Blind groove diamond coating milling cutter

A diamond coating and milling cutter technology, which is applied in metal material coating process, coating, milling cutter, etc., can solve the problems of inaccurate control of the cutting depth, tool wear, and inability to mill flat bottom blind slots, etc., to achieve the machined surface Low roughness, less tool wear, improved chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

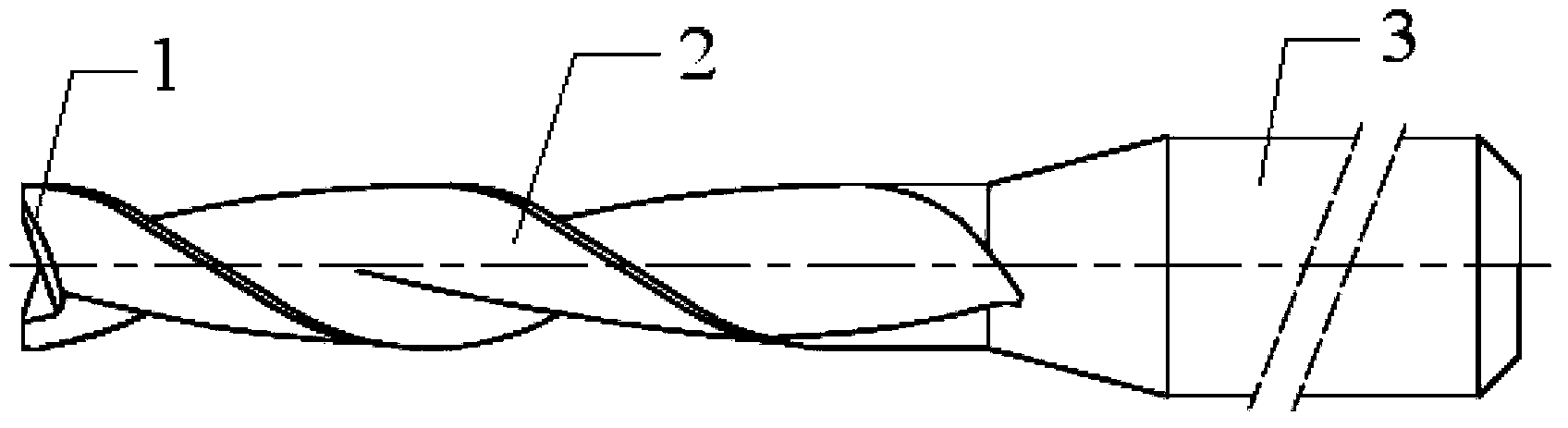

[0022] A kind of blind groove diamond coating milling cutter, its structure is as follows Figure 1-2 As shown, the milling cutter includes a milling cutter head 1 , a flute 2 and a shank 3 . The cutter head 1 of the milling cutter has a fishtail structure, and the blade of the head is inclined to the center, and the blade of the cutter head can effectively control the smoothness of the bottom of the flat-bottomed blind groove. The chip flute 2 is integrally arranged on the flank of the milling cutter head 1, and the outside of the chip flute is provided with a helix angle of 15-25°, and the helical flute with a large chip space makes chip removal smooth. The shank 3 is arranged at the rear of the flute 2 for connecting the main shaft of the PCB drilling and milling machine, and the diameter of the shank 3 is 3.175mm.

[0023] The HFCVD diamond composite coating is deposited on the surface of the milling cutter, the bottom layer is a deposited diamond film, and the surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com