Functional fluid compositions with improved seal swell properties

A technology of functional fluids and compositions, applied in lubricating compositions, base materials, additives, etc., which can solve problems such as product waiver, excessive swelling and complication of synthetic rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation of naphthenic base oils can be found in "Lubricants and Lubrication (Second Completely Revised and Extended Edition)", Chapter 4, pp. 46-48, published by Wiley-VCH Verlag GmbH & Co. KgaA.

[0020] Commercially available sources of naphthenic base oils include those commercially available from Calumet Lubricants Co. under the tradename HYDROCAL, those commercially available under the tradenames HYPRENE and HYGOLD from Ergon Petroleum Specialties, those commercially available from Nynas Alkanic base oils, and SNH series naphthenic base oils commercially available from Sankyo-Yuku.

[0021] Particularly preferred naphthenic base oils for use herein have a kinematic viscosity of 4.75-5.10 at 20°C, a kinematic viscosity of 2.90-3.20 at 40°C, a minimum flash point (ASTM D92) of 101°C, and a minimum pour point of -66°C.

[0022] Another major component of the base oil compositions herein are Fischer-Tropsch derived base oils.

[0023] The term "Fischer-Tropsc...

Embodiment 1-3

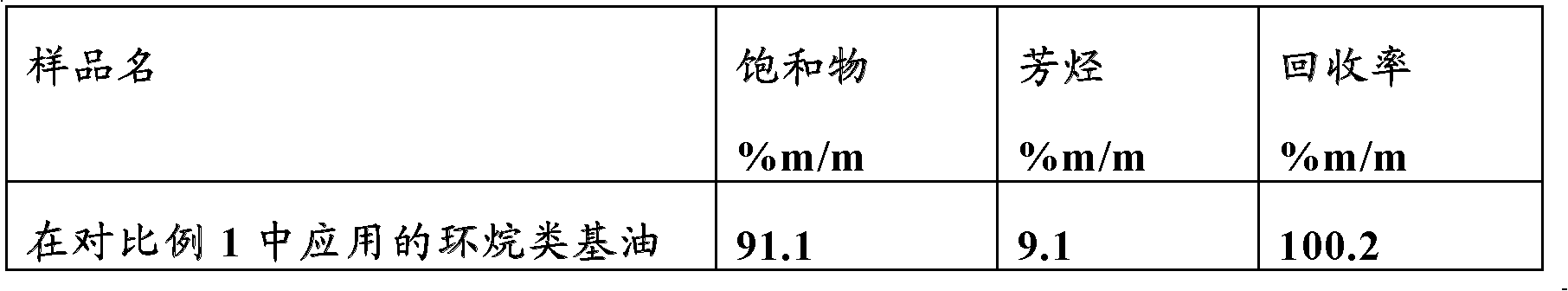

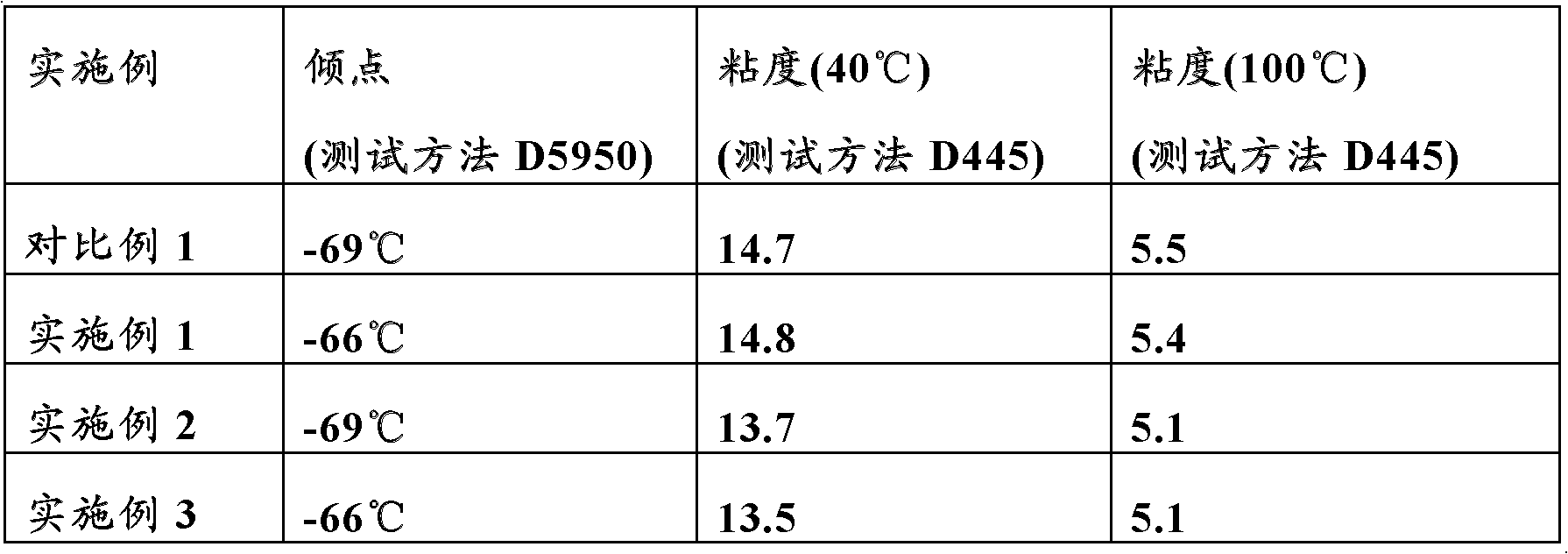

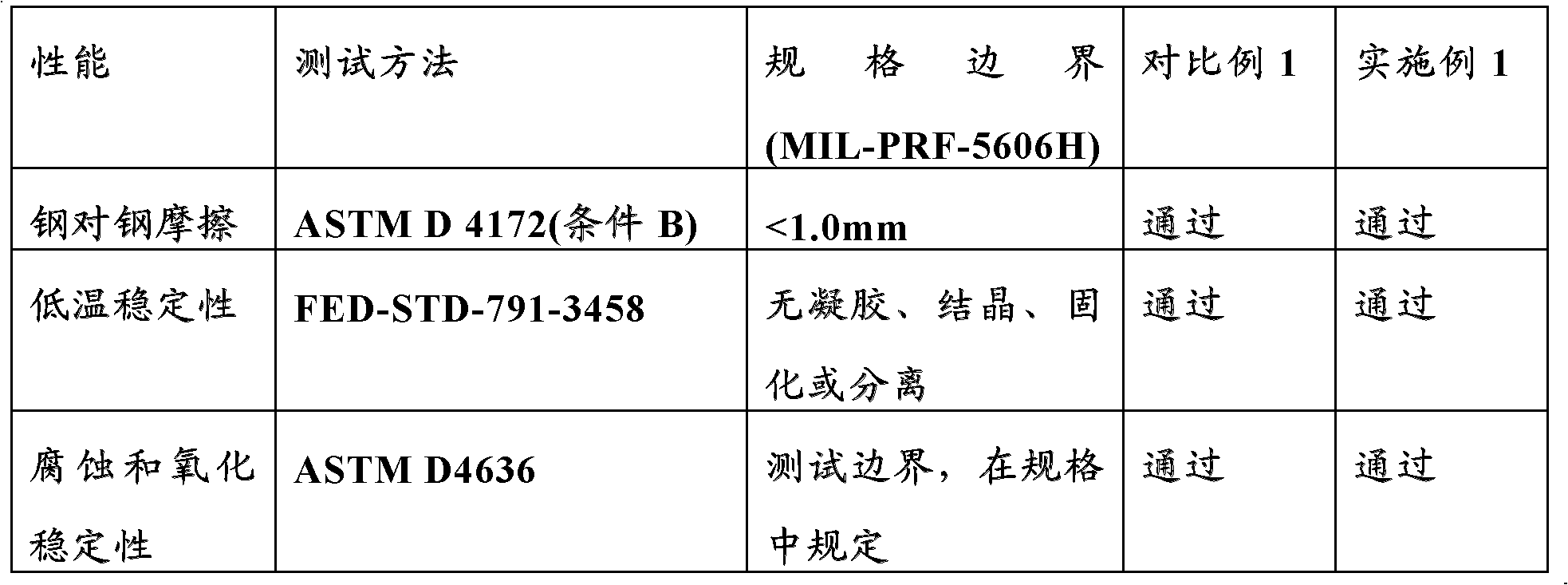

[0094] Examples 1-3 were prepared by mixing a naphthenic base oil with a Fischer-Tropsch derived base oil in the amounts shown in Table 6 below. The naphthenic base oil used in Examples 1-3 is the same as that used in Comparative Example 1.

[0095] The Fischer-Tropsch derived base oil used in Examples 1 and 2 had a viscosity of 2.68mm at 100°C 2 / s "GTL 3". The Fischer-Tropsch derived base oil used in Example 3 was "GTL-GO", i.e. a viscosity of 1.255 mm at 100°C 2 / s Fischer-Tropsch derived gas oil. GTL 3 and GTL-GO can be prepared as described in WO2004 / 07647. The performance of GTL3 and GTL-GO is shown in Table 5 below.

[0096] table 5

[0097] performance

testing method

unit

GTL 3

GTL-GO

Vk at 100°C

D445

mm 2 / s

2.68

1.255

Vk at 40°C

D445

mm 2 / s

9.581

3.128

Density at -40°C

D2983

CP

-

50 / 40

VI

D2270

119

-

pour point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com