Rubber deformation detection device

A detection device and deformation technology, which are applied in the direction of mechanical solid deformation measurement, etc., can solve the problems of lack of on-site batch detection equipment, unfavorable rubber test piece production and manufacturing, and inability to detect deformation in time, so as to reduce product failure rate, Low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

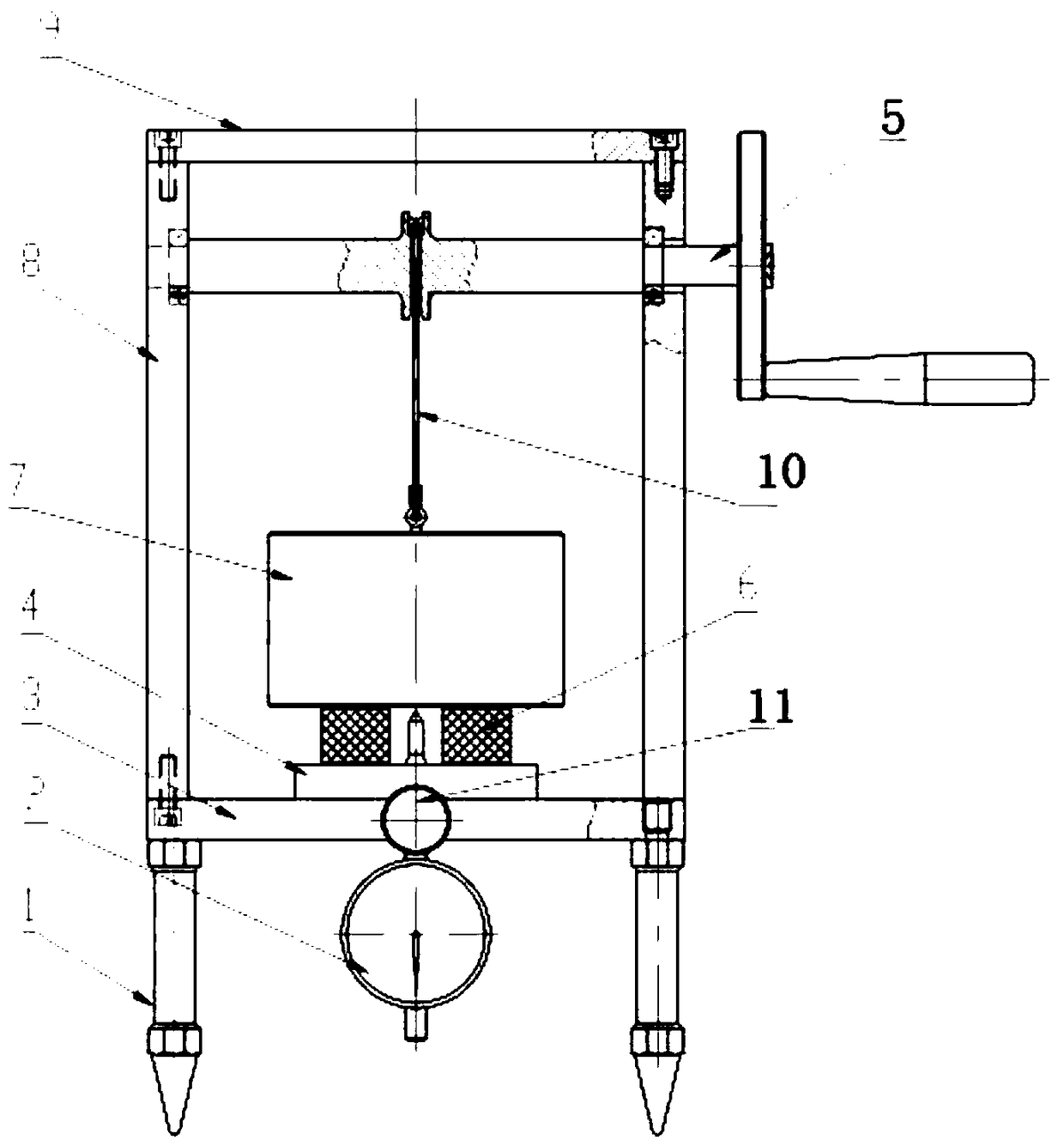

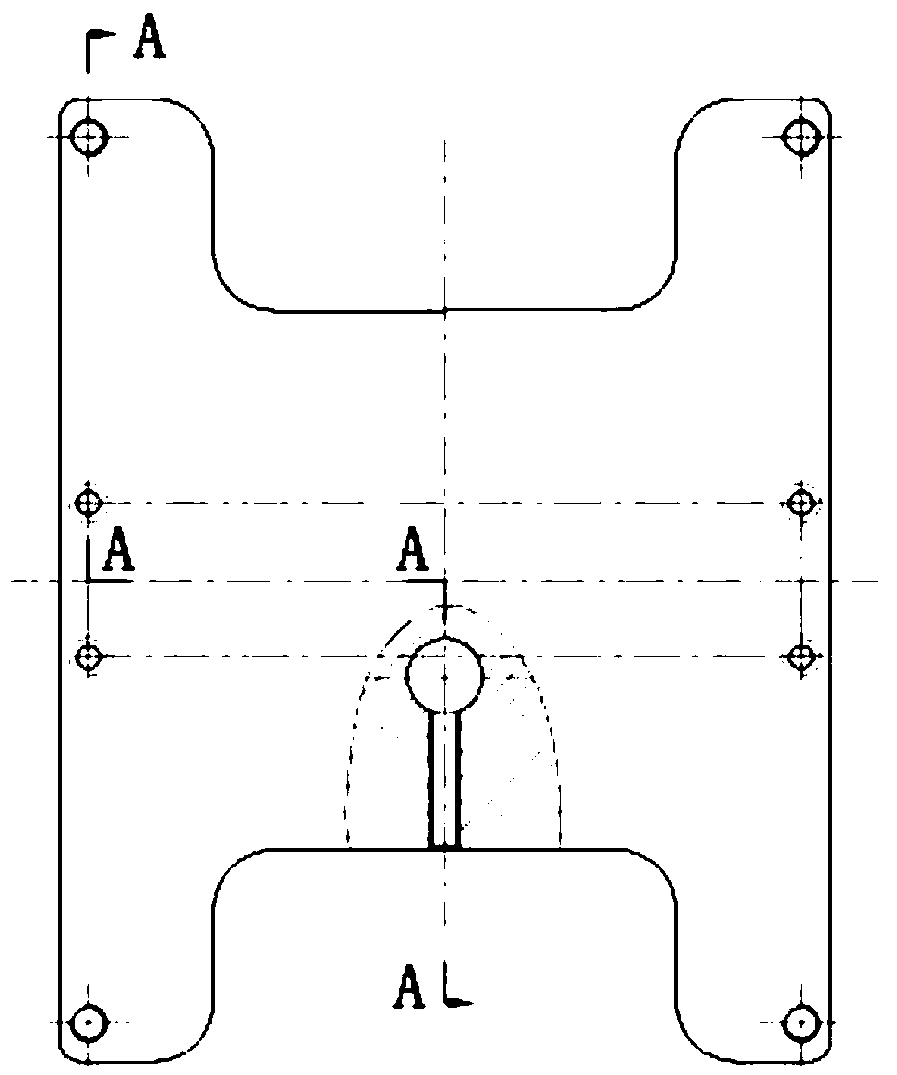

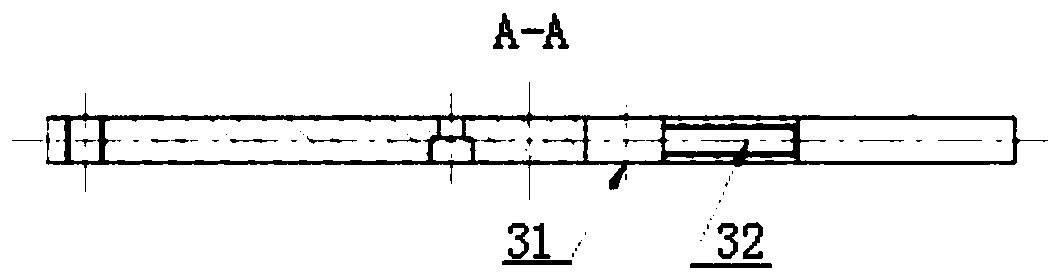

[0025] like Figure 1 to Figure 6 As shown, a rubber deformation detection device includes a base plate 3, the upper end of the base plate 3 is connected with a column 8, and the lower end is connected with a leg 1, the column 8 is fixed with a cover plate 9, and the base plate 3 is provided with There is a backing plate 4, a pair of watch blocks 6 is placed on the backing plate 4, and a weight 7 is supported on the upper end surface of the pair of watch blocks 6, and the weight 7 is connected to a wire rope assembly 10, and the column 8 is connected to There is a transmission mechanism 5 for winding the steel wire rope assembly 10 and lifting the weight 7 along the vertical line; the base plate 3 is provided with a dial indicator 2 with a measuring head passing through the base plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com