Method for detecting orientation of large-sized crystal grains

A technology of grain orientation and detection method, applied in measurement devices, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc., to achieve the effect of judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in the following examples.

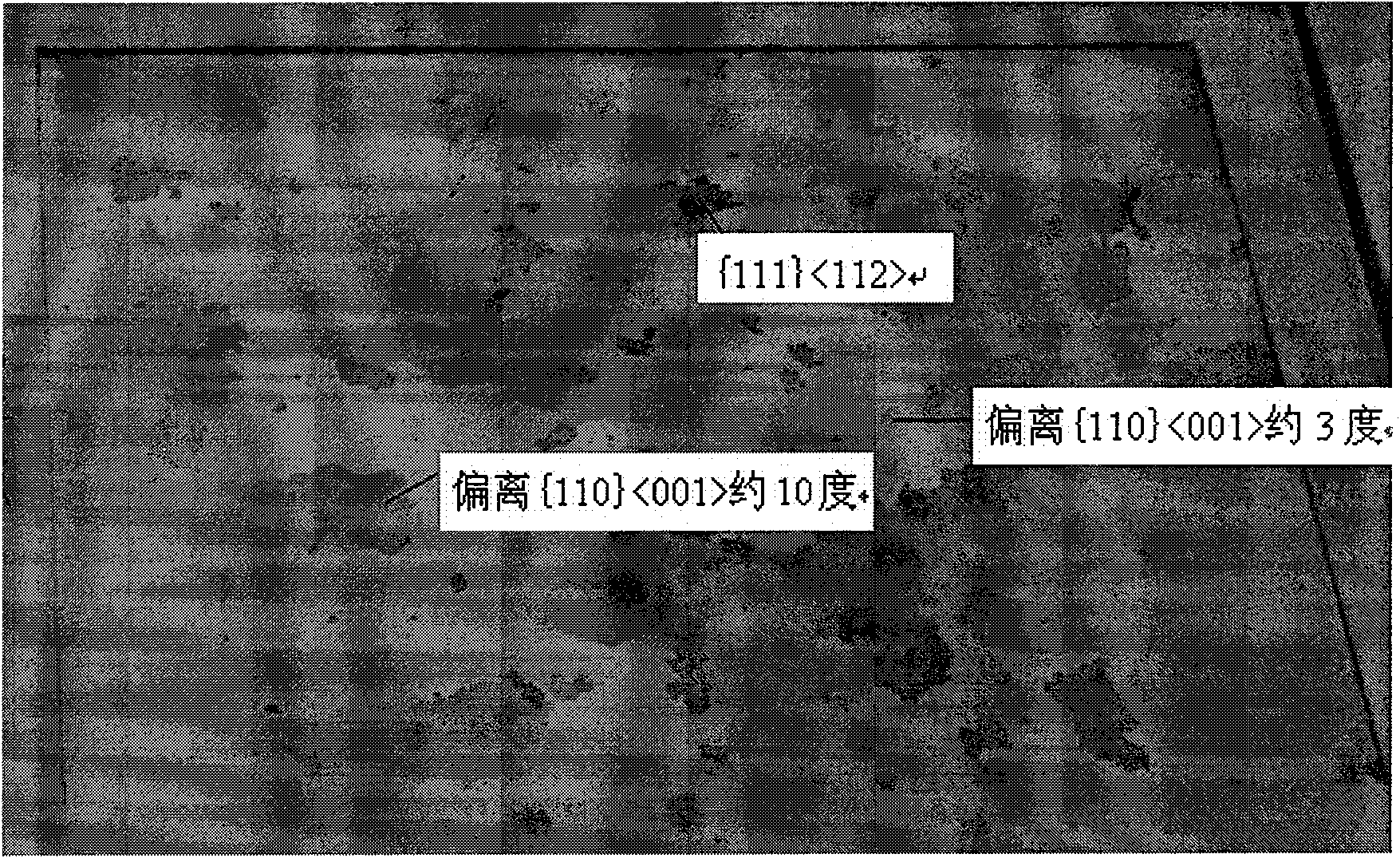

[0023] In the embodiment, taking 3 batches of 5 pieces of finished GO120 oriented silicon steel as an example, the texture components of 15 pieces of finished oriented silicon steel are counted.

[0024] The establishment of the database: each batch of finished GO120 oriented silicon steel, take 1 sample from each, use a grinder to remove the insulating layer of the two surface layers of the sample, both surface roughness is 1um, and then make 180mm (length) × 120mm (width) Specifications, where the length direction is the rolling direction.

[0025] Since the texture of the finished oriented silicon steel mainly has three surface textures of {100}, {110} and {111} or can be reduced to the high index texture components of the three surface textures, only three surface textures are calculated. The specific surface energy of each surface, calculated according to the theoretical specific surface energy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com