Ni/CeO2NP@PANI core-shell structural composite material and preparation method thereof

A composite material and shell structure technology, which is applied in the field of Ni/CeO2NP@PANI core-shell structure composite material and its preparation, and achieves the effects of good environmental protection, low temperature and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a preferred embodiment of the present invention, the above-mentioned Ni / CeO 2 Preparation method of NP@PANI core-shell structure composites, including: Ni / CeO 2 Preparation of NPs and Ni / CeO 2 Preparation of NP@PANI composites.

[0041] In a preferred embodiment of the present invention, the Ni / CeO 2 The preparation method of NPs comprises the following steps:

[0042] (1) Ce(NO 3 ) 3 ·6H 2 O was added to ethylene glycol and stirred until completely dissolved;

[0043] (2) Ni(NO 3 ) 2 ·6H 2 O joins in step (1) gained solution, continues to stir;

[0044] (3) Add acetic acid and deionized water to the solution obtained in step (2), and stir until uniform;

[0045] (4) Transfer the solution prepared in step (3) to an autoclave for hydrothermal reaction. After the hydrothermal treatment, the autoclave is cooled to room temperature to obtain a gray precipitate;

[0046] (5) The gray precipitate obtained in step (4) is centrifuged, washed, dried, ground and ca...

Embodiment 1

[0075] (1) 0.5g Ce(NO 3 ) 3 ·6H 2 O was added to 15 mL of ethylene glycol, and stirred at room temperature for 0.5 h;

[0076] (2) Add 460μL 0.5mol / L Ni(NO 3 ) 2 ·6H 2 O was added to the solution obtained in step (1), stirred at room temperature for 15min;

[0077] (3) Add 500 μL of acetic acid and 500 μL of deionized water into the solution obtained in step (2), and stir at room temperature for 0.5 h;

[0078] (4) the mixed solution that step (3) is obtained is transferred in the autoclave of the polytetrafluoroethylene liner of 20mL;

[0079] (5) Tighten the autoclave in step (4) and put it into an oven, and keep it warm at 180° C. for 3 hours; after the hydrothermal treatment, naturally cool the autoclave to room temperature;

[0080] (6) Centrifuge the precipitate obtained in step (5), wash with distilled water and ethanol three times respectively, dry in a blast drying oven at 80°C for 24 hours, and grind to obtain Ni / CeO 2 powder;

[0081] (7) Ni / CeO obtained in s...

Embodiment 2

[0090] Ni / CeO 2 NPs preparation method is with step (1)-(7) in example 1;

[0091] (8) Ni / CeO obtained in step (7) 2 Disperse 20mg of the powder in 25mL of deionized water, add 100mg of PVP to the ultrasonic condition, and continue ultrasonication for 0.5h;

[0092] (9) Disperse 20 μL of aniline in 25 mL of 2mol / L HCl solution and stir until uniformly dispersed;

[0093] (10) quickly add the solution obtained in (9) to the suspension obtained in (8), and stir at room temperature for 2 hours;

[0094] (11) Dissolve 52mg APS in 20mL deionized water;

[0095] (12) Add the solution prepared in step (11) to the suspension obtained in step (10), and stir at room temperature for 12 hours;

[0096] (13) Centrifuge the precipitate obtained in step (12), wash with distilled water and ethanol three times respectively, dry in a blast drying oven at 80°C for 24 hours, and grind to obtain Ni / CeO 2 NP@PANI powder.

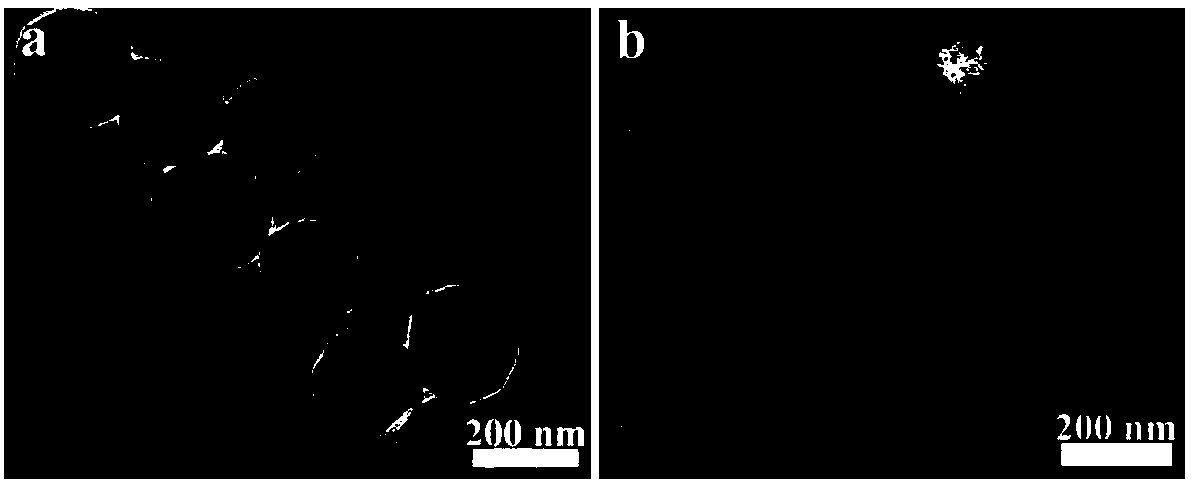

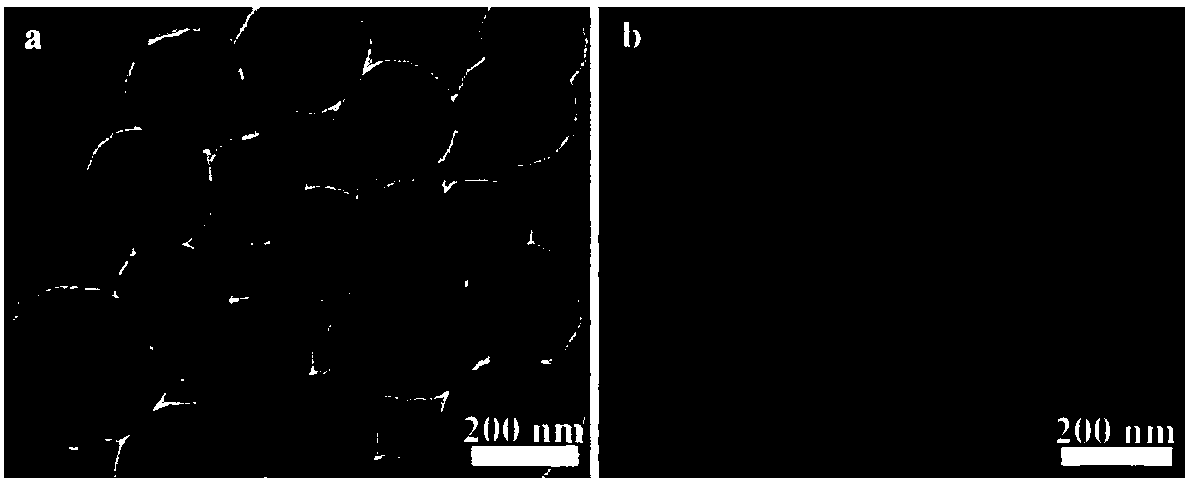

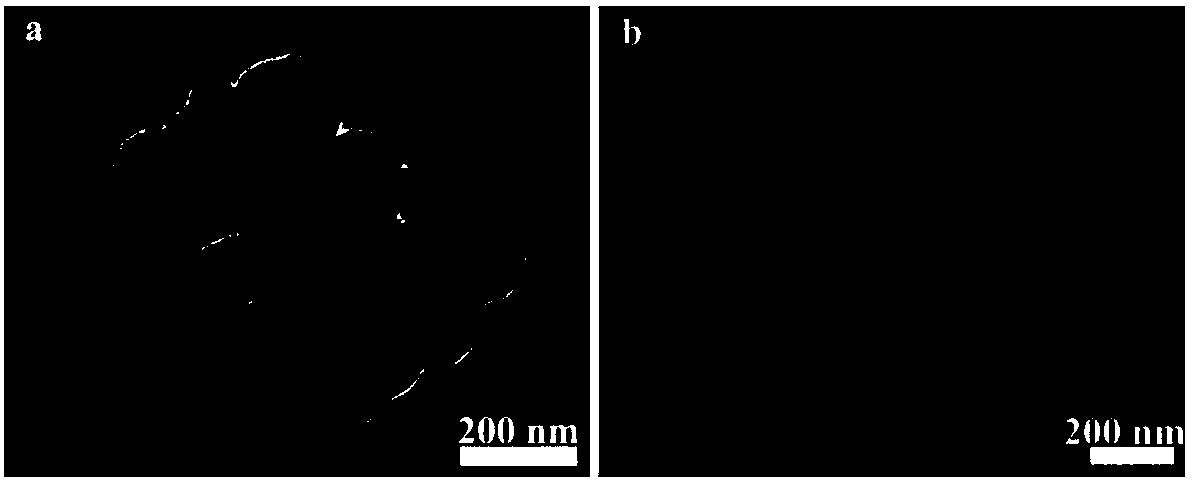

[0097] Observation with transmission electron microscope and scanning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com