Method of preparing high-oriented MFI type zeolite membrane by virtue of secondary growth under neutral condition

A secondary growth and orientation technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as danger, and achieve the effects of small destructiveness, continuous film layer, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

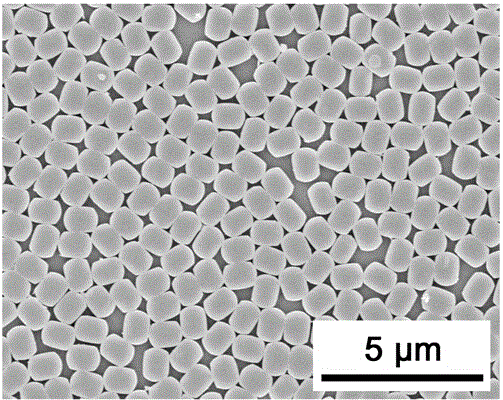

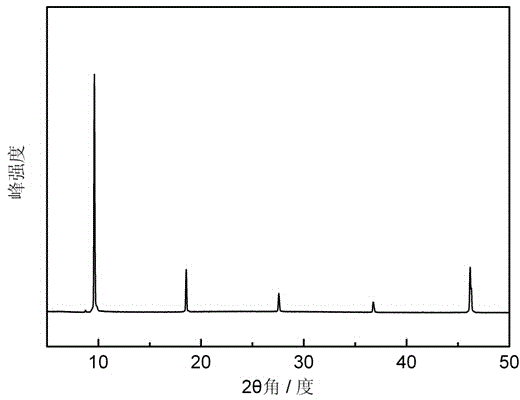

[0024] Wipe the micron-sized MFI type molecular sieve seed crystal powder on the surface of the glass sheet to get the b The glass sheet of the axis-oriented seed layer, the scanning electron microscope picture of the seed layer is as follows figure 1 As shown, the X-ray diffraction pattern is as figure 2 shown. The molar ratio is fumed silicon dioxide: tetrapropylammonium bromide: water = 1:0.1:165 synthetic solution was stirred at room temperature for 10 minutes, and then the synthetic solution and the glass sheet with the seed layer were put into In the synthesis kettle with polytetrafluoroethylene lining, the synthesis solution is immersed in the glass plate support, sealed and placed in a blast oven at 175°C for crystallization for 48 hours. After the reaction, the glass plate is taken out and washed with deionized water. After drying, get a high b The axis-oriented MFI molecular sieve membrane, the scanning electron microscope picture of the membrane layer is as foll...

Embodiment 2

[0026] The preparation method of the seed layer is the same as in Example 1, and the support body is a stainless steel sheet. The molar ratio is silica sol: tetrapropyl ammonium bromide: water = 1:5:2000 synthetic solution was stirred at room temperature for 10 minutes, then this synthetic solution was put into a In the polytetrafluoroethylene-lined synthesis kettle, the synthesis liquid is immersed in the stainless steel sheet support, sealed and placed in a blast oven at 200°C for crystallization for 72 hours. After the reaction, the stainless steel sheet is taken out, washed with deionized water, and then baked. dry, get high b Axially oriented MFI type molecular sieve membrane.

Embodiment 3

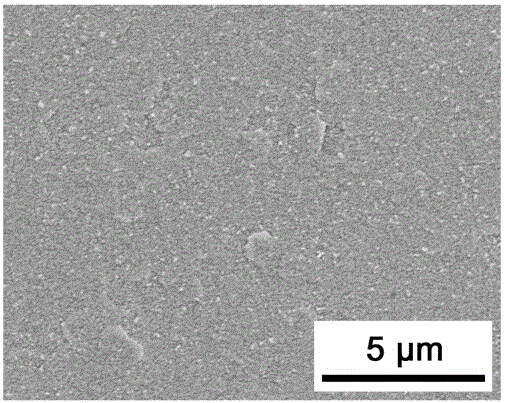

[0028] The preparation method of the seed layer is the same as in Example 1, and the support body is a glass sheet and a stainless steel sheet. The molar ratio is fumed silicon dioxide: tetrapropylammonium bromide: water=1:1:1650 synthetic solution was stirred at room temperature for 60 minutes, then this synthetic solution was mixed with stainless steel sheet and glass sheet with seed crystal layer Put them together into a synthetic kettle with a polytetrafluoroethylene liner, immerse the stainless steel sheet and glass sheet support in the synthetic solution, seal it and put it in a blast oven at 175°C for 24 hours of crystallization, and take out the glass sheet and glass sheet after the reaction is over. The stainless steel sheet was washed with deionized water and then dried to obtain a high b Axis-oriented MFI molecular sieve membrane, scanning electron microscope pictures of the membrane layer on the stainless steel sheet are as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com