Series parallel movement polisher with nine freedom degrees

A degree of freedom, polishing machine technology, applied in the field of polishing machines, can solve the problems of low efficiency, slow investment recovery, and expensive robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, and the present invention is relatively clear to those skilled in the art.

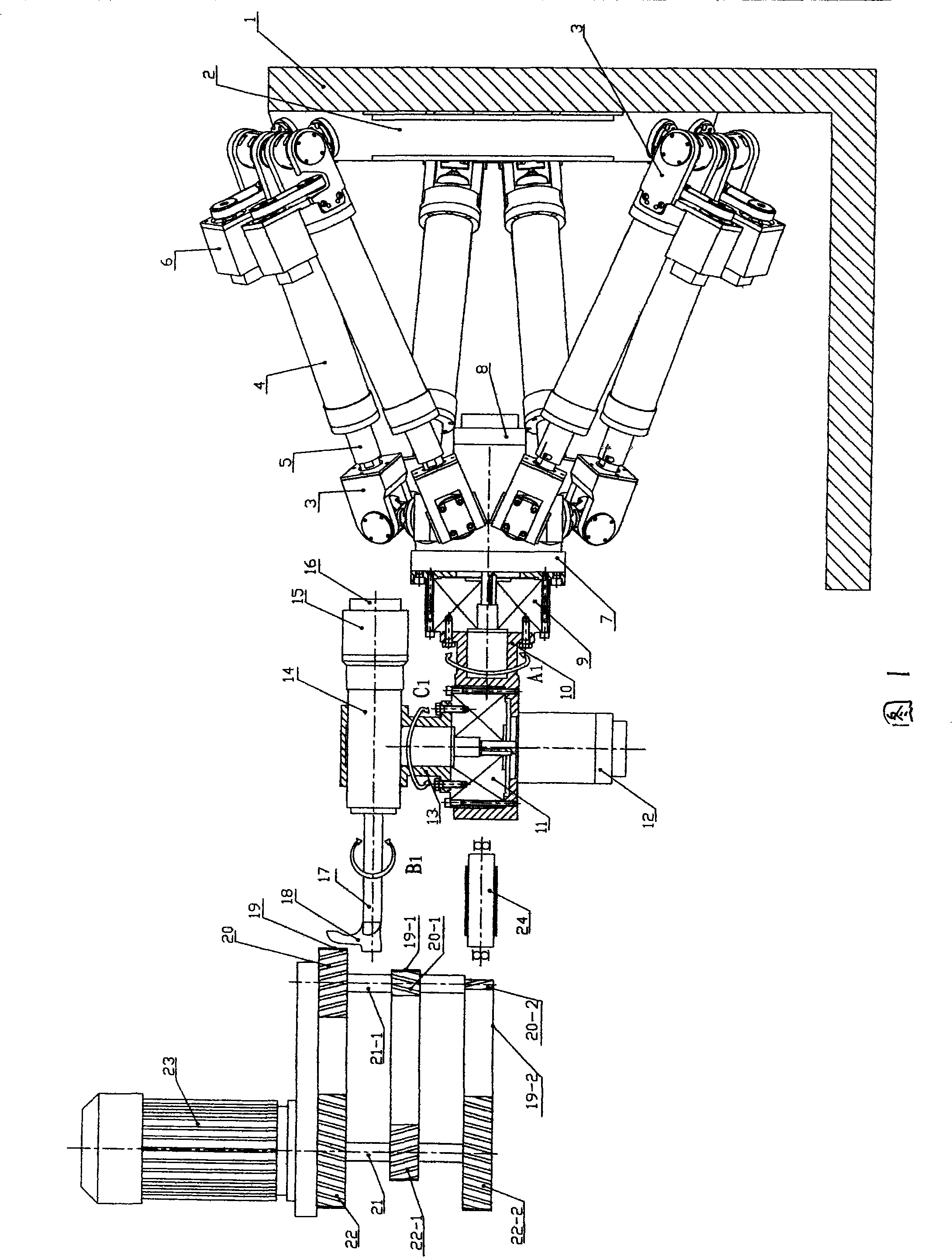

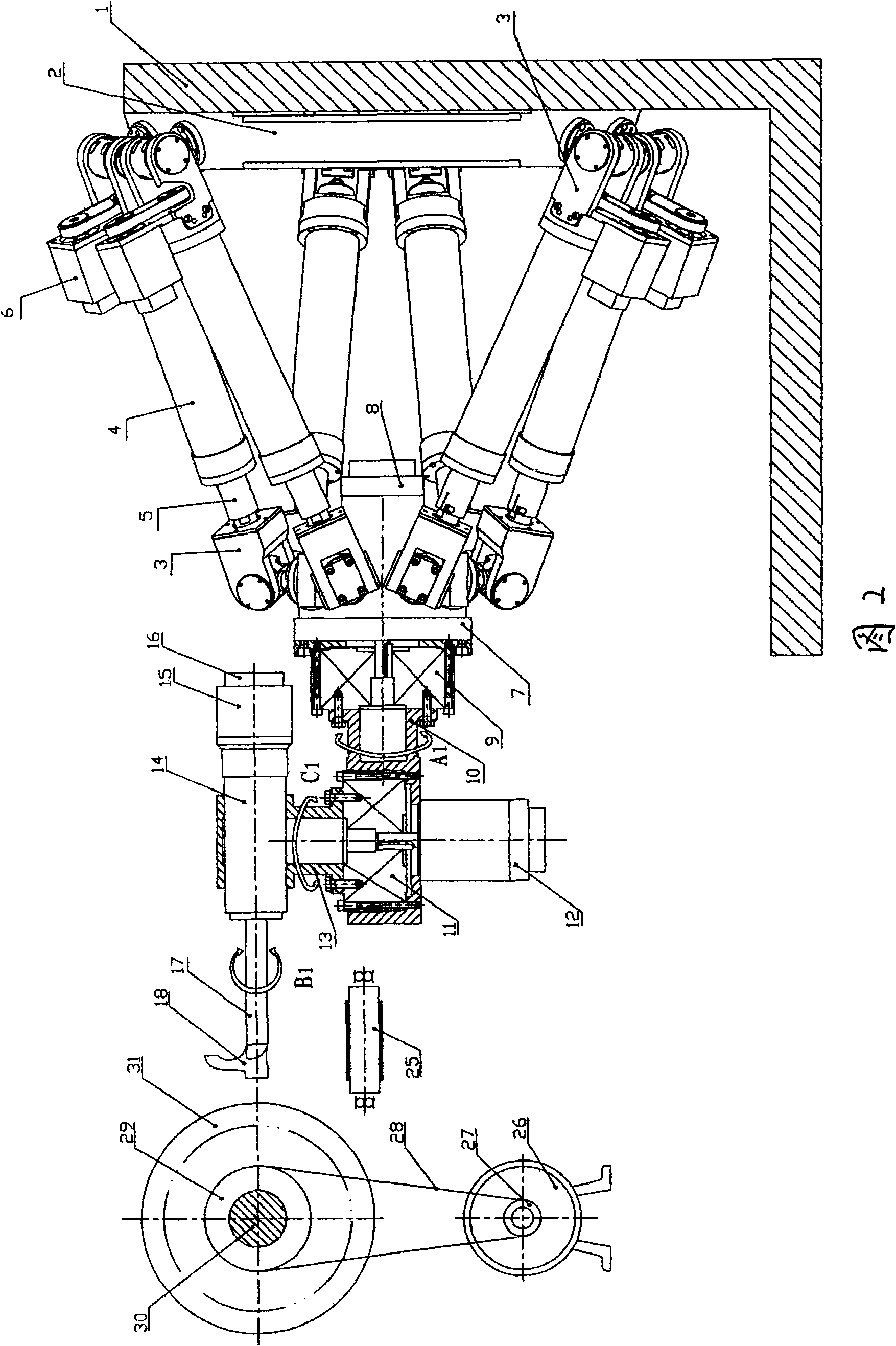

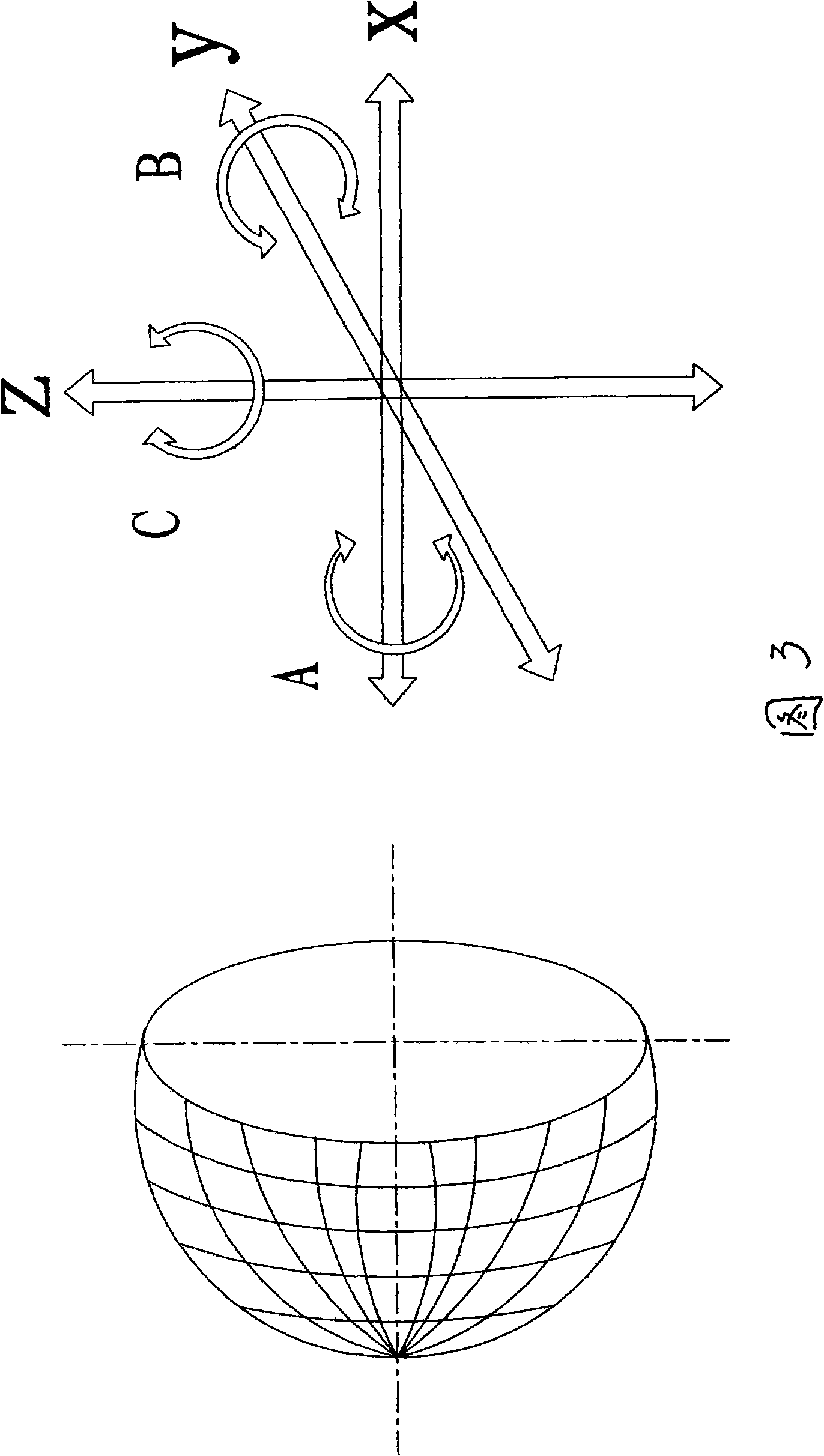

[0016] The existing 6-SPS parallel mechanism is adopted, and the ball screw pair in the rod is driven by the servo motor configured on each telescopic rod, so as to change the different telescopic values of the telescopic rod, so that the motion platform 7 can perform X, X, Y, Z movement, and take X, Y, Z axis as the axis image 3 The arrows A, B, and C shown in the figure swing to make swings and tilts at different angles, change the posture of the motion platform 7, and realize the image 3 The shown approximate spherical 6-DOF spatial motion.

[0017] In order to be able to perform rough polishing on the complex space art surface composed of a variety of curved surfaces, straight surfaces, inclined surfaces, and inertial surfaces without dead ends, the machine tool is mixed on the motion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com