Method for manufacturing soluble fixed soft abrasive-polishing film

A production method and soluble technology, applied in the direction of grinding/polishing equipment, polishing composition containing abrasives, abrasives, etc., can solve difficult small-diameter parts or non-planar parts processing, resin bond is easy to adhere to the polishing surface, Unable to meet the high-quality mass production of advanced ceramic material components, etc., to achieve the effect of reducing the content of resin binder, durable polishing performance, and high-efficiency polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

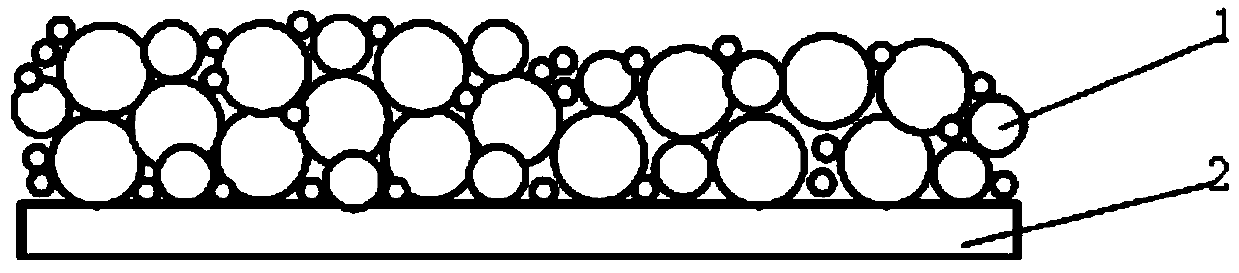

[0013] A method for making a soluble fixed soft abrasive polishing film, the structure of which is as follows figure 1 shown. Soft abrasive layer 1 adopts the following method to make: to make 100 grams of soft abrasive layer, take the composition quality of abrasive layer, as follows by mass percentage: binder (polyvinyl alcohol) quality is 10~25%, soft abrasive 50% to 60%, 1% to 5% furfural, 1% to 5% paraffin wax emulsion, 3% to 10% salt, 0.5% to 1% abrasive modified dispersant, and the sum of the mass percentages of each component is 100%. The soft abrasive is silicon oxide, and the particle size specifications are 300nm, 100nm, and 40nm. The mass ratio is 5:2:3.

[0014] Production process: first put deionized water into the reaction pot, add polyvinyl alcohol under stirring, heat to a constant temperature of 85-95 degrees Celsius, so that all polyvinyl alcohol is dissolved in water; add 10 grams of hydrochloric acid with a concentration of 20-30%, Stir for 10-20 minut...

Embodiment 2

[0018] A method for making a soluble fixed soft abrasive polishing film, the structure of which is as follows figure 1 shown. Soft abrasive material layer 1 adopts following method: to make 100 grams of soft abrasive material layer, weigh abrasive material layer composition and calculate as follows by mass percentage: bonding agent (alkyd resin) quality 12~20%, soft abrasive material quality are 40~60% %, the mass of furfural is 1-3%, the mass of paraffin wax emulsion is 1-5%, the mass of table salt is 3-8%, and the mass of abrasive modified dispersant is 0.5-1%. The abrasive is cerium oxide, and the particle size specifications are 50 μm, 15 μm, and 5 μm. The mass ratio is 6:2:2.

[0019] Production process: first put deionized water into the reaction pot, add alkyd resin under stirring, heat to a constant temperature of 85-95 degrees Celsius, so that the alkyd resin is completely dissolved in water; add 10 grams of hydrochloric acid with a concentration of 20-30%, Stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com