Soft abrasive fixing mould of polished tantalum-lithium wafer and manufacturing method of soft abrasive fixing mould

A lithium tantalate, soft technology, applied in abrasives, grinding/polishing equipment, chemical instruments and methods, etc., can solve the problems of low polishing efficiency and high cost, achieve low processing roughness, improve processing quality, and improve polishing effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below.

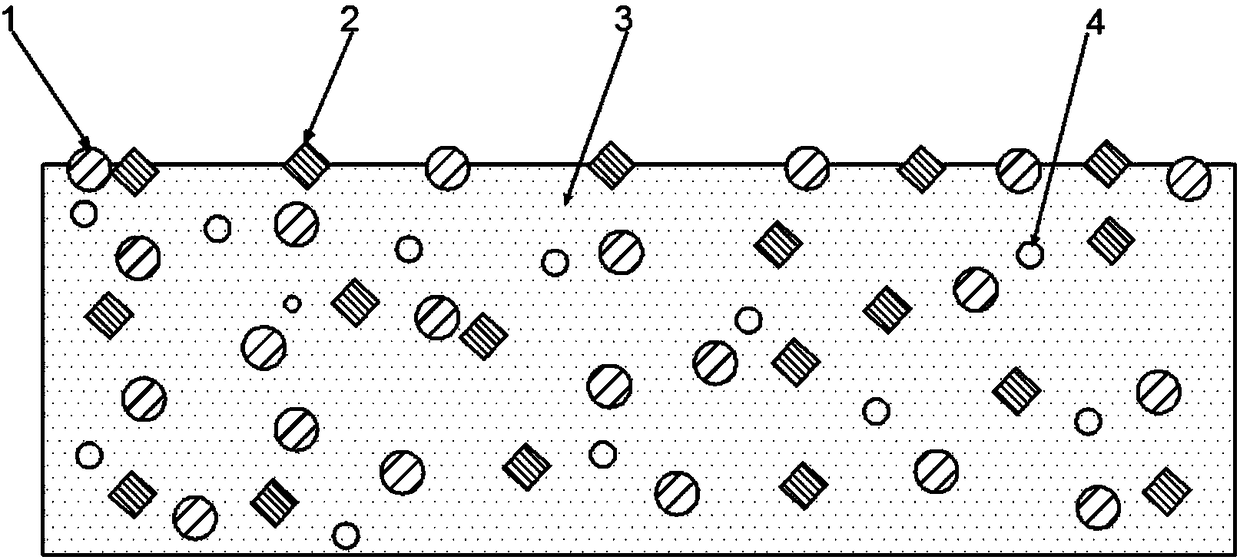

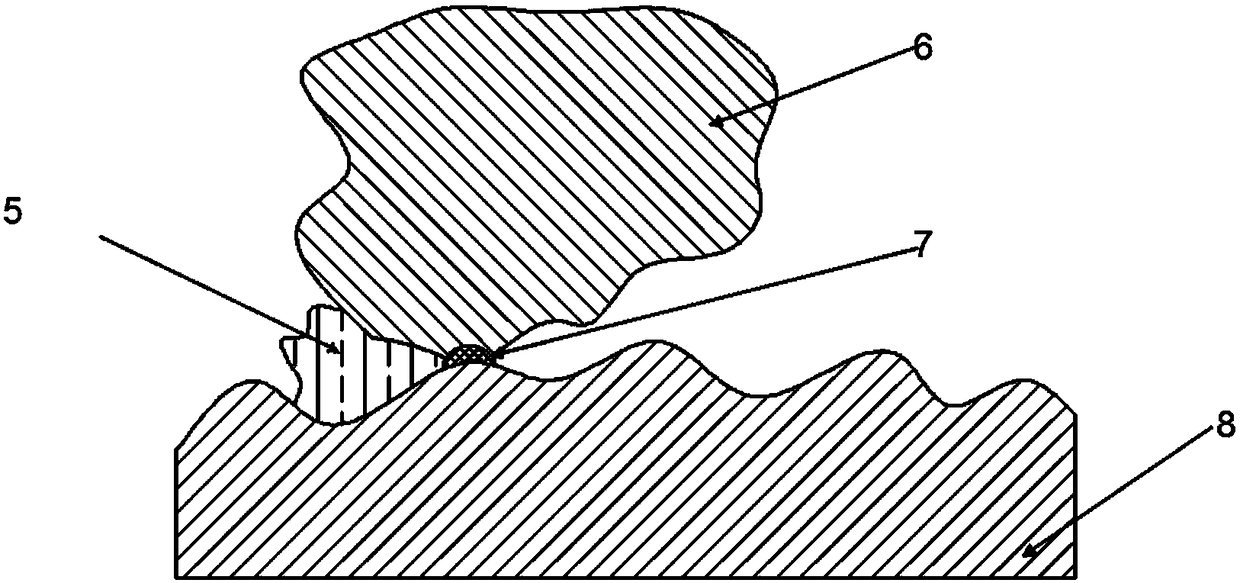

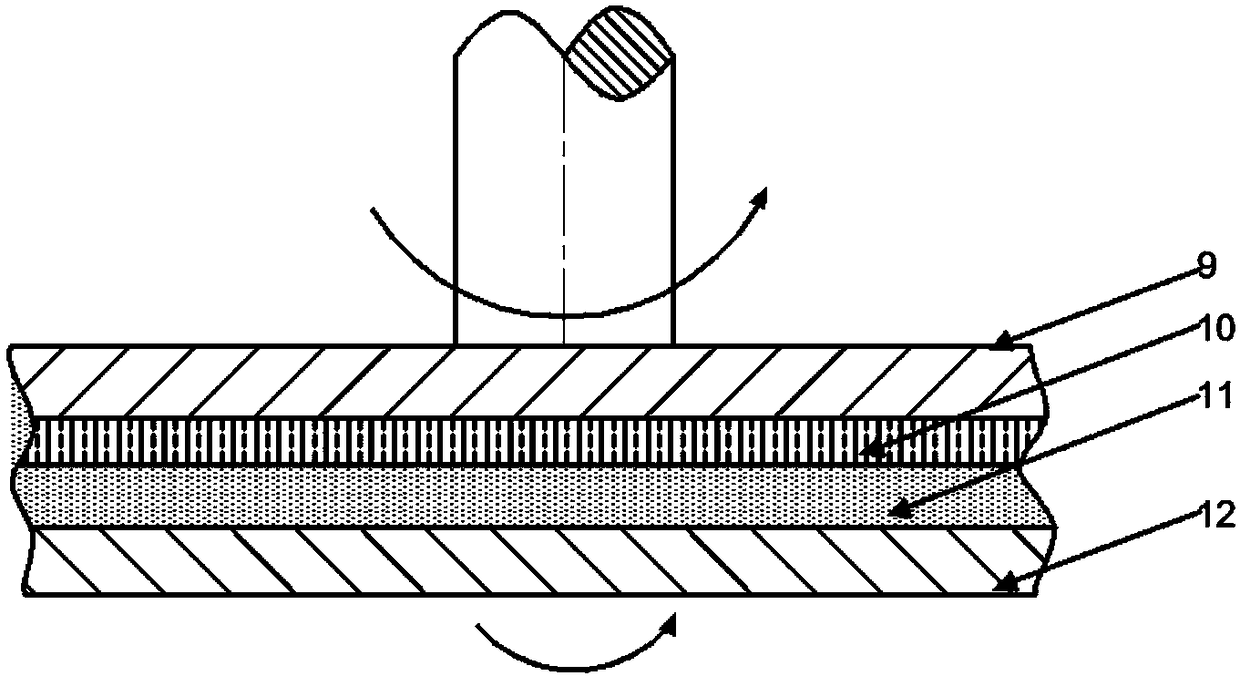

[0023] refer to Figure 1 ~ Figure 3 , a soft abrasive fixed abrasive tool for polishing lithium tantalate wafers, the preparation of the soft abrasive fixed abrasive tool raw materials: 40% to 60% of nano silicon dioxide, 20% to 40% of binder, and 10% of curing agent % to 15%, oxidant 5% to 10%, deionized water 10% to 15%, and alkaline pH regulator 5% to 10%.

[0024] Further, the binder is magnesium oxide.

[0025] Still further, the curing agent is magnesium chloride, phenolic-acetal resin or phenolic-epoxy resin.

[0026] Furthermore, the particle size of the nano silicon dioxide is 70-90nm.

[0027] The oxidizing agent is calcium hypochlorite, oxo acid salt, trivalent cobalt salt or potassium dichromate, all of which are nanoscale powder particles.

[0028] A method for making a soft abrasive fixed abrasive tool for polishing a lithium tantalate wafer, adding a curing agent to deionized water and stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com