Carbon-coated aluminum member and method for producing the same

A manufacturing method and carbon coating technology, which are applied in the field of carbon-coated aluminum materials and their manufacturing, can solve the problems of insufficient adhesion between the active material layer and the aluminum material, and the aluminum carbide film and the aluminum material have insufficient adhesion, so as to improve the adhesion. , the effect of improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

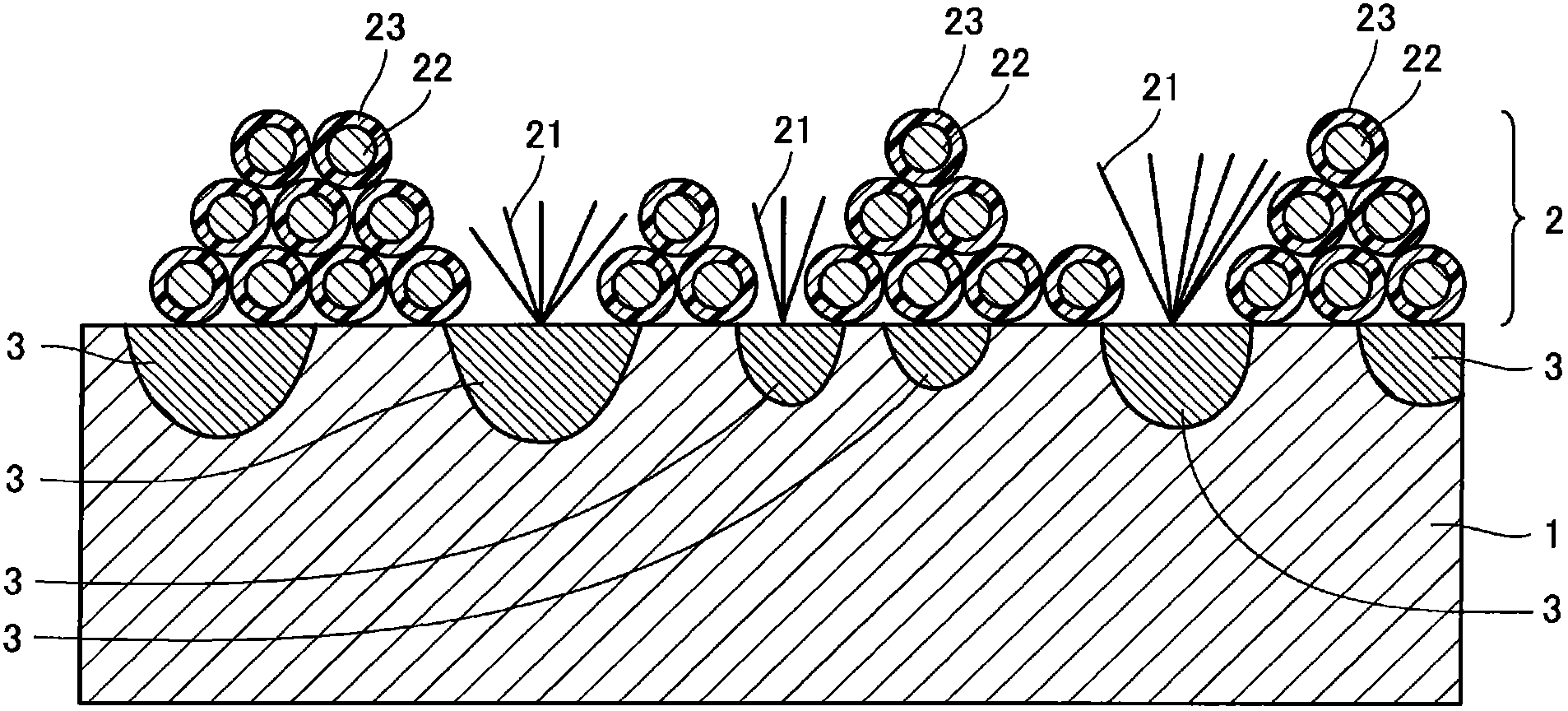

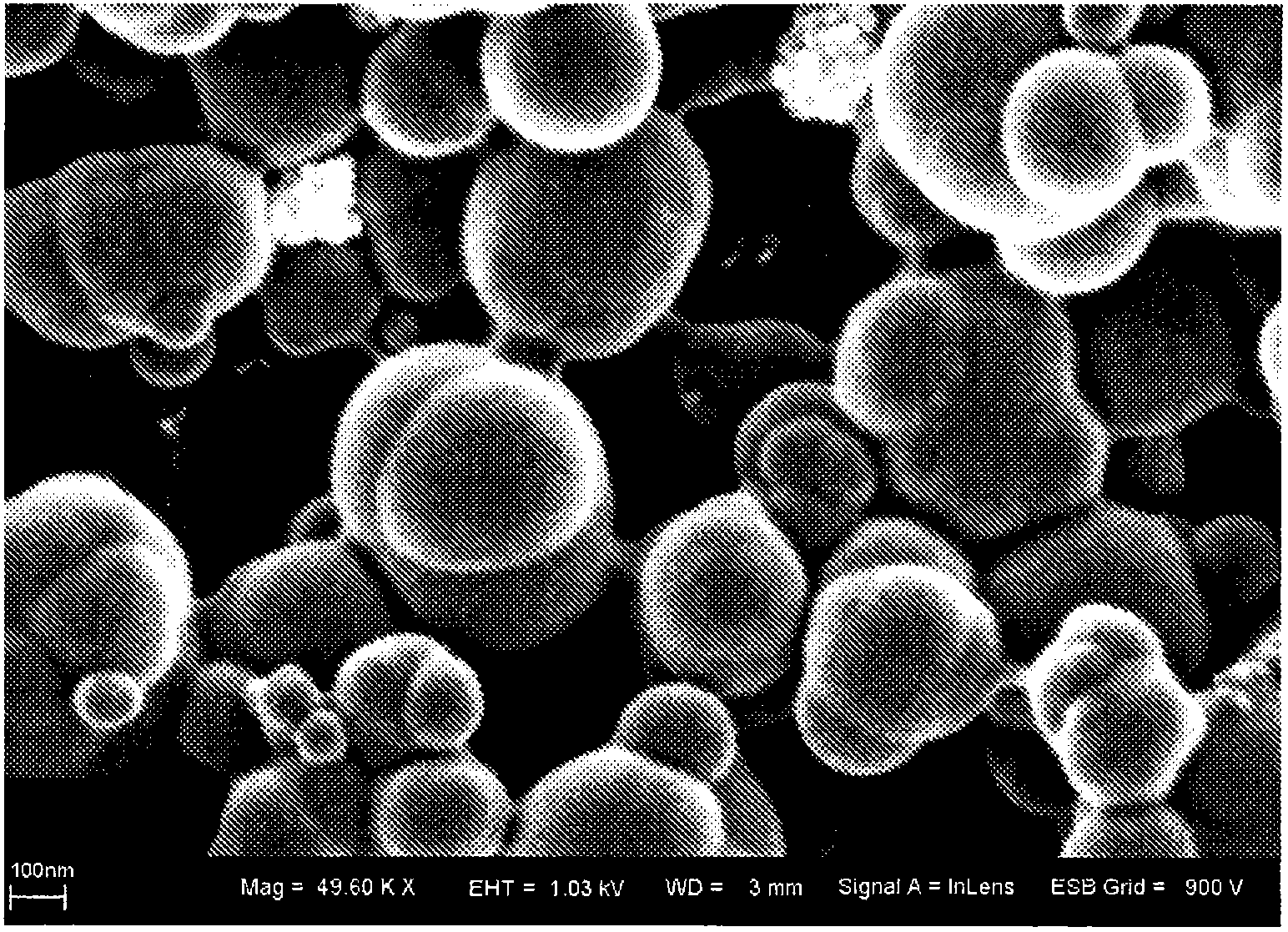

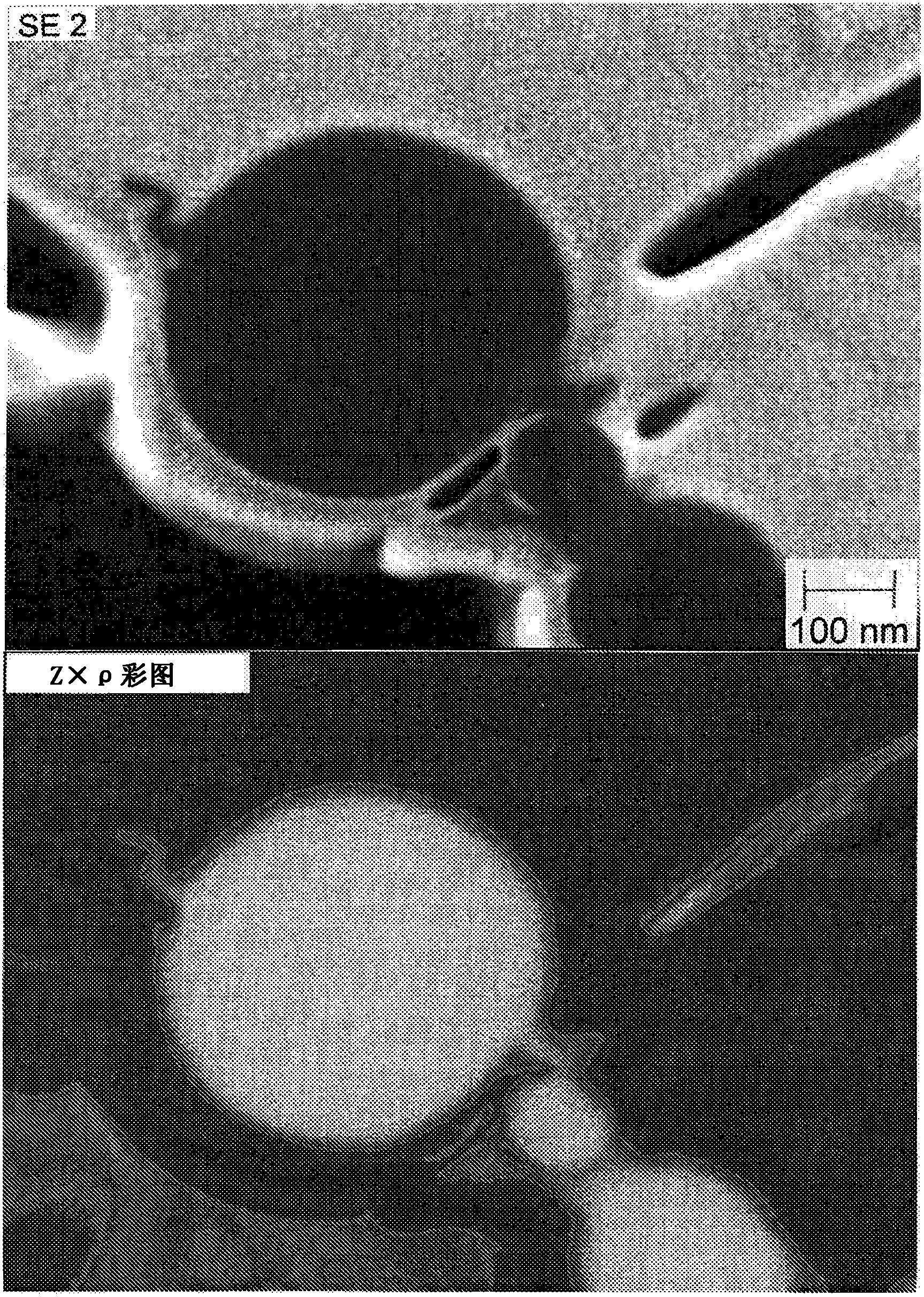

[0087] 2 parts by mass of carbon black particles having an average particle diameter of 300 nm as the carbon-containing particles 22, and 1 part by mass of various binders shown in "Binders used in the resin layer formation process" in Table 1 20% by mass of toluene was added to the binder, and this was sufficiently kneaded with a kneader to form a resin layer on the surface of the carbon black particles (resin layer forming step).

[0088] In Examples 1 to 3, the kneaded product containing carbon black particles with a resin layer formed on the surface was uniformly dispersed in the isopropyl group shown in the "solvent used in the carbon-containing particle adhesion process" in Table 1 using a disperser. In the alcohol solution, a coating liquid containing carbon black particles having a solid content of 20% by mass as a coating liquid used in the carbon-containing particle adhesion step was thereby obtained.

[0089] In Examples 4 to 6, the kneaded product containing carbon blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com