Cooling medium for phase change radiator

A technology for heat-dissipating working fluid and radiator, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of base liquid solidification, high fluid viscosity, limited heat-dissipation efficiency, etc., to achieve strong compatibility and large specific heat capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A heat dissipation working fluid for phase change radiators, including 7g n-octadecane, 10g sodium dodecylbenzenesulfonate, 10g butanediol, 0.2g ethanol, 0.2g n-propanol, 0.2g isopropanol Alcohol, 0.12g sodium chloride, 0.18g potassium chloride and 72.1g distilled water.

[0016] The preparation process of heat-dissipating working fluid described in the present invention is introduced in detail below:

[0017] In the first step, select 72.1g distilled water, 7g n-octadecane, 10g sodium dodecylbenzenesulfonate, 10g butanediol, 0.2g ethanol, 0.2g n-propanol, 0.2g isopropanol, 0.12g chlorine Sodium chloride, 0.18g potassium chloride;

[0018] In the second step, the ethanol, n-propanol, and isopropanol of the above-mentioned quality are successively put into the above-mentioned distilled water, and fully stirred to obtain the mixed solution A1;

[0019] In the third step, the n-octadecane of the above quality is put into the mixed solution A1, and fully stirred to obtain...

Embodiment 2

[0023] A heat dissipation working fluid for a phase change radiator, including 35g n-octadecane, 10.5g octadecyl polyoxyethylene ether, 10g ethylene glycol, 3g ethanol, 3g n-propanol, 3g isopropanol, 0.6g sodium chloride, 0.9g potassium chloride and 14g distilled water.

Embodiment 3

[0025] A cooling fluid for phase change radiators, including 17g n-octadecane, 10g octadecyl polyoxyethylene ether phosphate, 8g ethylene glycol, 3g ethanol, 3g n-propanol, 3g isopropanol , 1g sodium chloride, 1.5g potassium chloride and 53.5g deionized water.

[0026] The preparation process of Embodiment 2 and Embodiment 3 is the same as that of Embodiment 1, and will not be repeated here.

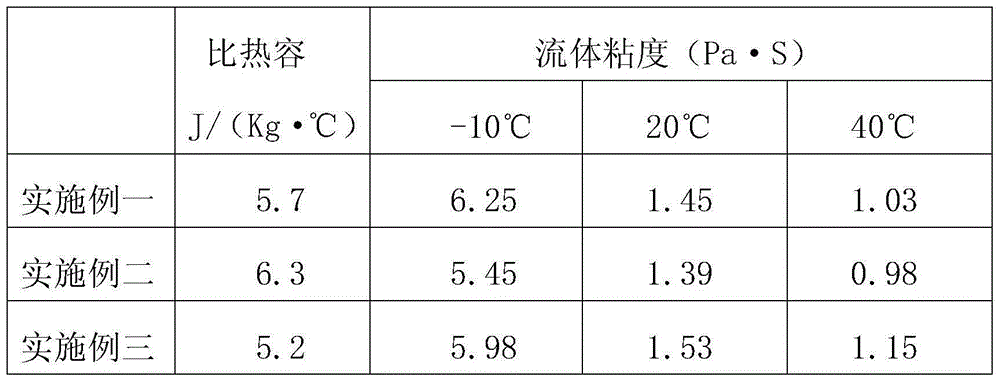

[0027] Table 1: Comparison of experimental data

[0028]

[0029] It can be seen from the above table that the heat-dissipating working medium prepared by mixing the mass fractions of the present invention has a higher specific heat capacity, better heat transfer effect, and is not easy to solidify in a low temperature environment, and the working state is relatively stable, and the technical effect is equivalent. obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com