Device and method for processing molten metals with ultrasound waves

A metal melt and ultrasonic technology, applied in the direction of improving process efficiency, etc., can solve the problems of high temperature resistance and corrosion resistance, serious ultrasonic attenuation, brittle fracture of assembly, etc., and achieve low cost, simple device and method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Device structure for ultrasonic treatment of molten metal

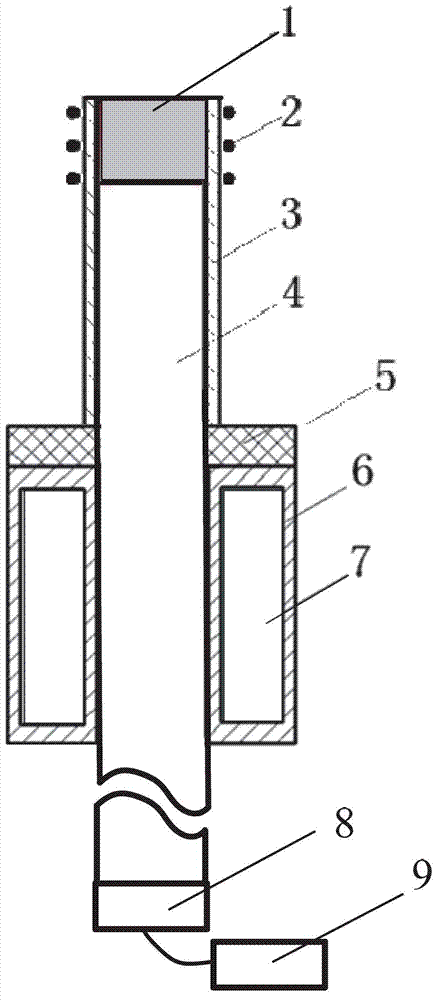

[0035] Such as figure 1 As shown, the structure of the device utilizing ultrasonic treatment of molten metal according to the present invention is as follows:

[0036] The metal 1 to be treated and the ultrasonic tool bar 4 are integrated rods with the same diameter, and the two are connected together by welding or casting; and the metal 1 to be treated is located at the top of the ultrasonic tool bar 4; the ultrasonic tool bar 4 The length of the ultrasonic wave is an integer multiple of the half-wavelength that the ultrasonic wave propagates in the metal material used in the ultrasonic tool bar 4; the length of the metal 1 to be processed is 0.5 to 3 times its diameter;

[0037] The metal 1 to be treated and the upper part of the ultrasonic tool bar 4 are encased by a quartz tube 3; the melting point of the quartz tube 3 is higher than the melting point of the metal 1 to be treated; the wall th...

Embodiment 2

[0041] Embodiment 2: Utilize the device for ultrasonic treatment of molten metal to process molten metal method

[0042] Such as figure 1 Shown, utilize the device of ultrasonic treatment metal melt of the present invention to process metal melt method as follows:

[0043] (1) Select the same material as the metal 1 to be processed to make the ultrasonic tool rod 4, wherein the metal 1 to be processed is located at the top of the ultrasonic tool rod 4, and the ultrasonic tool rod 4 and the metal 1 to be processed are directly melted or welded on the Together; wherein, the length of the ultrasonic tool bar 4 is 1 time of the half-wavelength that ultrasonic waves propagate in the tool bar material, and the length of the metal 1 to be processed is 1 time of the metal diameter to be processed; the ultrasonic tool bar 4 is placed vertically , so that one end of the metal 1 to be processed is upward;

[0044] (2) Select a quartz material with a higher melting point than the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com