A composite material tool electrode for electrodeposition electric discharge and its preparation method

A tool electrode and composite material technology, applied in the direction of electrode manufacturing, electric processing equipment, manufacturing tools, etc., can solve the problems such as the quality of the workpiece being processed needs to be improved, and the electrical corrosion resistance is poor, so as to increase the wettability and improve the electrical resistance. Erosion, enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

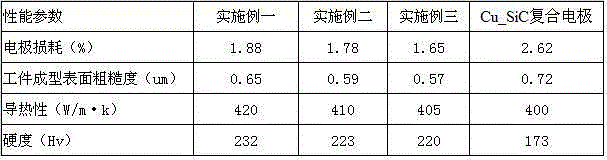

Embodiment 1

[0045] Composite material tool electrodes were prepared according to the following steps in turn:

[0046] (1) Equipped with an electroless plating solution: 14 parts by mass of copper sulfate pentahydrate, 25 parts by mass of formaldehyde and 10 parts by mass of sodium hydroxide were dissolved in 1000 parts by mass of water, and mixed uniformly to prepare an electroless plating solution;

[0047] (2) SiC particle removal treatment: Wash small SiC particles with a particle size of 7 microns and large SiC particles with a particle size of 15 microns with deionized water, and put the washed SiC particles into hydrofluoric acid with a concentration of 30% Immerse in the solution for 10 minutes, then wash with distilled water and dry;

[0048] (3) Pickling of SiC particles: Put the SiC particles treated in step (2) into 90% HNO 3 solution, make HNO 3 The solution was immersed in SiC particles, and boiled at normal pressure for 10 minutes, then filtered and washed with distilled ...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 lies in the following steps:

[0066] (1) In the step of preparing the electroless plating solution: the amount of raw materials is 15 parts by mass of copper sulfate pentahydrate, 28 parts by mass of formaldehyde and 11 parts by mass of sodium hydroxide dissolved in 1000 parts by mass of water;

[0067] (2) In the SiC particle removal treatment step: the particle size of the small SiC particles is 5 microns, the particle size of the large particles is 12 microns, and the immersion time in the hydrofluoric acid solution is 15 minutes;

[0068] (4) In the activation step of SiC particles: the stirring time of SiC particles in the activation solution is 6 minutes;

[0069] (5) TiB 2 In the particle removal treatment step: the particle size of the small SiC particles is 5 microns, the particle size of the large particles is 12 microns, and the immersion time in the hydrofluoric acid solution is 15 minutes;

[0070] ...

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 lies in the following steps:

[0079] (1) In the step of preparing the electroless plating solution: the amount of raw materials is 16 parts by mass of copper sulfate pentahydrate, 32 parts by mass of formaldehyde and 12 parts by mass of sodium hydroxide dissolved in 1000 parts by mass of water;

[0080](2) In the SiC particle removal treatment step: the particle size of the small SiC particles is 3 microns, the particle size of the large particles is 8 microns, and the immersion time in the hydrofluoric acid solution is 20 minutes;

[0081] (4) In the activation step of SiC particles: the stirring time of SiC particles in the activation solution is 7 minutes;

[0082] (5) TiB 2 In the particle removal treatment step: the particle size of the small SiC particles is 3 microns, the particle size of the large particles is 8 microns, and the immersion time in the hydrofluoric acid solution is 20 minutes;

[0083] (7)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com