Powder-mixed near-dry type electric spark machining device and method thereof

A processing method and processing device technology, which is applied in the field of mixed powder quasi-dry EDM devices, can solve the problems of difficult discharge of electric corrosion products, affect processing quality, and high processing short-circuit rate, so as to improve processing stability and processing stability Good, low roughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

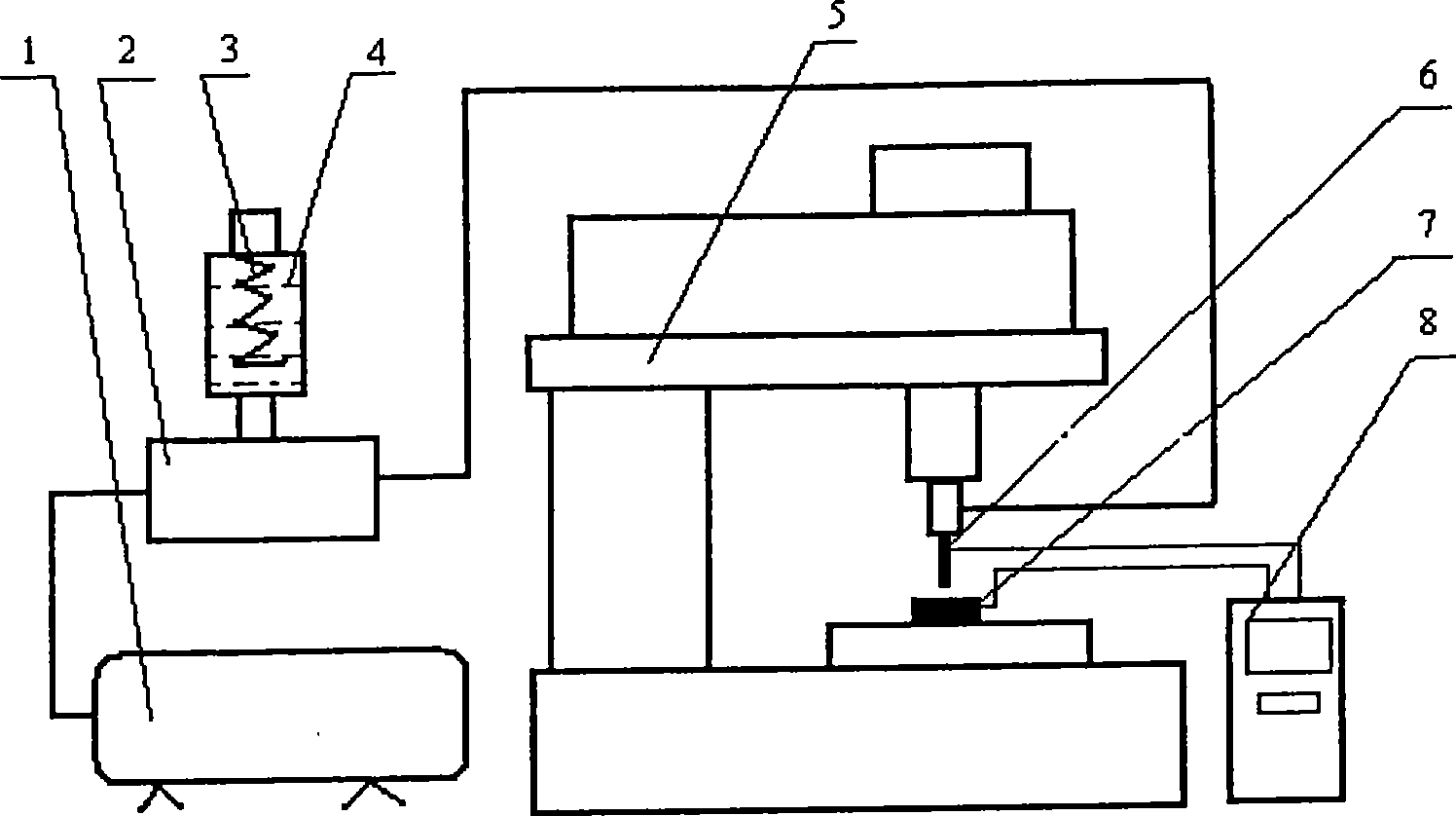

[0026] The two output terminals of the pulse power supply 8 are respectively connected with the workpiece 7 and the tool electrode 6 . The control system controls to keep the tool electrode 6 and the workpiece 7 at a certain gap. The solid-liquid mixture is contained in the liquid cup 4, and the stirring device 3 stirs it evenly. The air compressor 1 is connected with the micro-quantity lubrication device 2, and the air and the solid-liquid mixture are mixed through the micro-quantity lubrication device to transfer the gas-liquid-solid three-phase flow mixture to Tubular tool electrode 6. The desired shape is machined by electric discharge at different corresponding positions between the electrode and the workpiece.

[0027] The processing polarity is negative, the pulse width is 2.4μs, the pulse interval is 5.6μs, the current is 1.6A, the servo voltage is 100V, the workpiece material is stainless steel, the electrode is copper, the tool electrode is copper tube, the outer di...

Embodiment 2

[0029] The processing polarity is negative, the pulse width is 2.4μs, the pulse interval is 5.6μs, the current is 25.6A, the servo voltage is 100V, the workpiece material is stainless steel, the electrode is copper, the tool electrode is copper tube, the outer diameter is 4mm, the inner diameter is 2mm, and the speed is 1000 / min, the air pressure is 0.6MPa, the powder is aluminum powder, the particle size is 5μm, the concentration is 2g / L, the liquid is kerosene, and the flow rate of solid-liquid mixture is 1.5ml / min. Using layered milling, the layered thickness is 20 μm, and the milling length is 15 mm. The surface roughness of the processed workpiece is Ra 1.7μm, and the material removal rate is 0.25mm 3 / min.

Embodiment 3

[0031] In this embodiment, the gas supply pressure is 0.2 MPa; the particle size of the silicon powder is 5 μm, and the concentration in the liquid is 0.5 g / L; the flow rate of the liquid-solid mixture is 3 ml / min; the rest are the same as those in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com