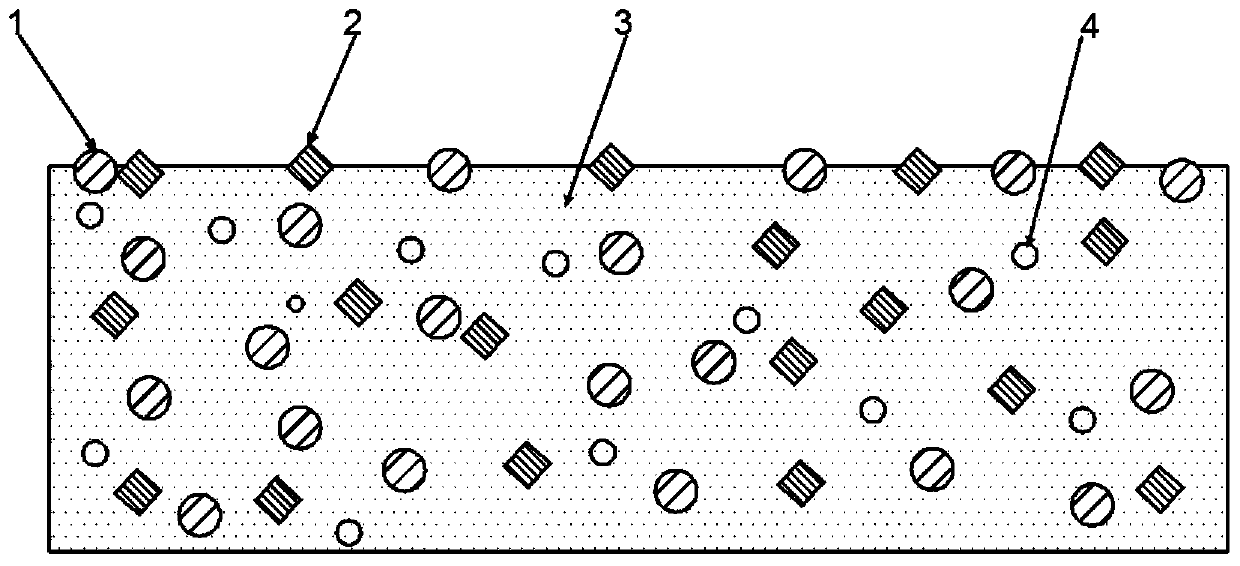

A fixed abrasive tool containing neodymium compound soft abrasive for polishing sapphire wafer and its manufacturing method

A sapphire wafer and neodymium technology, which is applied in the direction of grinding tools, grinding/polishing equipment, grinding devices, etc., can solve the problems of high cost and low polishing efficiency, and achieve improved processing quality, low processing roughness, and high polishing effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

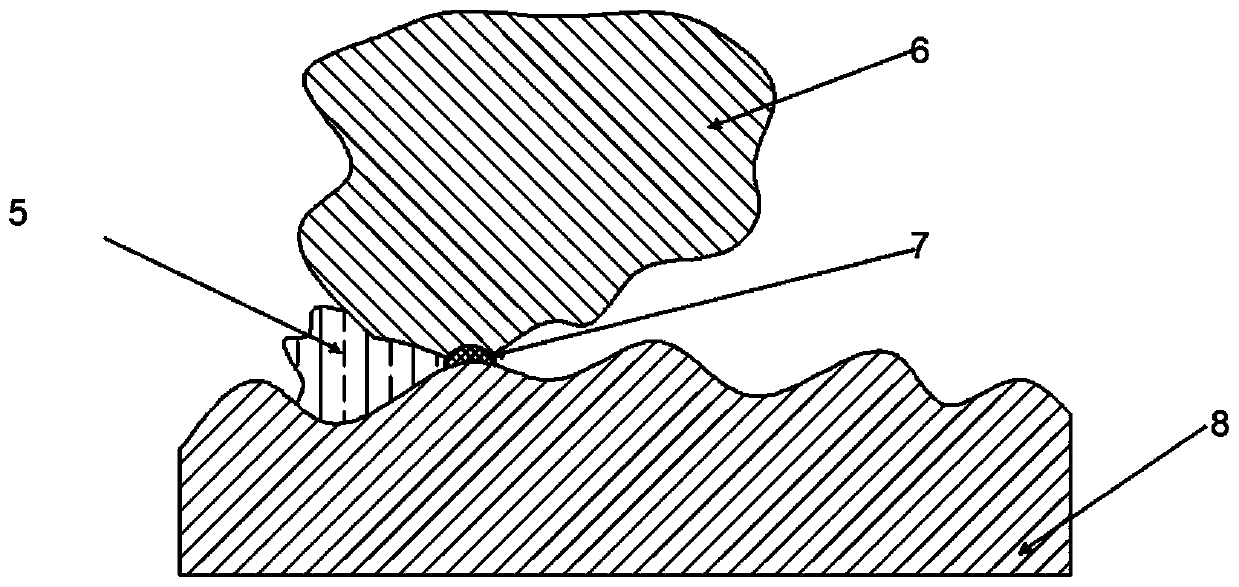

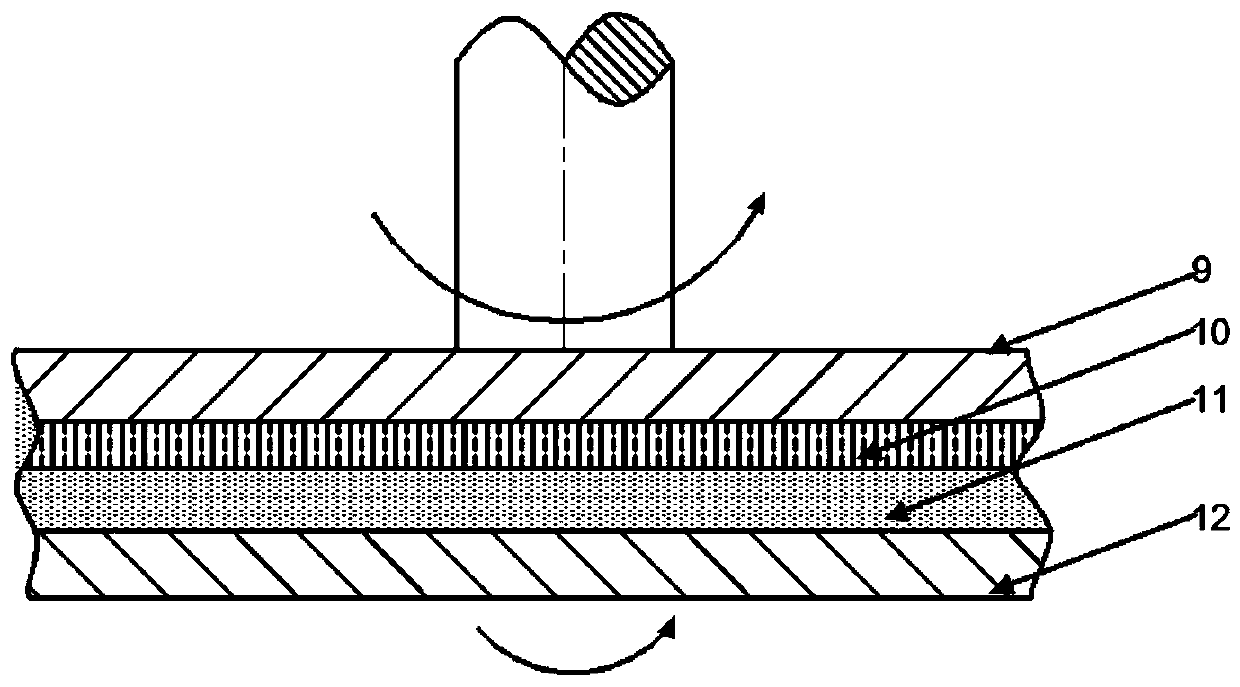

[0031] The polishing of the sapphire wafer by the fixed abrasive tool containing the neodymium compound soft abrasive in this embodiment: the fixed abrasive tool containing the neodymide soft abrasive material is installed on the upper plate of the polishing machine, and the sapphire wafer to be processed is placed on the rotating polishing machine. Fix the lower plate of the machine with a fixture, start the polishing machine, and inject alkaline water-based coolant between the upper and lower plates; the neodymium and abrasive grains on the fixed abrasive tool scratch the sapphire surface with soft abrasives containing neodymium And a solid phase reaction occurs to realize the polishing of the sapphire wafer.

[0032] Further, under the action of pressure and relative velocity, neodymium is not only a catalyst, which reduces the energy required for the reaction between the sapphire wafer and silicon dioxide, but also acts as a reactant and can undergo a solid-state reaction w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com