Preparation method of a nitrogen-doped activated carbon-supported Cu catalyst and its application in catalytic furfural hydrogenation

An activated carbon, nitrogen doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of conversion rate to be improved, metal loss, high temperature and pressure, and achieve excellent recovery performance, reaction Easier to carry out and improved dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

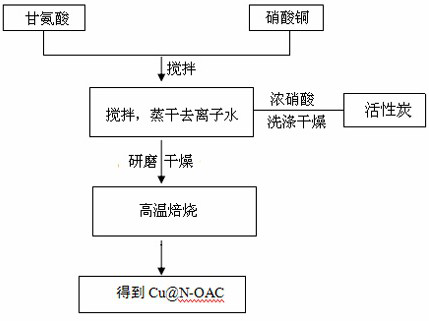

[0030] (1) Take 10g of activated carbon in a 250ml round bottom flask, add 135ml of concentrated nitric acid with a mass fraction of 65%, and reflux at 120°C for 12h;

[0031] (2) After the reflux is completed, cool to room temperature, filter and wash with deionized water several times until neutral;

[0032] (3) Dry the solid obtained in step (2) at 60°C for 12 hours to obtain oxidized activated carbon (OAC);

[0033] (4) Weigh 0.135g of copper nitrate and 0.2g of glycine and dissolve them in 20ml of water, stir at 50°C for 30min to prepare a copper glycinate solution with excess glycine;

[0034] (5) Add 0.5 g of the OAC obtained in step (3) to the copper glycinate solution obtained in step (4), and continue stirring at 50°C for 3h until the deionized water evaporates to dryness, and then dry at 60°C for 12h;

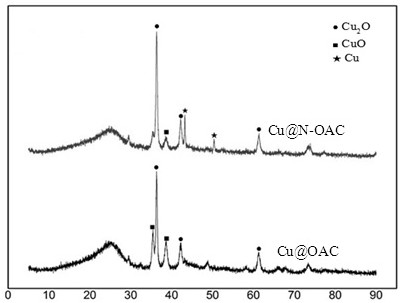

[0035] (6) Grinding the solid obtained in step (5), and calcining at 850°C for 2 hours under a nitrogen atmosphere to obtain a nitrogen-doped copper oxidation activ...

Embodiment 2

[0043] The rest are the same as in Example 1, except that the reaction time of step (10) is 5 hours.

[0044] The analysis of the experimental results showed that the conversion rate of furfural was 88%, and the selectivity of furfuryl alcohol was 93%.

Embodiment 3

[0046] The rest are the same as in Example 1, except that the mass of glycine in step (4) is 0.1 g.

[0047] The analysis of the experimental results showed that the conversion rate of furfural was 68%, and the selectivity of furfuryl alcohol was 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com