Resin composition for medical use, manufacturing method thereof, and medical kit

一种树脂组合物、制造方法的技术,应用在医药配方、牙科制剂、外科黏合剂等方向,能够解决内衬材料弹性率低、韧性不充分等问题,达到高弹性率、简便制造、韧性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The method for preparing the resin composition of the present invention is not particularly limited, but it is preferably prepared by mixing the powder of the polymer (A) and the liquid of the monomer (B). At this time, the polymerization initiator (C) may be previously contained in at least one of the powder formulation or the liquid formulation, or may be added when preparing the resin composition. When the powder and the liquid are mixed, the powder swells through the liquid, and then becomes a cake after passing through the starch syrup. When the resin composition is used as a material for denture bases, etc., the resin composition can be shaped even if it is in the form of starch syrup when working on the model. Formed into the female mold to form the desired shape. Therefore, in the work of shaping the resin composition, the resin composition is preferably maintained in a cake-like state. After shaping the resin composition, a cured molded article can be obtaine...

Embodiment 1

[0091] Mix the powder of polymethyl methacrylate produced by suspension polymerization (“Hi-Pearl D-100M” manufactured by Negami Industry Co., Ltd.: weight-average molecular weight 500,000, average particle size about 50-80 μm, containing benzoyl peroxide 0.5 ~1.0% by weight) 4 g and 2 ml of a solution of diethylene glycol dimethacrylate (hereinafter, sometimes abbreviated as 2G) and left still. After about 24 hours, fill the mixture in a cake state into a Teflon (registered trademark) mold of 2 mm × 2 mm × 25 mm, which can be formed as a test piece, and clamp it, and place it in a constant temperature chamber ("ST-101B1" manufactured by ESPEC Corporation) Internally heated at 65°C for 60 minutes, and then heated at 100°C for 90 minutes to carry out polymerization. After cooling naturally, the test piece taken out of the Teflon (registered trademark) mold was left in the air for a day, and then a three-point bending test was performed with a universal testing machine (Instron ...

Embodiment 2 and 3

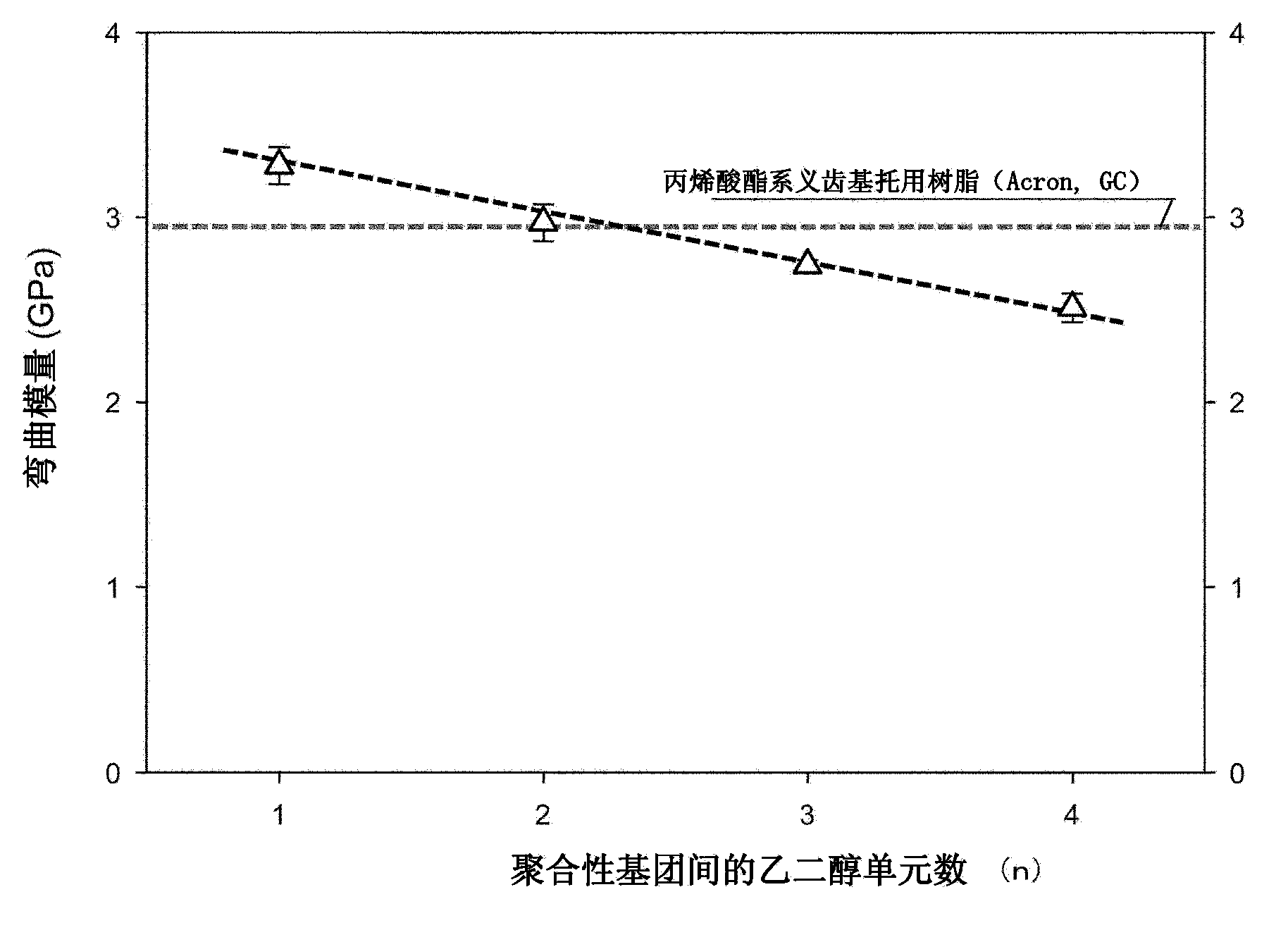

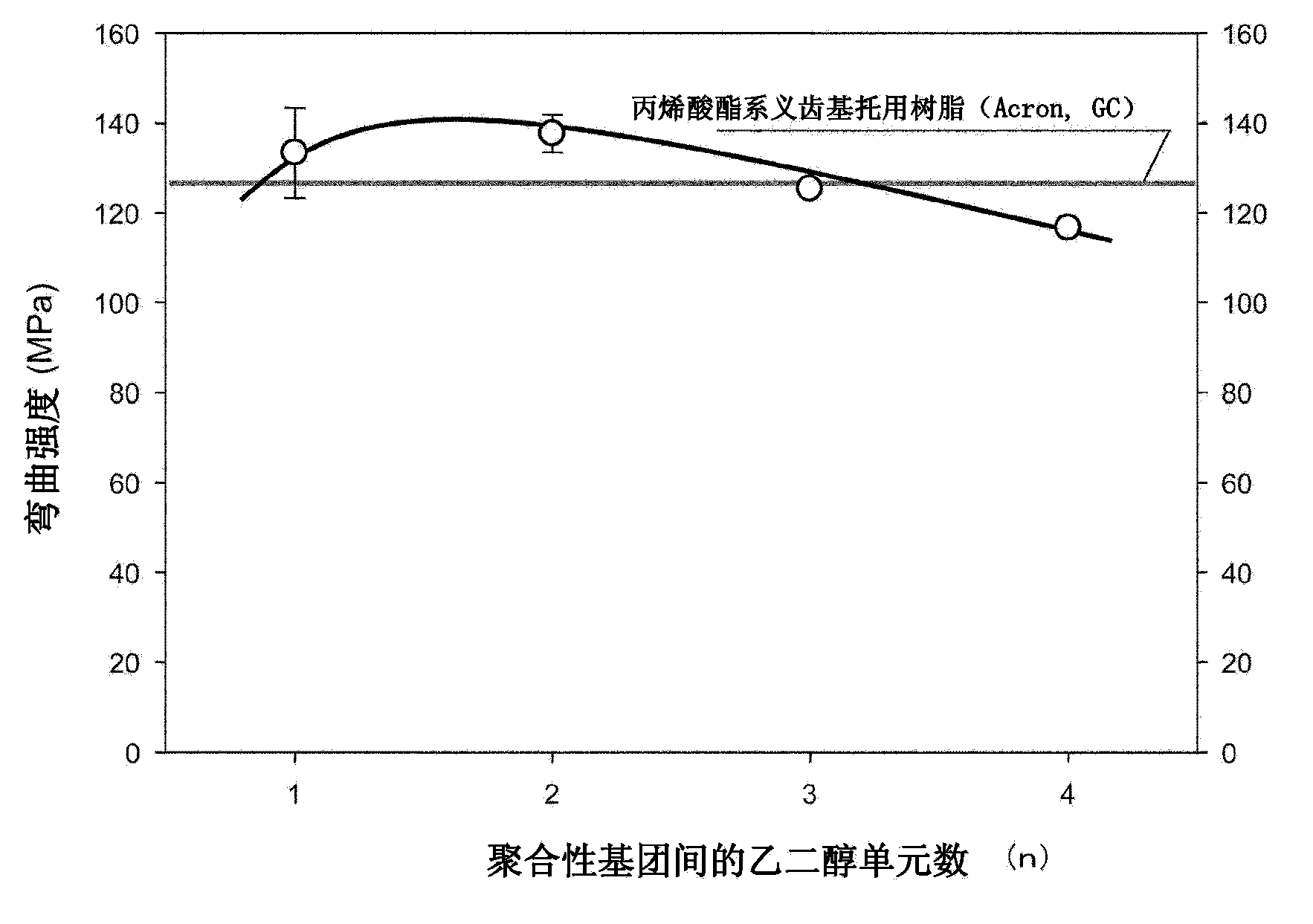

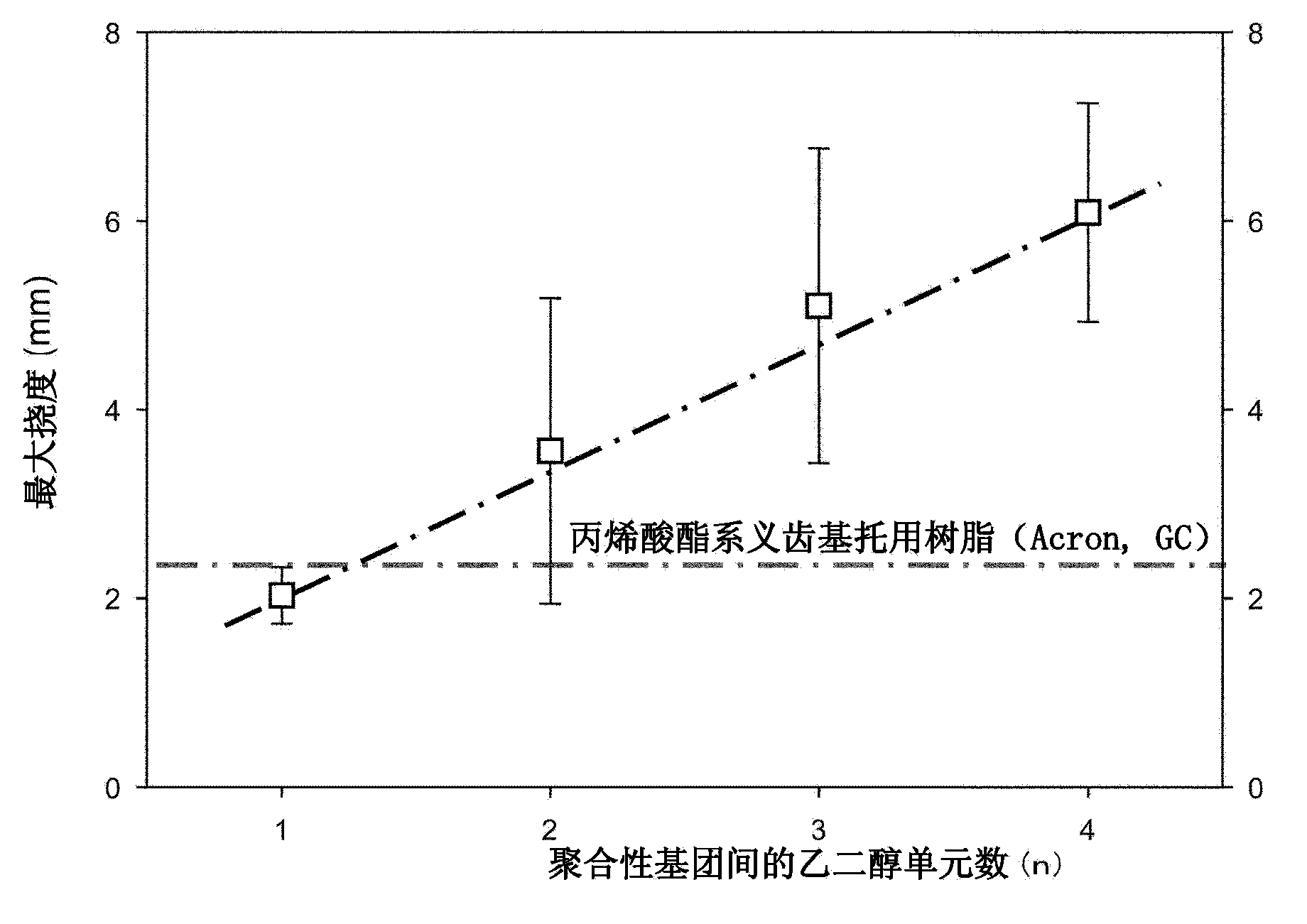

[0093] In Example 1, instead of 2G, triethylene glycol dimethacrylate (hereinafter, sometimes abbreviated as 3G) or tetraethylene glycol dimethacrylate (hereinafter, sometimes abbreviated as 4G) was used as the liquid preparation , except that, in the same manner as in Example 1, the liquid and powder were mixed and left to stand. As a liquid, in the case of using 3G, after about 48 hours, in the case of using 4G, after about 96 hours, use a cake-like mixture, and prepare test pieces in the same manner as in Example 1, and use a universal The testing machine performs a three-point bending test of the test piece. For each test, the results of four kinds of bending characteristics measurements are shown in Table 1 and Figure 1~4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com