Ion-Conducting Ceramic Apparatus, Method, Fabrication, and Applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

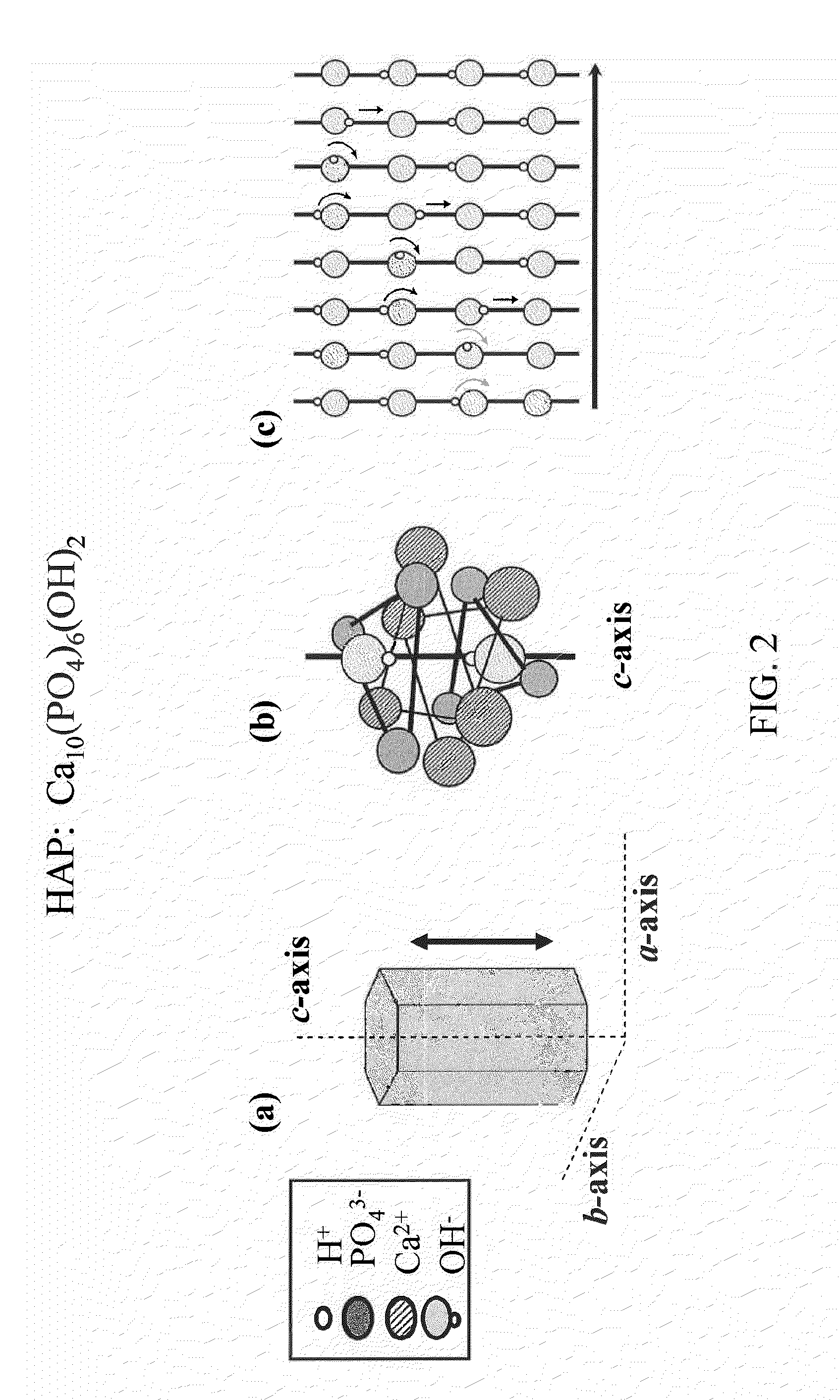

[0038]As mentioned above, optimal performance of a hydroxyapatite ion- / proton-conducting membrane occurs when the crystal domains span the entire thickness of the membrane to eliminate grain boundary resistance across the thickness of the membrane. In addition, the crystal's c-axis would be aligned so that the proton transport path is optimized, as illustrated in FIGS. 2(a-c).

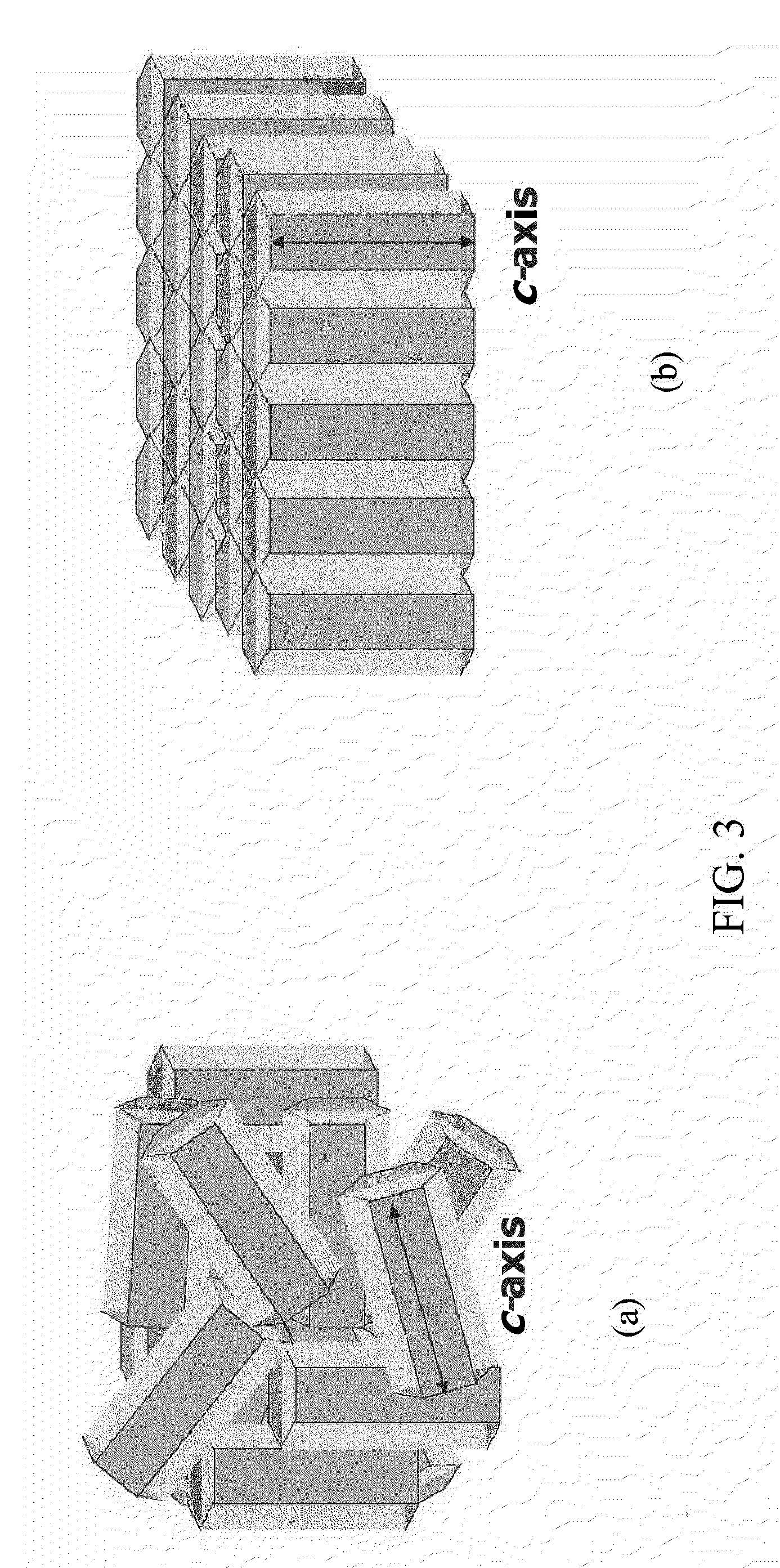

[0039]FIG. 3(a) schematically shows HAP crystals that are randomly oriented. FIG. 3(b), on the other hand, schematically shows an ideal HAP membrane structure with the c-axes of crystal domains spanning the entire membrane thickness to optimize proton transport;

[0040]A non-limiting, exemplary ion / proton conducting membrane 400-1 as illustrated in FIG. 4(c) includes a substrate 402 and a crystalline ion-conducting thin film 304 (also shown in FIG. 3(b)) having a thickness t. The thin film is characterized by a plurality of single apatite crystals 304′ each having its c-axis oriented normal to the substrate (as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com