Method of manufacturing a polarizing plate, and a cutting mat used in the method

A manufacturing method and polarizing plate technology, applied in the direction of optics, optical elements, polarizing elements, etc., can solve problems such as adhesion to polarizing plates, and achieve the effects of reducing sinking, suppressing warping, and high elastic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

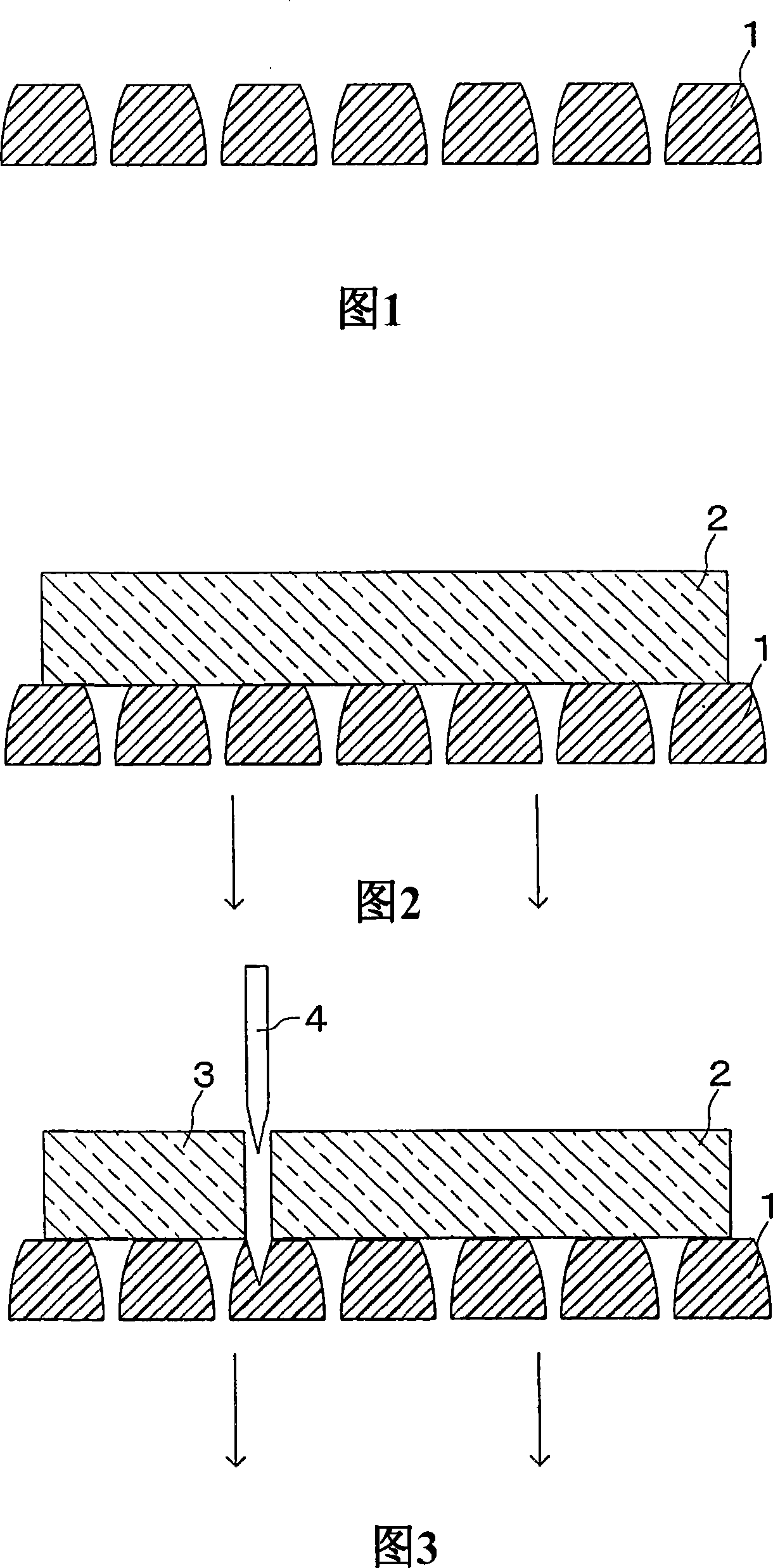

[0033] Prepare an ultra-high molecular weight polyethylene resin porous sheet (Nitto Denko "sun map"; viscosity average molecular weight 6 million, compression elastic modulus 250kgf / cm 2 , average pore diameter of 17 μm, thickness of 0.3 mm, Shore hardness of 48, and coefficient of dynamic friction of 0.08) as a cutting mat, and a four-layer polarizing original plate was fixed on the porous sheet. The original polarizer is fixed by attracting the original polarizer through the porous sheet from below the porous sheet.

[0034] Next, a guillotine blade (single-piece blade) with a tip angle of 25 degrees was moved from above to below the polarizing original plate at a speed of 50 mm / sec to cut the polarizing original plate. At this time, the guillotine blade was moved so that its tip reached a depth of 0.1 mm from the surface of the porous sheet. This operation was repeated so that the cutting lines on the polarizing original plate were parallel to each other and at equal inte...

Embodiment 2

[0037] The pores of the same ultrahigh molecular weight polyethylene resin porous sheet used in Example 1 were impregnated with an ultraviolet curable ink (Dainippon Ink Chemicals Co., Ltd. "Daiku ink (Daikyuaiink)") , and irradiated with an ultraviolet lamp to cure the ultraviolet curable ink, an ink-impregnated porous sheet was obtained. Ten polarizing plates were obtained in the same manner as in Example 1, except that the porous sheet was impregnated with this ink as a cutting mat. Furthermore, in the same manner as in Example 1, the maximum crack depth generated on the cut surface of the polarizing plate, the cutting dimension error, and the appearance were evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com