Method for oriented growth of diamond film on aluminium oxide ceramic

A technology of alumina ceramics and diamond films, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as the difficulty of directional growth, and achieve the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

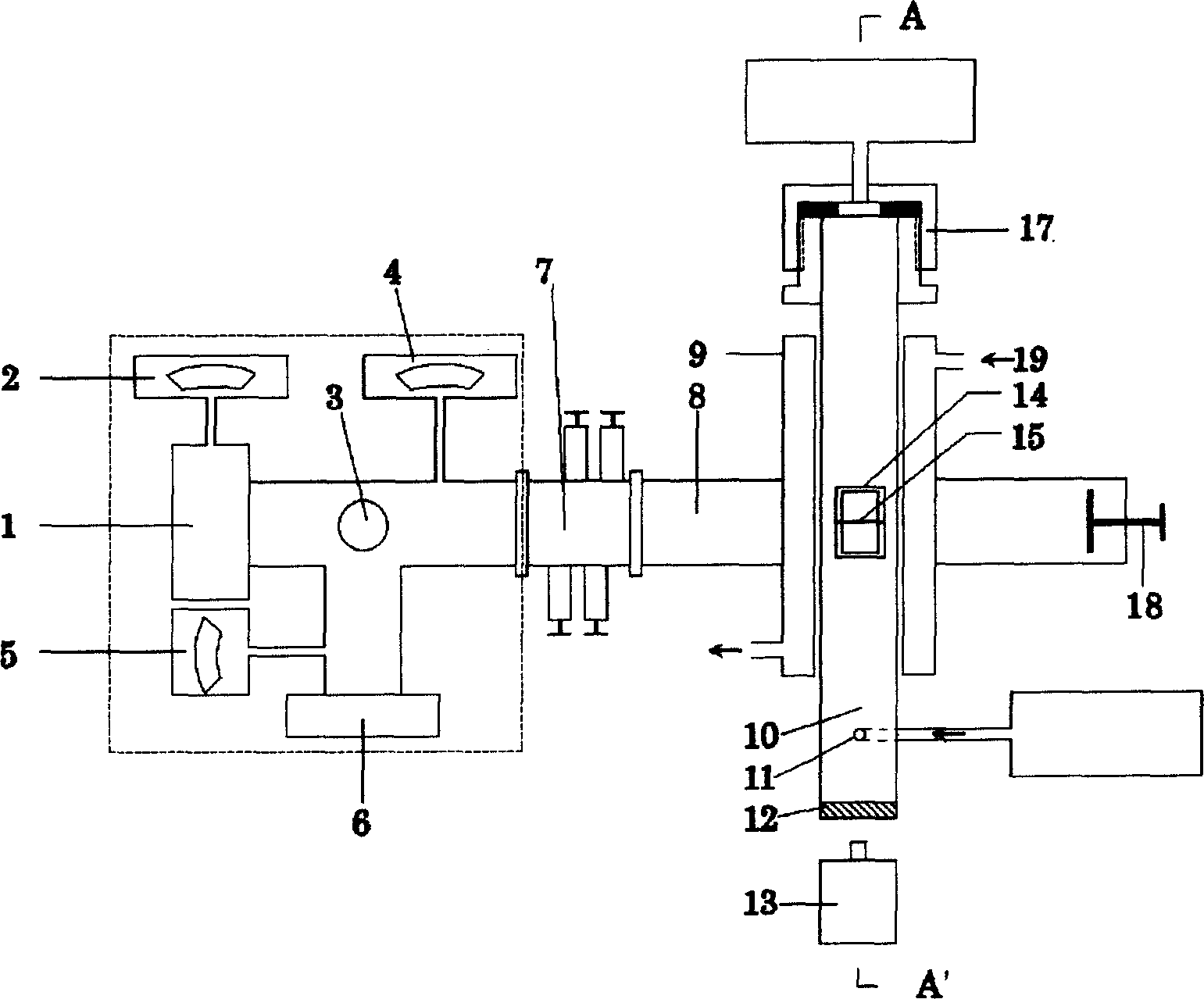

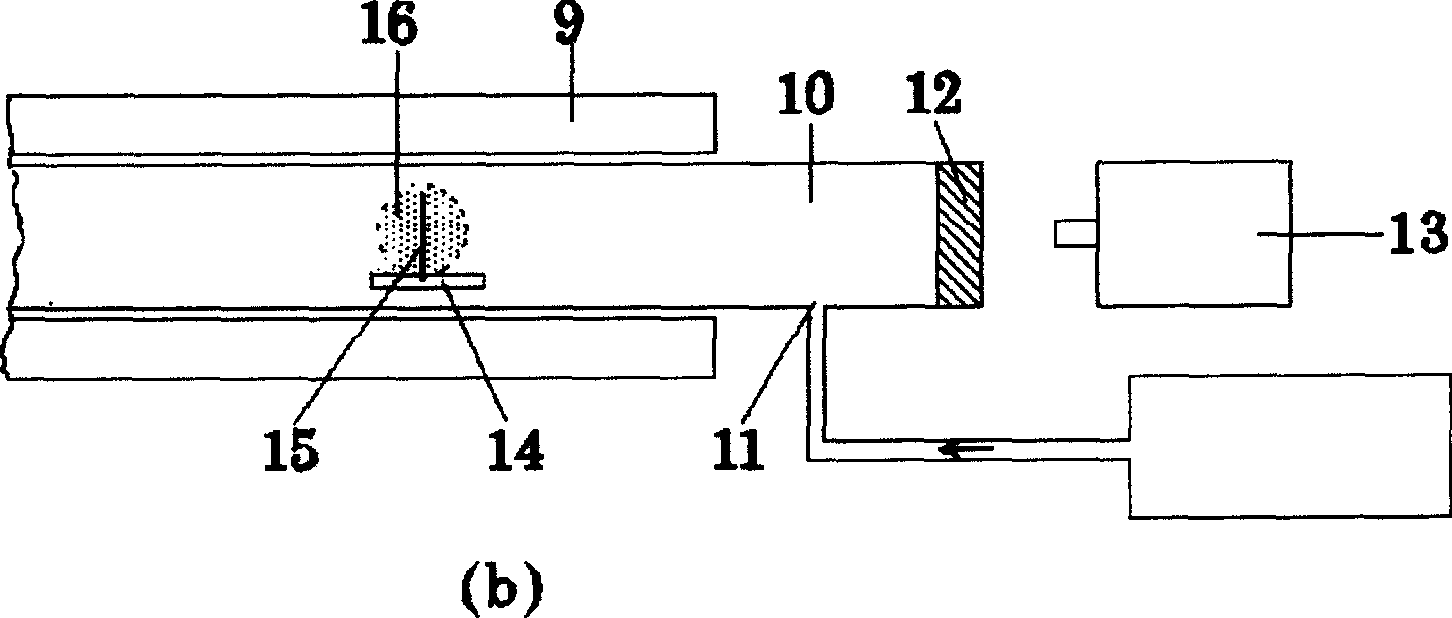

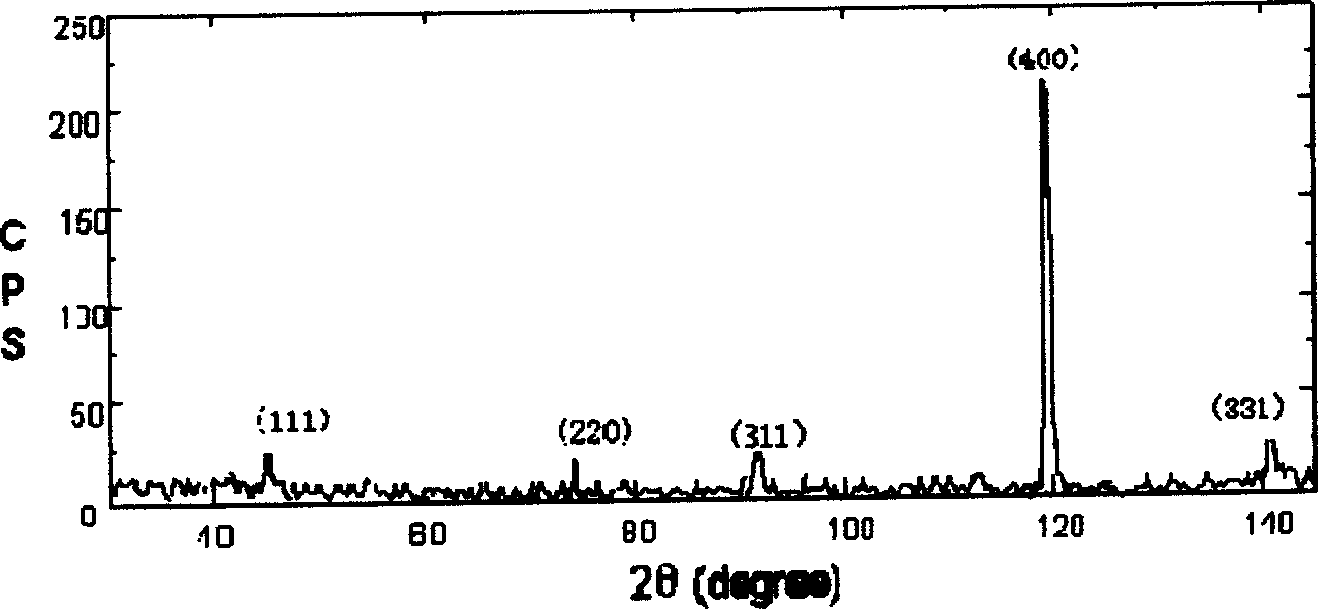

[0017] Embodiment 1: After the alumina ceramic sheet is polished on the surface, it is placed in an ion implanter, and carbon ions of 100 KeV are used for implantation treatment, and the implantation dose is 7×10 18 cm -2 , and then put the injected sample into figure 1 The annealing treatment is performed in the MPCVD equipment shown. Such as figure 1 and figure 2 As shown, the microwave source (marked by the dotted line) is composed of a magnetron 1 with a frequency of 2.45 GHz, an anode ammeter 2, an incident power meter 4, a reflected power meter 5, an air load 6 and a four-screw adjuster 7. The source output power is continuously adjustable, and the maximum power can reach 1000W. The microwave generated by the microwave source has a size of 110×55mm 2 The brass rectangular waveguide 8, the cut-off waveguide 9 and the short-circuit piston 18 are transmitted into the Φ39mm quartz reaction tube 10 in the TE10 mode. The quartz reaction tube 10 is placed horizontally, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com