Hardened steel test piece, process testing method, design method, door milling method

A technology for process design and hardening steel, applied in metal processing equipment, measuring/indicating equipment, milling machine equipment, etc., it can solve the problems of process design conflict, no solution or multiple solutions in design scheme, inconsistent evaluation index model, etc. Time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

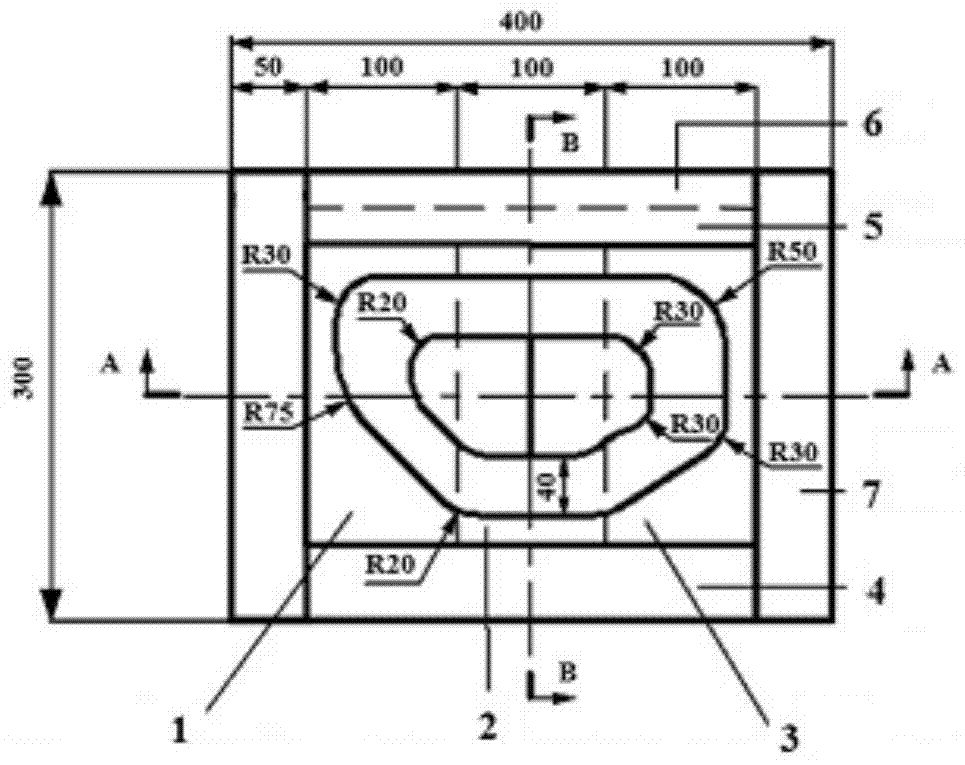

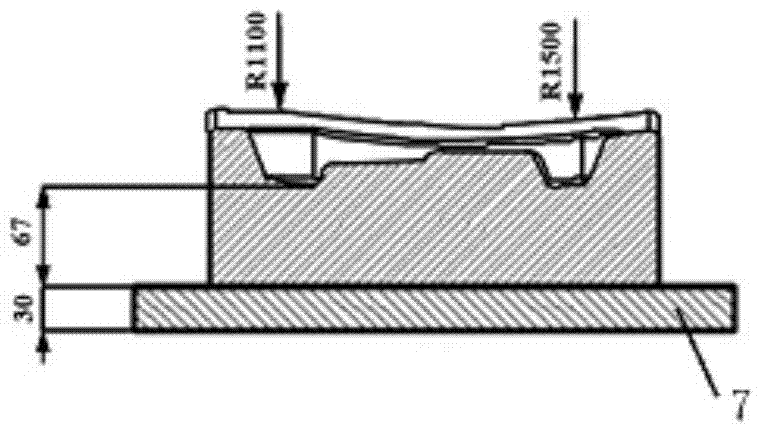

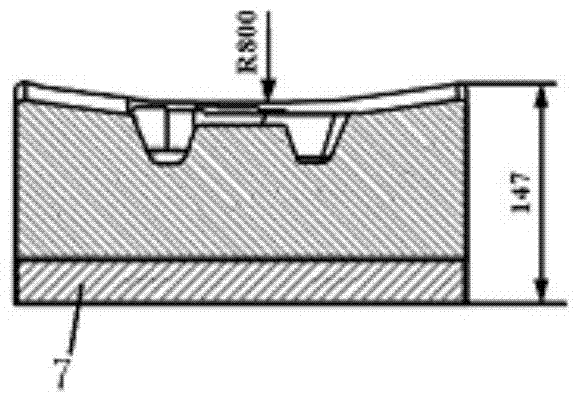

[0114] This embodiment provides a multi-hardness splicing hardened steel concave curved test piece, which is spliced by 5 Cr12MoV quenched parts, 1 7CrSiMnMoV part and 1 45# steel part; The radius distribution is 1100mm, 1500mm and the concave curved surface is distributed along the width direction of the specimen with a curvature radius of 800mm, and it is composed of a 35mm deep polygonal annular concave surface; the upper surface of the specimen is distributed with 4 kinds of hardness, respectively HRC30~35 , HRC40~45, HRC50~55, HRC60~65; the hardness of the middle part of the test piece is HRC50~55;

[0115] For the specific structure of the specimen, see Figure 1-Figure 4 :

[0116] (1) The test piece is a cuboid structure composed of 7 parts, with an outline size of 400mm×300mm×147mm, such as figure 1 , figure 2 , image 3 , Figure 4 shown;

[0117] (2) The seven parts that make up the test piece are part 1, part 2, part 3, part 4, part 5, part 6, and part 7; ...

Embodiment 2

[0134] This embodiment relates to the cutting path design and cutting area division scheme of the milling cutter of the hardened steel concave mold test piece.

[0135] Using three kinds of milling cutter cutting paths, 15 kinds of cutting areas with the characteristics of machining surface curvature and hardness variation were designed on the upper surface of the specimen; among them, the parallel milling cutter cutting paths along the direction of the length of 400mm of the specimen were divided into 6 different Machining the cutting area where the surface curvature and hardness change; along the parallel milling cutter cutting path in the direction of the width of 300mm of the test piece, divide 7 kinds of cutting areas with different machining surface curvature and hardness change; milling cutter cutting along both sides of the polygonal annular concave surface The path divides two cutting areas with different machining surface curvature and hardness changes.

[0136] As s...

Embodiment 3

[0143] This embodiment relates to the design of an experimental program for performance testing of a high-speed milling hardened steel die milling cutter.

[0144] (1) The experiment uses two identical two-tooth indexable high-speed ball-end milling cutters with a diameter of 20mm and an overhang of 75mm installed with coated carbide inserts. On a five-axis CNC machine tool UCP710, the The cutting path of the parallel milling cutter in the direction of 400mm and the alternate milling method of forward and reverse milling, using two identical milling cutters with a speed of 2000rpm and a feed speed of 2000mm / min and a milling cutter with a speed of 4000rpm and a feed speed of 2200mm / min respectively, Cut 5 cutting areas with different surface curvature and hardness changes, conduct high-speed ball-end milling cutter vibration, surface roughness, and milling cutter wear and damage test experiments, and verify the use of this specimen to test high-speed ball-end milling cutters fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com