Barrel assembly of a revolving weapon

A barrel and component technology, which is applied in the field of conventional rotating barrel weapons, can solve problems such as poor processing and assembly manufacturability, and achieve the effects of ensuring the lock size, simple structure and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

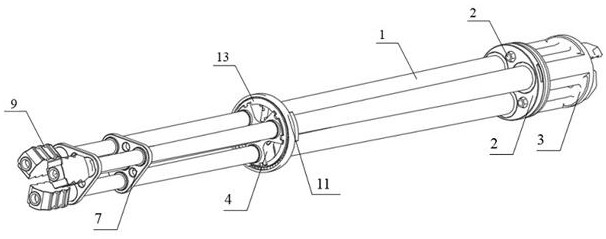

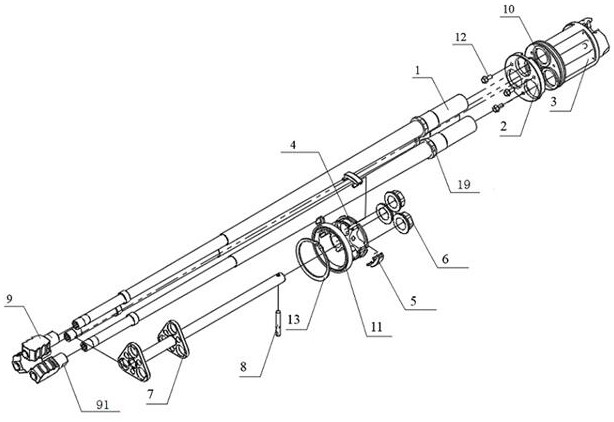

[0021] A revolving weapon barrel assembly, comprising a barrel 1, a cover plate 2, a section sleeve 3, a bearing ring 4, a positioning hoop 5, a positioning screw sleeve 6, a barrel hoop component 7, a barrel hoop fixing pin 8, a muzzle Device 9; body tube 1 and section sleeve 3 are connected by thread; cover plate 2 and body tube 1 are fitted by anti-rotation plane; each body tube 1 is installed with a positioning screw sleeve 6, a positioning hoop 5 and a muzzle device 9. The plurality of anti-rotation planes 19 on the barrel 1 are evenly distributed along the circumference. The number of inner holes of the cover plate 2 corresponds to the number of the barrels and is evenly distributed along the circumference. The cover plate 2 is fixedly mounted on the segment sleeve 3 by means of screws 12 .

Embodiment 2

[0023] A barrel assembly of a rotary weapon of the present invention includes a barrel 1, a cover plate 2, a segment sleeve 3, a bearing ring 4, a positioning hoop 5, a positioning screw sleeve 6, a barrel hoop component 7, and a barrel hoop fixing pin 8 , the muzzle device 9; the rear part of the barrel 1 and the section sleeve 3 are fixed by threaded connection; the middle part of the barrel 1 is provided with a bearing, and the bearing is connected with the barrel through the bearing ring 4; the front part of the barrel 1 is provided with a barrel hoop part 7 , the body tube hoop part 7 includes a front hoop and a middle hoop, and the front hoop and the middle hoop are provided with a through hole that fits with the body tube 1; The muzzle device 9 is fixedly connected with the body tube 1 through the thread; the outer circle of the body tube 1 is provided with an anti-rotation plane 19, and the section sleeve 3 is fixed with a cover plate 2, and the cover plate 2 is provide...

Embodiment 3

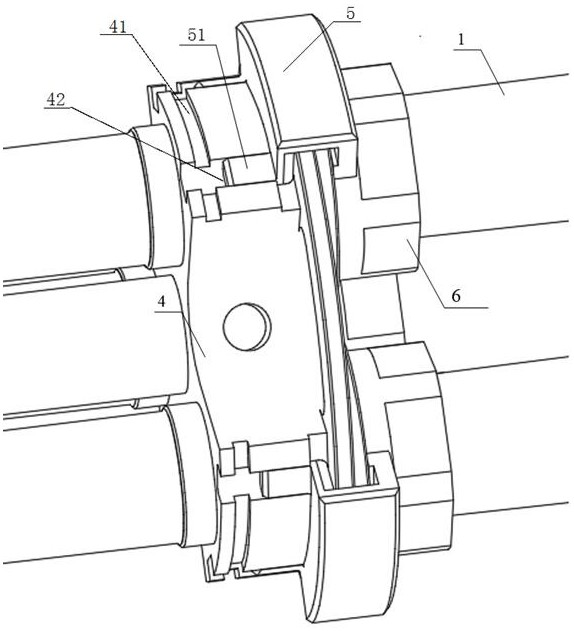

[0026] A barrel assembly of a rotary weapon of the present invention includes a barrel 1, a cover plate 2, a segment sleeve 3, a bearing ring 4, a positioning hoop 5, a positioning screw sleeve 6, a barrel hoop component 7, and a barrel hoop fixing pin 8 , the muzzle device 9; the muzzle device 9 is connected with the barrel 1 through the thread, and the muzzle device 9 is provided with an anti-rotation plane 91, which is fitted with the anti-rotation plane of the inner hole of the barrel hoop part 7; the barrel hoop part is 7 sets Insert all the barrels 1 of the assembly to provide radial support and auxiliary positioning for the front part of the barrel 1; , the body tube fixing pin 8 and the positioning hoop 5 are fixed by the bearing 11 at the same time, the front end of the bearing ring 4 is provided with an annular groove 42, and the collar 13 is installed in the annular groove 42, so that the bearing 11 is positioned by the collar 13 back and forth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com