Sapphire wafer polishing method based on fixed abrasive tool containing neodymium compound and soft abrasive materials

A sapphire wafer and neodymium technology, applied in the field of polishing, can solve the problems of low polishing efficiency and high cost of sapphire wafers, achieve good polishing effect, improve processing quality, and improve polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

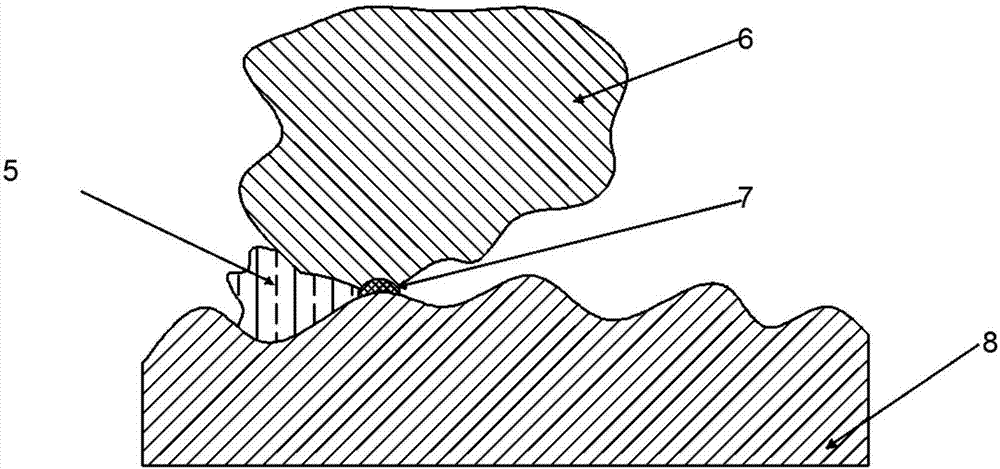

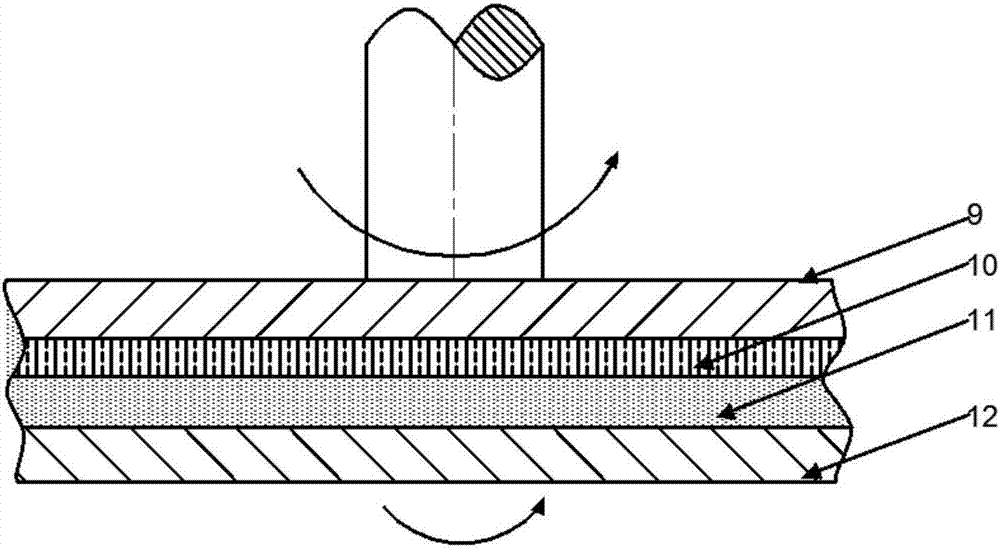

[0027] refer to Figure 1 ~ Figure 3 , a kind of sapphire wafer polishing method that contains the soft abrasive fixed grinding tool of neodymide, described polishing method comprises the following steps:

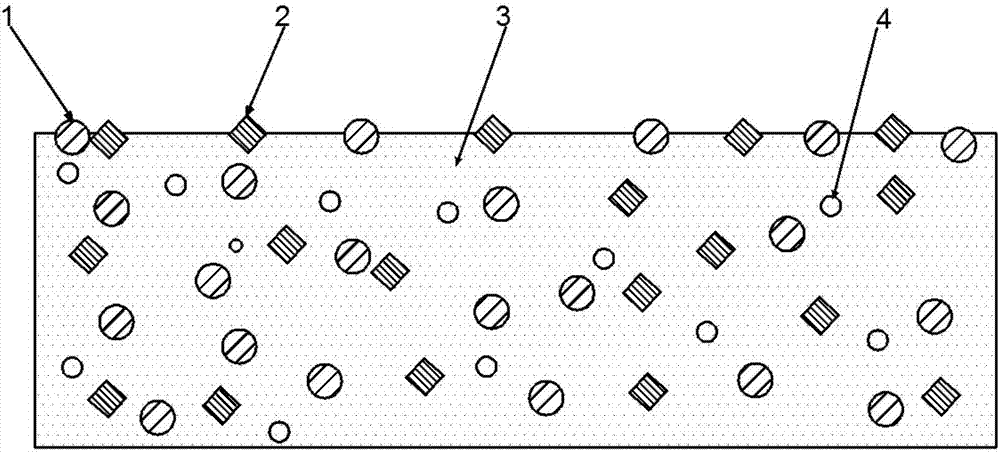

[0028] 1) Preparation of raw materials for soft abrasive fixed abrasives containing neodymium: 40% to 60% of nano-silica, 20% to 40% of binder, 10% to 15% of curing agent, and 5% to 10% of neodymium , the rest is deionized water;

[0029] 2) Production of fixed abrasives with soft abrasives containing neodymium: add curing agent to deionized water, stir to dissolve, then add binder, nano-silica, and neodymium, and stir evenly; The ingredients are hot-pressed and formed in the mould, and the heat curing is completed after demoulding, and the upper and lower end surfaces are trimmed to ensure the flatness and parallelism of the upper and lower end surfaces of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com