Novel superspeed point grinding wheel and grinding method thereof

An ultra-high-speed, grinding wheel technology, applied in the direction of bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of difficult discharge of grinding debris, increased grinding wheel loss, high material removal rate, etc., to reduce the cost and difficulty of dressing, high Precision grinding effect and smooth grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

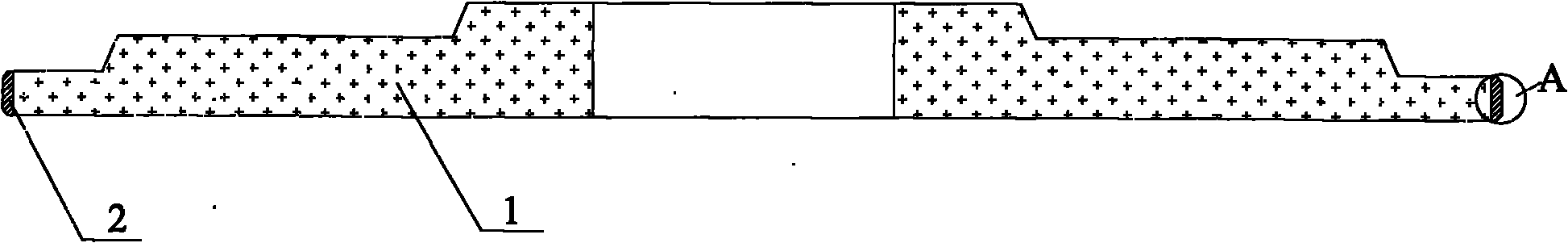

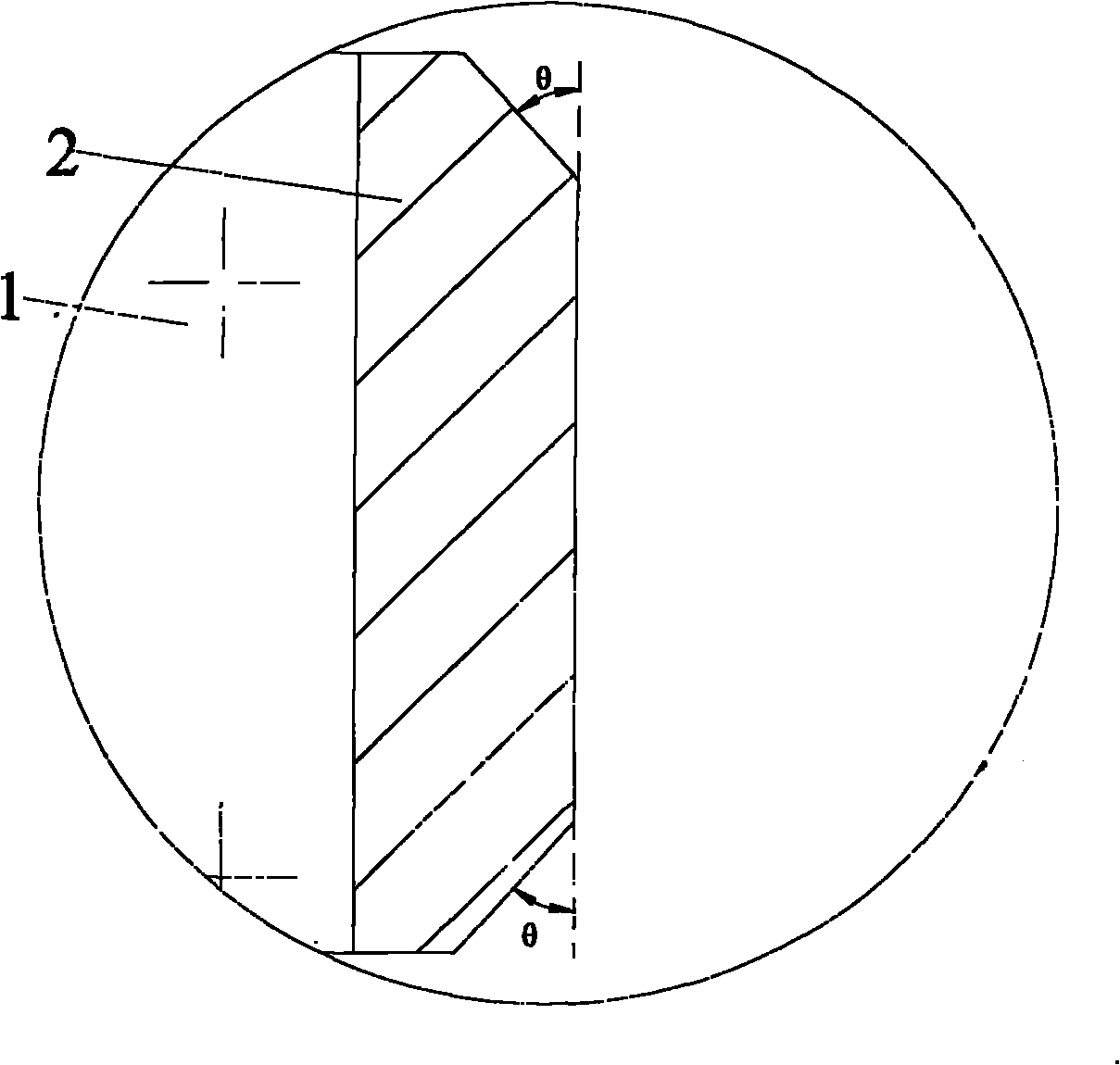

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

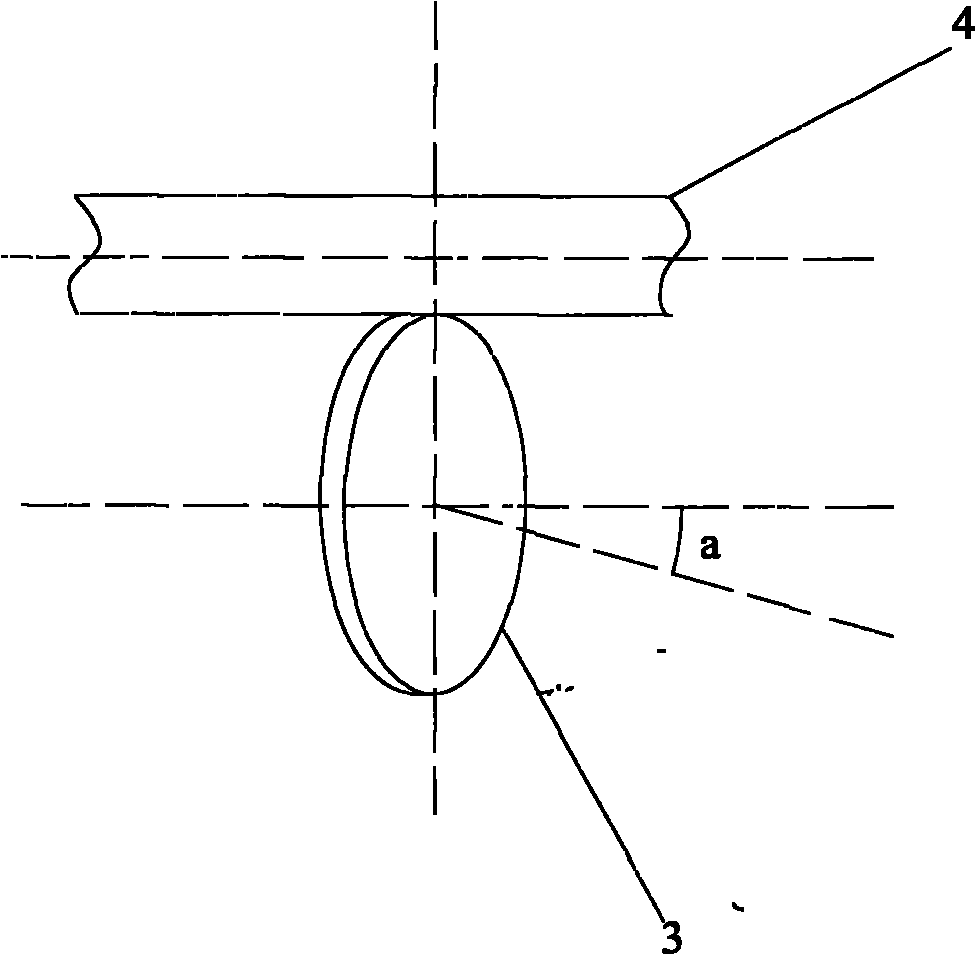

[0030] One way to solve the problem of wear and chip removal is to improve the structure and grinding form of the grinding wheel, so that the grinding fluid can enter the grinding area more easily and provide a larger space for chips. The invention is to set the abrasive layer at the axial front end of the grinding wheel There is an inclination angle, thereby changing the structure of the grinding wheel, making the grinding fluid more liquid into the grinding area, and at the same time, the grinding debris is also easier to discharge. The invention also changes the grinding method of the grinding wheel, see the attached image 3 , during grinding, make the ultra-high-speed point grinding wheel of the present invention parallel to the axis of the workpiece in the vertical direction, and the variable angle α ∈ (-0.5°, +0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com