Manufacturing method of large-size C-oriented sapphire crystals

A large-size, sapphire technology, which is applied in the field of growth of large-size (maximum crystal diameter: 14 inches) C-oriented sapphire single crystal, can solve problems such as sapphire single crystal cracking and sapphire crystal difficulty, and achieve core competitiveness and high weight , good crystal growth stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

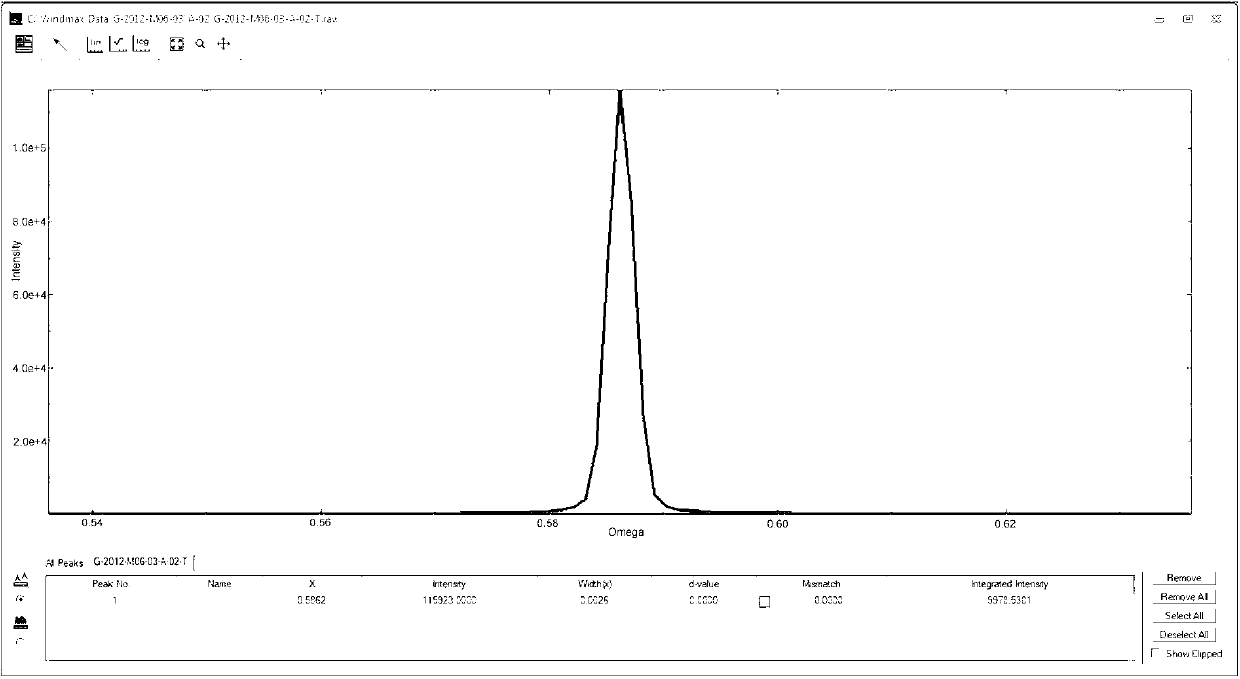

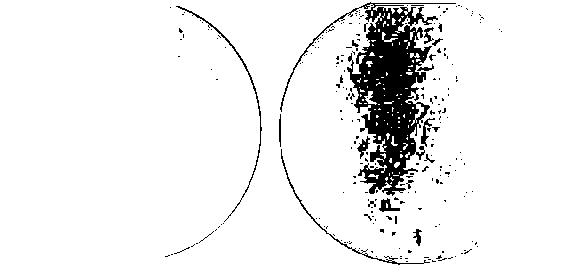

Image

Examples

Embodiment Construction

[0036] (1) The main ingredient ingredients are 99.999wt% high-purity alumina round cake with a diameter of 50mm and some irregular-shaped particles shown in Table 1;

[0037] (2) Filling: put the weighed alumina raw material into the crucible, and place the round cakes in a cross to prevent the liquid from splashing during melting, and fill with irregular-shaped particles;

[0038] (3) Adjust and install the heater and thermal field: adjust and install the tungsten dual heater and the tungsten-molybdenum thermal field, close the furnace cavity and install the camera, install the C-direction 30×30mm seed crystal, and adjust the position (according to theoretical calculation). , keep the seed crystal above the liquid level at a distance of 200mm from the liquid level), and start the monitor and recorder.

[0039] (4) Heating: set the heating program in the automatic control program, set the power of the main heater between 20KW and 80KW, set the power of the sub-heater between 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com