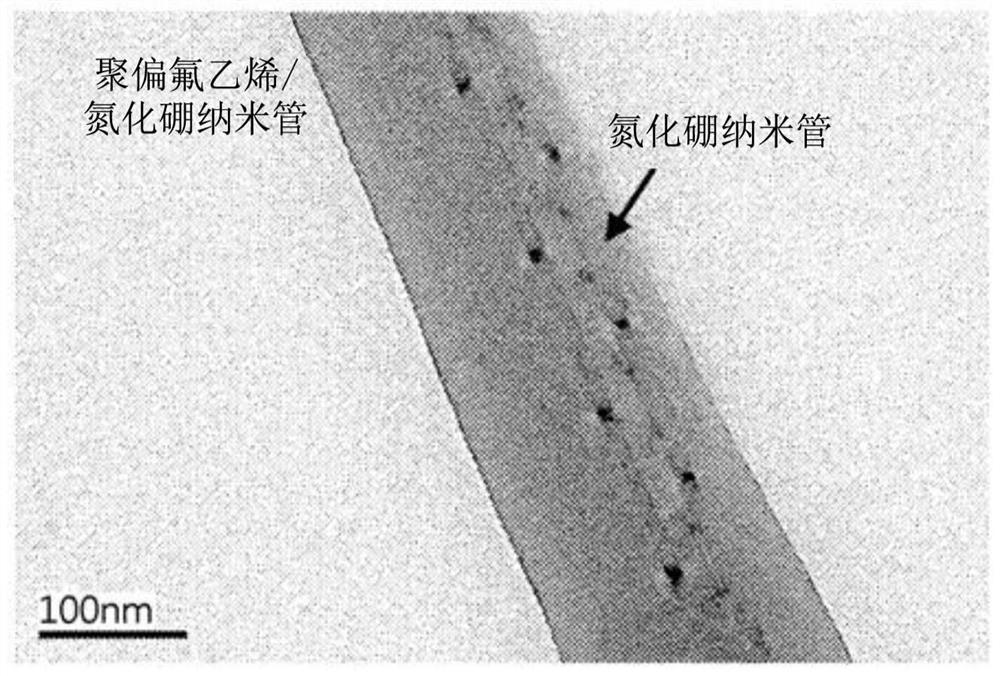

[0068] First refer to figure 1 According to an embodiment of the present invention, the method for preparing a composite piezoelectric material dispersed with boron nitride nanotubes may include: a solution preparation step S100, preparing a polymer solution containing polymers; a dispersion step S200, dissolving boron nitride nanotubes Dispersed in the above-mentioned polymer solution; electrospinning step S300, by using an electrospinning method to electrospin the above-mentioned polymer solution dispersed with the above-mentioned boron nitride nanotubes to prepare a composite piezoelectric material with a nanofiber phase; and In the characteristic evaluation step S400, evaluate the piezoelectric characteristics of the composite piezoelectric material.

[0069] Through this step-by-step structure, the boron nitride nanotubes can be aligned in the same direction as the fibers by electrospinning without a separate polarization alignment process, so composite piezoelectric mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com