Method for measuring chute deformation of burden distribution of blast furnace

A technology for distributing chute and blast furnace, which is applied in the field of blast furnace maintenance and measuring the deformation of blast furnace distributing chute, which can solve the problems of difficulty in moving position and leveling, heavy weight of distributing chute, deformation of distributing chute, etc., and achieves good promotion and application value and practicability Strong, Measuringly Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

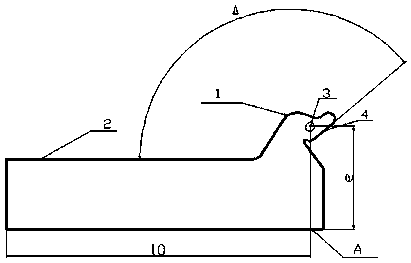

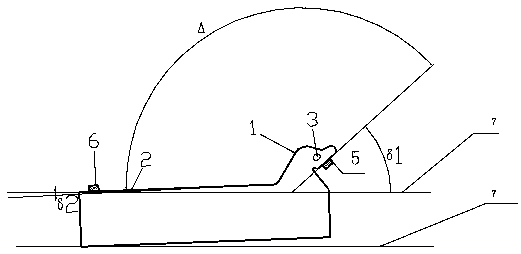

[0031] Normal distribution matrix α in the production process of a blast furnace max =45°, when the condition of the raw material and fuel is stable, the edge airflow gradually weakens, and it is forced to gradually increase α max , and finally fixed at 42°, the furnace condition is stable. Measure the deformation of the distribution chute after replacing the distribution chute on a regular basis. The inclination angle of the assembly surface 4 of the goose head body of the distribution chute is 39.5°, and the inclination angle of the side end surface 2 of the U-shaped groove at the front end of the distribution chute is -4°. The included angle of the side end surface 2 of the U-shaped groove at the front end is 180°-(39.5°+4°)=136.5°, and the deviation is 140°-136.5°=3.5°.

Embodiment 2

[0033] A blast furnace replaced the distribution chute, and measured the deformation of the new chute. The inclination angle of the goose head body assembly surface 4 of the distribution chute is 40.5° on one side, and 40.5° on the other side, with an average of 40.5°; the inclination angle of one side of the U-shaped groove at the front end of the distribution chute is 0.5°, and the inclination angle of the other side is 0°, with an average of 0.25°; calculation The angle between the assembly surface 4 of the goose head body of the distribution chute and the U-shaped groove side end surface 2 at the front end of the distribution chute is 180°-(40.5°+0.25°)=139.2°, and the deviation is 140°-139.2°=0.8°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com