Bismuth-containing free-cutting pre-hardened plastic die steel and preparation method thereof

A plastic mold steel, easy-cutting technology, applied in the field of alloy steel, can solve the problems of anisotropy of mechanical properties, affecting the mechanical properties of steel, lead pollution, etc., and achieve the effect of improving cutting performance, reducing processing costs, and improving transverse impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

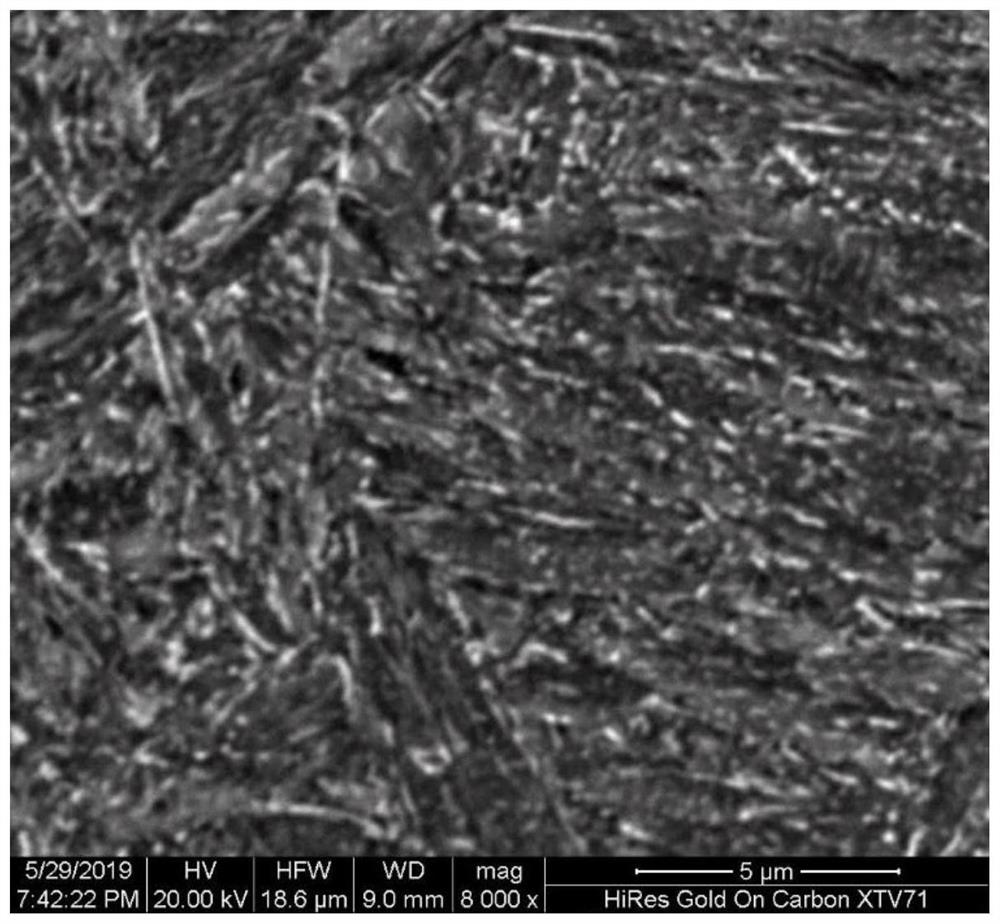

Embodiment 1

[0029] A kind of bismuth-containing free-cutting pre-hardened plastic mold steel provided by the invention has the following chemical composition by mass percentage:

[0030] C: 0.36%, Si: 0.30%, Mn: 1.70%, Cr: 2.00%, Ni: 1.00%, Mo: 0.40%, P≤0.015%, S≤0.005%, V: 0.05%, Bi: 0.10%, The balance is Fe.

[0031] Its preparation method is carried out according to the following steps:

[0032] (1) The above-mentioned raw materials are smelted into molten steel by means of vacuum induction smelting and cast into cylindrical steel ingots with a diameter of 180 mm and a height of 300 mm;

[0033] (2) Heating the steel ingot to 1200°C at a rate of 70°C / h, holding time for 6h;

[0034] (3) The forging process is three times of axial piercing and elongation, the initial forging temperature is 1200 ℃, the final forging temperature is 820 ℃, the upsetting ratio is 2.0, the elongation ratio is 4.0, and the furnace is heated after each upsetting or elongation Keep it warm for 1 hour at the ...

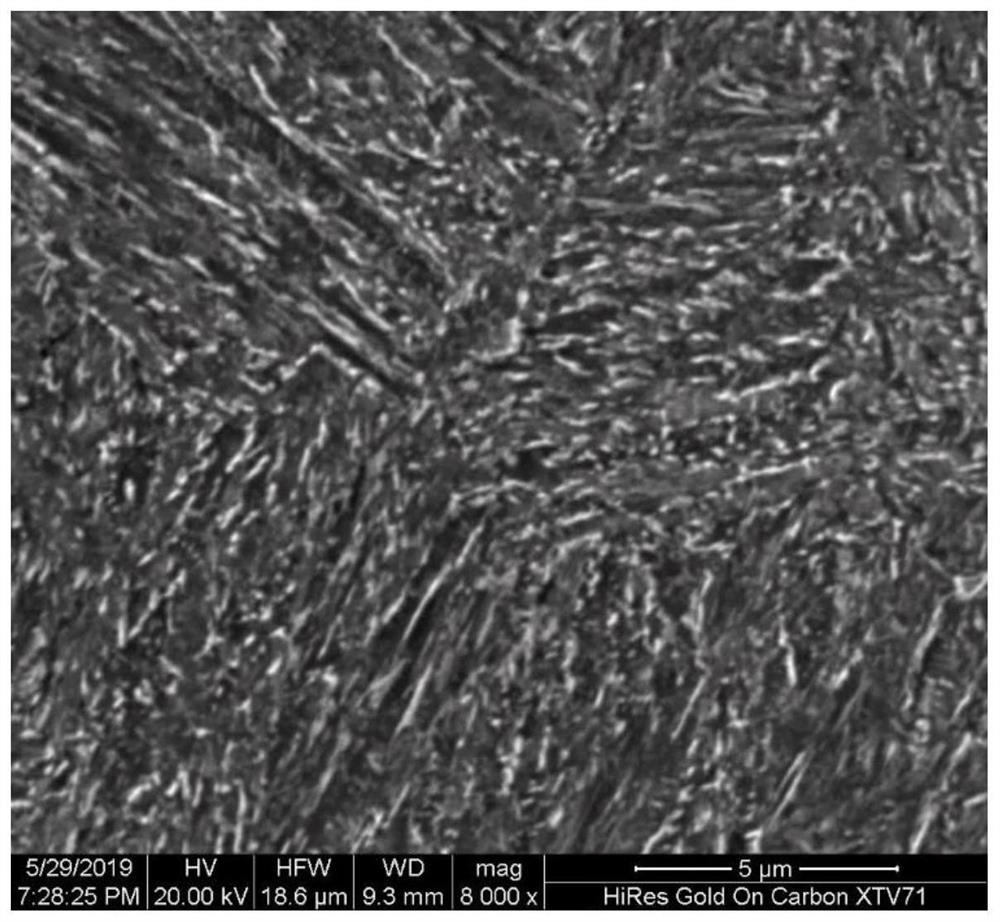

Embodiment 2

[0038] A kind of bismuth-containing free-cutting pre-hardened plastic mold steel provided by the invention has the following chemical composition by mass percentage:

[0039] C: 0.38%, Si: 0.25%, Mn: 1.60%, Cr: 1.90%, Ni: 1.10%, Mo: 0.35%, P≤0.015%, S≤0.005%, V: 0.10%, Bi: 0.05%, The balance is Fe.

[0040] Its preparation method is carried out according to the following steps:

[0041] (1) The above-mentioned raw materials are smelted into molten steel by means of vacuum induction smelting and cast into a cylindrical steel ingot with a diameter of 190 mm and a height of 320 mm;

[0042] (2) Heating the steel ingot to 1180°C at a rate of 90°C / h for a holding time of 8h;

[0043] (3) The forging process is three times of axial pier roughing-drawing, the initial forging temperature is 1180°C, the final forging temperature is 810°C, the upsetting ratio is 1.8, the drawing-length ratio is 3.8, and it is returned to the furnace for heating after each upsetting or drawing Keep it...

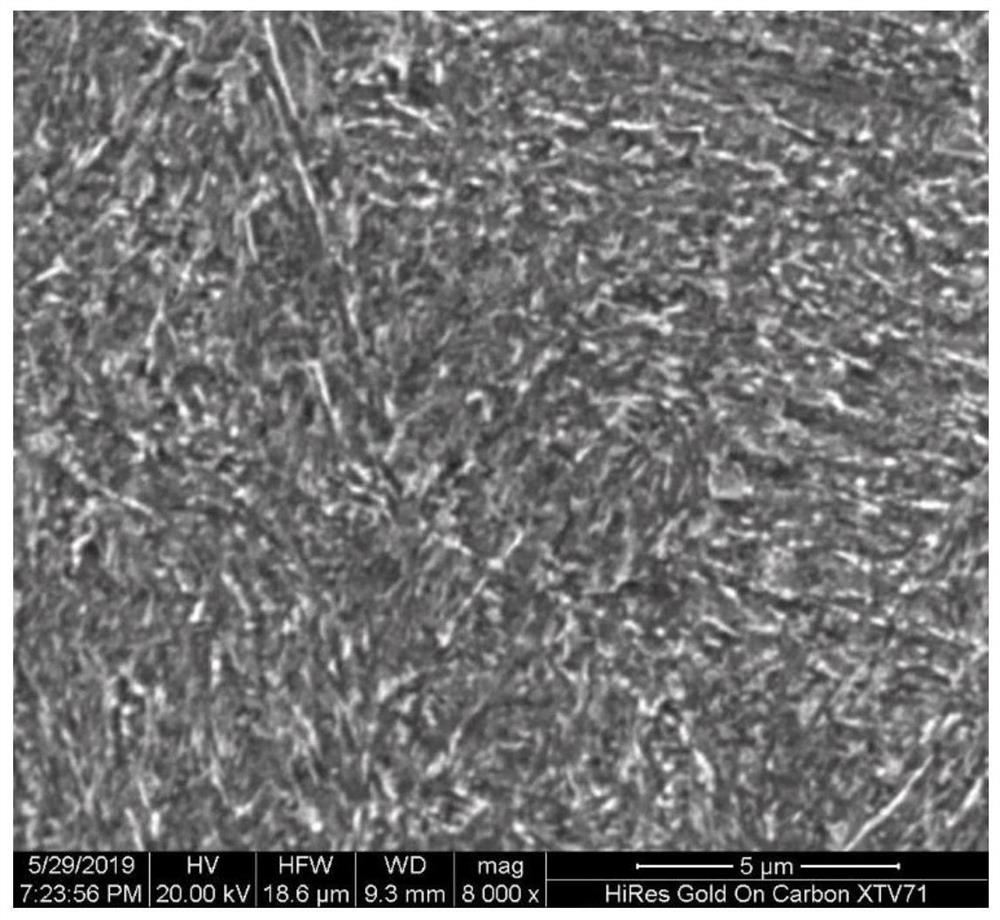

Embodiment 3

[0047] A kind of bismuth-containing free-cutting pre-hardened plastic mold steel provided by the invention has the following chemical composition by mass percentage:

[0048] C: 0.38%, Si: 0.25%, Mn: 1.60%, Cr: 1.90%, Ni: 1.10%, Mo: 0.35%, P≤0.015%, S≤0.005%, V: 0.10%, Bi: 0.14%, The balance is Fe.

[0049] Its preparation method is carried out according to the following steps:

[0050] (1) The above-mentioned raw materials are smelted into molten steel by means of vacuum induction smelting and cast into a cylindrical steel ingot with a diameter of 180 mm and a height of 310 mm;

[0051] (2) Heating the steel ingot to 1250°C at a rate of 100°C / h for a holding time of 6 hours;

[0052] (3) The forging process is three times of axial pier roughing-drawing, the initial forging temperature is 1250°C, the final forging temperature is 850°C, the upsetting ratio is 2.2, the drawing-length ratio is 3.0, and it is returned to the furnace for heating after each upsetting or drawing K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Average yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com