Double-component polyurethane white high-gloss woodware paint, and preparation method and application thereof

A two-component polyurethane and wood lacquer technology, applied in the coating field, can solve the problems of long drying time of two-component glossy coatings, achieve the effects of shortening the production cycle, improving production efficiency, and saving financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0082] Main paint (parts by mass):

[0083] Short oil synthetic fatty acid modified alkyd resin: 50.0%

[0084] Rutile Titanium Dioxide 35.0%

[0085] Acidic group-containing copolymer dispersant 2.0%

[0086] Modified polysiloxane defoamer 1%

[0087] Polyether modified polydimethylsiloxane leveling agent: 1%

[0088] Propylene Glycol Methyl Ether Propionate 11%

[0089] Curing agent (parts by mass):

[0090] High boiling point mixed environment-friendly solvent: 40.5%

[0091] Water absorbent: 0.5%

[0092] Polyisocyanate resin A: 29.0%

[0093] Polyisocyanate resin B: 30.0%

[0094] Diluent (parts by mass):

[0095] Propylene Glycol Methyl Ether Propionate: 30%

[0096] Xylene: 60%

[0097] Butyl acetate: 10%

[0098] The above-mentioned formula is filtered and packaged after production according to the production steps.

example 2

[0100] Main paint (parts by mass):

[0101] Short oil synthetic fatty acid modified alkyd resin: 60.0%

[0102] Rutile Titanium Dioxide 25.0%

[0103] Acidic group-containing copolymer dispersant 0.5%

[0104] Modified polysiloxane defoamer 0.5%

[0105] Polyether modified polydimethylsiloxane leveling agent: 0.5%

[0106] Propylene Glycol Methyl Ether Propionate 13.5%

[0107] Curing agent (parts by mass):

[0108] High boiling point mixed environmental solvent: 29.5%

[0109] Water absorbent: 0.5%

[0110] Polyisocyanate resin A: 45.0%

[0111] Polyisocyanate resin B: 25.0%

[0112] Diluent (parts by mass):

[0113] Propylene Glycol Methyl Ether Propionate: 20%

[0114] Xylene: 50%

[0115] Butyl acetate: 30%

[0116] The above-mentioned formula is filtered and packaged after production according to the production steps.

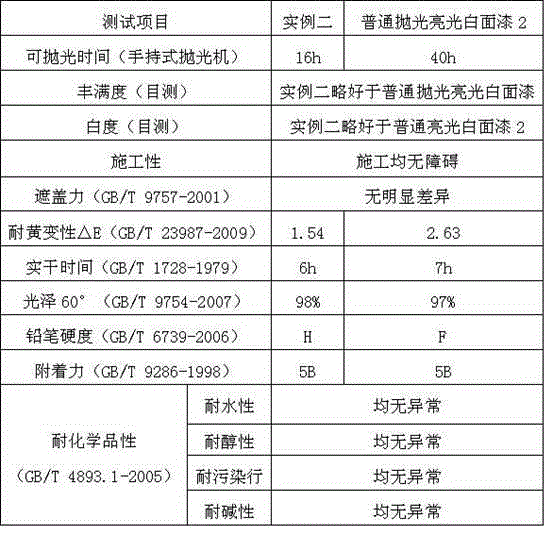

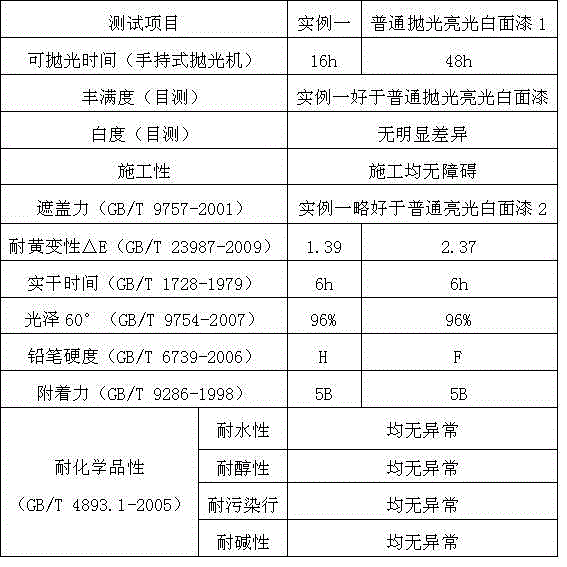

[0117] The two-component polyurethane (PU) white glossy wood lacquer example obtained in the above two examples and the ordinary white glossy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com