Semi-active vehicle suspension intelligent friction cylinder shock absorber

A vehicle suspension, semi-active technology, applied in the direction of friction damper, non-rotational vibration suppression, etc., can solve the problems of difficulty in changing damping, low life, high cost, etc., and achieve simple structure, better safety, and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

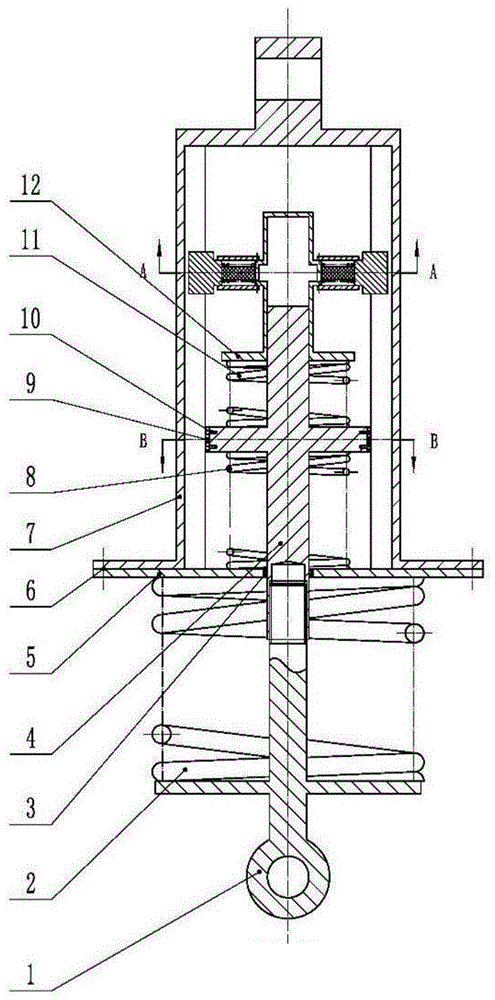

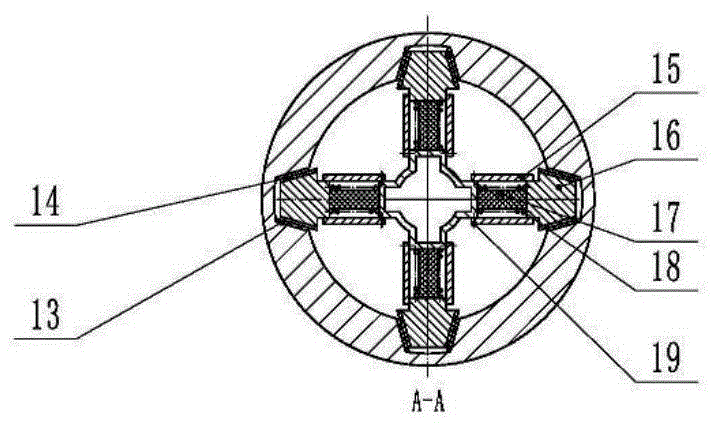

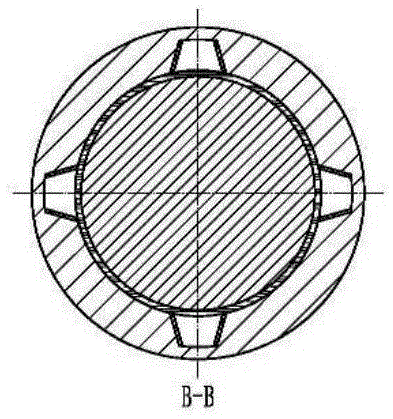

[0026] The present invention will be further described in detail below in conjunction with accompanying drawings and examples.

[0027] The vehicle suspension system must meet two requirements of good ride comfort (small stiffness, large damping) and good handling stability (high stiffness, small damping), no matter from the point of view of stiffness design or damping design, These two requirements are contradictory, and it is difficult for passive suspension design to meet them simultaneously. On the other hand, the current semi-active suspension can only adjust the damping but not the stiffness; in view of this situation, the present invention realizes a semi-active vehicle suspension shock absorber with adjustable stiffness and damping by introducing an intelligent material actuator. The shock absorber does not require major changes to the main elastic support of the existing vehicle suspension.

[0028] The present invention is a semi-active vehicle suspension intelligen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com