Multi-layer tube

A technology of multi-layer tubes and tube mothers, applied in the field of multi-layer tubes, can solve the problems of not being able to meet pressure resistance and flexibility at the same time, and achieve the effects of excellent chemical resistance, strong bending resistance, and high non-adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] [Molding of multilayer tubes]

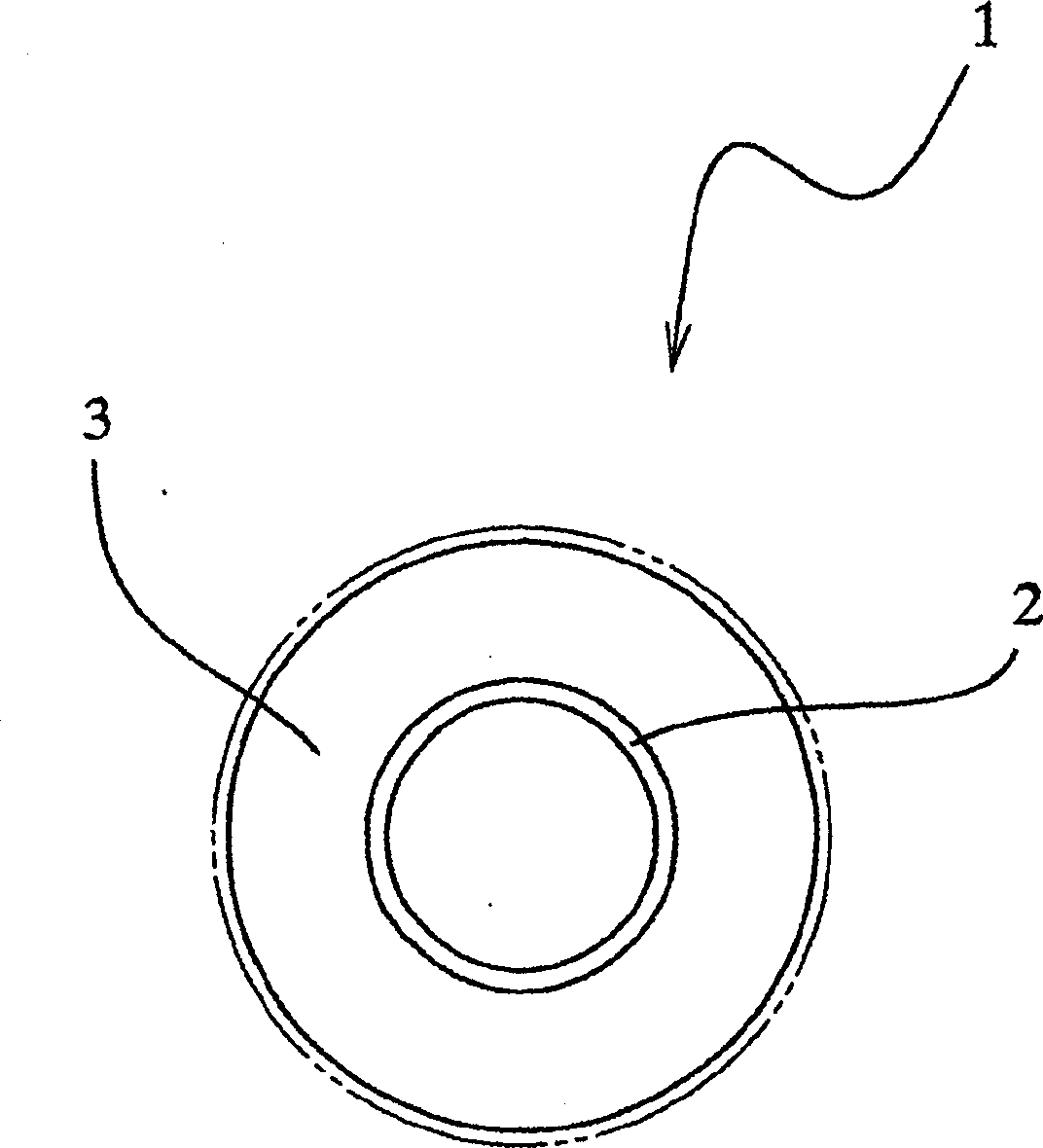

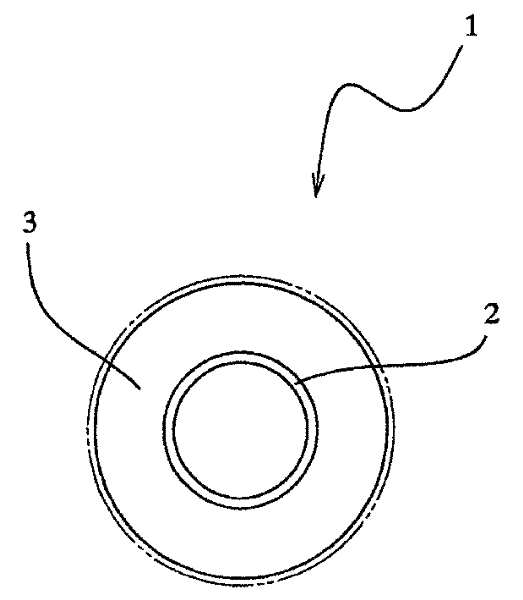

[0040] use figure 1 The multilayer pipe shown is Example 1. As the fluororubber-based thermoplastic elastomer (A) of the pipe base material 3, Daiel thermoplastic fluororubber T-530 is used, and the vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene terpolymer (B) is used as a mixture of the coating layer 2 , using THV-500G. The coating layer 2 is a mixture of a fluororubber-based thermoplastic elastomer (A) and a vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene terpolymer (B) at a ratio of 1:1.

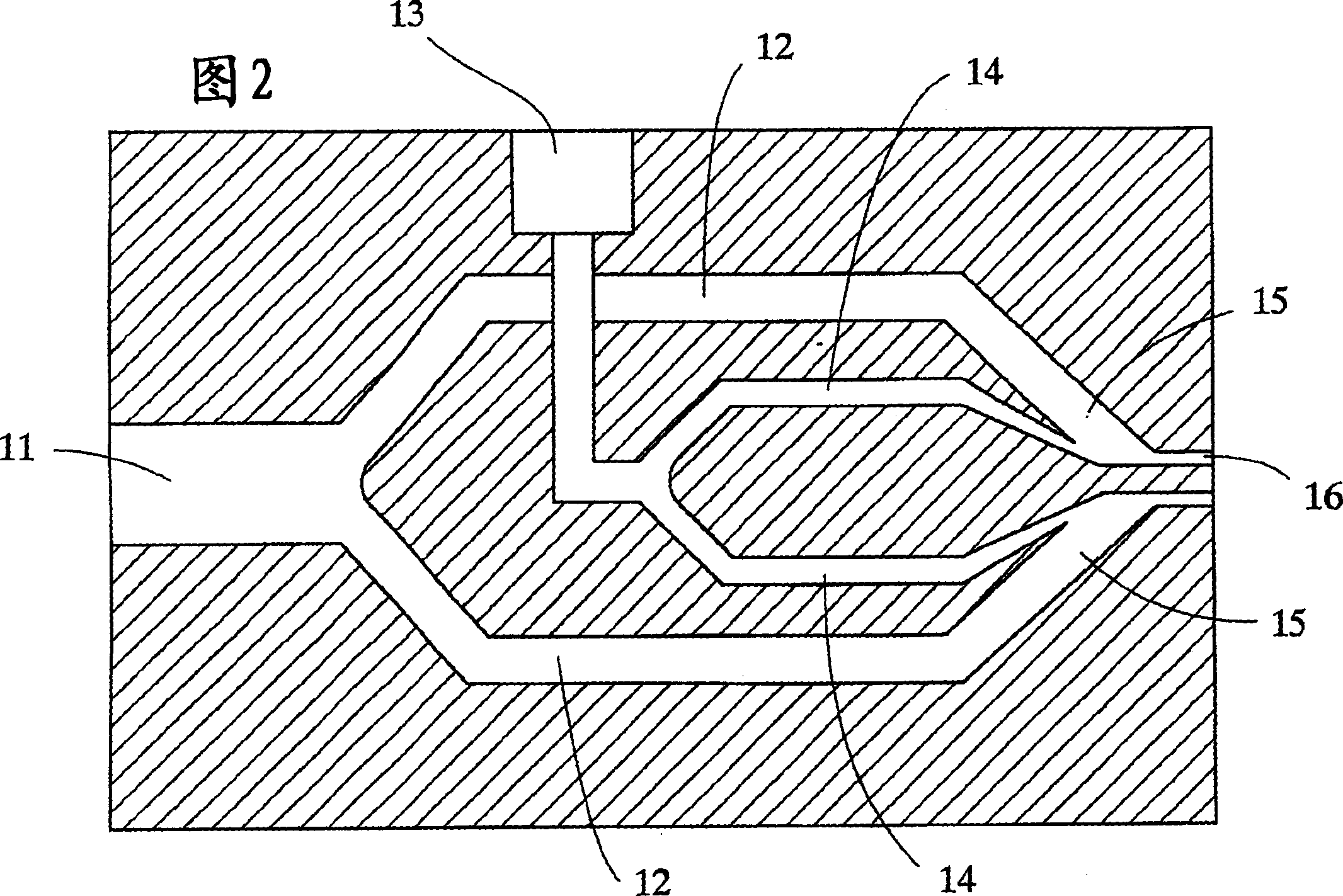

[0041] Figure 2 shows the molded figure 1 Cross-section of the extrusion die of the multilayer tube 1. Barrel diameter: 40mm, L / D: 25 extruder is connected to the pipe base material inlet 11 of the mold, and the fluororubber thermoplastic elastomer (A) melted at a temperature of 260°C is injected from the pipe base material inlet 11 Injection passes through the pipe base material flow path 12. In addition, an extruder w...

Embodiment 2

[0051] Ethylene-tetrafluoroethylene (ETFE) whose hardness is JIS D55.

Embodiment 3

[0053] Vinylidene fluoride (PVDF) whose hardness is JIS D75.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com