Patents

Literature

111results about How to "Reduce interfacial resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

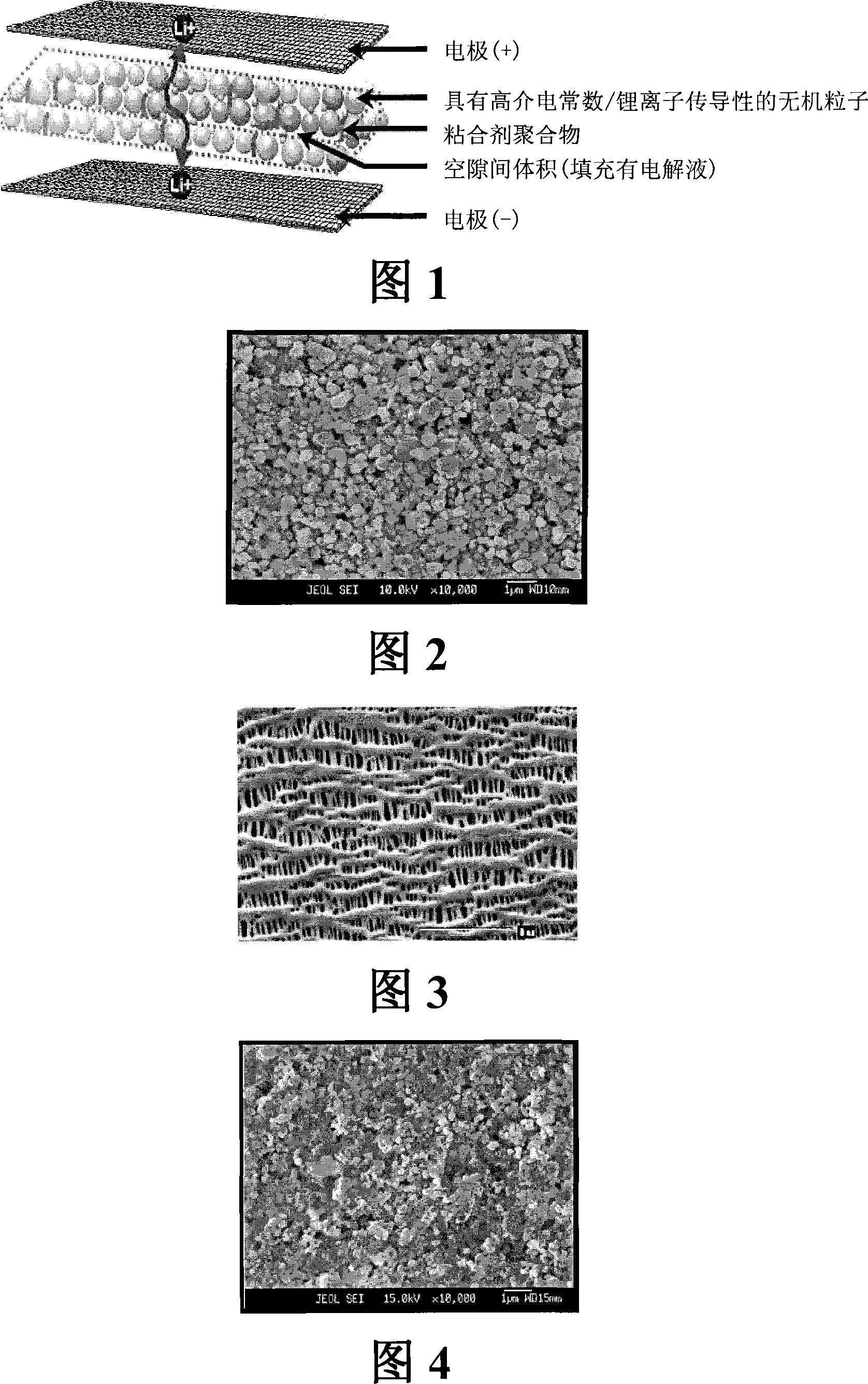

Organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveCN101002347AImprove thermal safetyImprove performanceLi-accumulatorsCell component detailsInorganic particleInorganic particles

Disclosed is an organic / inorganic composite porous film comprising: (a) inorganic particles; and (b) a binder polymer coating layer formed partially or totally on surfaces of the inorganic particles, wherein the inorganic particles are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a micropore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality.

Owner:LG ENERGY SOLUTION LTD +1

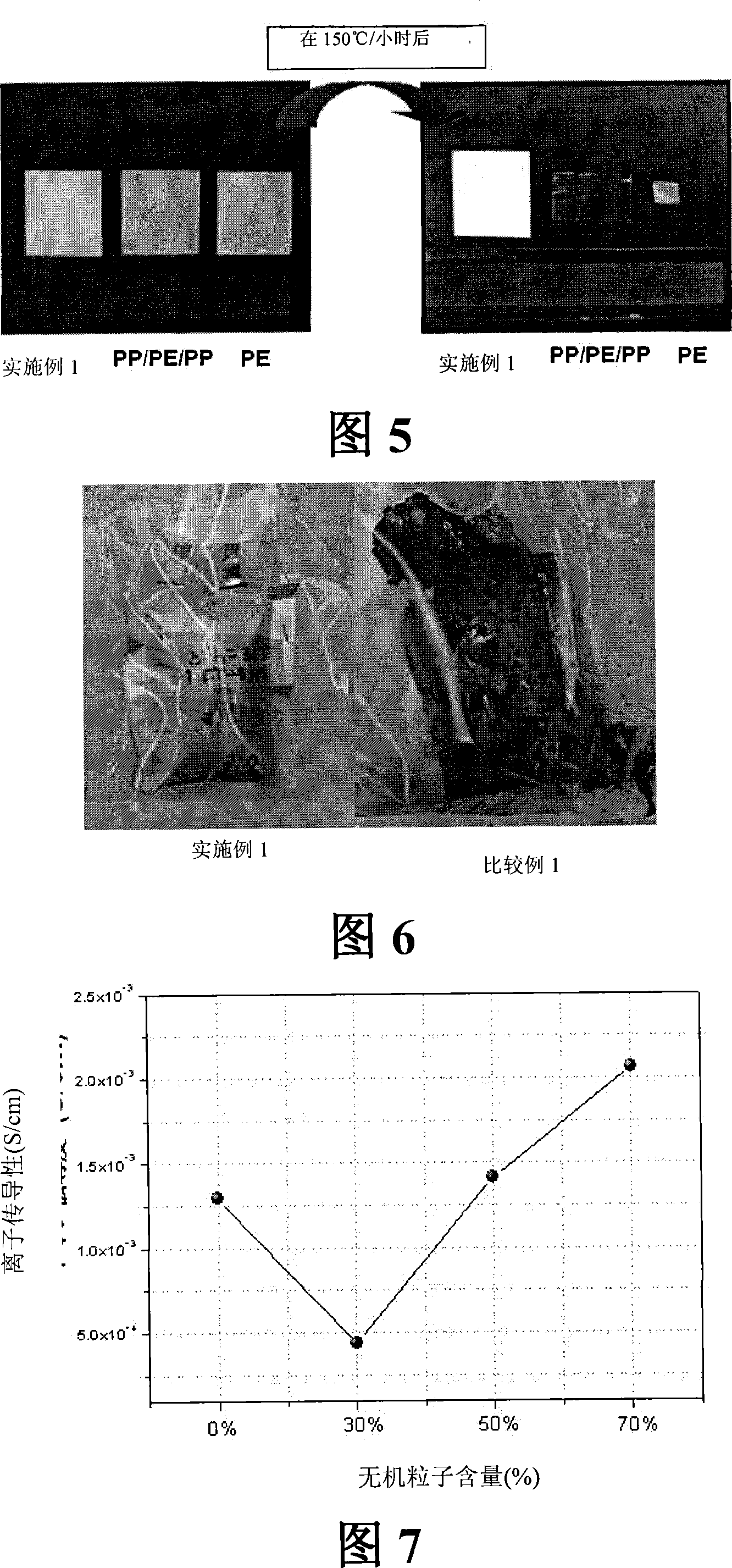

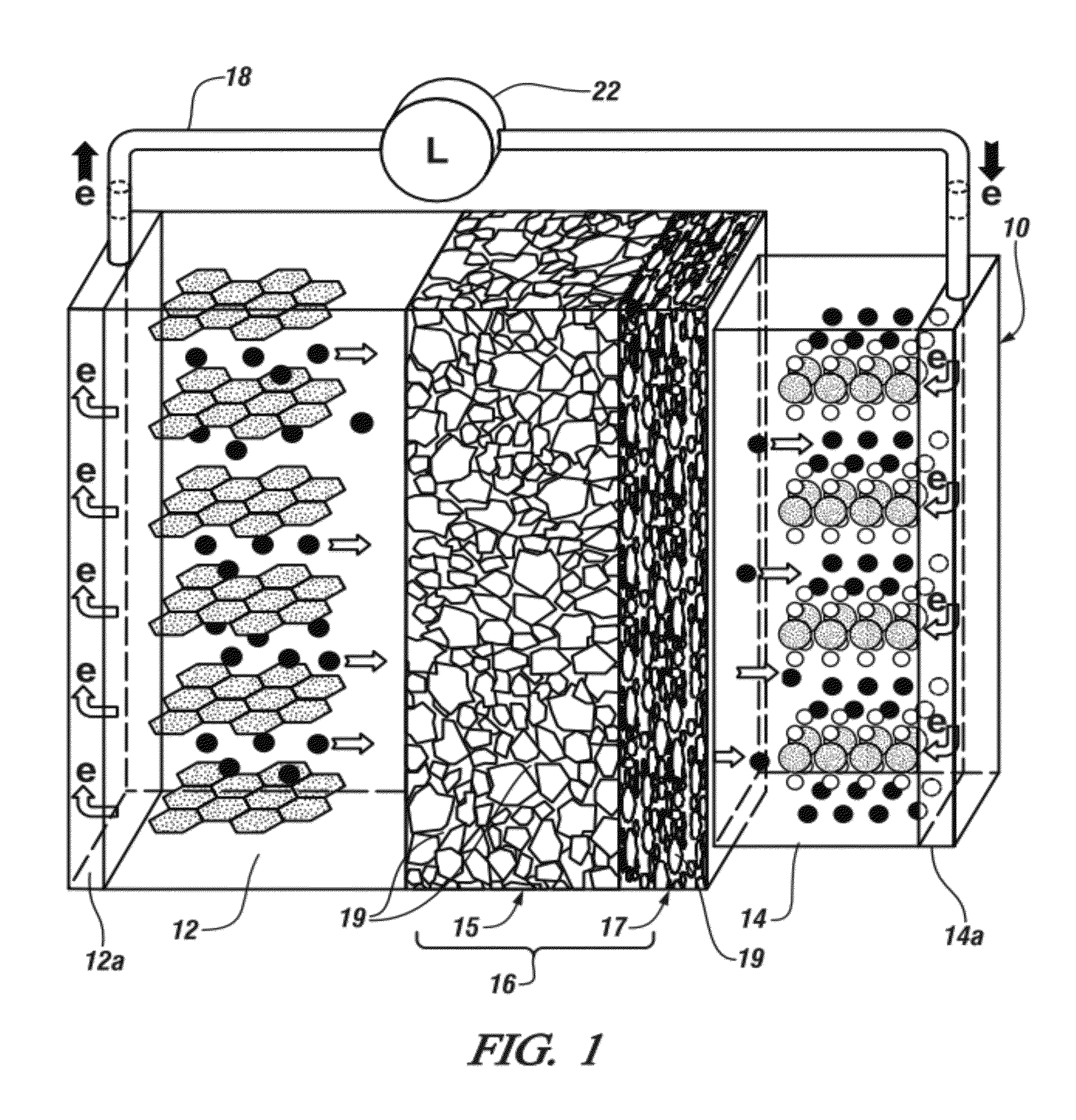

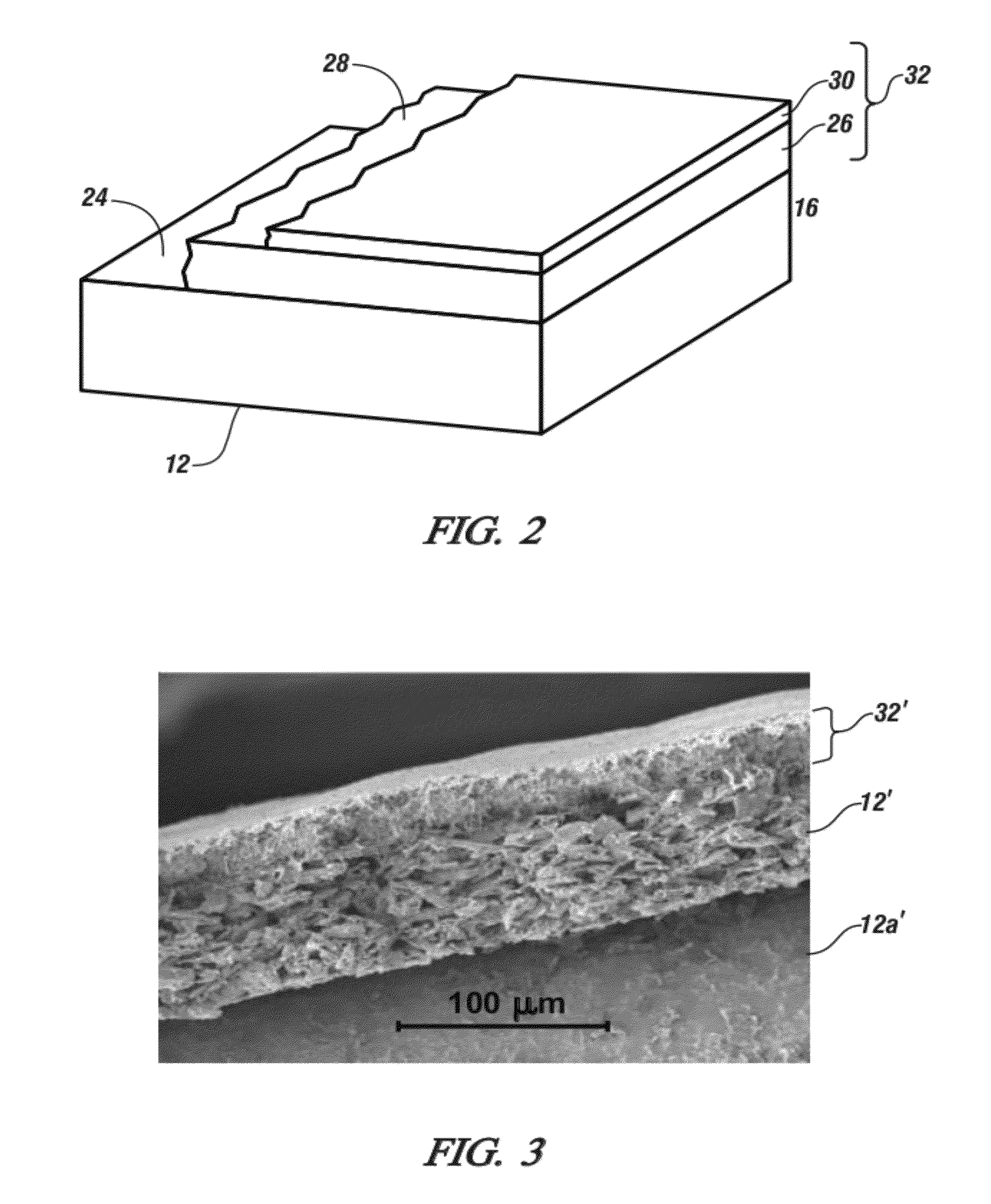

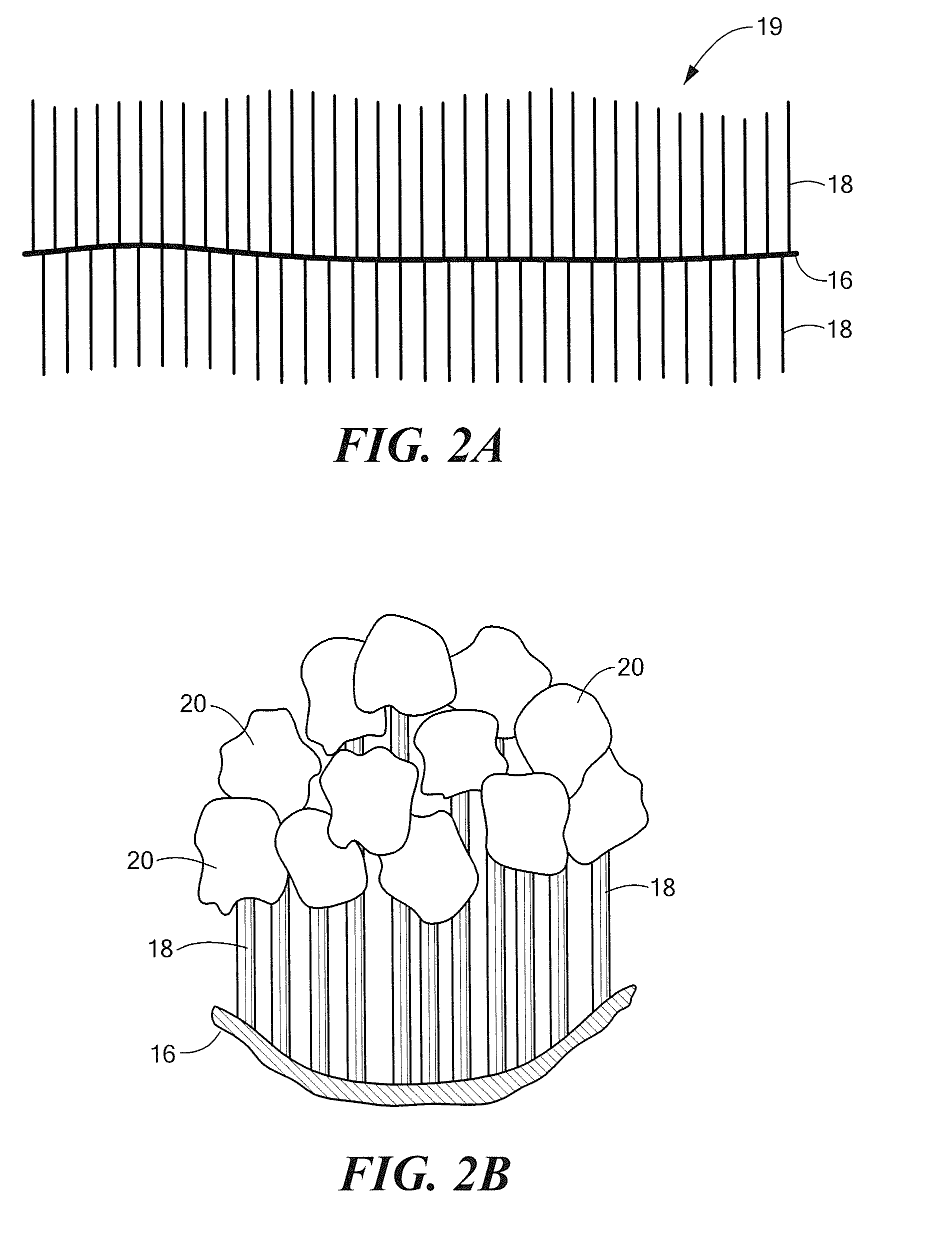

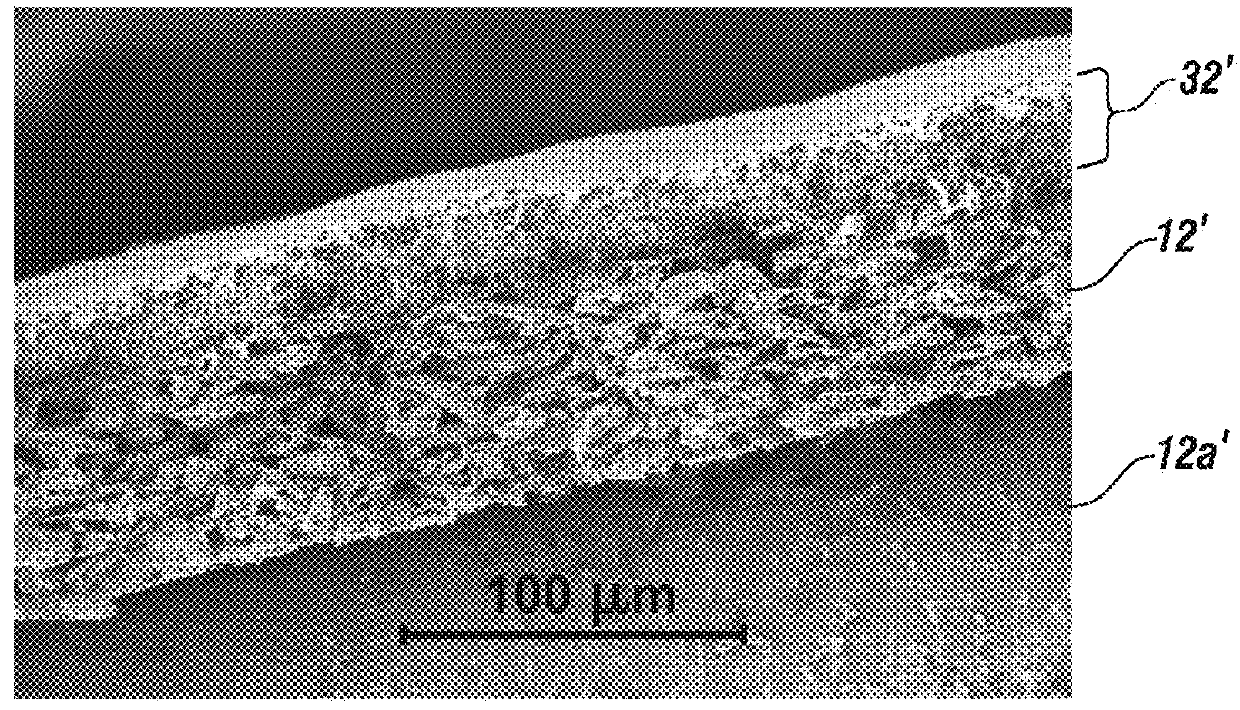

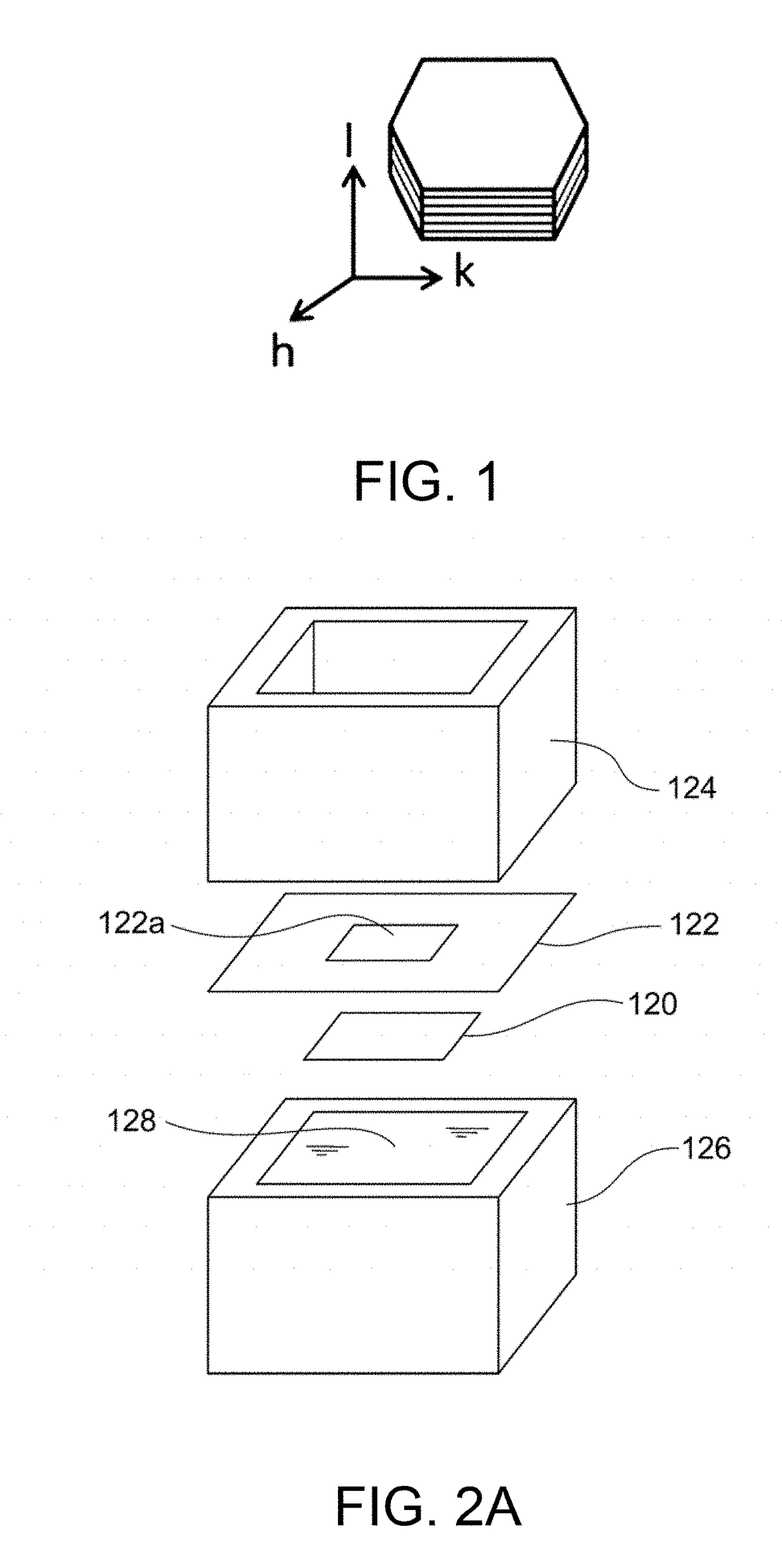

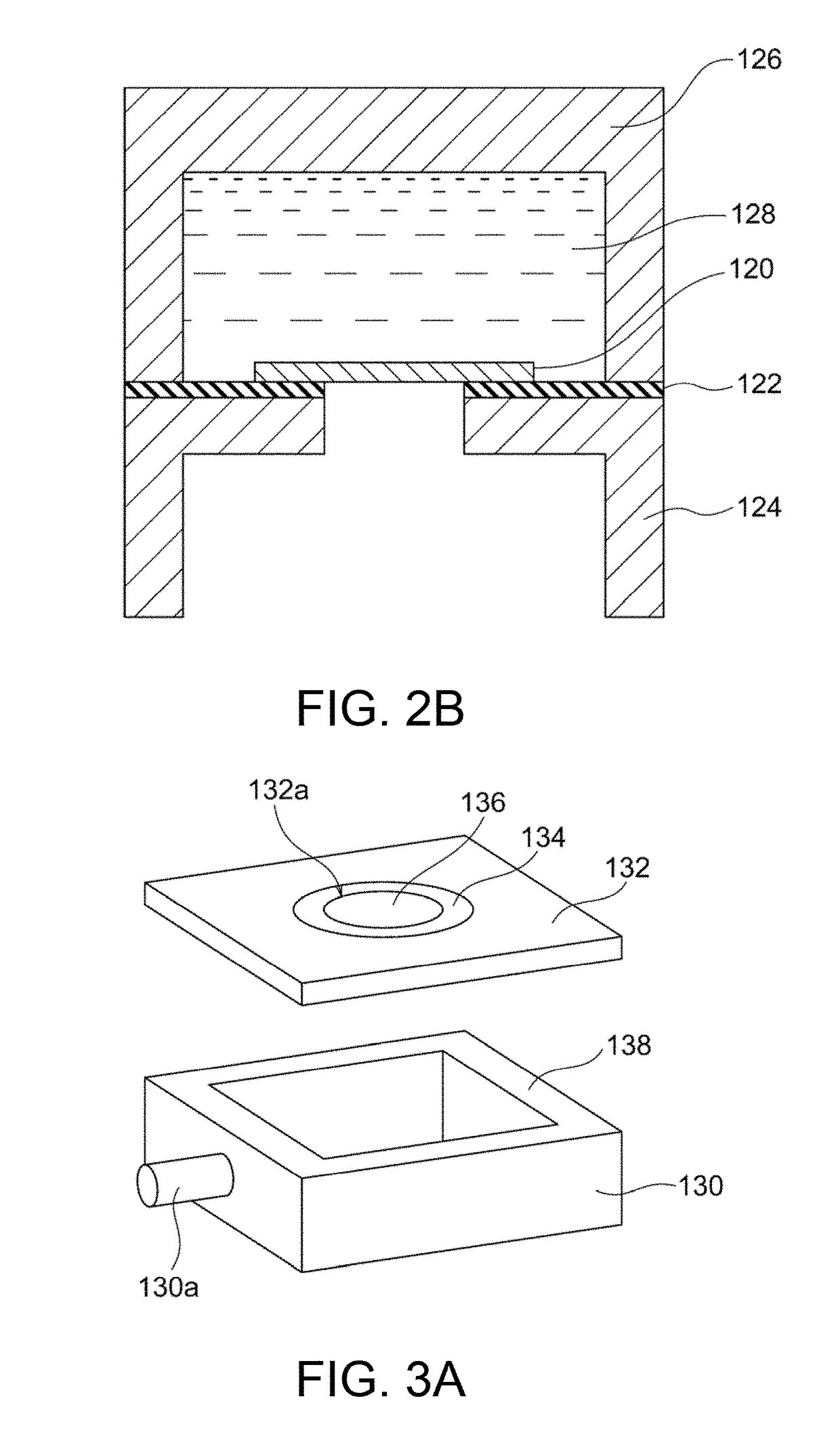

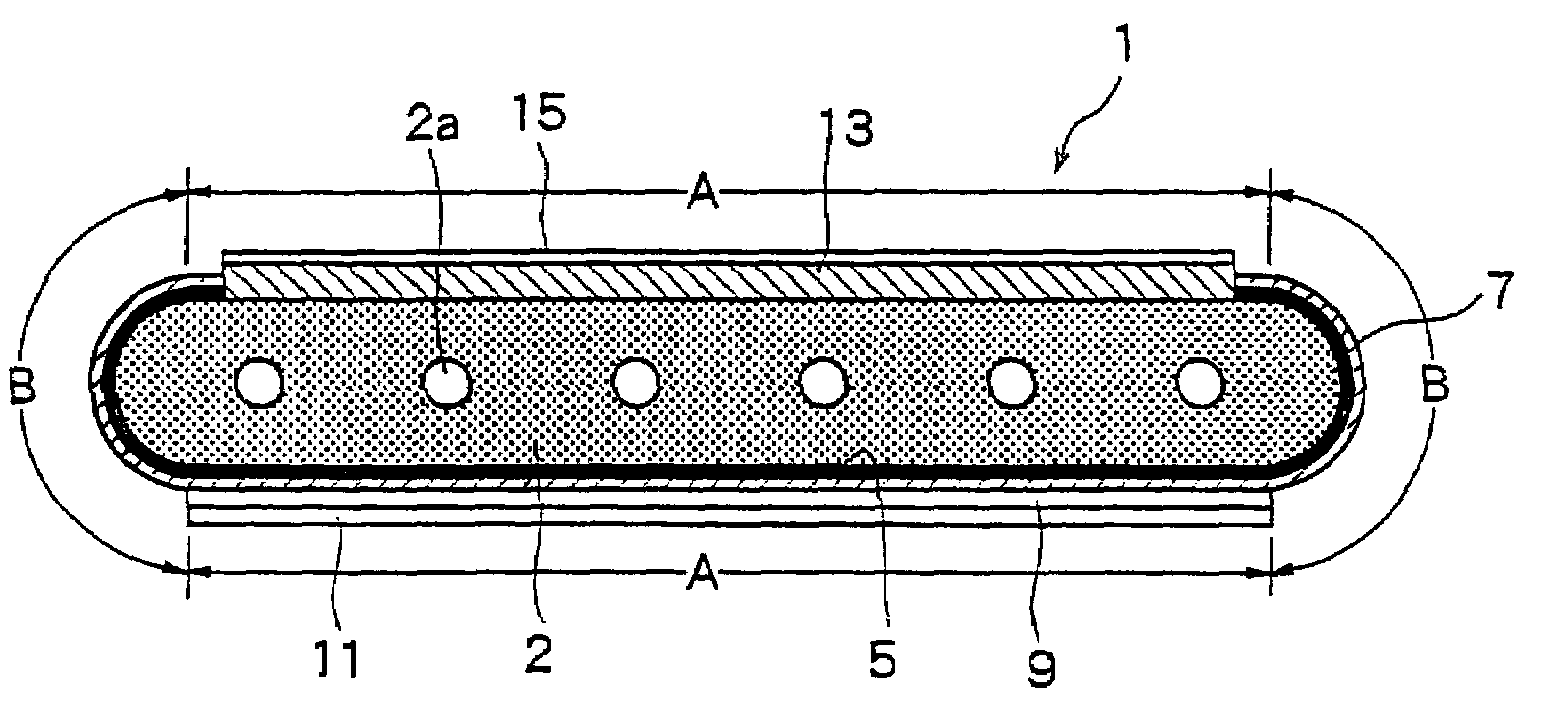

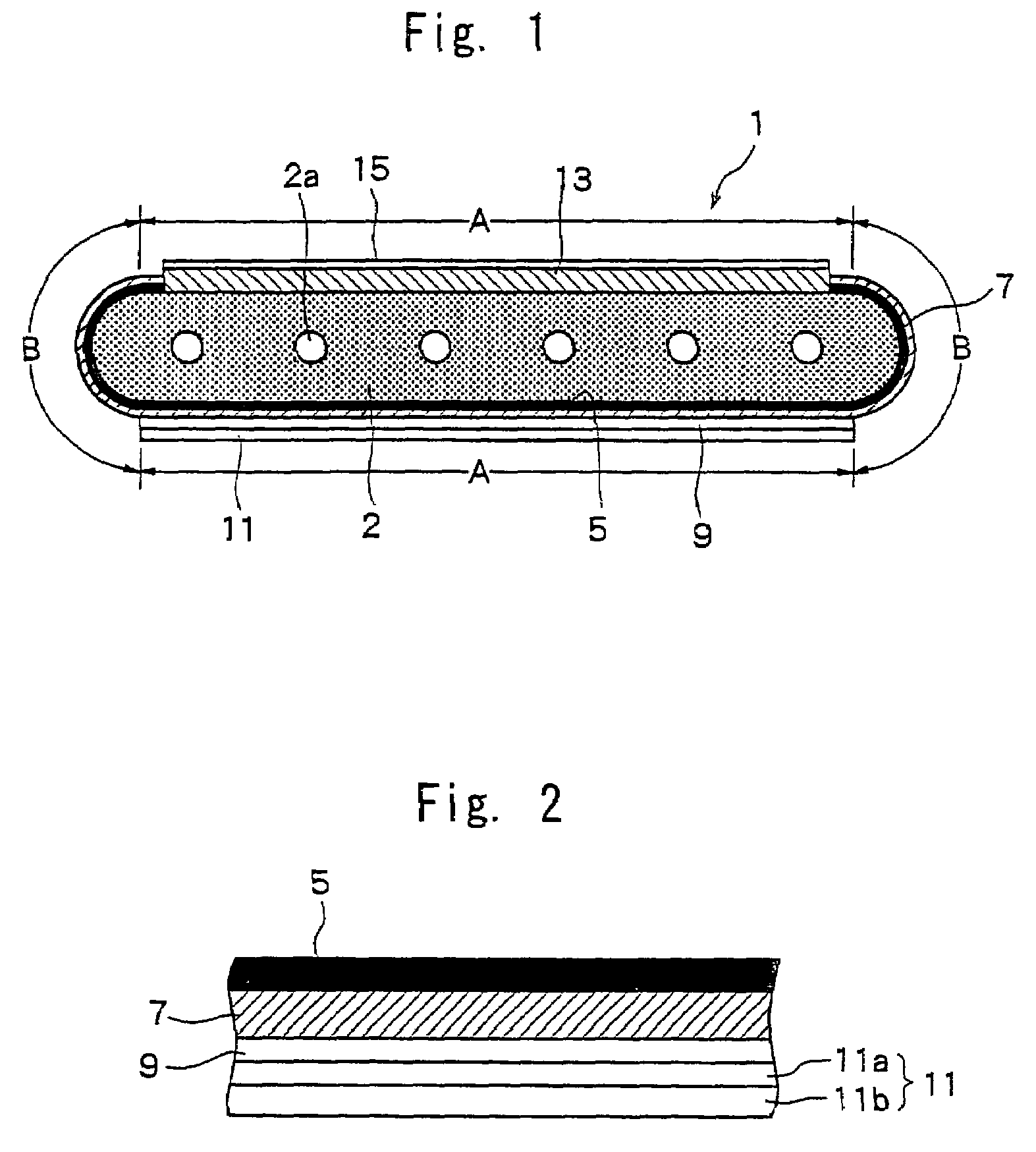

Integral bi-layer separator-electrode construction for lithium-ion batteries

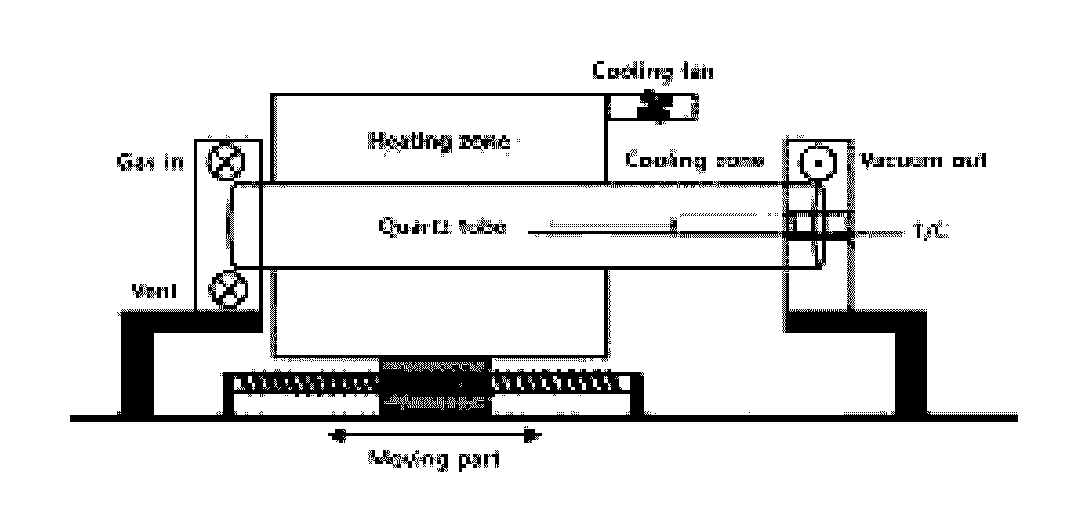

InactiveUS20120231321A1Improve temperature resistanceImprove the immunityFinal product manufacturePrimary cellsEvaporationSlurry

A porous bi-layer separator composed of a first layer with a contacting array of non-conducting particles overlaid with a second layer of a microporous polymer layer, may be fabricated on the electrode surface of the anode of a lithium-ion battery to form an integral electrode-separator construction. The bi-layer separator may prevent development of a direct electronic path between the anode and cathode of the battery while accommodating electrolyte solution and enabling passage of lithium ions. Such an integral separator should be mechanically robust and tolerant of elevated temperatures. Exemplary bi-layer separators may be fabricated by sequential deposition of solvent-containing slurries and polymer solutions with subsequent controlled evaporation of solvent. The elevated temperature performance of lithium-ion battery cells incorporating such integral electrode-bi-layer separators was demonstrated to exceed the performance of similar cells using commercial and experimental single layer polymer separators.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

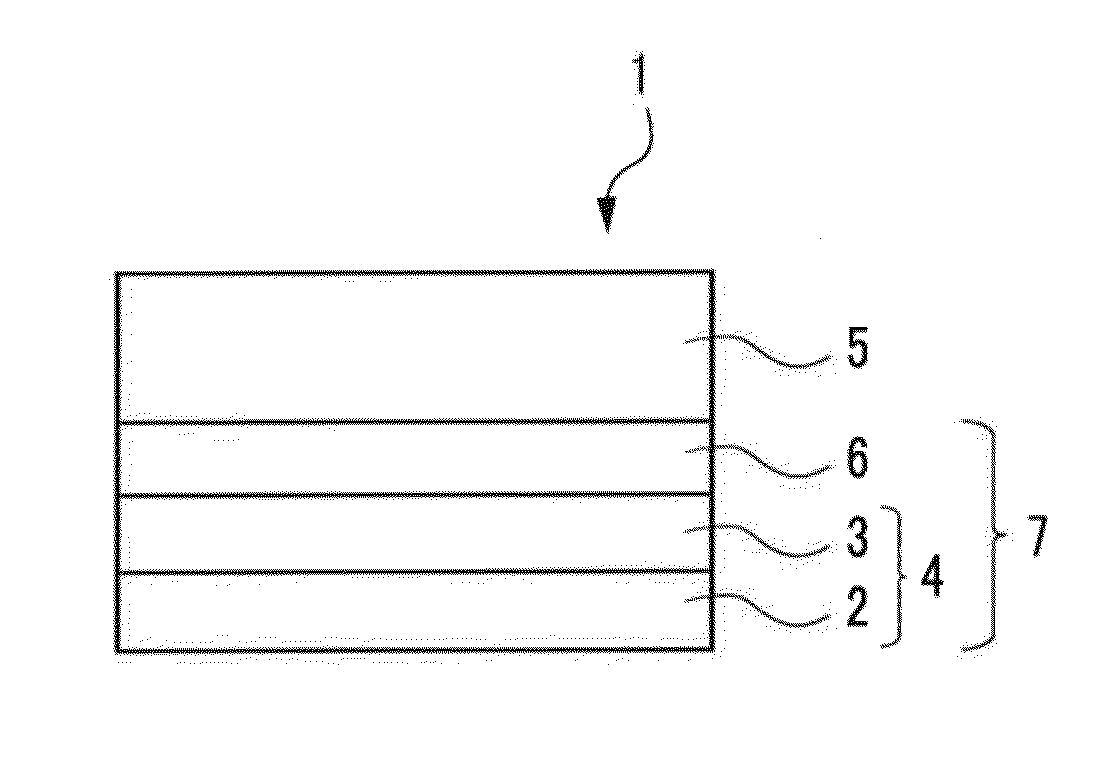

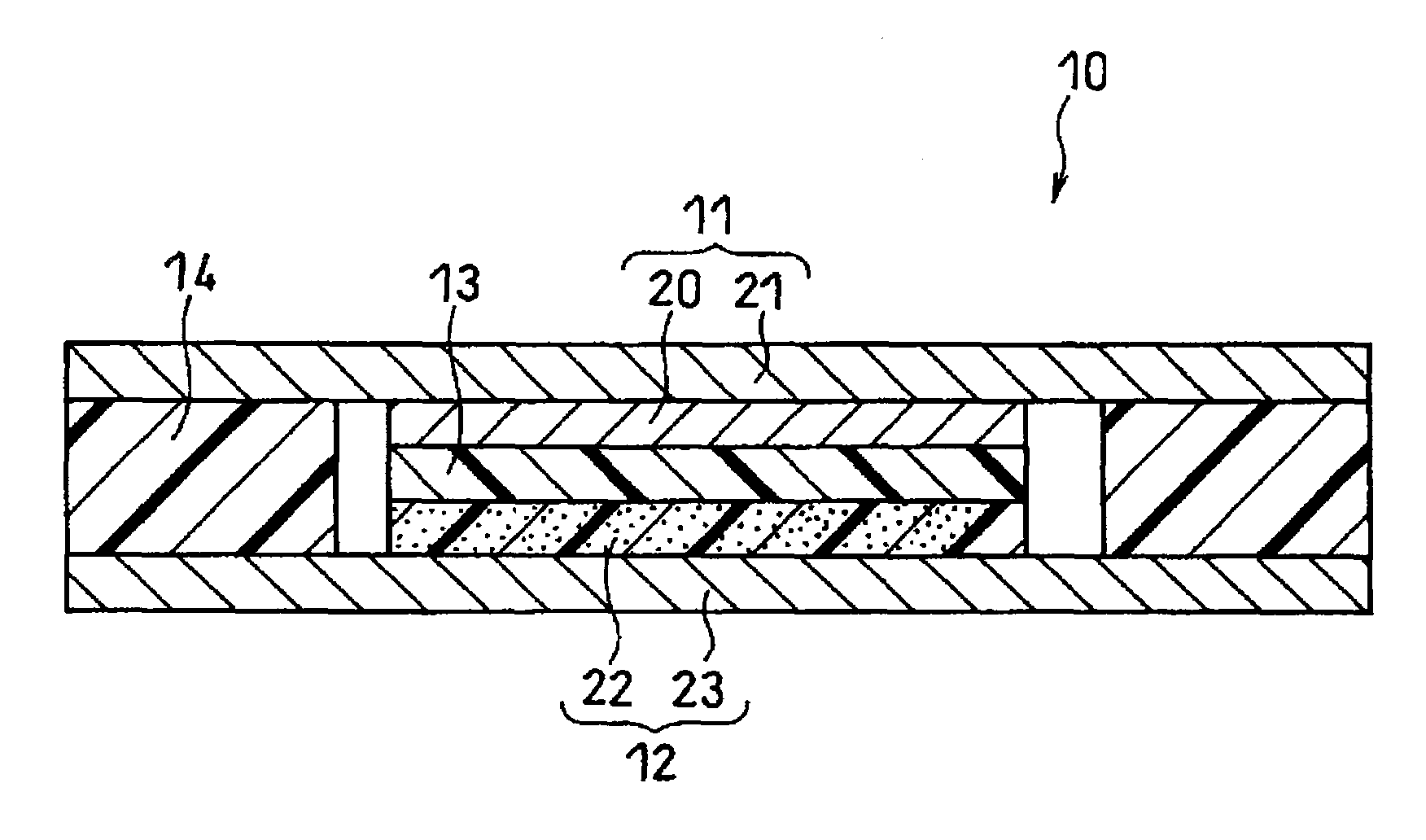

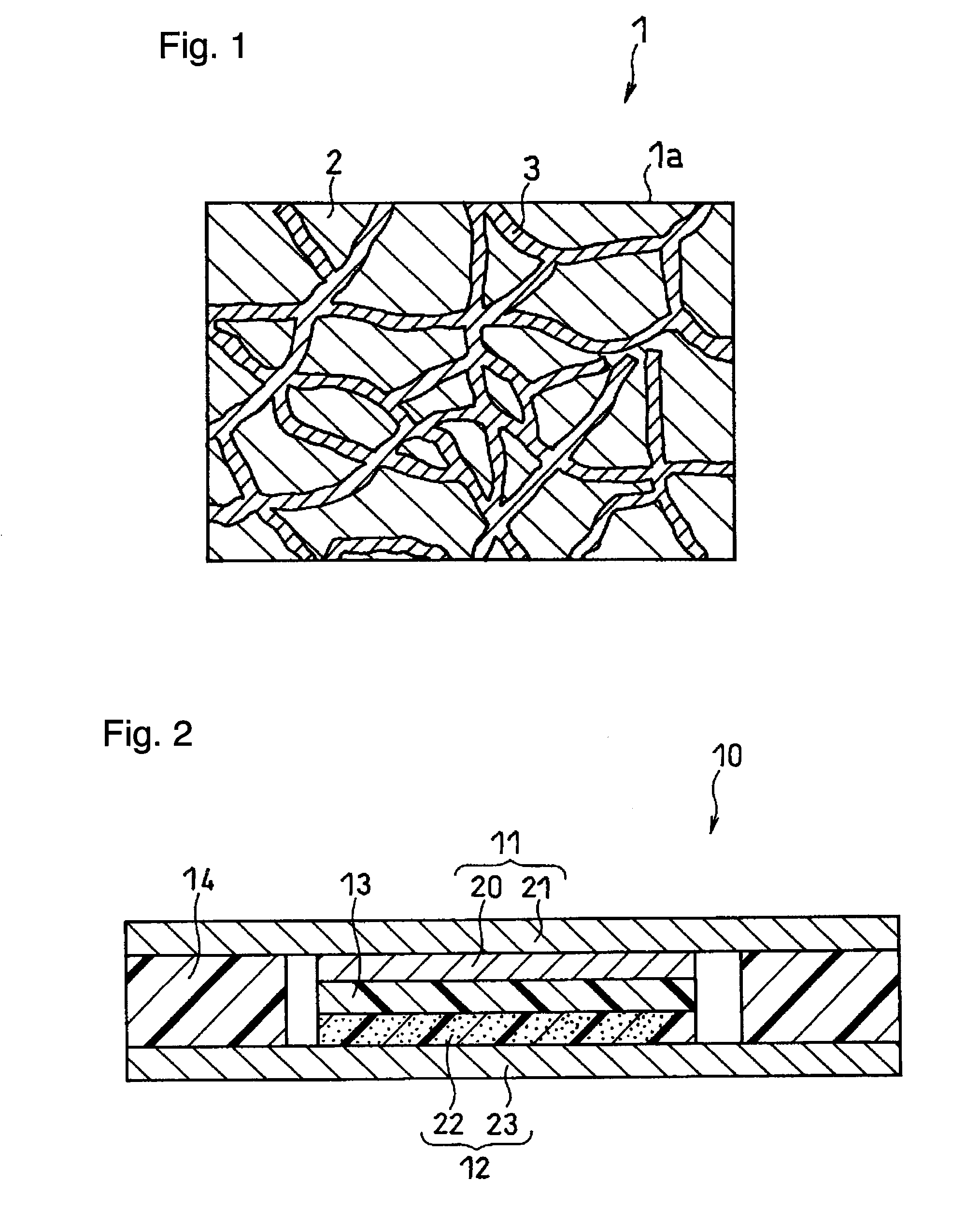

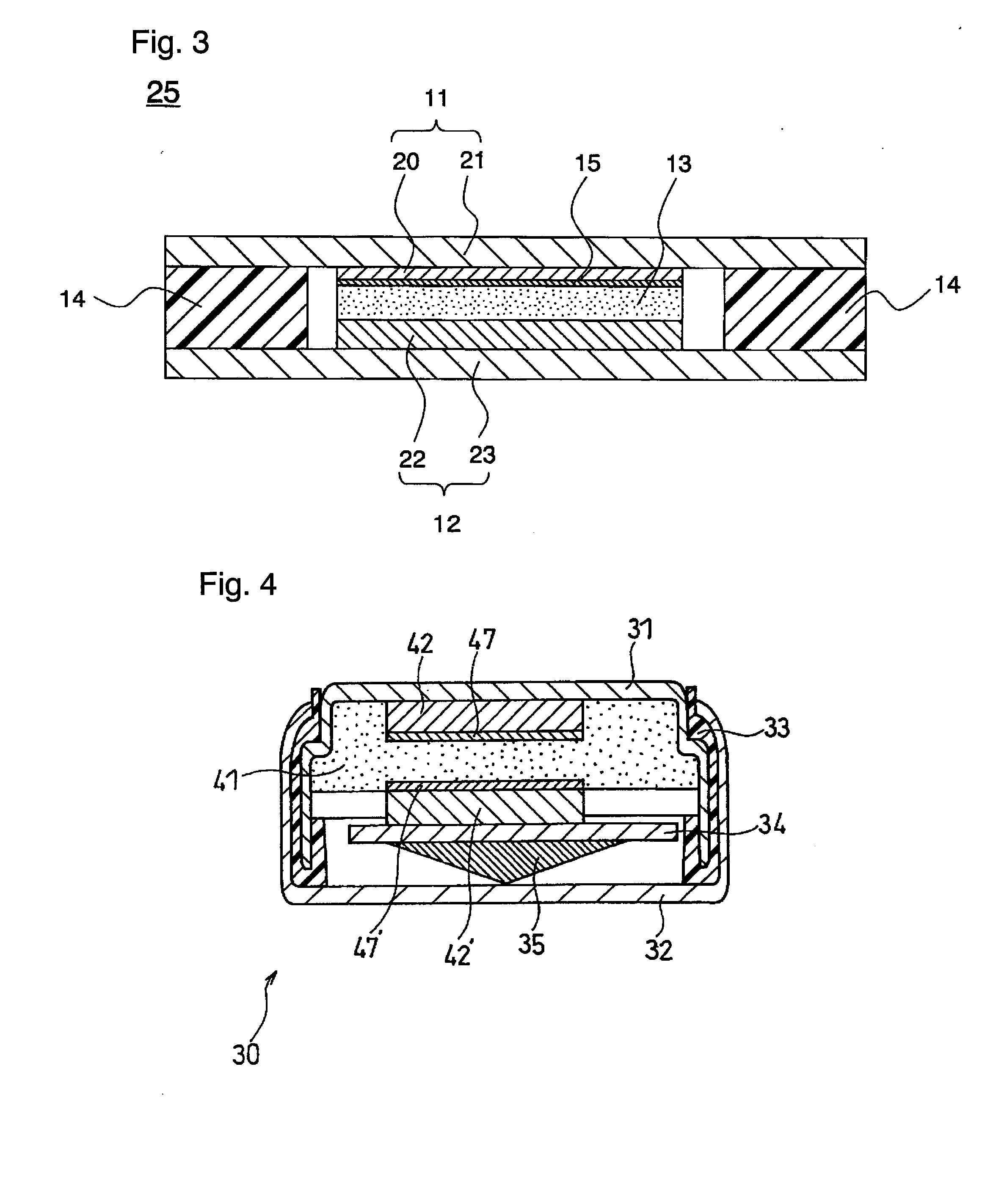

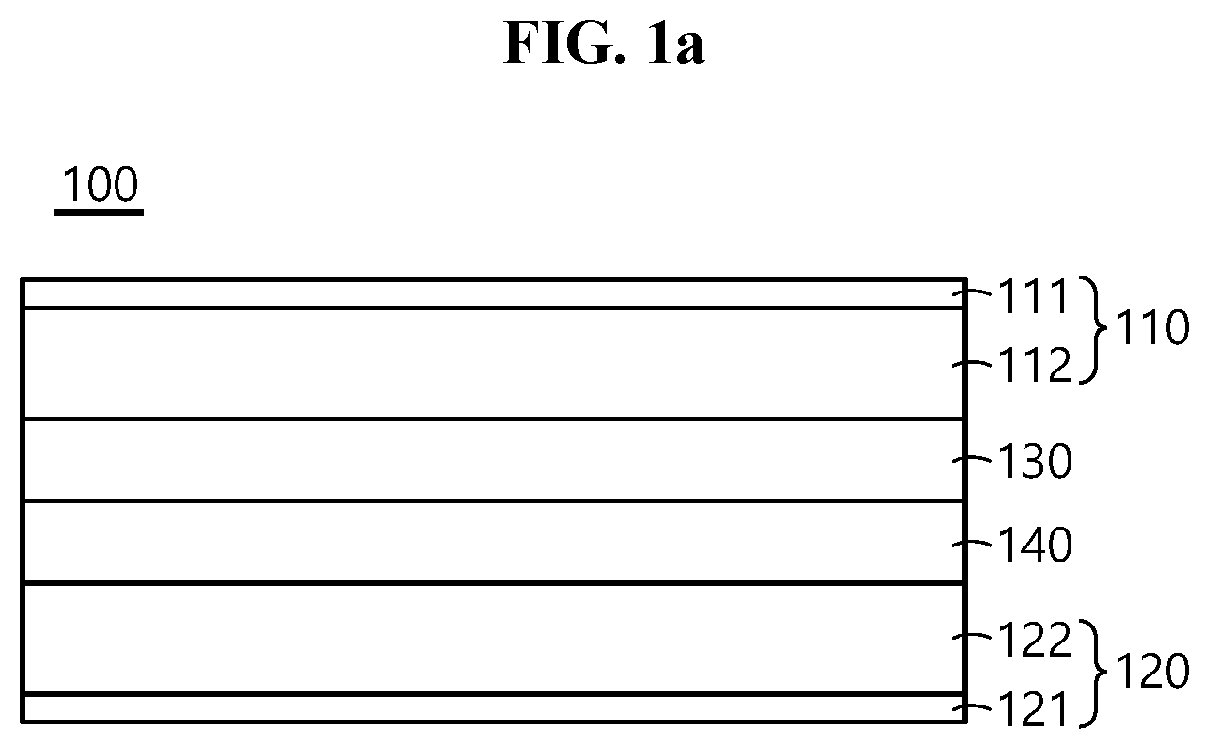

Electrolyte-positive electrode structure, and lithium ion secondary battery comprising the same

ActiveUS20140302399A1Small reduction potentialSuppress oxidation-reduction reactionSecondary cellsSolid electrolyte cellsLithiumInorganic particle

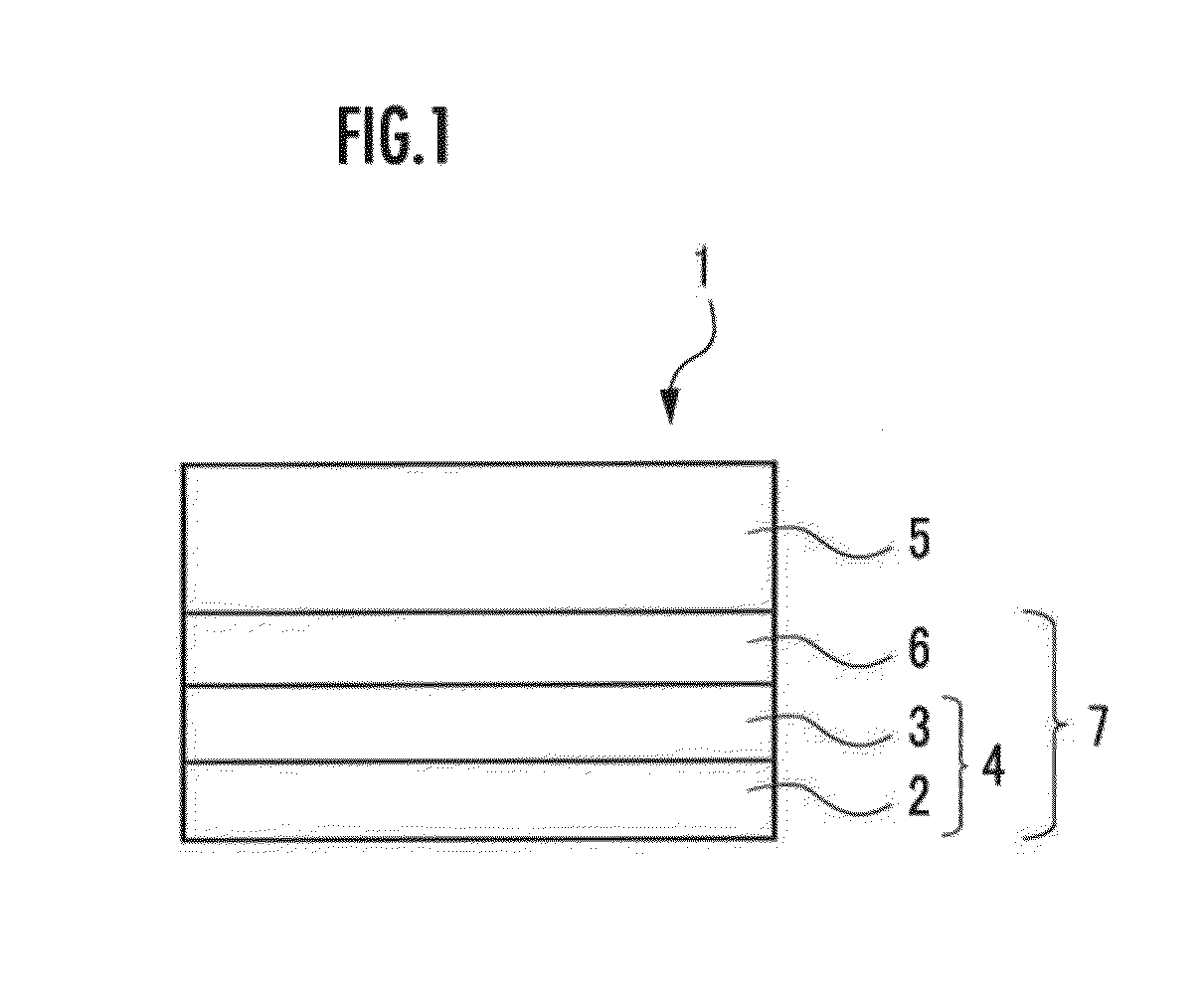

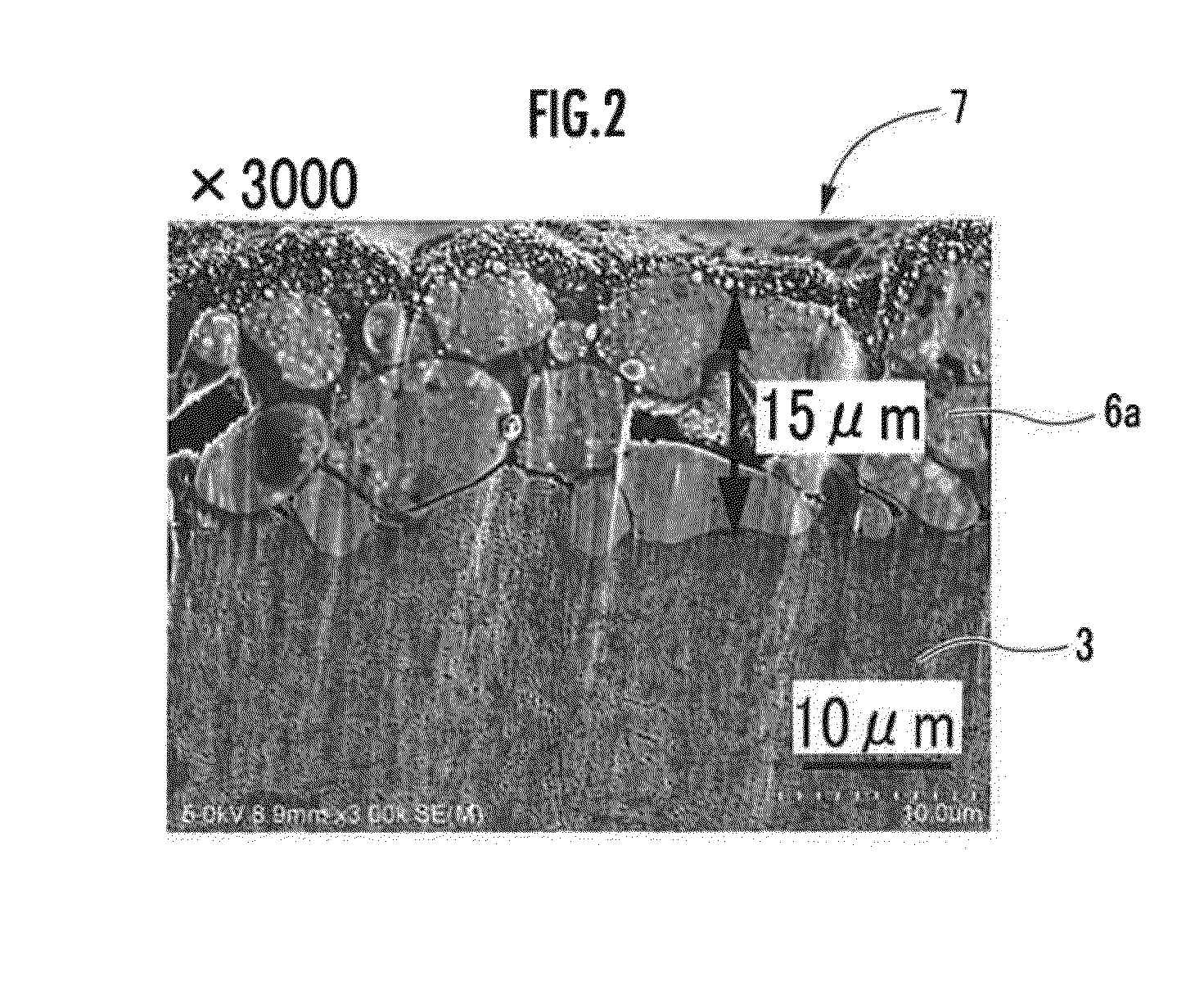

There are provided an electrolyte-positive electrode structure which comprises a thin solid electrolyte and can develop excellent capacity and output, and a lithium ion secondary battery comprising the same. An electrolyte-positive electrode structure 7 comprises: a positive electrode 4 comprising a positive electrode active material layer 3 formed on a current collector 2; and a solid electrolyte 6 containing inorganic particles having lithium ion conductivity, an organic polymer, and a polymer gel, in which the organic polymer binds the inorganic particles and can be impregnated with the polymer gel, and the polymer gel holds an electrolyte solution and is impregnated into the organic polymer, wherein the positive electrode active material layer 3 is integrated with the solid electrolyte 6 using the organic polymer as a medium.

Owner:HONDA MOTOR CO LTD

Nano-tube thermal interface structure

ActiveUS20110032678A1Minimize application timeMaximize reworkabilityNanotechSemiconductor/solid-state device detailsSemiconductor structureHeat spreader

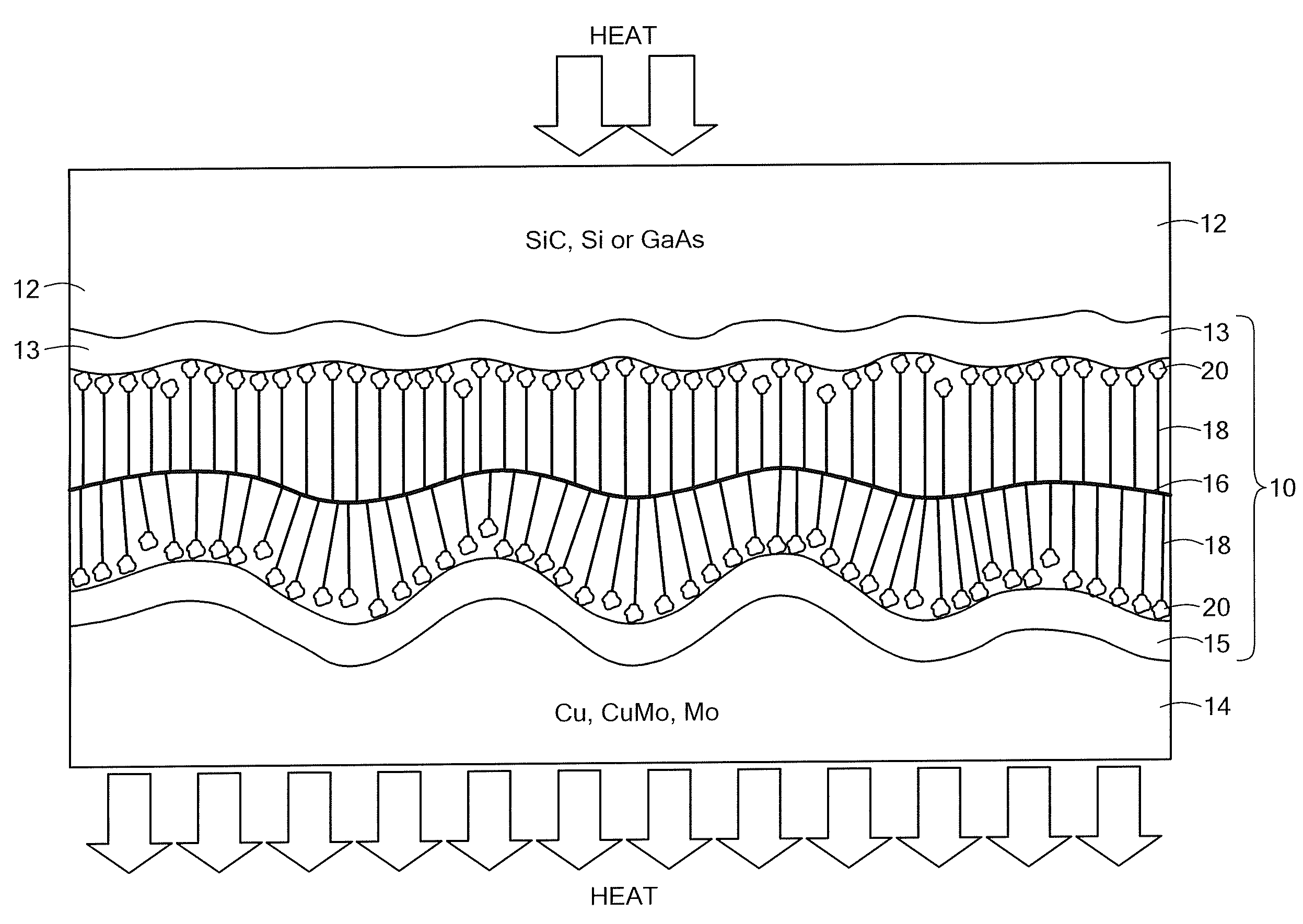

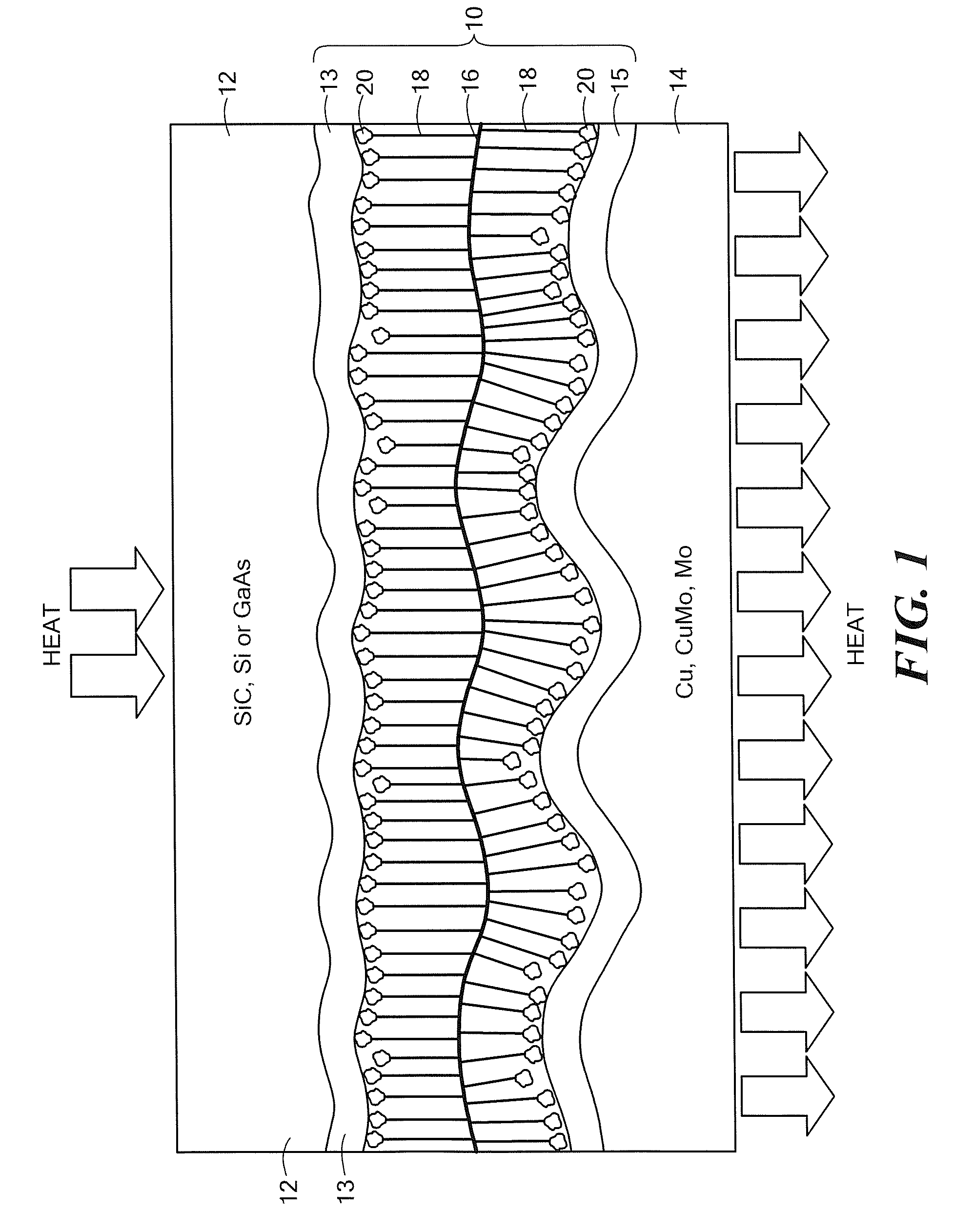

A structure, comprising: a semiconductor structure having an electrically and thermally conductive layer disposed on one surface of the semiconductor structure; an electrically and thermally conductive heat sink; a electrically and thermally conductive carrier layer; a plurality of electrically and thermally nano-tubes, a first portion of the plurality of nano-tubes having proximal ends disposed on a first surface of the carrier layer and a second portion of the plurality of nano-tubes having proximal ends disposed on an opposite surface of the carrier layer; and a plurality of electrically and thermally conductive heat conductive tips disposed on distal ends of the plurality of nano-tubes, the plurality of heat conductive tips on the first portion of the plurality of nano-tubes being attached to the conductive layer, the plurality of heat conductive tips on the second portion of the plurality of nano-tubes being attached to the heat sink.

Owner:RAYTHEON CO

All solid-state polymer battery

InactiveUS20100068628A1Increase resistanceReduce interfacial resistanceCell electrodesSolid electrolyte cellsPolymer scienceHigh rate

An all solid-state polymer battery uses: 1) a lithium based negative electrode active material including crystal grains and crystal grain boundaries, wherein at least part of the crystal grain boundaries are exposed on a surface of the lithium-based negative electrode active material, and the area of the exposed surface of the crystal grain boundaries is 0.02 to 0.5 cm2 per square centimeter of surface; 2) a dry polymer electrolyte including a specific ethylene glycol ether, a polymer containing electron-donating oxygen atoms in the skeleton, and a lithium salt; or 3) an amorphous lithium nitride layer formed between the negative electrode and the polymer electrolyte. This reduces the resistance at the interface between the negative electrode and the polymer electrolyte, thereby providing an all solid-state polymer battery with high capacity and excellent cycle characteristics. This also suppresses an increase in internal resistance during storage, thereby providing an all solid-state polymer battery with excellent high-rate discharge characteristics after storage.

Owner:PANASONIC CORP

Lithium-ion-conducting composite material and process for producing

ActiveUS20190173130A1High particle fill levelSimple and economical to produceElectrolytesLi-accumulatorsLithiumPolymer chemistry

A lithium-ion-conducting composite material and process of producing are provided. The composite material includes at least one polymer and lithium-ion-conducting particles. The particles have a sphericity Ψ of at least 0.7. The composite material includes at least 20 vol % of the particles for a polydispersity index PI of the particle size distribution of <0.7 or are present in at least 30 vol % of the composite material for the polydispersity index in a range from 0.7 to <1.2, or are present in at least 40 vol % of the composite material for the polydispersity index of >1.2.

Owner:SCHOTT AG

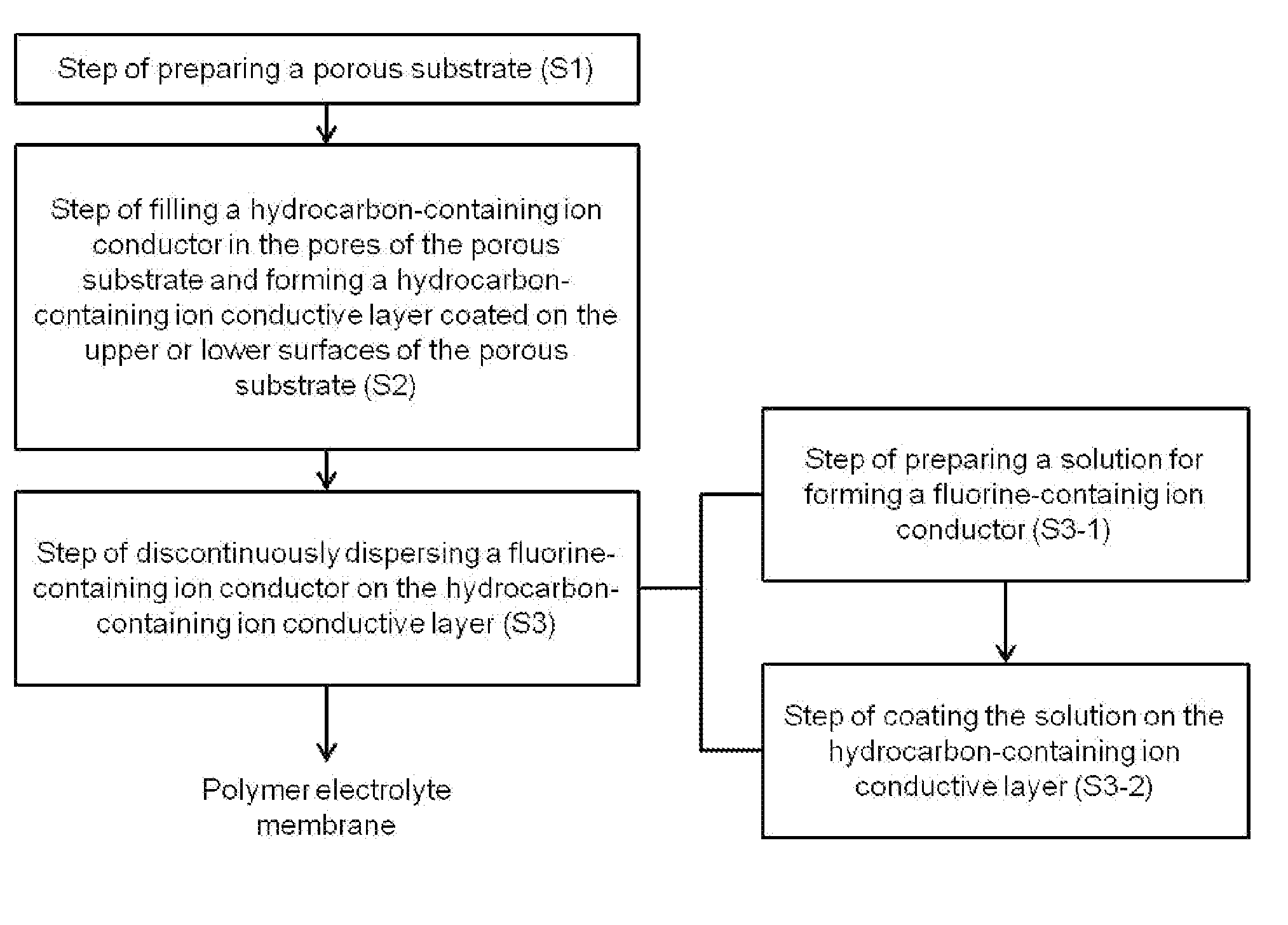

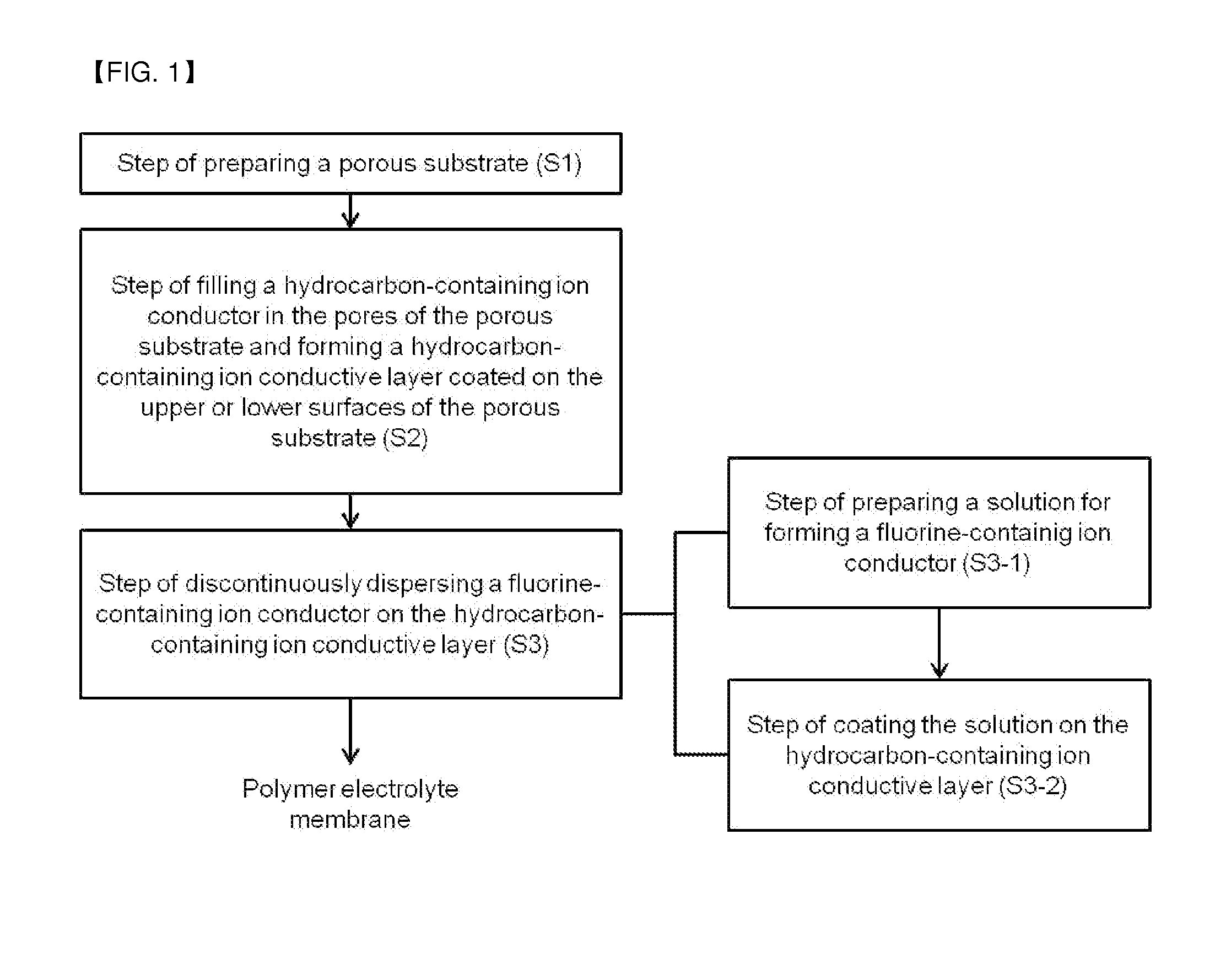

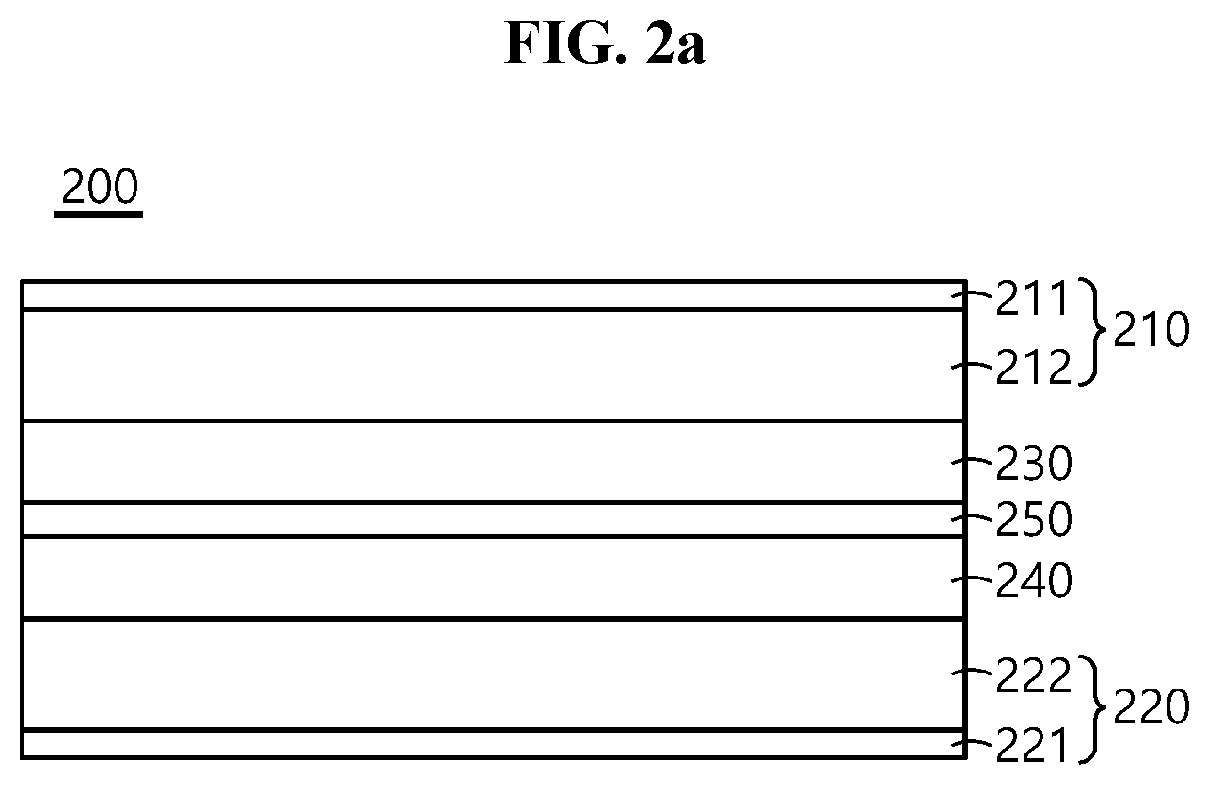

Polymer electrolyte membrane, a method for fabricating the same, and a membrane-electrode assembly including the same

ActiveUS20150064602A1Excellent adhesionImprove performanceSolid electrolytesFinal product manufactureIonPolymer chemistry

Disclosed are a polymer electrolyte membrane, a method for manufacturing the same and a membrane-electrode assembly comprising the same, the polymer electrolyte membrane includes a hydrocarbon-containing ion conductive layer; and a fluorine-containing ion conductor discontinuously dispersed on the hydrocarbon-containing ion conductive layer.

Owner:KOLON IND INC

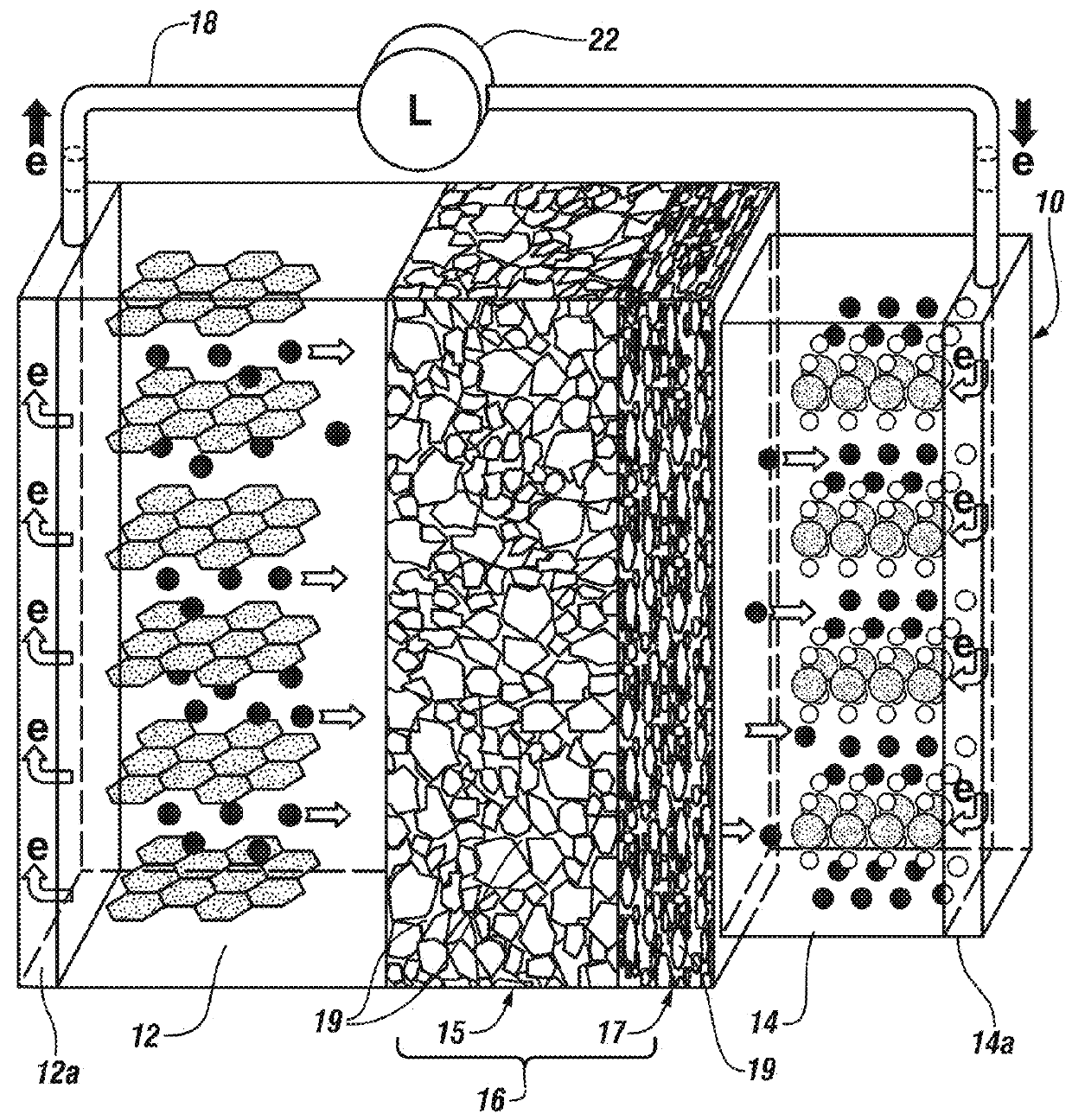

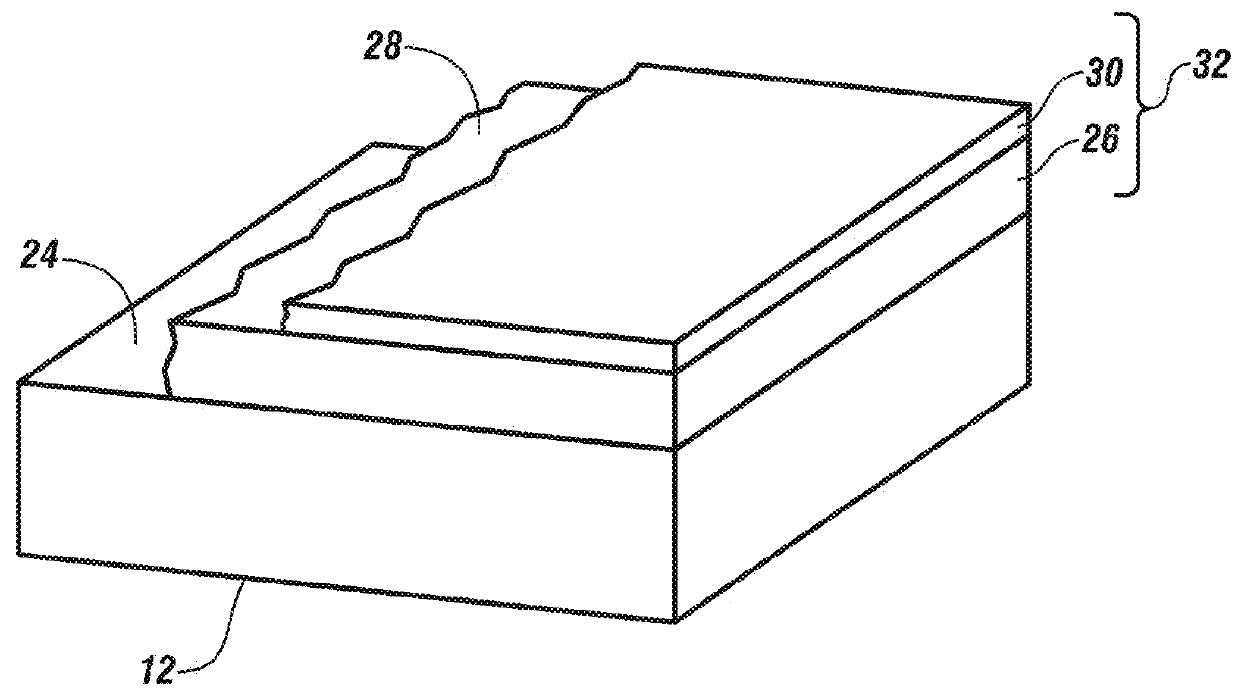

Integral bi-layer separator-electrode construction for lithium-ion batteries

ActiveUS20160056437A1Improve performanceImprove the immunityFinal product manufactureSecondary cellsEvaporationSlurry

A porous bi-layer separator is composed of a first separator layer with a contacting array of non-conducting particles overlaid with a second separator layer of a microporous polymer layer, fabricated on the electrode surface of the anode of a lithium-ion battery to form an integral electrode-separator construction. Exemplary bi-layer separators may be fabricated by deposition of solvent-containing slurries of separator particles followed by solvent evaporation to produce the particle layer with subsequent application of polymer solutions followed by controlled evaporation of solvent to produce the microporous polymer layer. The elevated temperature performance of lithium-ion battery cells incorporating such integral electrode-bi-layer separators was demonstrated to exceed the performance of similar cells using commercial and experimental single layer polymer separators.

Owner:GM GLOBAL TECH OPERATIONS LLC

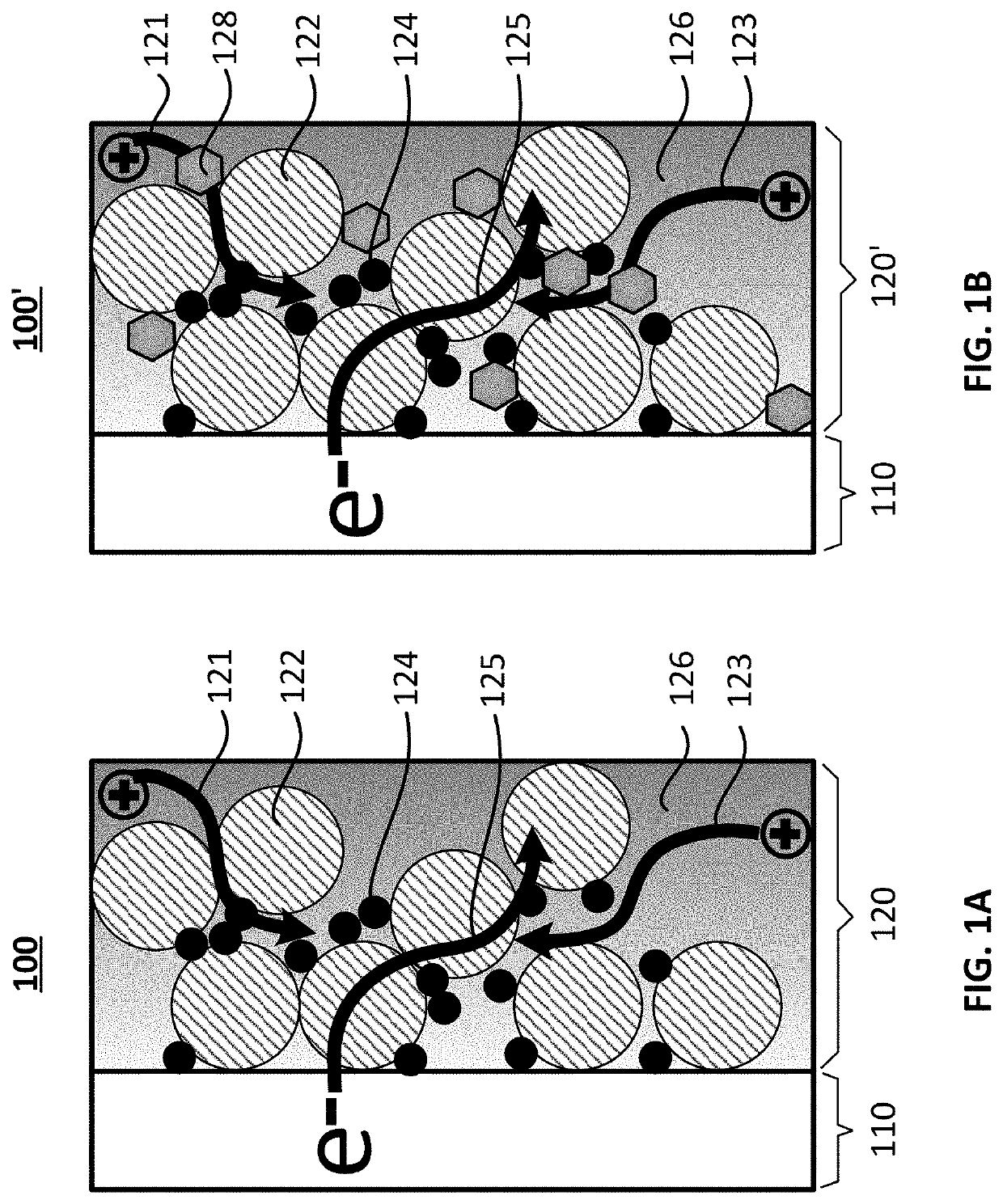

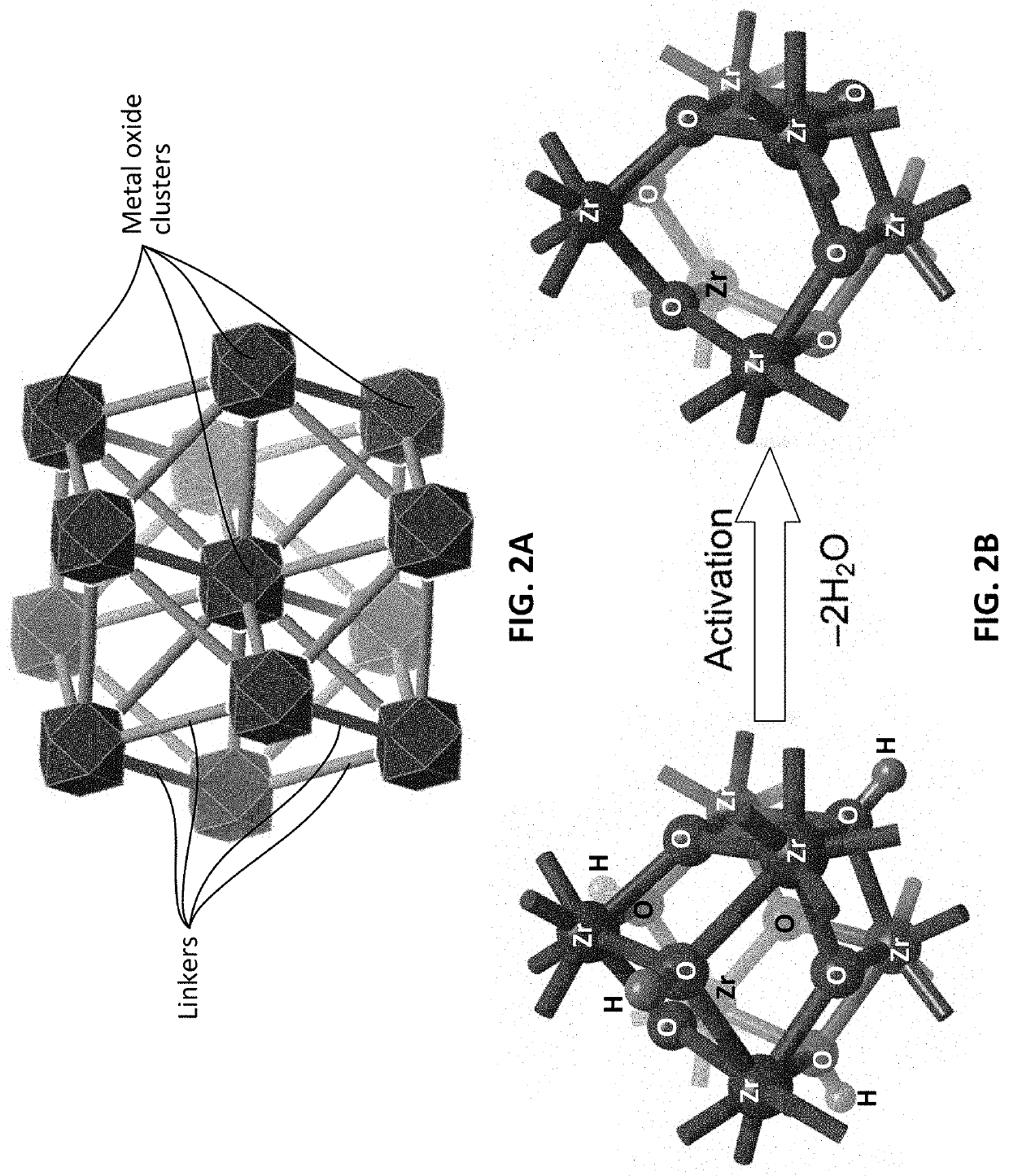

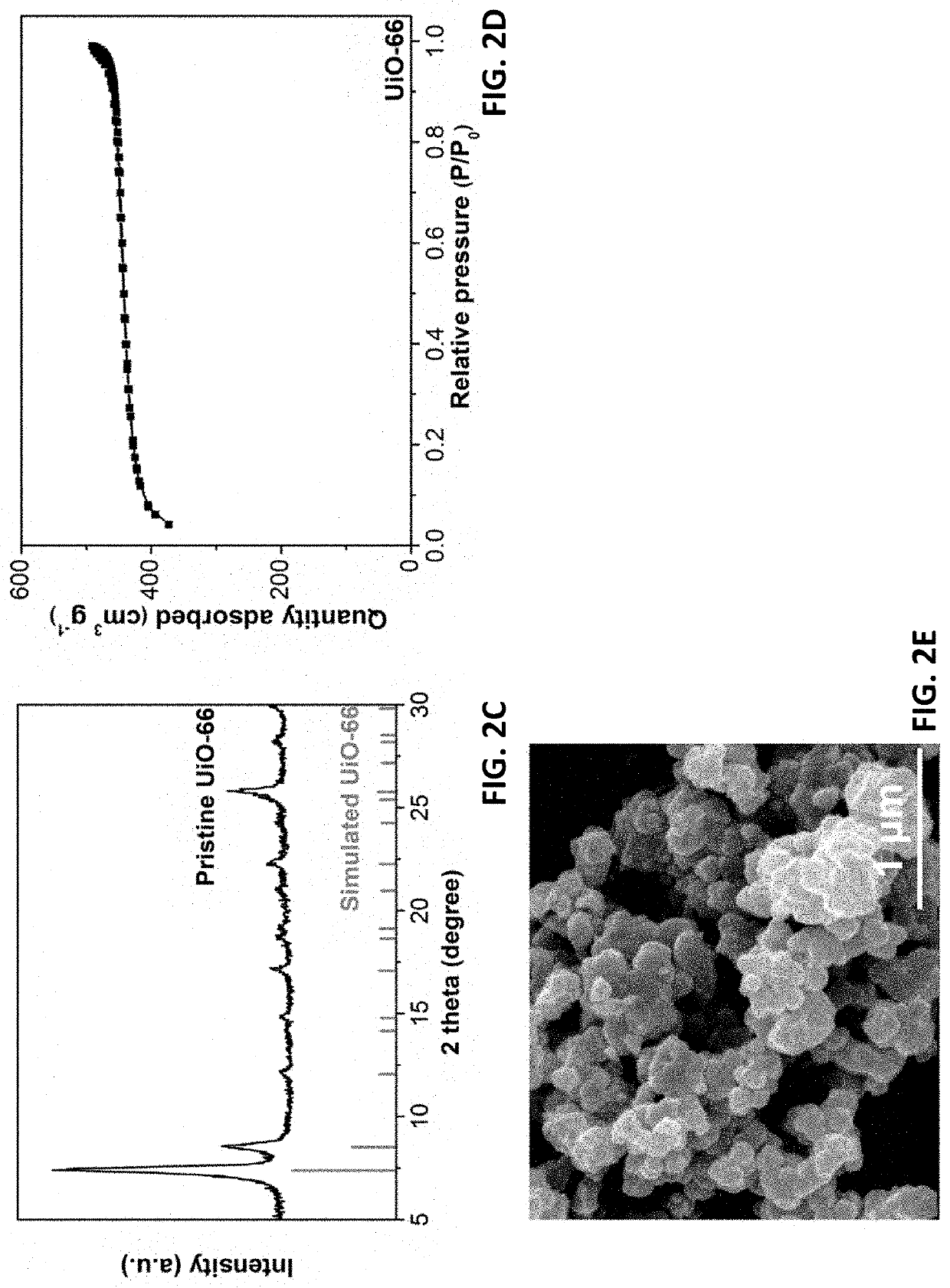

Electrodes having electrode additive for high performance batteries and applications of same

PendingUS20200185788A1Improve thermal stabilityIncrease ratingsCell electrodesWaste accumulators reclaimingInterfacial resistanceElectrical battery

The invention provides a general type of porous coordination solids, metal-organic frameworks (MOFs), as an electrode additive to improve thermal stability, rate and cycle performances of batteries, and an electrode having the electrode additive. The incorporation of the MOF additive into the electrode is fully compatible with current battery manufacturing process. Activated MOF additive serves as an electrolyte modulator to enhance cationic transport and alleviates interfacial resistance by interacting liquid electrolyte with unsaturated open metal sites. Moreover, the flow-free liquid in solid configuration is realized by encapsulating liquid electrolyte into porous scaffold of MOF, which offers superior thermal stability.

Owner:RGT UNIV OF CALIFORNIA +1

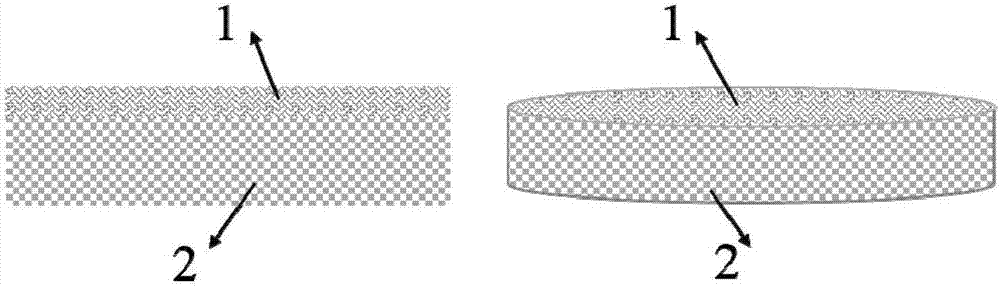

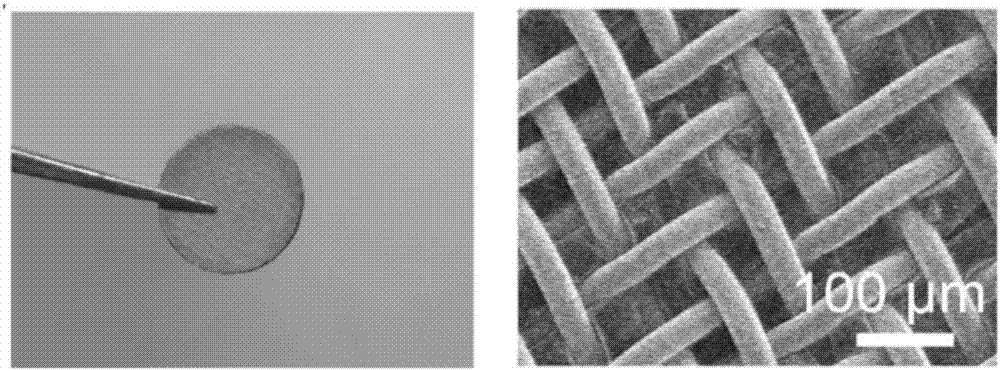

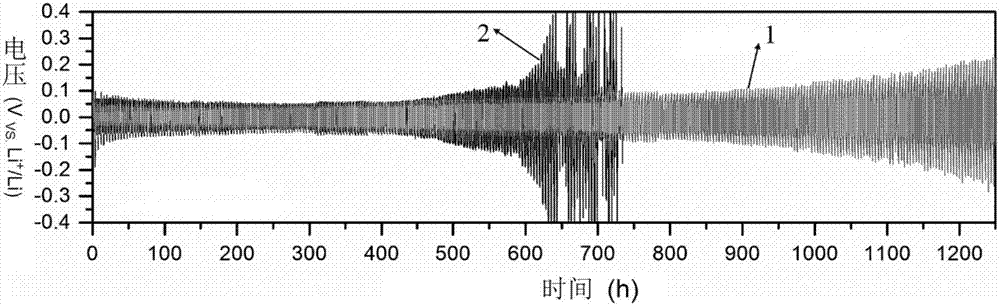

Metal electrode with three-dimensional structure

The invention discloses a metal electrode with a three-dimensional structure. The metal electrode comprises a substrate, wherein at least one surface of the substrate is provided with an embedded layer with a netlike structure; the substrate is selected from metal lithium, sodium, magnesium or aluminum, or an alloy consisting of at least two of the metal lithium, sodium, magnesium and aluminum; the embedded layer with the netlike structure is of a single-layer or multi-layer structure, and is selected from at least one of a metal layer, a polymer layer, a semiconductor layer and an insulator layer; the netlike structure is a planar netlike structure or a three-dimensional netlike structure; and the embedded layer is made of a material different from the material of the substrate. Through adoption of the metal electrode with the three-dimensional structure provided by the invention, the aims of restraining dendritic crystal growth and reducing volume expansion can be fulfilled, thereby increasing the coulombic efficiency of a battery and prolonging the service life the battery.

Owner:ZHEJIANG UNIV

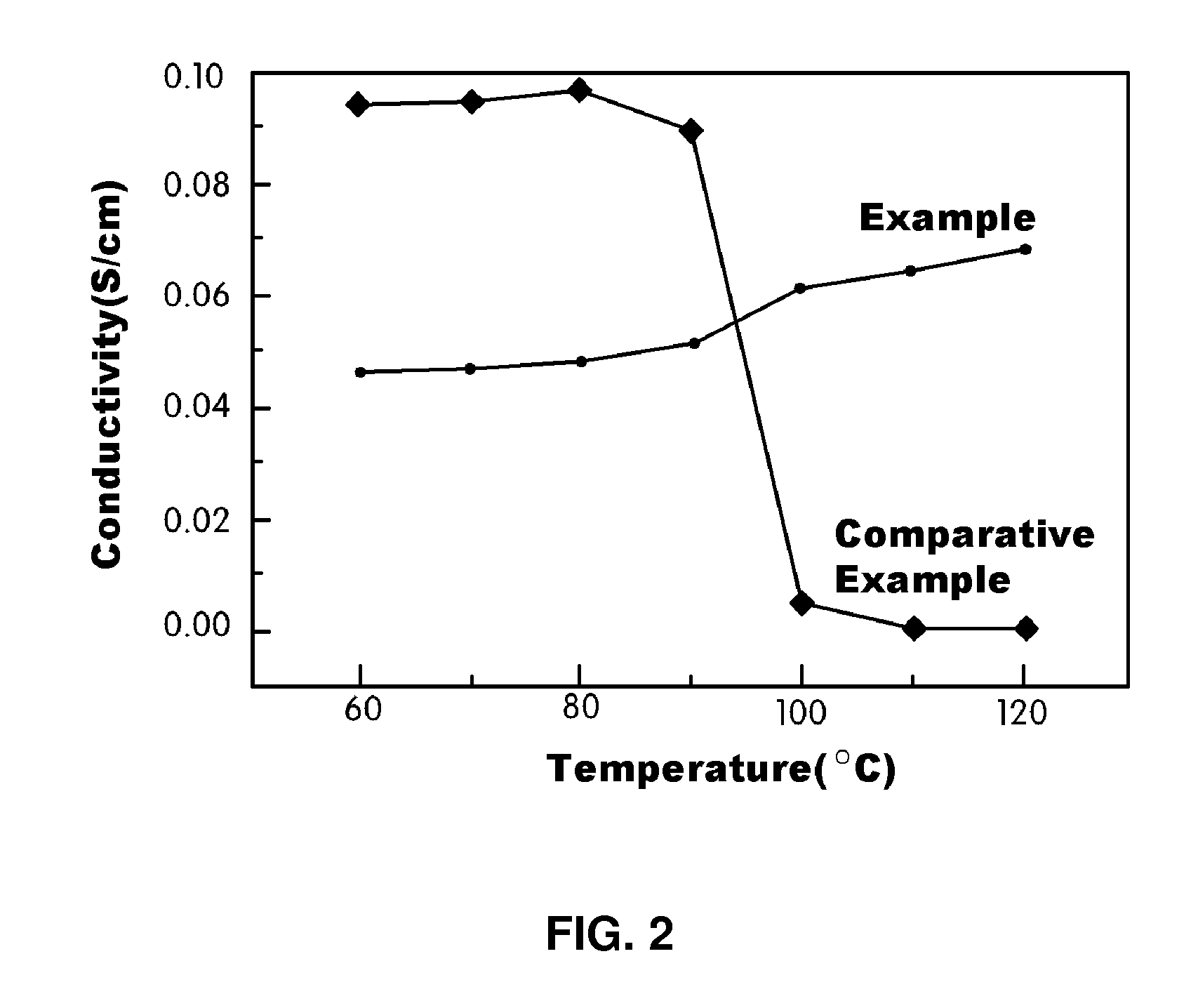

Polymer blend electrolyte membrane for use at high temperature and manufacturing method thereof

ActiveUS20090208848A1Maintain good propertiesExcellent mechanical and thermal propertiesSolid electrolytesIon-exchanger regenerationSilicic acidSide chain

The present invention relates to a polymer blend electrolyte membrane comprising an inorganic polymer having polydimethylsiloxane as a main chain, which has a pore structure at both ends formed by condensation reaction between 3-aminopropyltriethoxysilane and tetraethylorthosilicate, wherein phosphoric acid is chemically linked to an amino group of the pore structure; and a proton-conducting polymer having a cation exchange group at the side chain thereof, as well as a manufacturing method thereof. Generally, proton-conducting electrolyte membranes have significantly reduced ion conductivity at high temperatures. However, proton-conducting electrolyte membranes have advantages in terms of efficiency and cost, and thus it is needed to develop an electrolyte membrane, which has excellent ion conductivity even at high temperature. Accordingly, the present invention aims to provide a polymer blend electrolyte membrane for use at high temperature and a manufacturing method thereof.

Owner:HYUNDAI MOTOR CO LTD +1

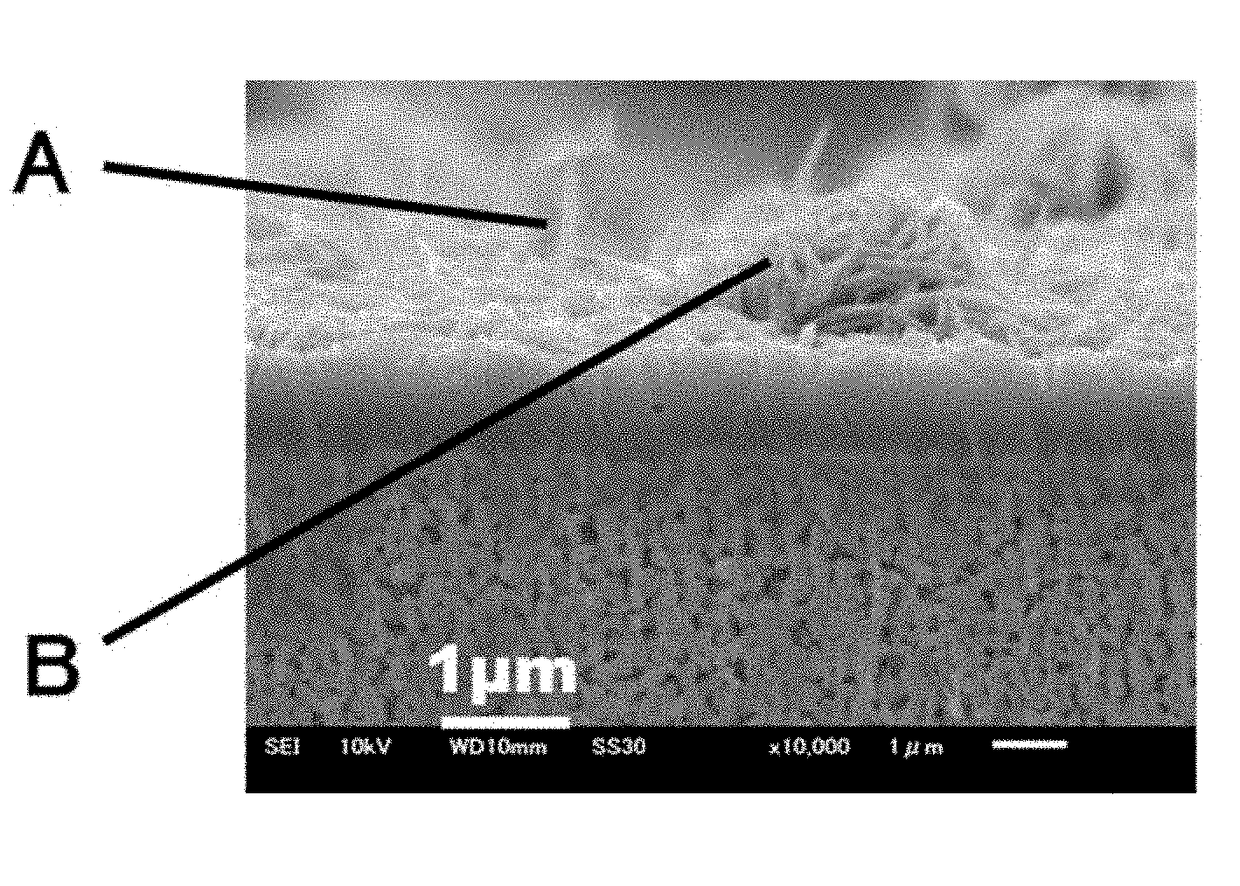

Layered double hydroxide film and composite material containing layered double hydroxide

InactiveUS20170260048A1Reduce interfacial resistanceFuel and primary cellsFuel and secondary cellsHydrogenInterfacial resistance

Provided is a layered double hydroxide membrane containing a layered double hydroxide represented by the formula: M2+1−xM3+x(OH)2An−x / n.mH2O (where M2+ represents a divalent cation, M3+ represents a trivalent cation, An− represents an n-valent anion, n is an integer of 1 or more, and x is 0.1 to 0.4), the layered double hydroxide membrane having water impermeability. The layered double hydroxide membrane includes a dense layer having water impermeability, and a non-flat surface structure that is rich in voids and / or protrusions and disposed on at least one side of the dense layer. The present invention provides an LDH membrane suitable for use as a solid electrolyte separator for a battery, the LDH membrane including a dense layer having water impermeability, and a specific structure disposed on at least one side of the dense layer and suitable for reducing the interfacial resistance between the LDH membrane and an electrolytic solution.

Owner:NGK INSULATORS LTD

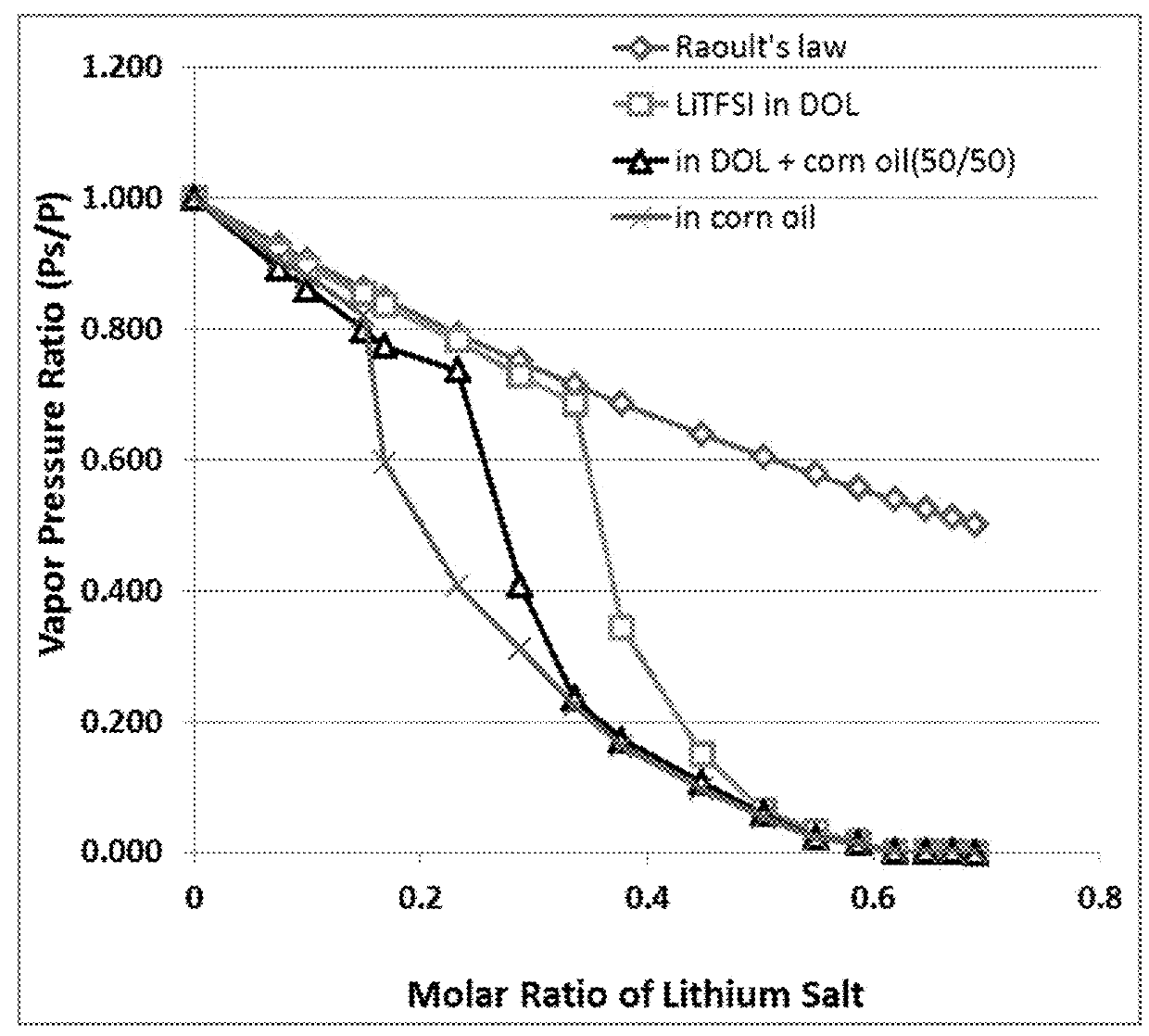

Lithium Secondary Battery Containing Non-flammable Electrolyte and Manufacturing Method

ActiveUS20180277894A1Trend downFlammability is suppressed and eliminatedFuel and secondary cellsFinal product manufactureSolventCooking oil

A rechargeable lithium cell comprising a cathode, an anode, a non-flammable electrolyte, wherein the electrolyte contains a lithium salt dissolved in a liquid solvent having a lithium salt concentration from 0.01 M to 10 M so that the electrolyte exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the liquid solvent alone, a flash point higher than 200° C., or no flash point, wherein the liquid solvent contains a cooking oil selected from palm oil, palm olein, coconut oil, corn oil, soybean oil, cottonseed oil, peanut oil, sunflower oil, canola oil, rice bran oil, olive oil, sesame oil, safflower oil, avocado oil, flaxseed oil, grapeseed oil, walnut oil, almond oil, lard, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

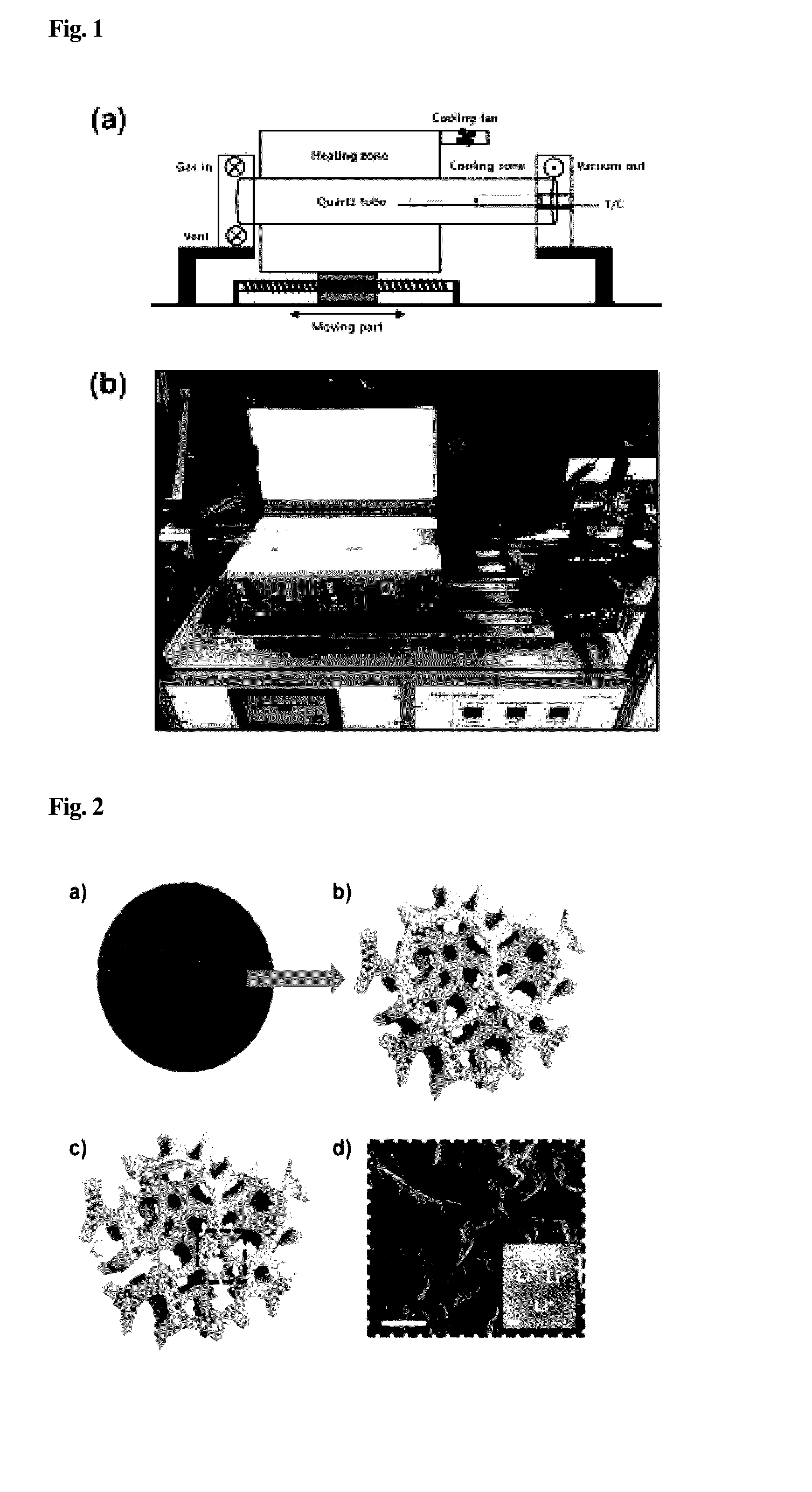

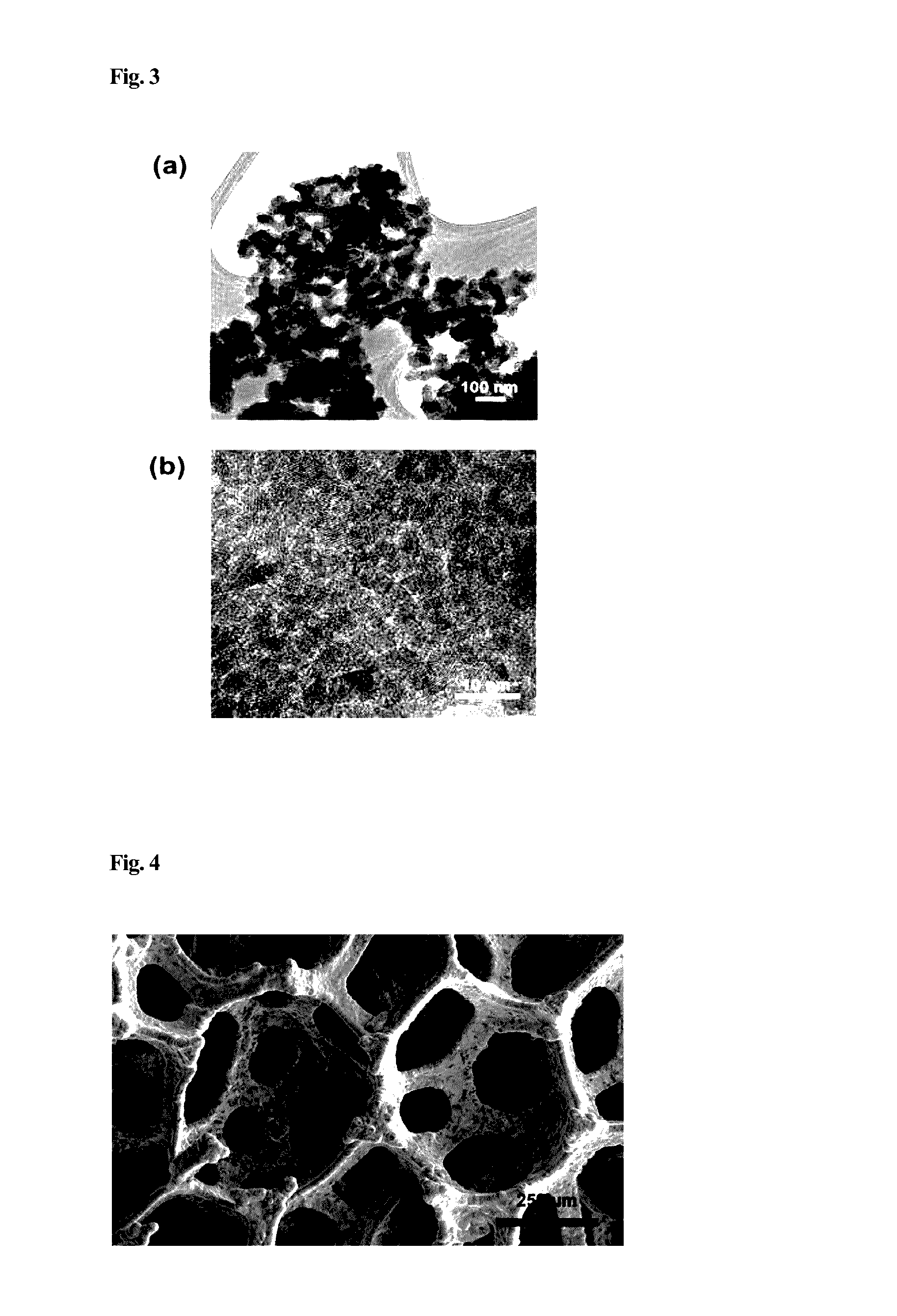

Ultra-high output power and extremely robust cycle life negative electrode material for lithium secondary battery and method for manufacturing the same, using layer structure of metal oxide nanoparticles and porous graphene

InactiveUS20170054138A1Improve conductivityLarge capacitySecondary cellsGraphenePorous grapheneMetal oxide nanoparticles

Disclosed is a negative electrode material for a lithium secondary battery, using a layer structure of porous graphene and metal oxide nanoparticles, with remarkably fast charge / discharge characteristics and long cycle life characteristics, wherein macropores of the porous graphene and a short diffusion distance of the metal oxide nanoparticles enable rapid migration and diffusion of lithium ions. The present invention may achieve remarkably fast charge / discharge behaviors and exceedingly excellent cycle life characteristics of 10,000 cycles or more even under a current density of 30,000 mA·g−1. Accordingly, the structure of the present invention may implement very rapid charge / discharge characteristics and stable cycle life characteristics while having high capacity by combining the structure with negative electrode nanostructures of the porous graphene network structure, and thereby being widely used in a variety of applications.

Owner:KOREA ADVANCED INST OF SCI & TECH

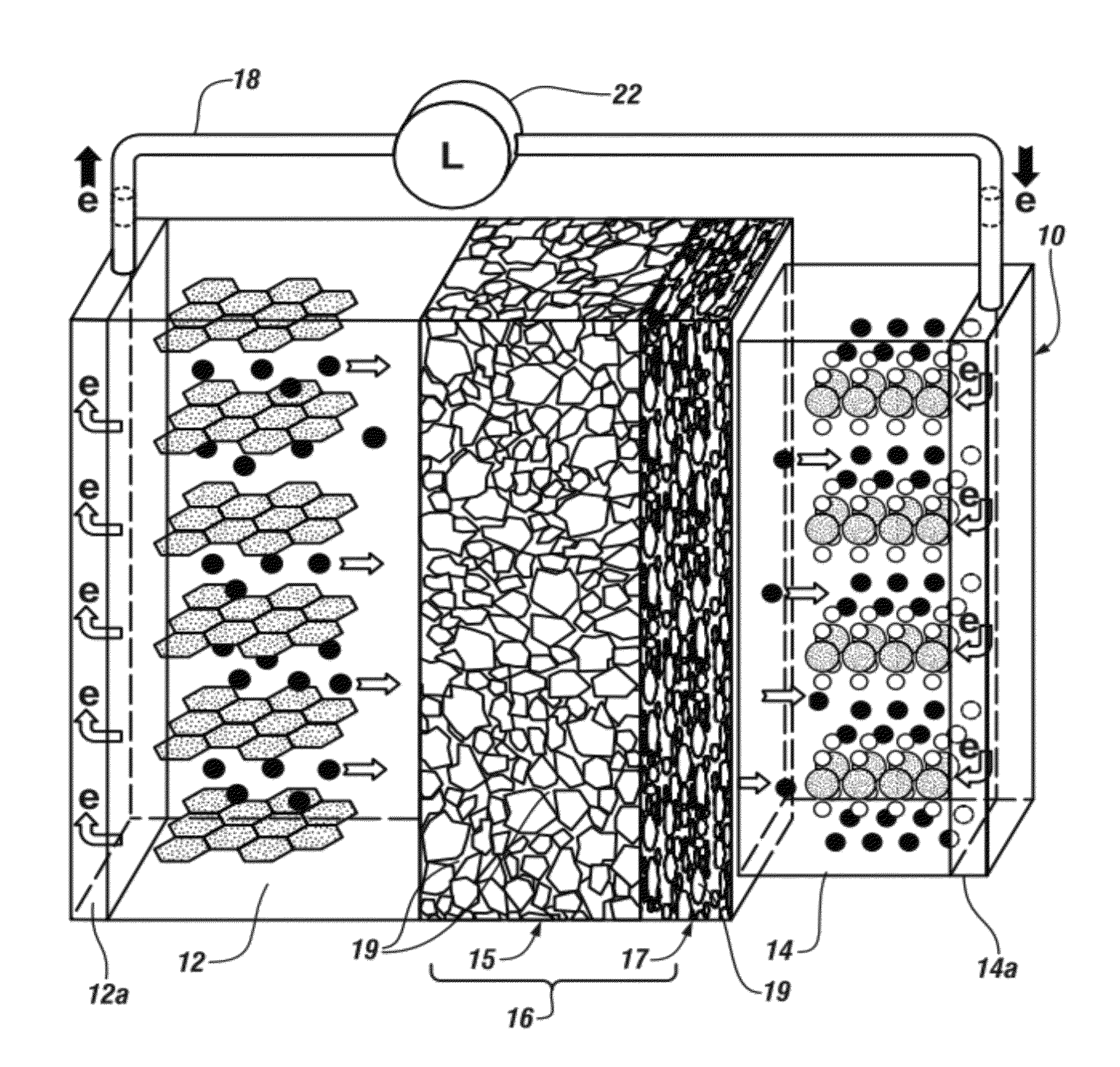

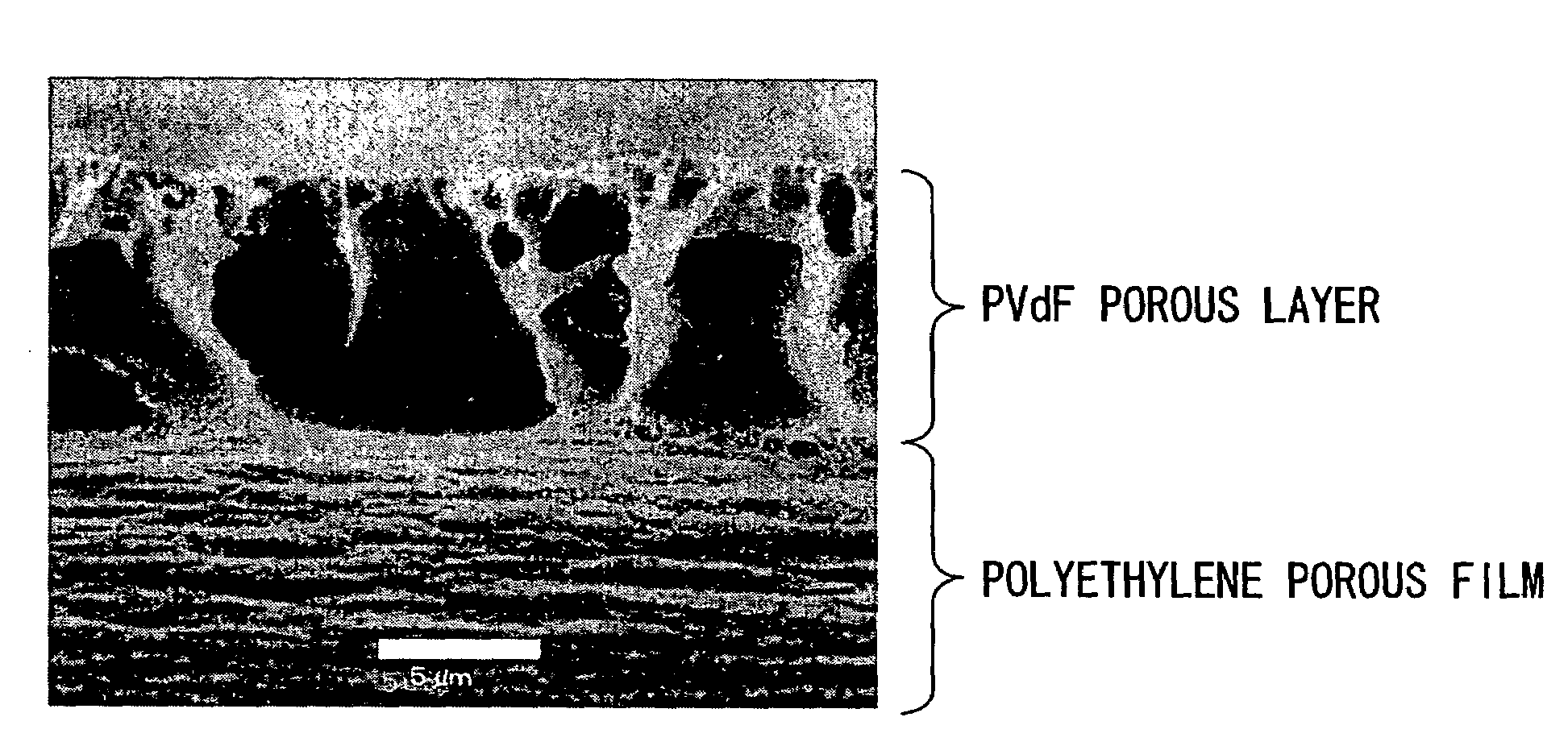

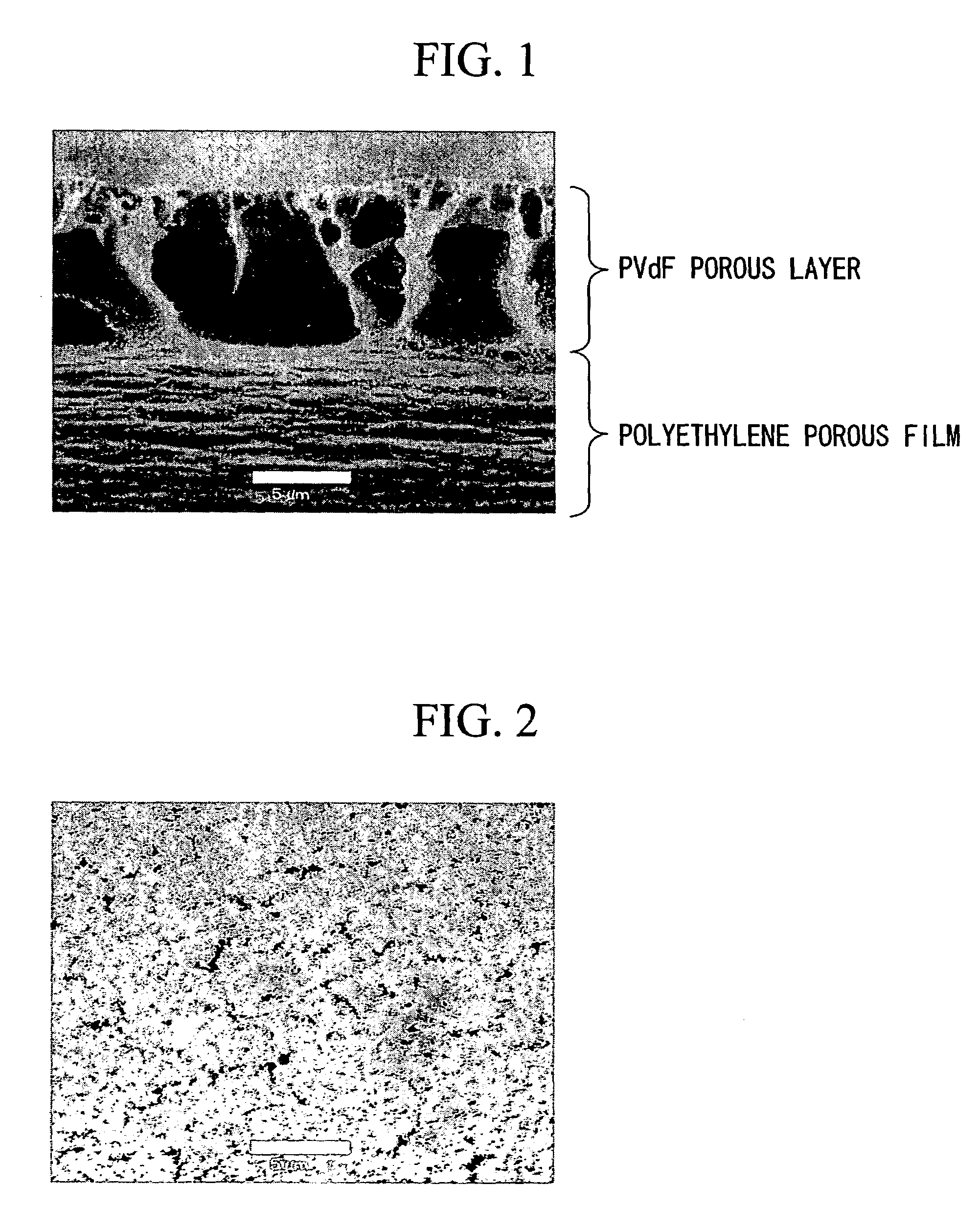

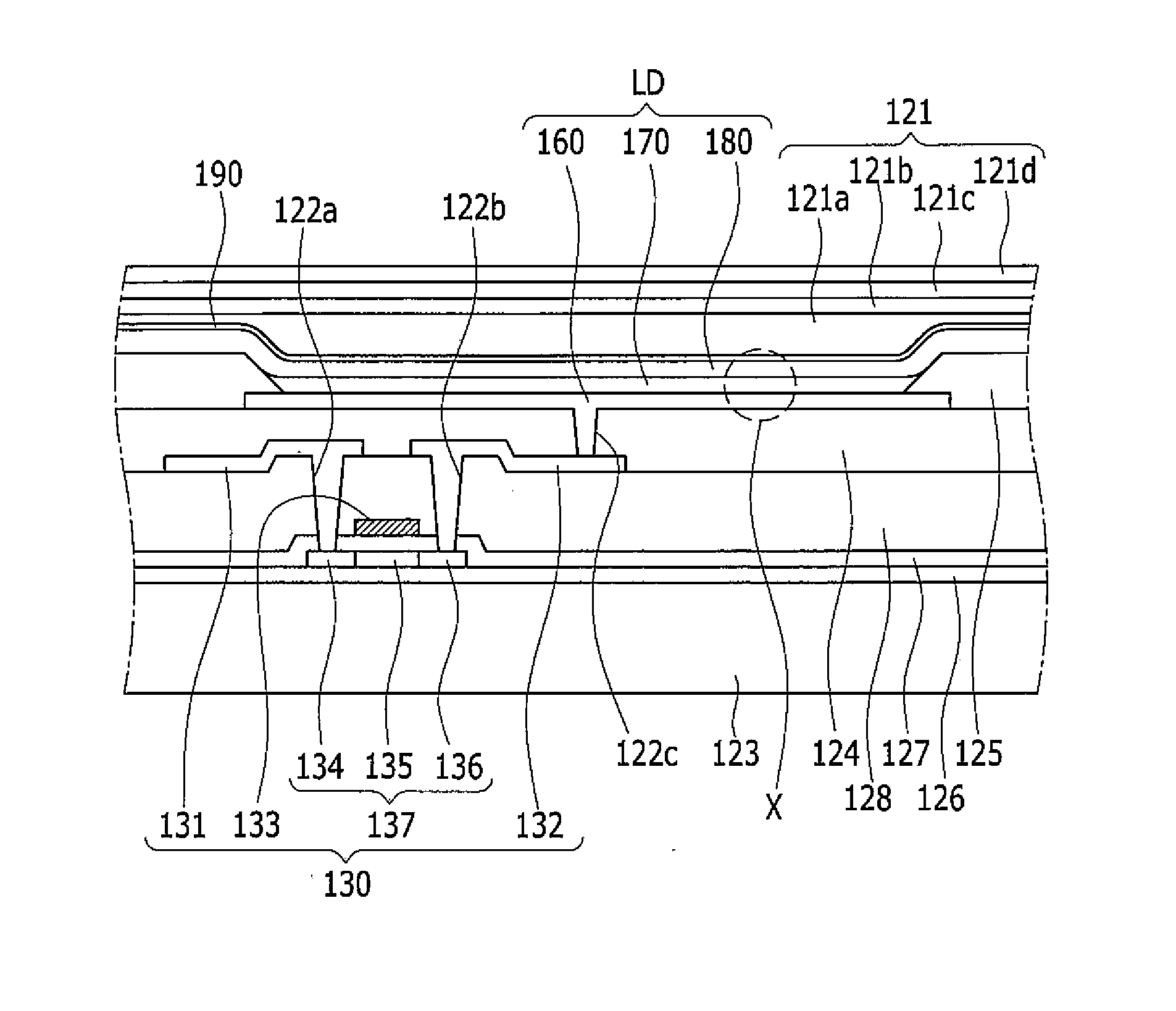

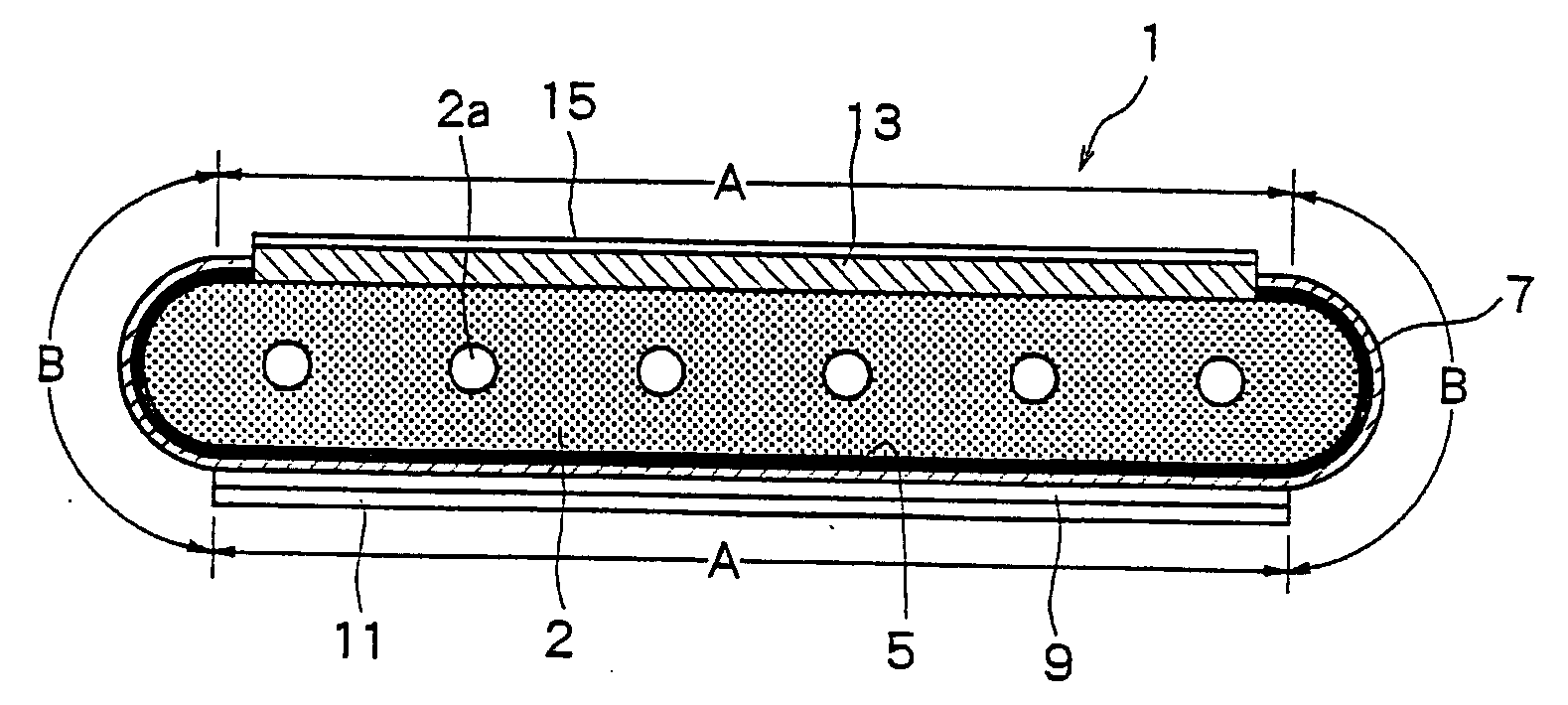

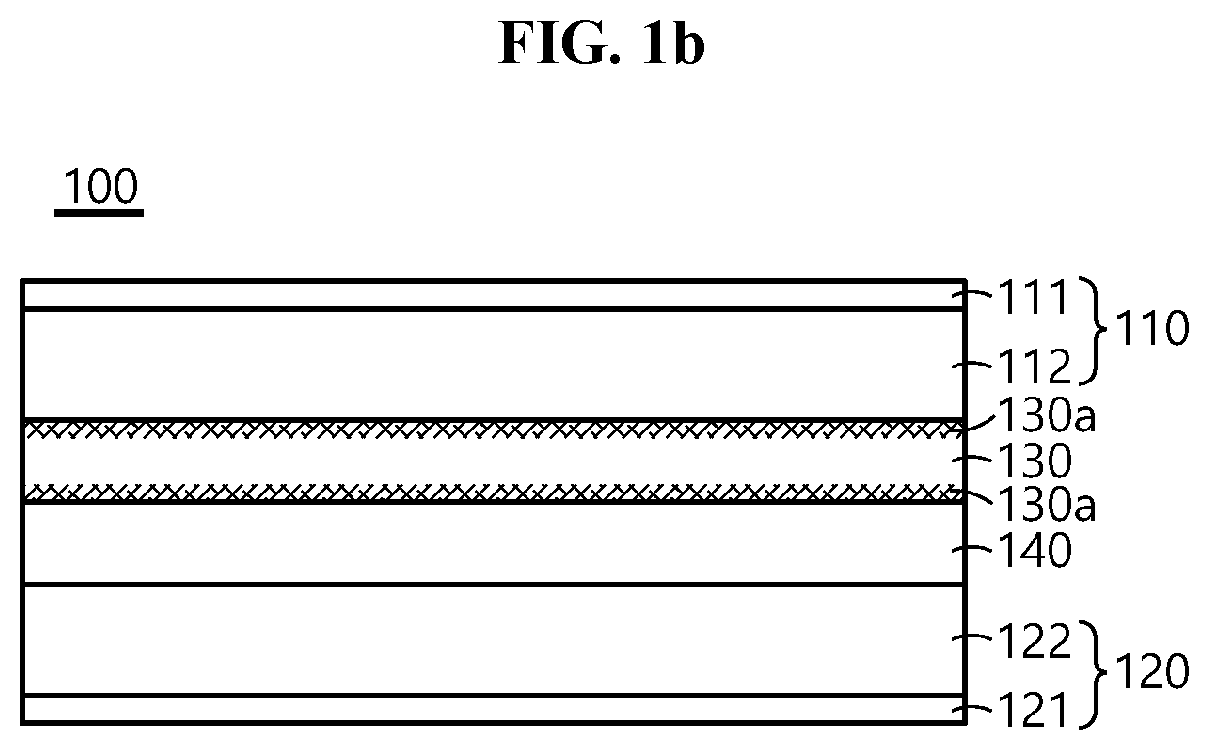

Separator for lithium ion secondary battery and lithium ion secondary battery provided therewith

InactiveUS7311994B2High and uniform ionic conductivityReduce interfacial resistanceCell seperators/membranes/diaphragms/spacersLi-accumulatorsPolyolefinPorous layer

A separator for a lithium ion secondary battery, comprising a porous base material containing polyolefin, and a porous layer containing a vinylidene fluoride resin as a main component provided on at least one surface of the porous base material is excellent in electrolytic solution retention properties, adhesion and bondability to electrodes, and dimensional stability, and also has high and uniform ionic conductivity, reduced interfacial resistance to electrodes, and shutdown properties. A lithium ion secondary battery having excellent capacity characteristics, charge and discharge characteristics, cycle characteristics, safety and reliability can be provided by using the separator.

Owner:SUMITOMO CHEM CO LTD

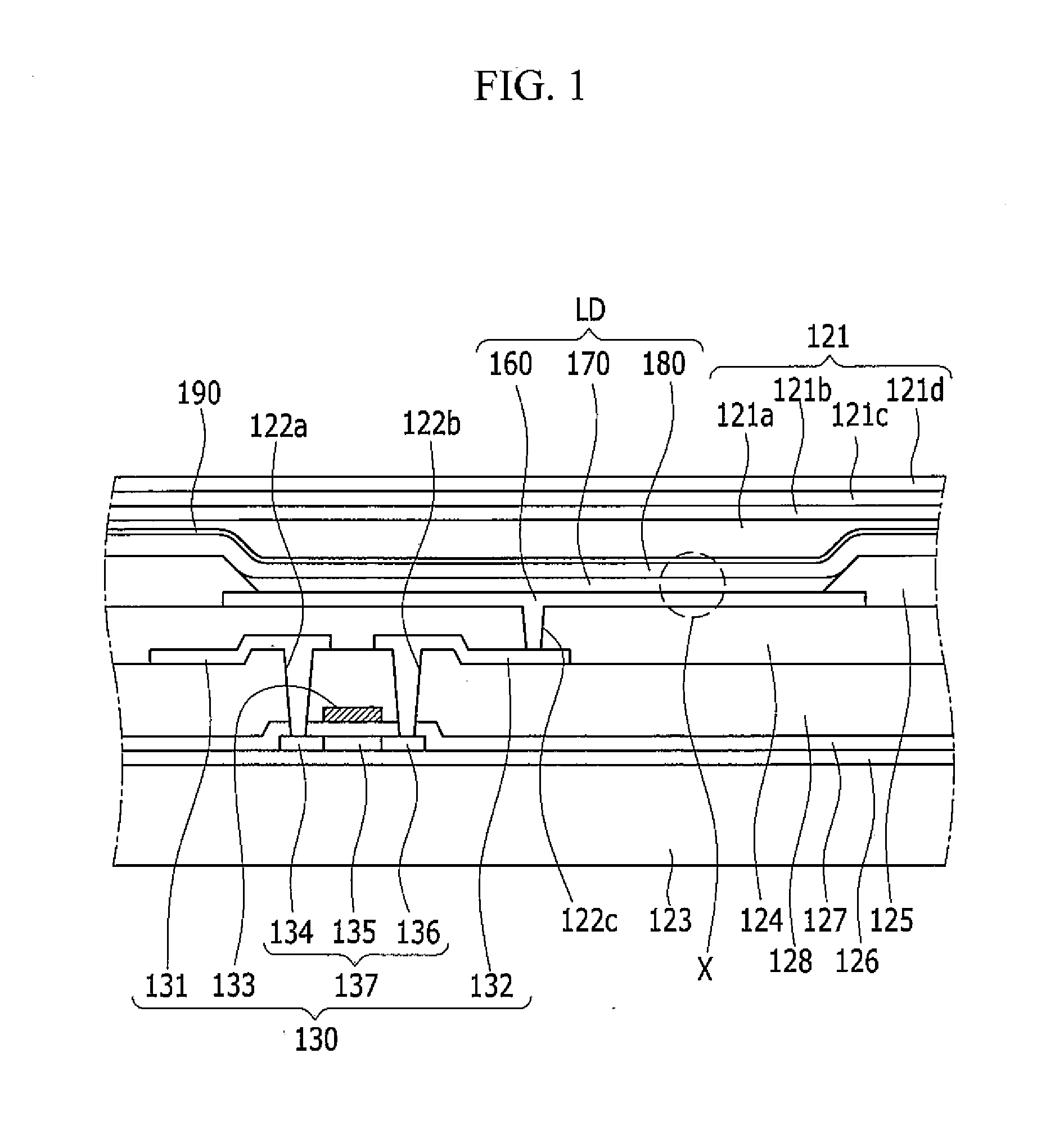

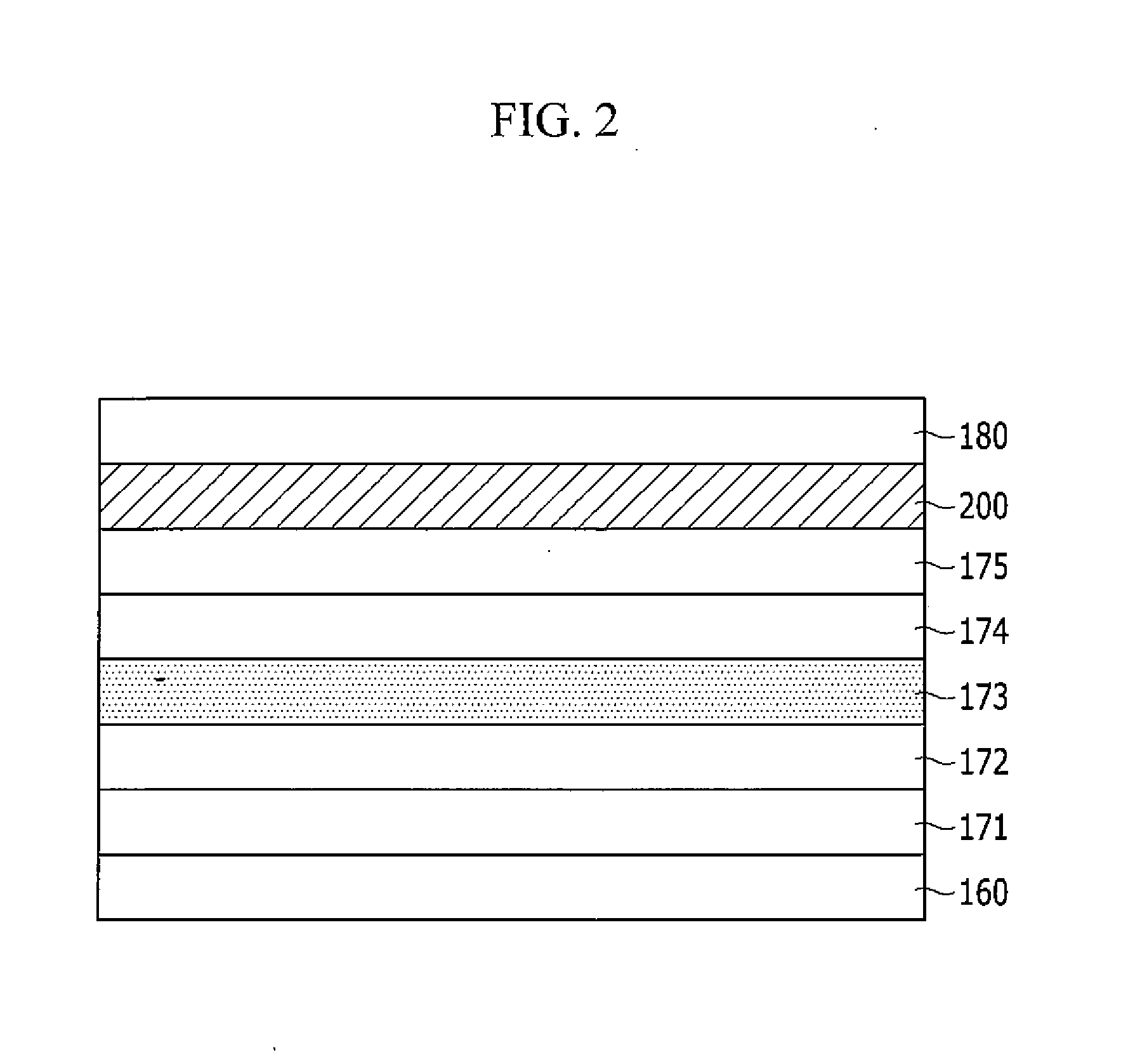

Organic light emitting diode display

ActiveUS20160351845A1Reduce interfacial resistanceImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerInter layer

An organic light emitting diode (OLED) display includes: a thin film transistor on the substrate; a first electrode electrically connected to the thin film transistor; a hole injection layer on the first electrode; an emission layer on the hole injection layer; an electron injection layer on the emission layer; a first intermediate layer on the electron injection layer; and a second electrode on the first intermediate layer.

Owner:SAMSUNG DISPLAY CO LTD

Preparation method of high-density silicon carbide ceramic composite material

InactiveCN112279650ANot easy to pile upNot easy to reuniteCeramic shaping apparatusCeramic compositeBoron nitride

The invention discloses a preparation method of a high-density silicon carbide ceramic composite material. The preparation method comprises the following steps of: S1, putting silicon carbide powder,carbon black, boron nitride nanosheets and a combustion assistant into a grinder, carrying out wet ball-milling mixing, drying, and screening to obtain mixed powder; S2, carrying out compression molding on the mixed powder by adopting a cold isostatic pressing molding process to obtain a biscuit; S3, performing pressureless vacuum sintering on the biscuit so as to obtain a presintered body; and S4, performing spark plasma sintering on the presintered body to obtain the silicon carbide ceramic composite material. According to the preparation method, wet ball-milling mixing is performed on the raw materials in a reasonable ratio to obtain the mixed powder; compression molding is performed on the mixed powder by adopting the cold isostatic pressing process to obtain the biscuit with relatively high density; and the biscuit issintered through a pressureless sintering and spark plasma sintering combined manner; and therefore, the preparation of the high-density, high-hardness and high-strength silicon carbide ceramic composite material is realized. The method is simple in process and convenient for industrial production.

Owner:段深圳

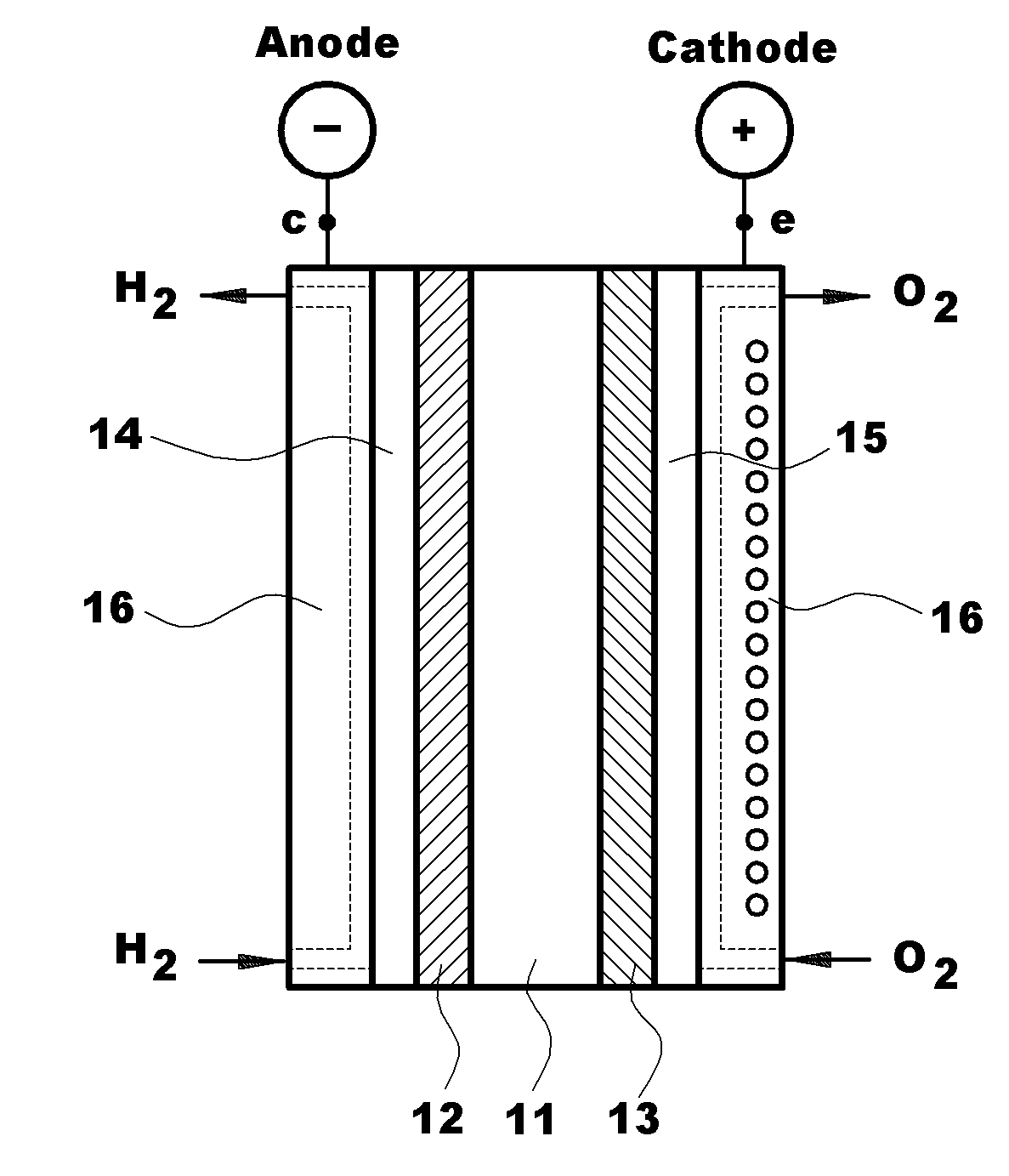

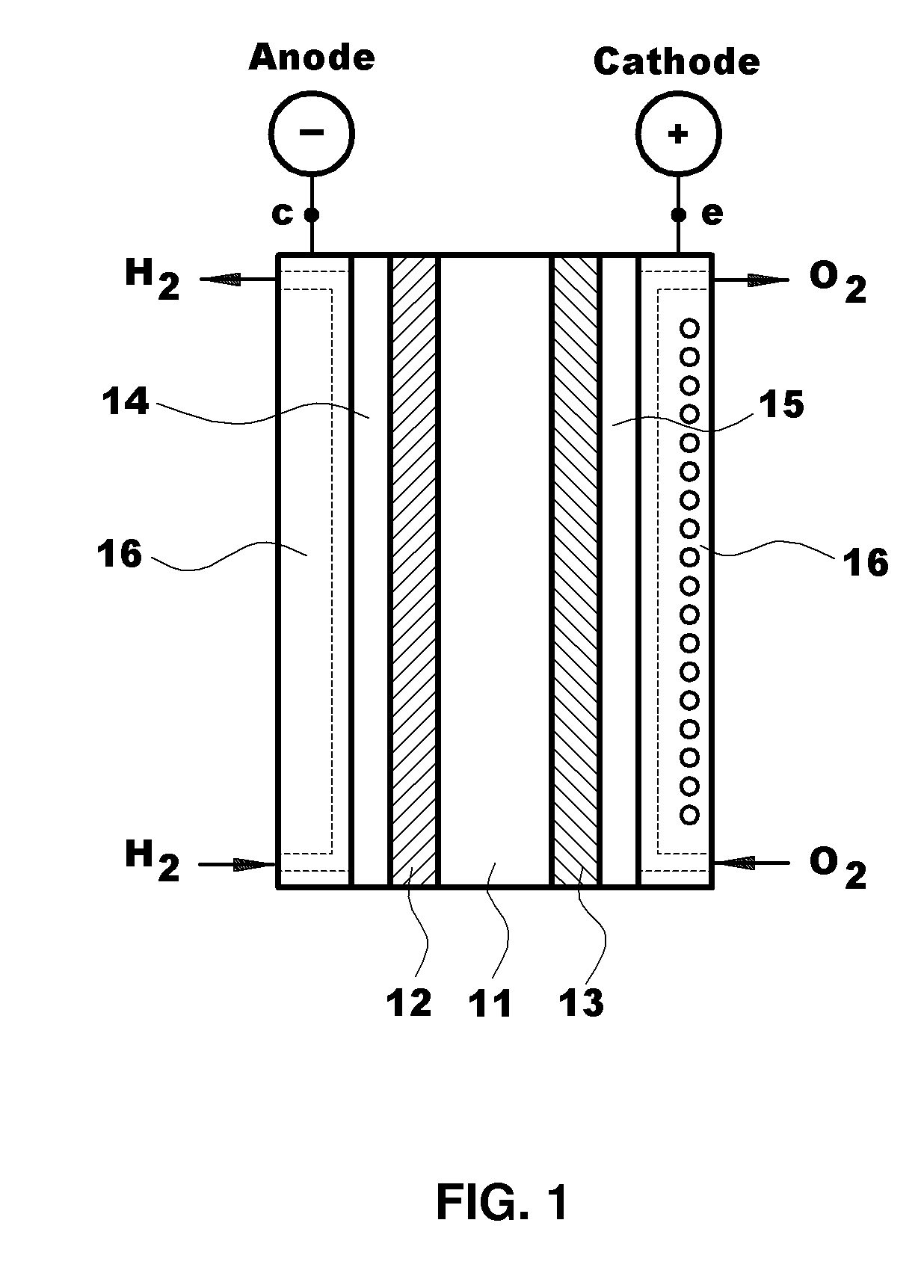

Fuel cell

ActiveUS20050095496A1Reduce interfacial resistanceHigh strengthFuel cells groupingFinal product manufactureFuel cellsSurface layer

A solid electrolytic fuel cell having an oxygen electrode layer on one surface of a solid electrolytic layer, having a fuel electrode layer on the other surface thereof, and having a reaction-preventing layer comprising a sintered body of an oxide between the upper surface of the solid electrolytic layer and the oxygen electrode layer for preventing elements from diffusing from the oxygen electrode layer into the solid electrolytic layer, wherein the oxygen electrode layer has a two-layer structure including an inner layer on the side of the reaction-preventing layer and a surface layer on the inner layer; the surface layer of the oxygen electrode layer comprises a sintered body of a perovskite composite oxide; and the inner layer of the oxygen electrode layer comprises a sintered body of a mixture of particles of an oxide for preventing the diffusion of elements and particles of the peroviskite composite oxide, and is formed more densely than said surface layer. The fuel cell has a decreased interfacial resistance between the oxygen electrode layer and the reaction-preventing layer, an increased junction strength between the oxygen electrode layer and the reaction-preventing layer, and generates electricity of a large output.

Owner:KYOCERA CORP

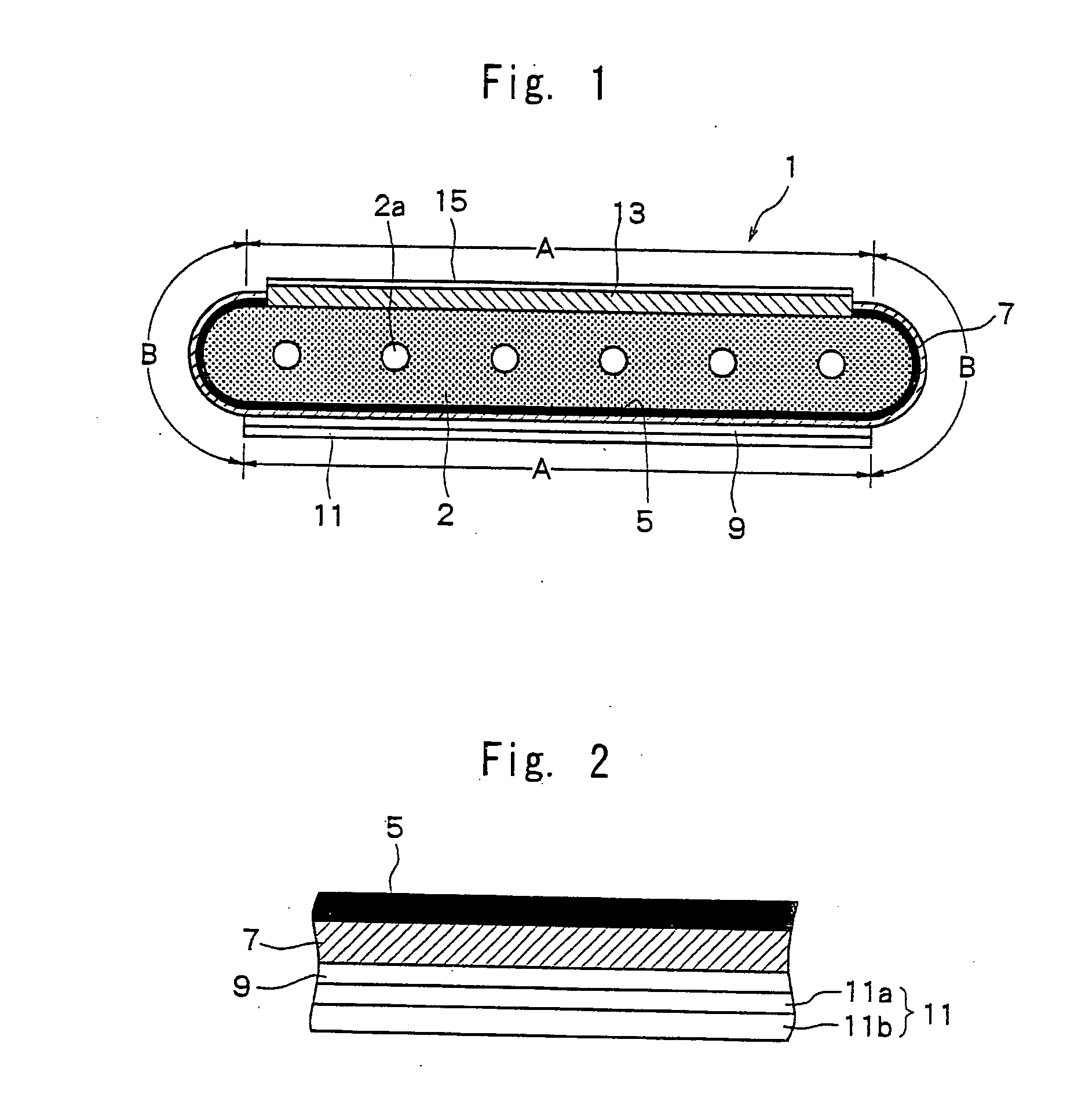

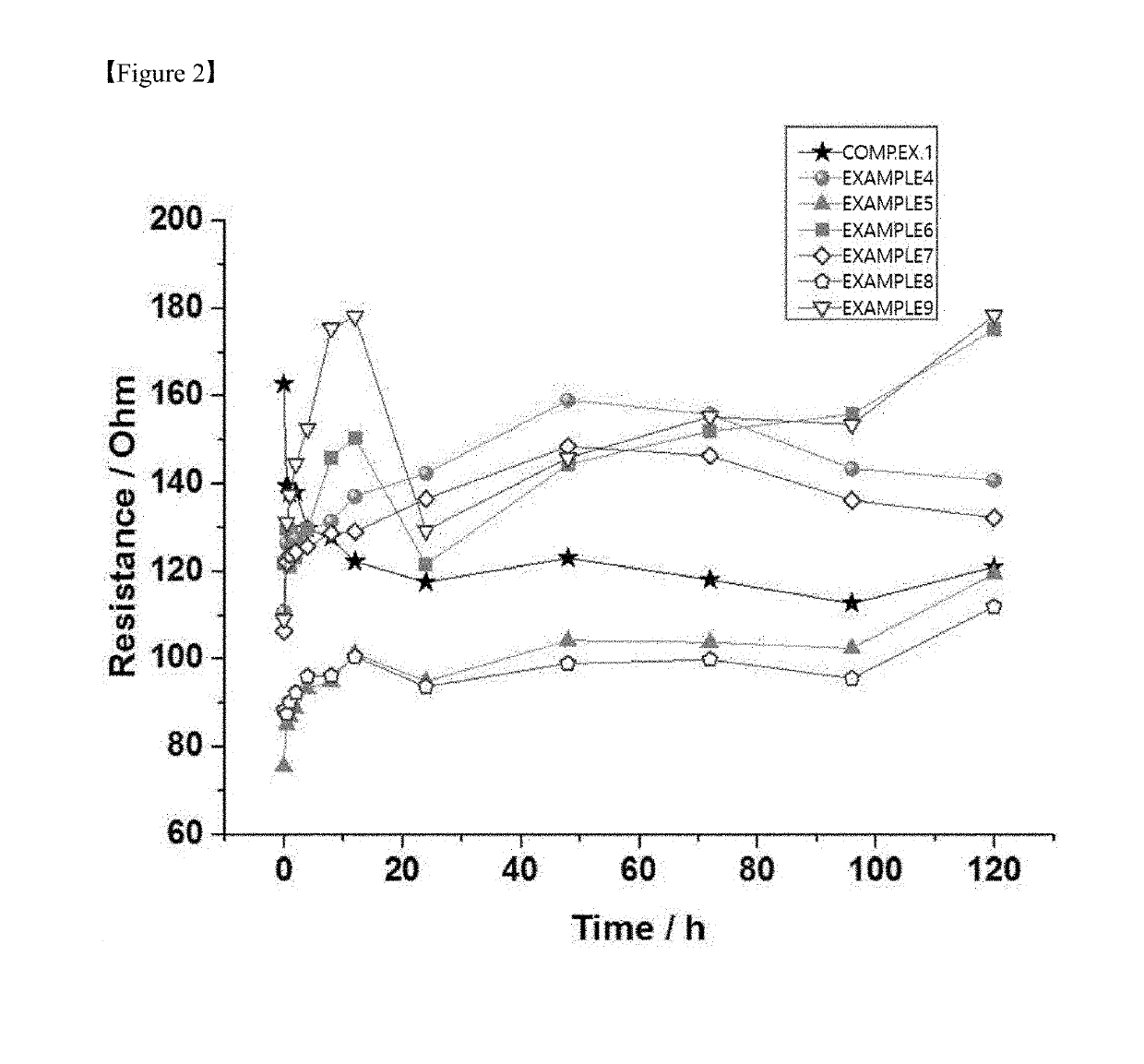

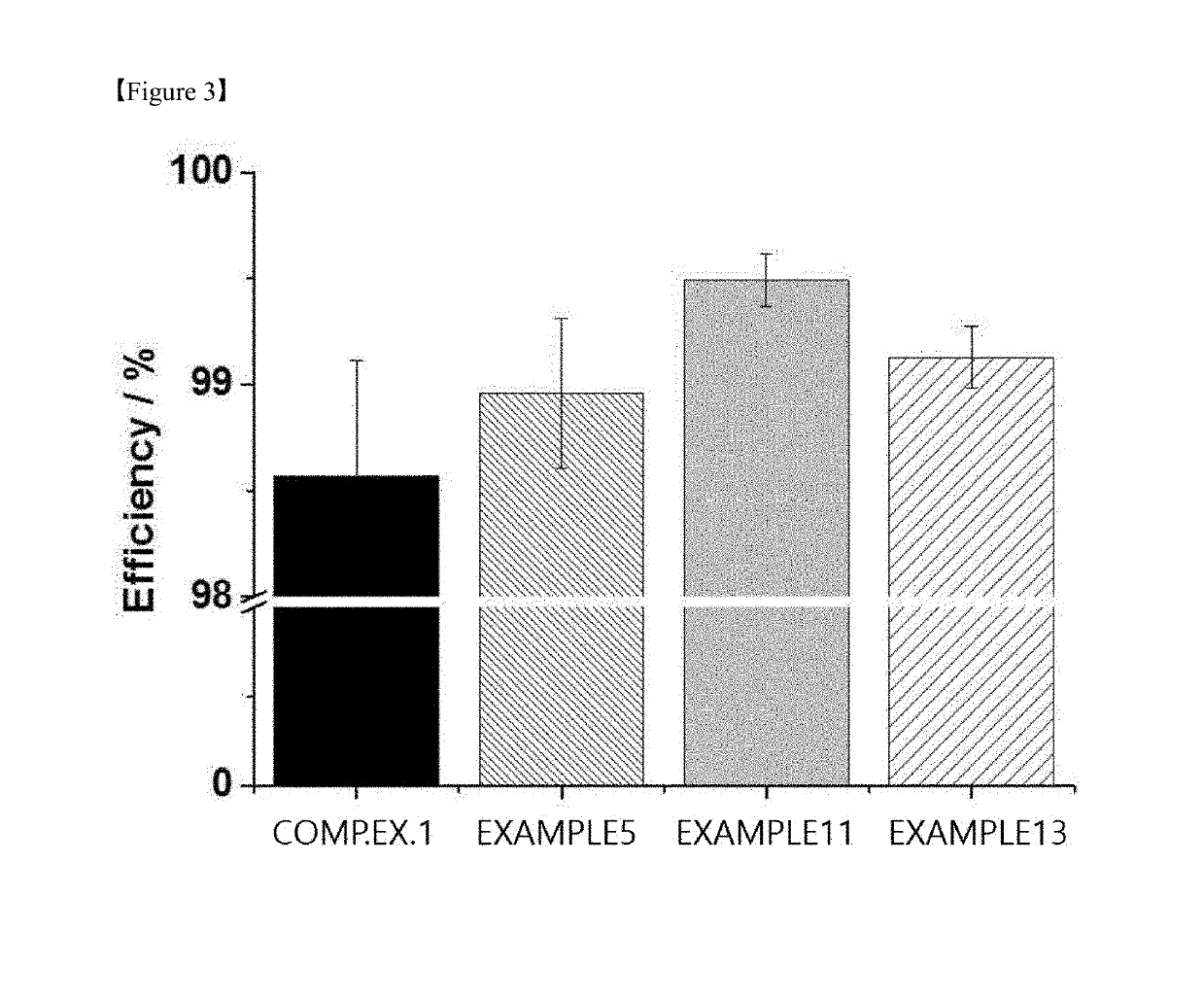

Pretreatment method for lithium electrode, and lithium metal battery

ActiveUS20190157714A1Reduce interfacial resistanceEasy dischargeFinal product manufactureLi-accumulatorsPretreatment methodLithium metal

A method for pretreating a lithium electrode, and a lithium metal battery, and in particular, a method for stabilizing a lithium electrode through pretreatment of being immersed in a composition for forming a solid electrolyte interphase, and a lithium metal battery including such a lithium electrode. Effects of decreasing interfacial resistance and enhancing Li charge and discharge efficiency are obtained when forming a solid electrolyte interphase (SEI) on a lithium electrode in advance using a pretreatment process of the lithium electrode, and then using the SEI layer-formed lithium electrode in a lithium metal battery.

Owner:LG ENERGY SOLUTION LTD

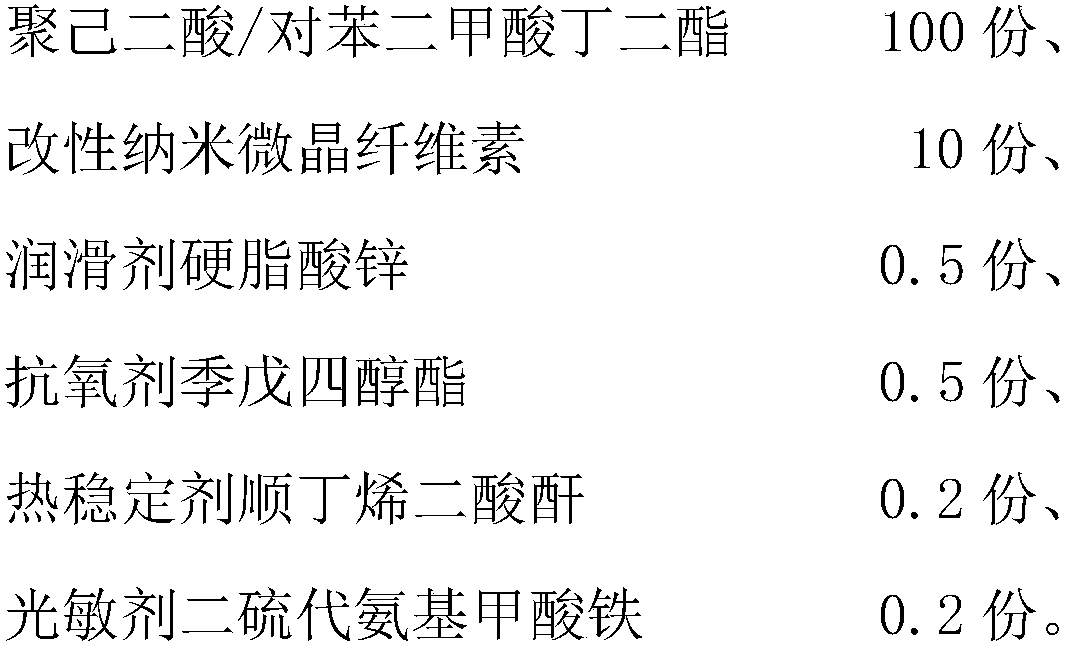

Polyadipic acid/butylene terephthalate composite material containing modified nanometer microcrystalline cellulose, and preparation method thereof

InactiveCN109666269AMeet modification needsShort degradation cyclePolyethylene terephthalateRoom temperature

The invention discloses a polyadipic acid / butylene terephthalate composite material containing modified nanometer microcrystalline cellulose, wherein the material comprises, by mass, 100 parts of polyadipic acid / butylene terephthalate, and 1-20 parts of modified nanometer microcrystalline cellulose, and is prepared sequentially through high speed blending and extrusion granulation, wherein the preparation method of the modified nanometer microcrystalline cellulose comprises: mixing nanometer microcrystalline cellulose and anhydrous ethanol, ultrasonically dispersing to obtain a nanometer microcrystalline cellulose suspension liquid, dissolving a coupling agent in absolute ethanol to form a coupling agent solution, mixing the nanometer microcrystalline cellulose suspension liquid and the coupling agent solution, refluxing for 2-4 h at a temperature of 75-85 DEG C, cooling to a room temperature, carrying out centrifugal separation, and drying to obtain the modified nanometer microcrystalline cellulose. According to the present invention, by organically modifying the nanometer microcrystalline cellulose, the interface resistance can be effectively reduced, the compatibility with the matrix material can be improved, and the modification requirements polyadipic acid / butylene terephthalate can be met.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Fuel cell

ActiveUS7297436B2Reduce interfacial resistanceHigh strengthFuel cells groupingFinal product manufactureFuel cellsSurface layer

A solid electrolytic fuel cell having an oxygen electrode layer on one surface of a solid electrolytic layer, having a fuel electrode layer on the other surface thereof, and having a reaction-preventing layer comprising a sintered body of an oxide between the upper surface of the solid electrolytic layer and the oxygen electrode layer for preventing elements from diffusing from the oxygen electrode layer into the solid electrolytic layer, wherein the oxygen electrode layer has a two-layer structure including an inner layer on the side of the reaction-preventing layer and a surface layer on the inner layer; the surface layer of the oxygen electrode layer comprises a sintered body of a perovskite composite oxide; and the inner layer of the oxygen electrode layer comprises a sintered body of a mixture of particles of an oxide for preventing the diffusion of elements and particles of the peroviskite composite oxide, and is formed more densely than said surface layer. The fuel cell has a decreased interfacial resistance between the oxygen electrode layer and the reaction-preventing layer, an increased junction strength between the oxygen electrode layer and the reaction-preventing layer, and generates electricity of a large output.

Owner:KYOCERA CORP

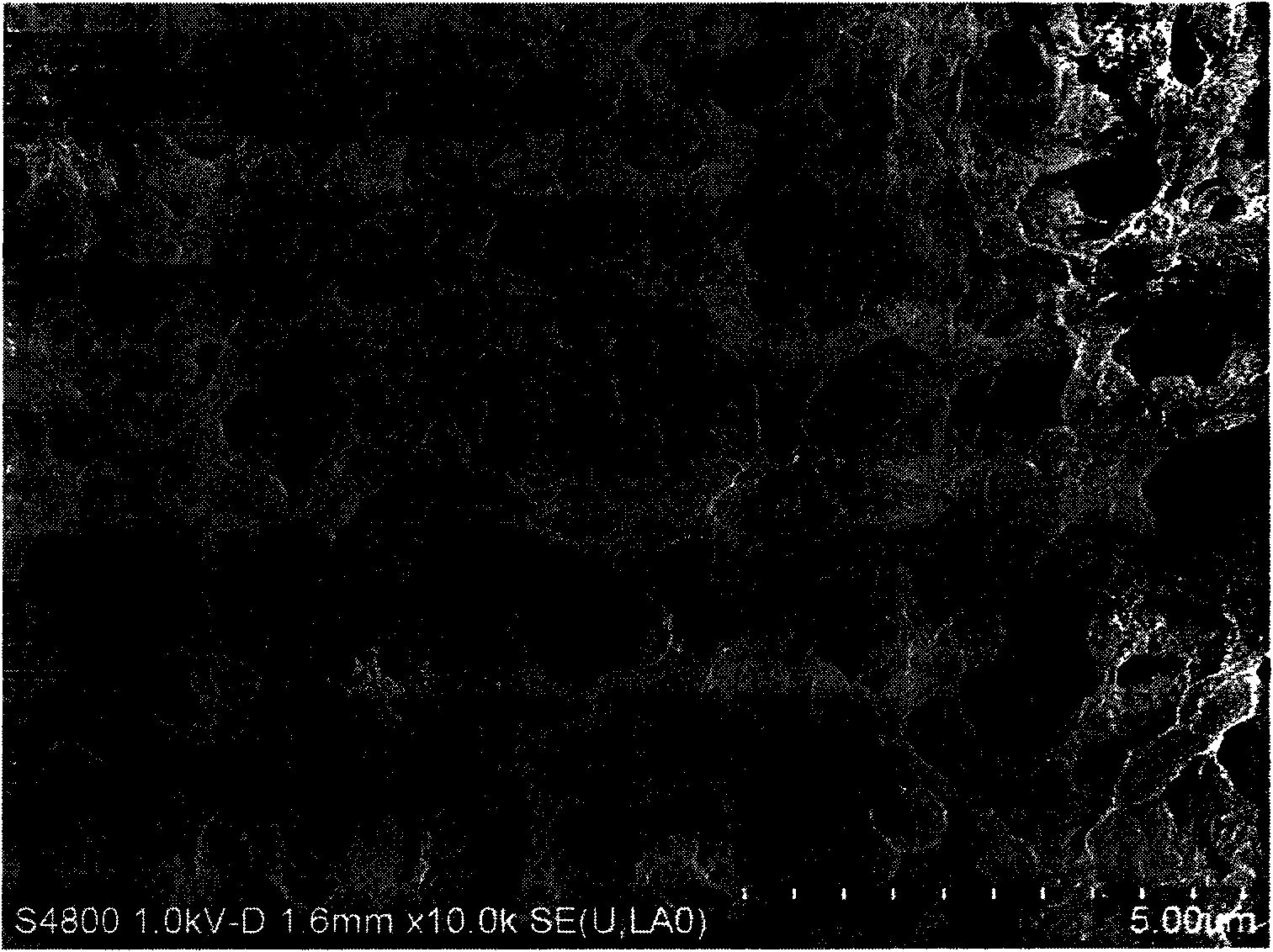

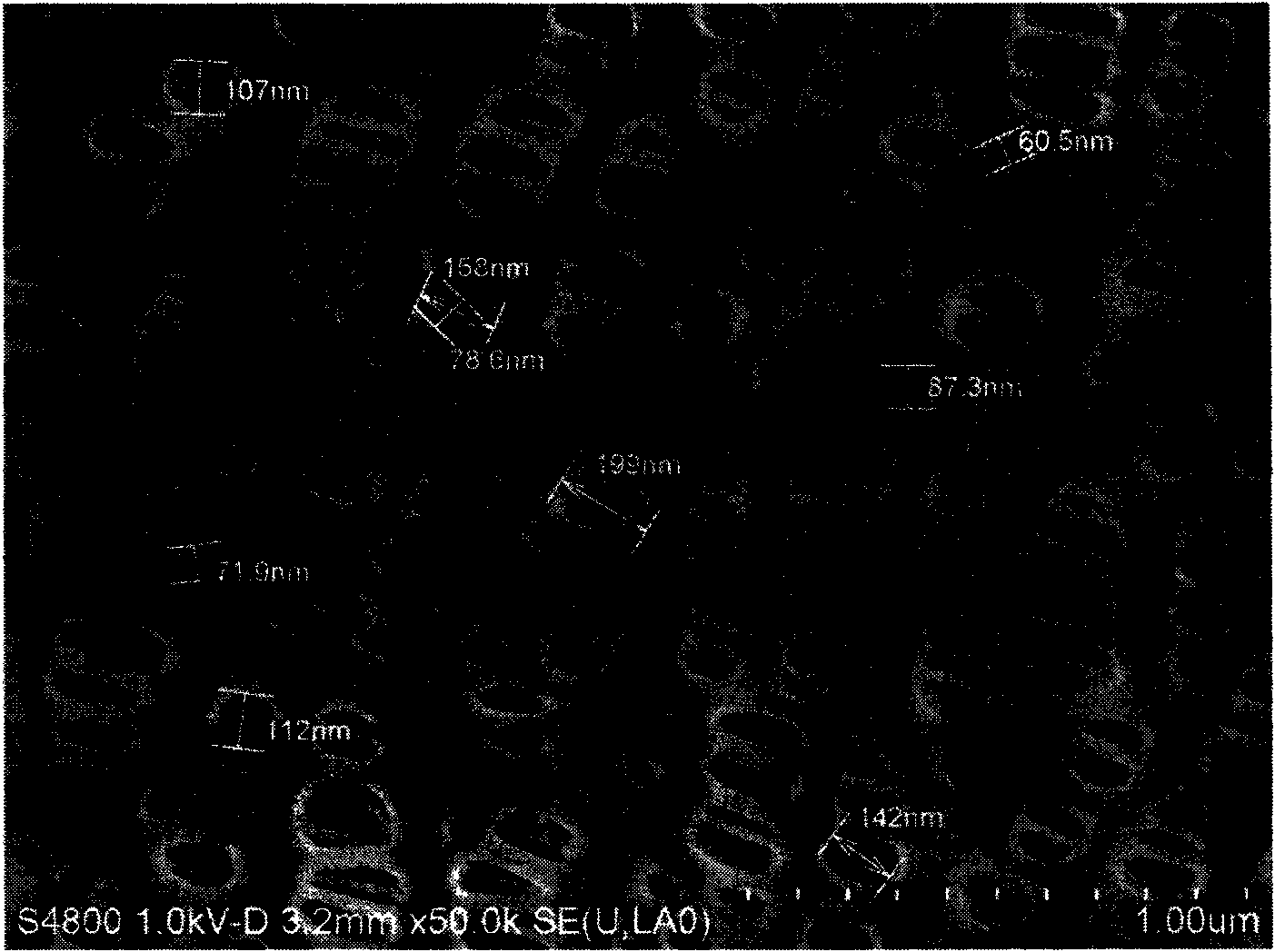

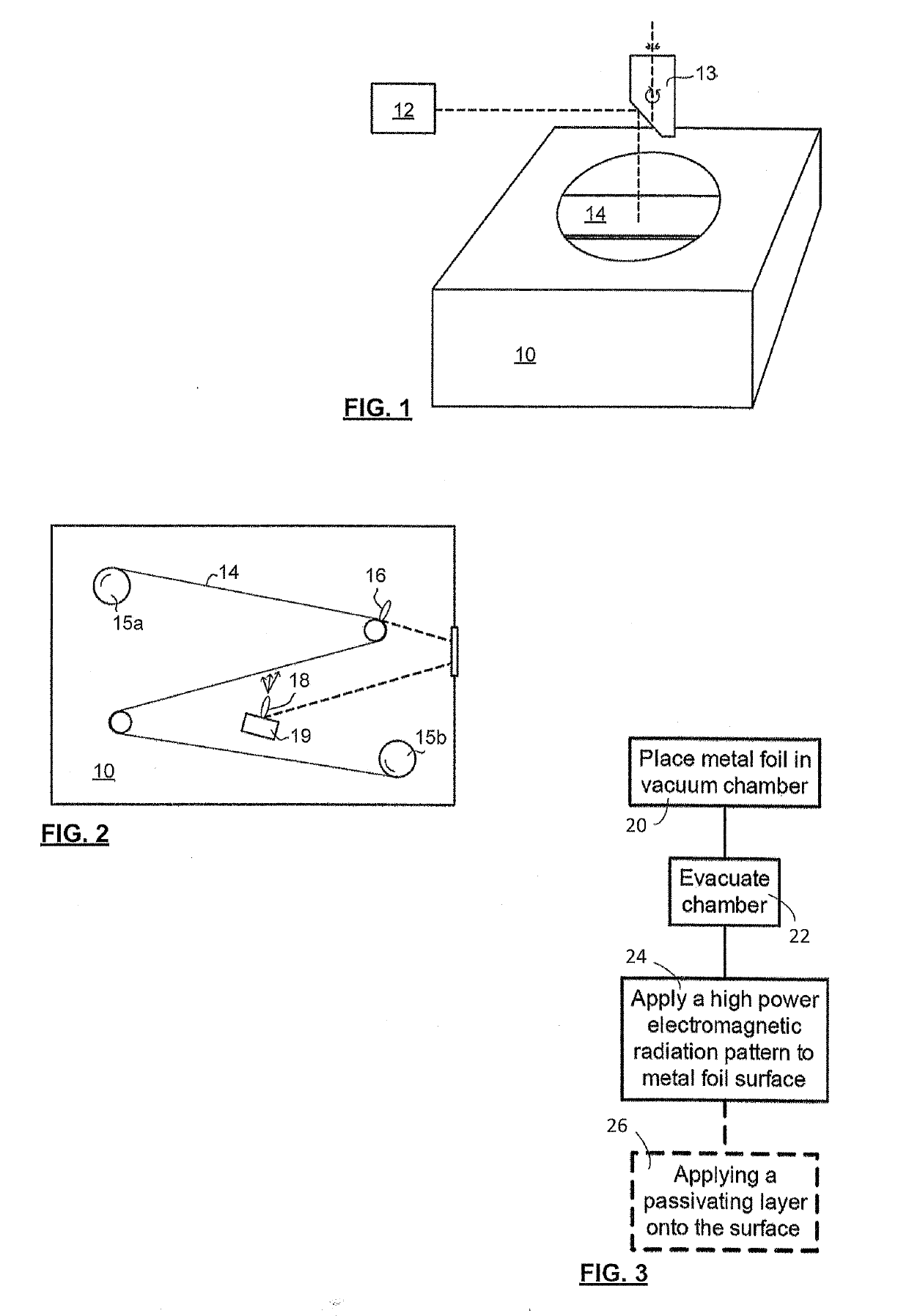

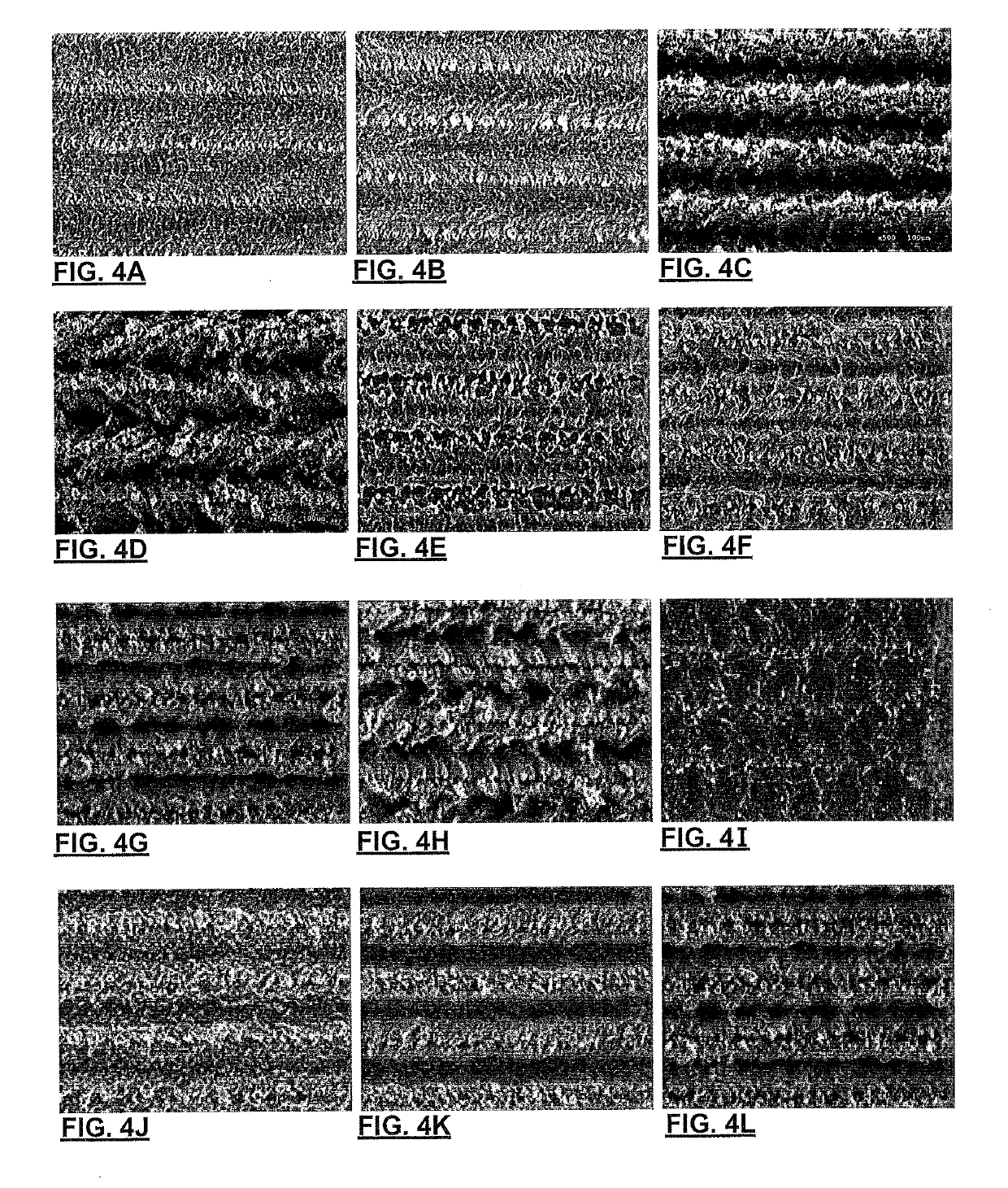

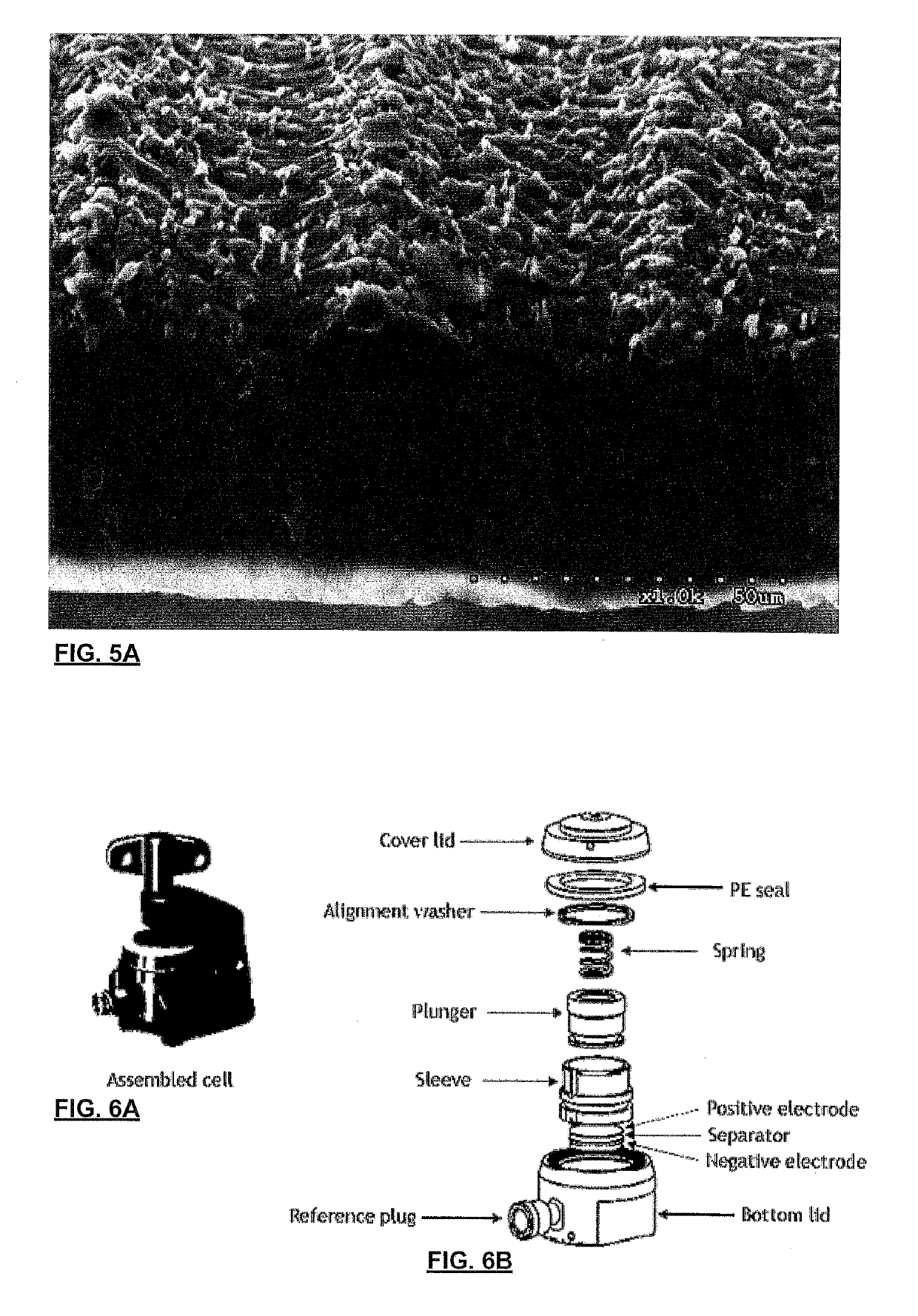

Metallic surface with karstified relief, forming same, and high surface area metallic electrochemical interface

ActiveUS10522300B2Efficiently karstifiedKarstifies surfaceElectrode carriers/collectorsVacuum evaporation coatingMetal foilRms roughness

A metal foil with a karstified topography having a surface morphology in which a maximum peak height minus a maximum profile depth is greater than 0.5 μm and extends into the surface at least 5% of the foil thickness, a root mean square roughness is at least about 0.2 μm measured in a direction of greatest roughness, and an oxygen abundance is less than 5 atomic %. The foil may be composed of aluminum, titanium, nickel, copper, or stainless steel, or an alloy of any thereof, and may have a coating composed of nickel, nickel alloy, titanium, titanium alloy, nickel oxide, titanium dioxide, zinc oxide, indium tin oxide, or carbon, or a mixture or composite of any thereof. The foil may form part of a metal electrode, current collector, or electrochemical interface. Further described is a method for producing the foil by laser ablation in a vacuum.

Owner:NAT RES COUNCIL OF CANADA

Composite electrolyte membrane and all-solid-state battery comprising the composite electrolyte membrane

PendingUS20210280908A1Reduce interfacial resistanceIncrease internal temperatureSolid electrolytesFinal product manufactureAll solid stateComposite electrolyte

A composite electrolyte membrane according to the present disclosure includes a phase change layer on a surface in contact with an electrode, for example, a positive electrode. The phase change layer includes a filler, and a physically isolated area between the positive electrode and the composite electrolyte membrane, known as a dead space, is filled with the filler that is liquefied by heat resulting from the increased internal temperature of the battery, thereby reducing the interfacial resistance between the electrolyte membrane and the electrode.

Owner:LG ENERGY SOLUTION LTD

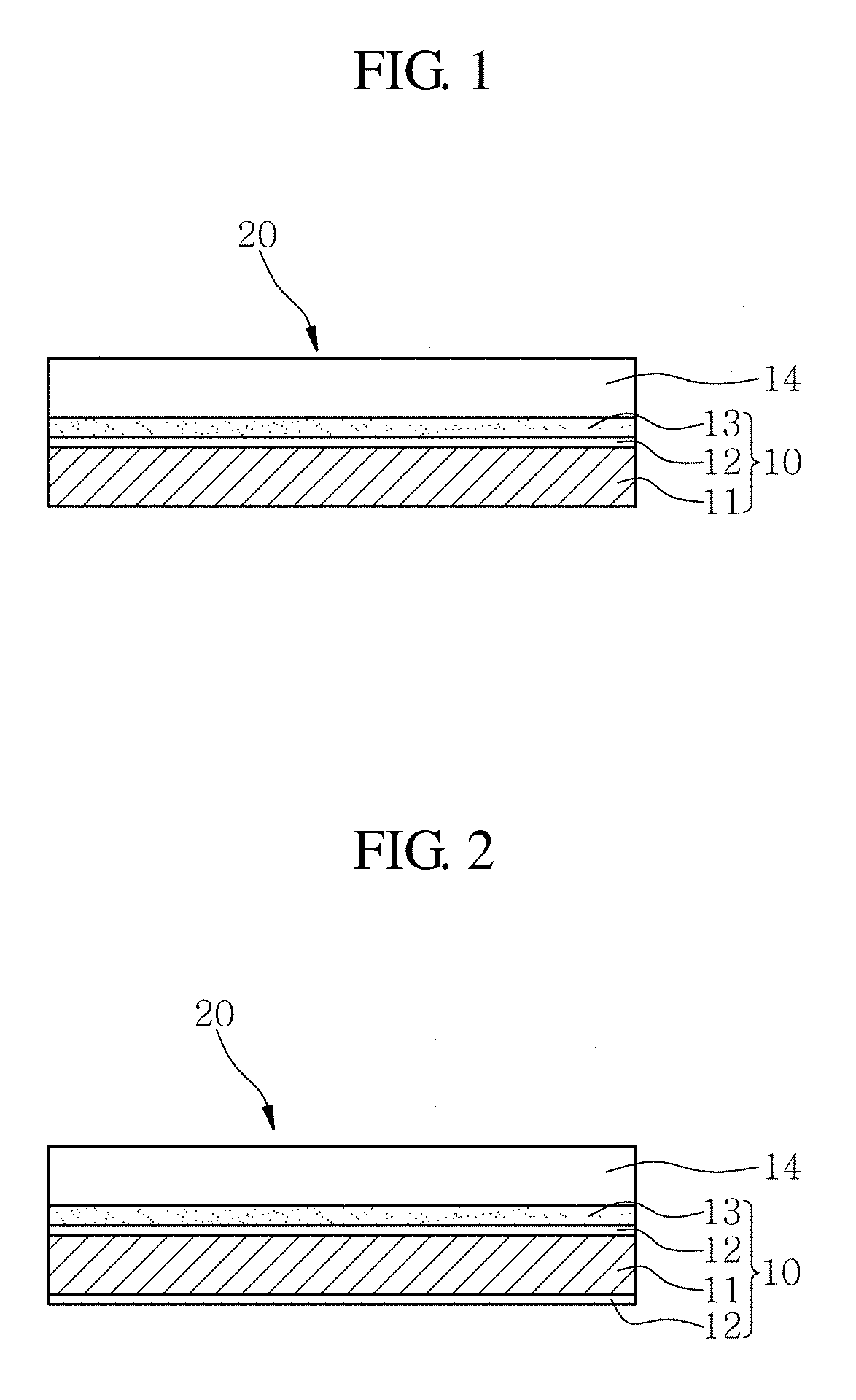

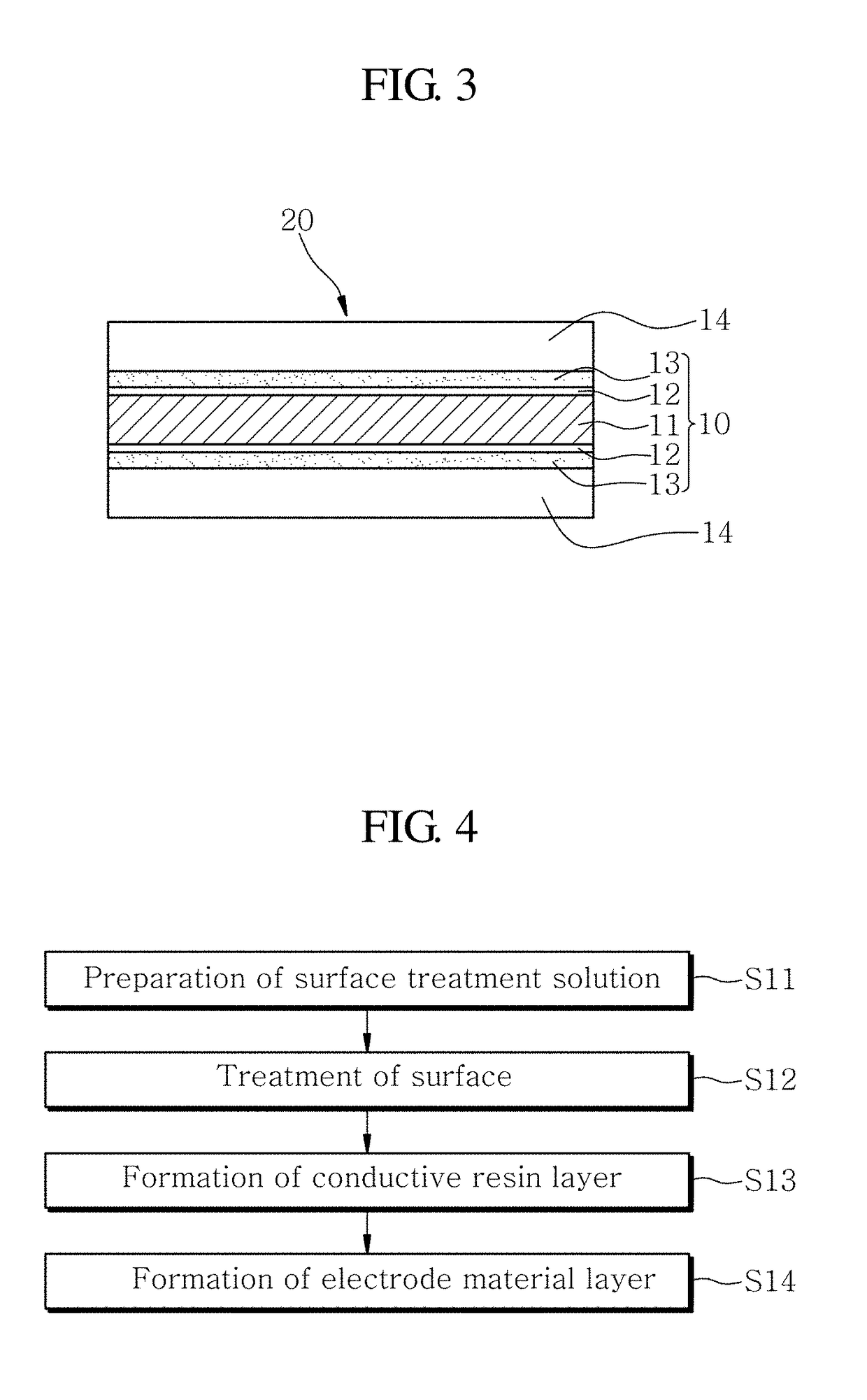

Metal foil, metal foil manufacturing method and method for manufacturing electrode using the same

ActiveUS9825302B1Good coating effectReduce flakingElectrode carriers/collectorsElectrode collector coatingDyneMetal foil

Provided are a metal foil, a metal foil manufacturing method and a method for manufacturing an electrode using the same, in which the adhesion between the metal foil and a conductive resin layer and the coating performance of the conductive resin layer can be improved by treating the surface of the metal foil. The metal foil comprises: a metal base substrate; a surface treatment layer formed on at least one surface of the metal base substrate by treating the surface of the metal base substrate; and a conductive resin layer applied to the surface of the surface treatment layer, wherein the surface treatment layer has a surface energy of 34-46 dyne / cm.

Owner:KOREA JCC CO LTD

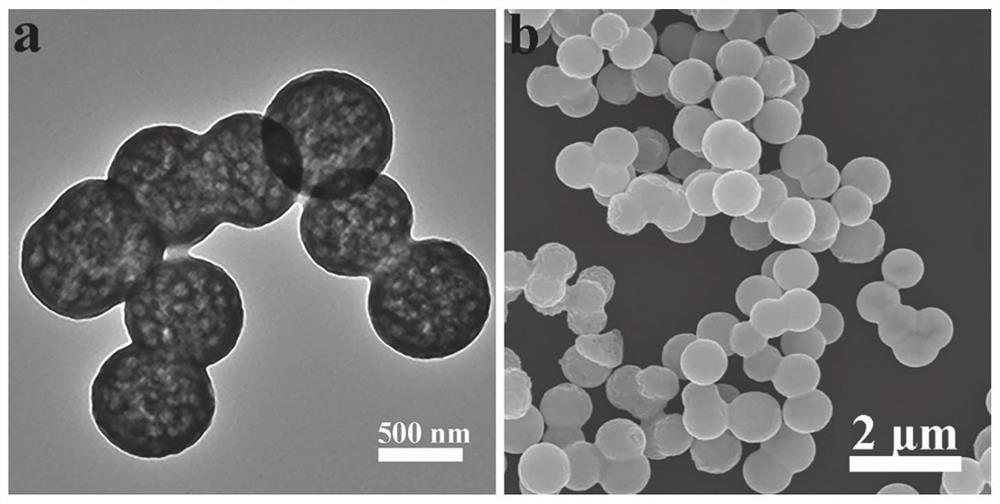

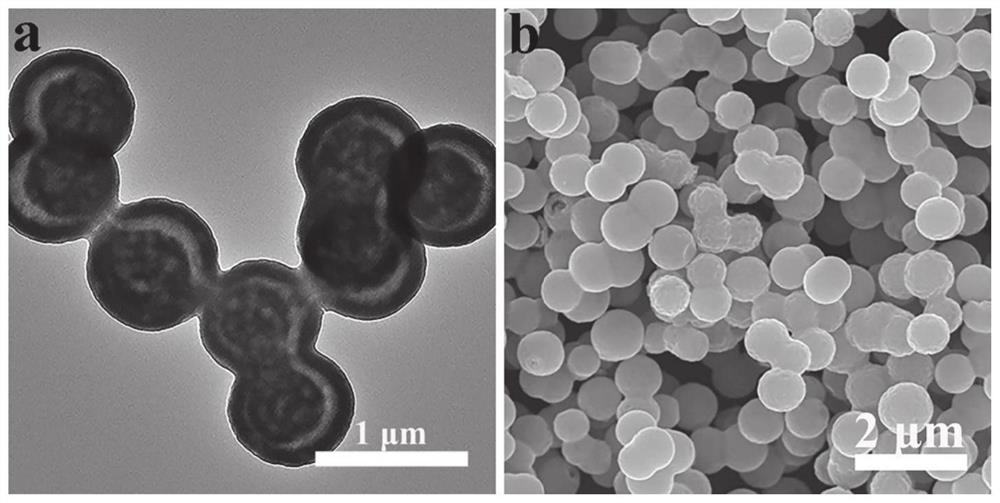

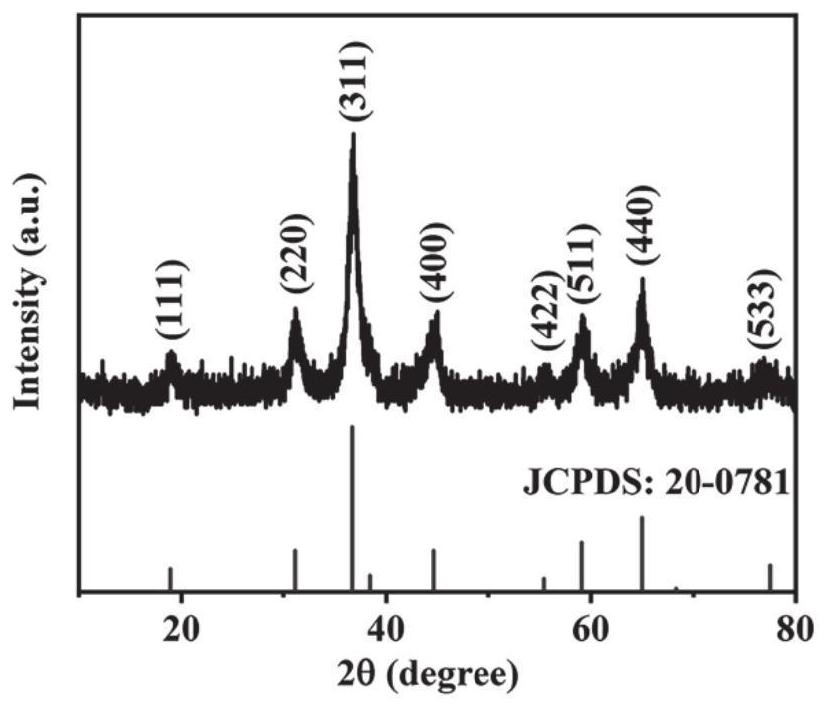

Molybdenum-doped nickel cobaltate porous yolk-shell-structure material as well as preparation method and application thereof

ActiveCN112614989AAchieve transformationEasy to prepareSecondary cellsNegative electrodesYolkNickel salt

The invention discloses a molybdenum-doped nickel cobaltate porous yolk-shell-structure material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing a precursor containing Ni, Co and Mo from a nickel salt, a cobalt salt and a molybdenum salt by adopting a solvothermal method, heating the precursor to 490-510 DEG C, and conducting calcining to obtain the molybdenum-doped nickel cobaltate porous yolk-shell-structure material. According to the invention, NiCo2O4 crystal lattices are doped with Mo, so Mo replaces a part of Co<3+> in NiCo2O4; and a porous yolk-shell structure is formed by wrapping a yolk inner core with a shell, the shell has a nanoscale diameter, the sum of the thickness of the shell and the radius of the yolk inner core is smaller than the radius of the porous yolk-shell structure, and the yolk inner core is porous particles. According to the preparation method, the molybdenum-doped nickel cobaltate porous yolk-shell-structure material can be prepared only through a two-step method. The prepared molybdenum-doped nickel cobaltate porous yolk-shell-structure material has better electrochemical performance when used as a lithium ion battery negative electrode material.

Owner:QILU UNIV OF TECH

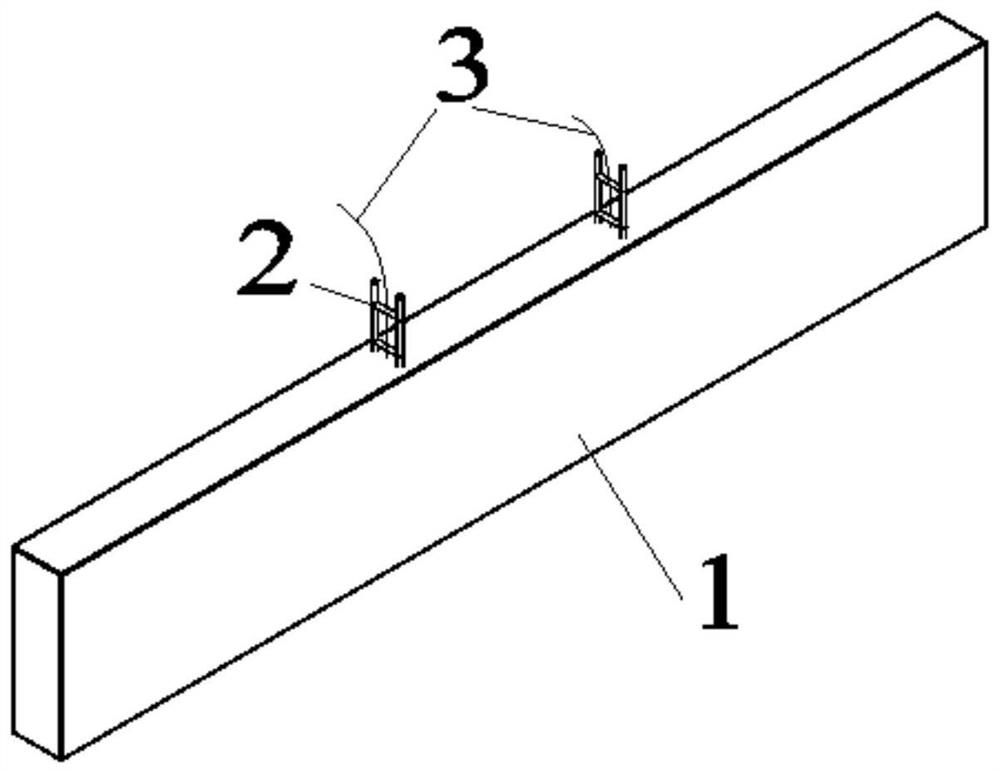

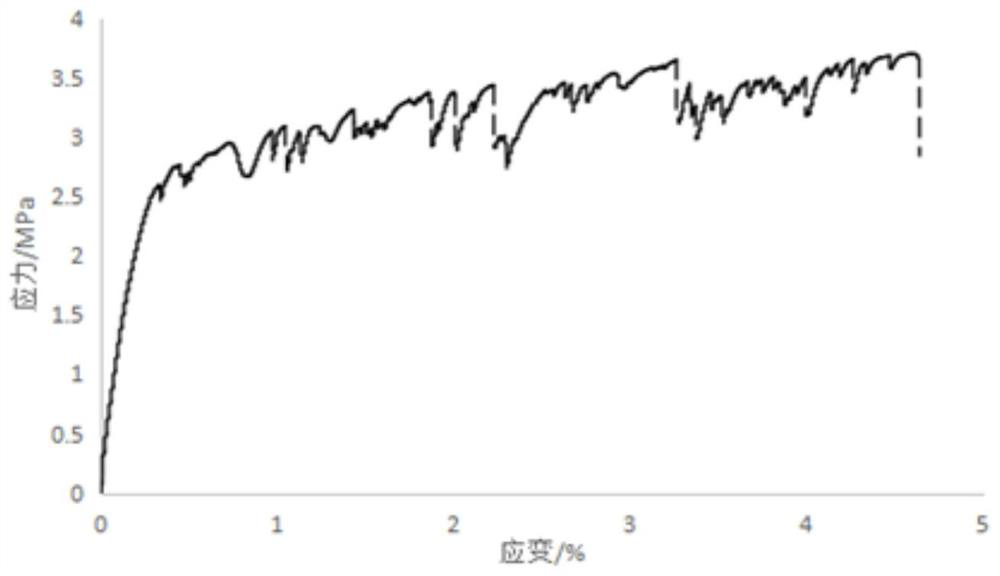

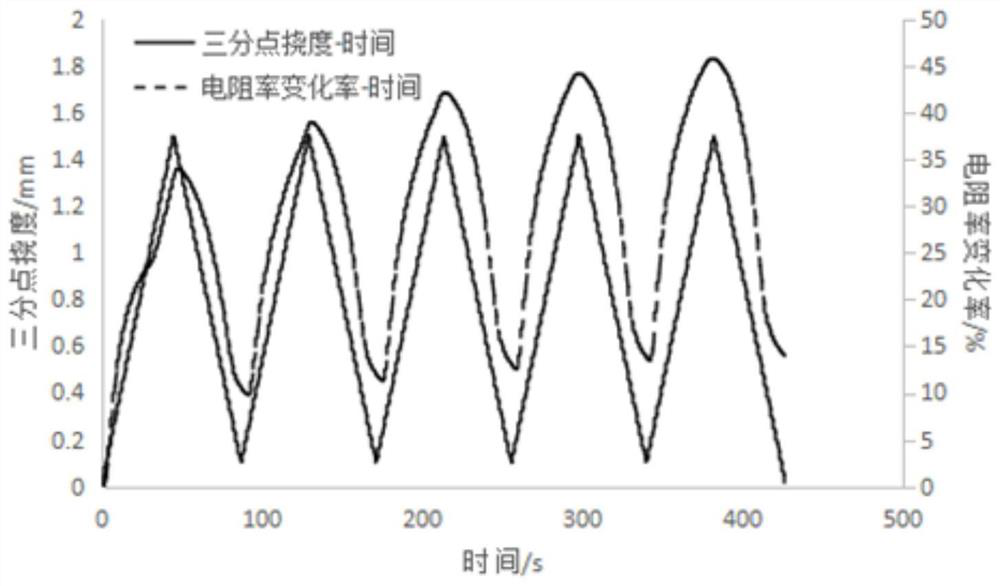

Ultra-high performance cement-based composite material for sensor, sensor and preparation method thereof

InactiveCN111620617ALow resistivityImprove frost resistanceElectrical/magnetic solid deformation measurementFiberSurface-active agents

The invention relates to an ultra-high performance cement-based composite material for a sensor, the sensor and a preparation method thereof, and belongs to the technical field of civil engineering materials, and the ultra-high performance cement-based composite material comprises cement, fly ash, quartz sand, fibers, a water reducing agent, starch gel, water, carbon nanotubes, graphite powder anda surfactant. The tensile strain of the ultra-high-performance cement-based composite material is 3% or above; the defects of brittleness, low tensile strength, poor toughness, easiness in cracking and the like of a common cement-based material are overcome; the strain monitoring range of the manufactured sensor is far larger than that of a sensor made of a common smart cement-based material; thecarbon nano tube and the graphite powder are used as conductive phase materials, the manufacturing cost is low, the sensor is good in compatibility with a concrete structure, excellent in conductivity and smart, stable and reliable in performance, long in service life and easy to manufacture, and due to the addition of the starch gel, shrinkage deformation of the composite material is greatly reduced.

Owner:SHANDONG UNIV

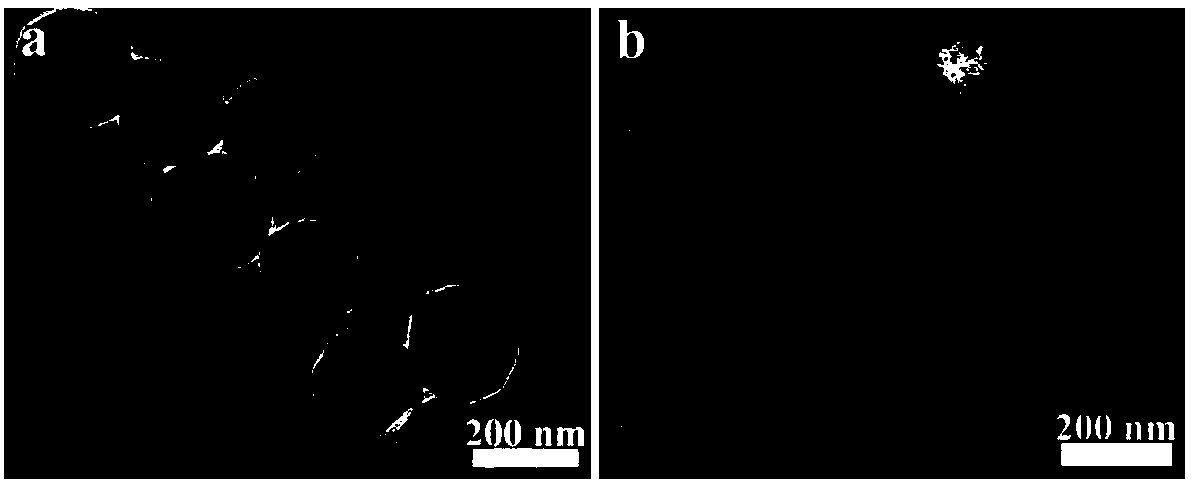

Ni/CeO2NP@PANI core-shell structural composite material and preparation method thereof

The invention discloses a Ni / CeO2NP@PANI core-shell structural composite material and a preparation method thereof. The method comprises the following steps: firstly, Ni / CeO2 NPs are prepared througha hydrothermal method; and then aniline is polymerized on the surfaces of the Ni / CeO2 NPs by adopting a chemical oxidation polymerization method, and in the polymerization process of the aniline, through changing a concentration of HCl, conversion from a Ni / CeO2NP@PANI core-shell structure to a spaced Ni / CeO2NP@PANI core-shell structure to PANI hollow spheres is realized. In the process, templatesare not needed, the method is green and environmentally friendly, the preparation method is simple, the preparation process is safe, the energy consumption is low, and the operability is strong; andthe Ni / CeO2 NPs prepared by the method have rough surfaces, so that the specific surface area can be increased to increase the contact area of the Ni / CeO2 NPs and the PANI, and the diffusion of ions and electrons can be promoted to effectively improve the electrochemical performance.

Owner:QILU UNIV OF TECH

Device and method for processing molten metals with ultrasound waves

ActiveCN102876900ASolving Corrosion ProblemsEasy to installProcess efficiency improvementMelting tankUltrasonic sensor

The invention discloses a device and a method for processing molten metals with ultrasound waves, belonging to the technical field of molten metal treatment. Metals to be processed and ultrasonic tool rods are integrated rods with the same diameter; quartz tubes are sleeved the upper portions of the metals to be processed and the ultrasonic tool rods; heating devices are arranged on peripheries of the quartz tubes; the lower portions of the ultrasonic tool rods are sleeved with water cooling sleeves; the quartz tubes are separated from the water cooling sleeves by insulation cottons; ultrasonic transducer and ultrasonic controllers are connected below the ultrasonic tool rods. The heating devices start when using; inert gas is led on the top ends of the metals to be processed to protect; cooled water is led into the water cooling sleeves; the heating devices start again to melt the metals to be processed to form a molten metal tank; the ultrasonic transducer and ultrasonic controllers start; the frequency of the ultrasound waves are regulated to make the ultrasonic tool rods and the molten metal tank resonate and process the molten metals to be processed. The device and the method have the advantages of convenience, low cost, no loss of ultrasonic energy and wide use.

Owner:TSINGHUA UNIV

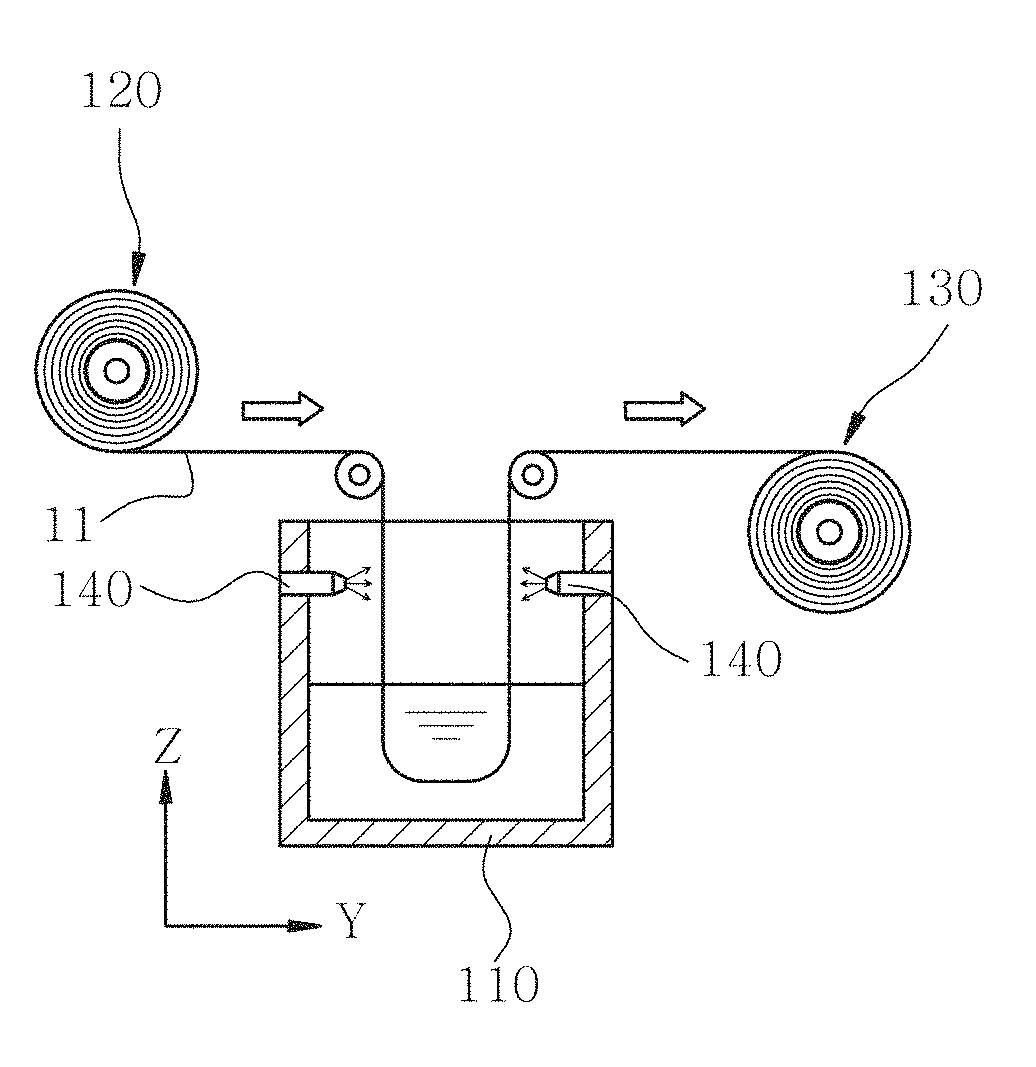

Method for preparing lithium ion battery

InactiveCN109962211ALower internal resistanceImprove acceleration performanceElectrode manufacturing processesFinal product manufactureInternal resistanceElectrical battery

The invention relates to a method for preparing a lithium ion battery, and belongs to the technical field of batteries. In order to solve the poor synchronism and the large internal resistance of an existing battery, a method for preparing the lithium ion battery is provided, which comprises steps of transferring the positive electrode paste and the negative electrode paste to a positive syringe and a negative syringe respectively; coating the two opposite sides of a diaphragm with the positive electrode paste and the negative electrode paste respectively by electrospinning; after drying, forming a positive active layer and a negative active layer on the two opposite sides of the diaphragm respectively; hot-rolling a positive electrode current collector and a negative electrode current collector onto the surfaces of the positive active layer and the negative active layer respectively; and obtaining the corresponding lithium ion battery by die cutting and subsequent processing. The method can reduce the internal resistance of the battery, improves the chemical performance of the battery, has a simple process and is easy to operate.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com