A chemical mechanical polishing fluid

A chemical mechanical and polishing liquid technology, applied in the direction of polishing composition containing abrasives, etc., can solve the problems of increasing organic phosphoric acid, not being able to concentrate at a high rate, and inhibiting the polishing rate of tungsten, so as to achieve high colloidal stability and meet the requirements of polishing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

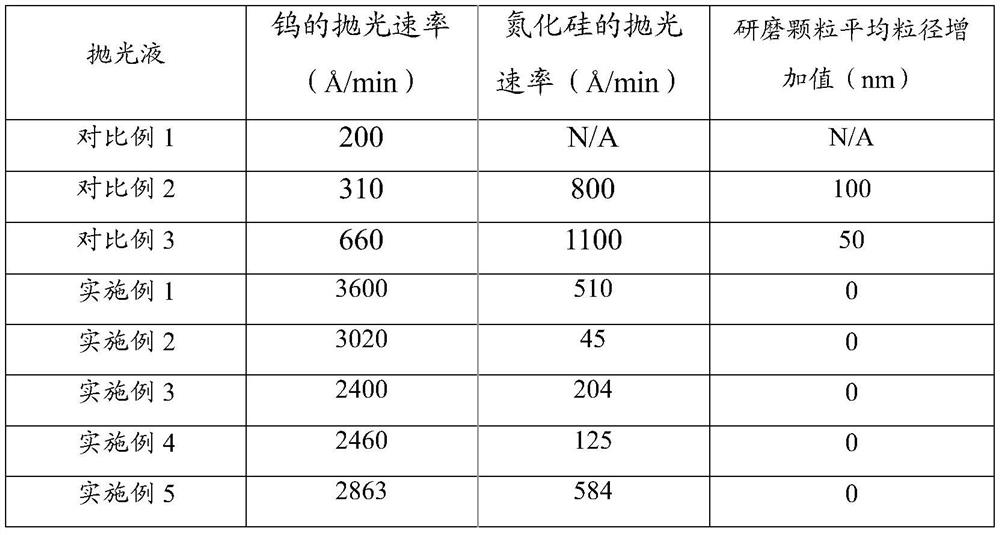

[0024] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

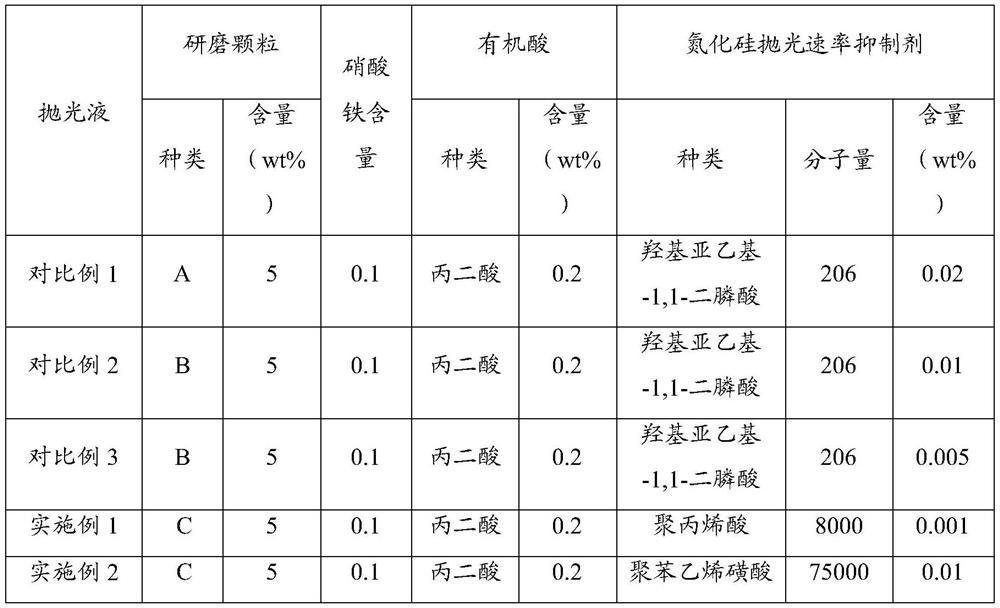

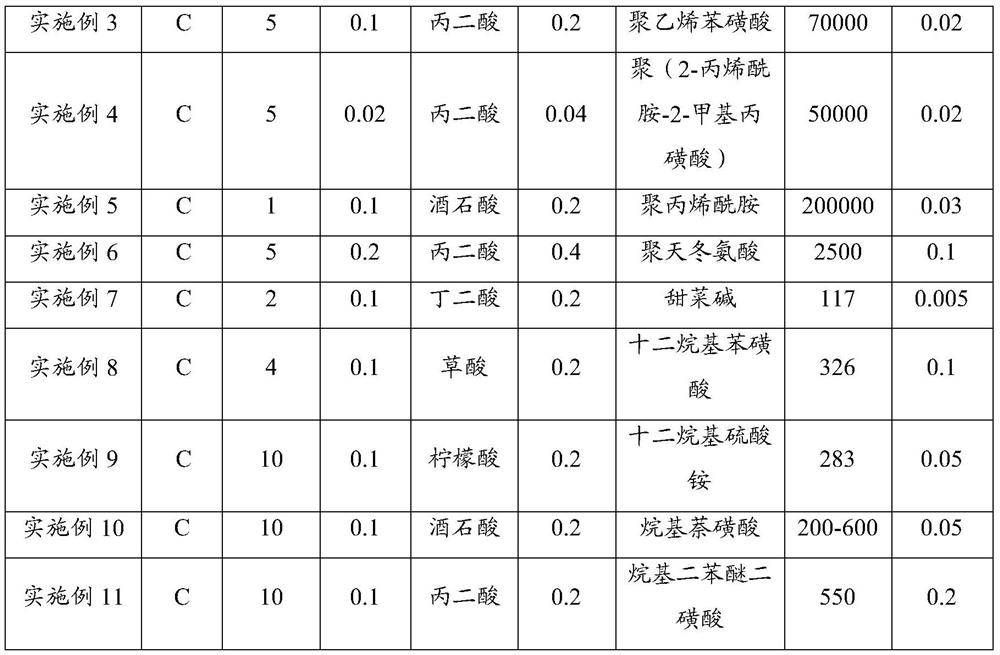

[0025] Table 1 shows the components and contents of the polishing solutions of Examples 1-11 of the present invention and Comparative Examples 1-3. Prepare the chemical mechanical polishing solution according to the formula in the table, mix well, adjust the pH value to 2.0-2.5 with nitric acid or KOH, add 2.5% hydrogen peroxide before use, and make up the mass percentage to 100% with water to obtain various embodiments of the present invention and comparative example.

[0026] In Table 1, abrasive particle A is a conventional silica abrasive particle, which is PL-3 silica sol from FUSO Company, abrasive particle B is PL-3C silica sol from FUSO Company, and its surface is positively charged, and abrasive particle C is a Propyltriethoxysilane treated silica abrasive grit with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com