Battery grid with varied corrosion resistance

A corrosion-resistant, grid technology, applied in the battery field, can solve the problems of limited battery space, limited grid, damaged capacity and high-rate performance, etc., to achieve the effect of reducing stress accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

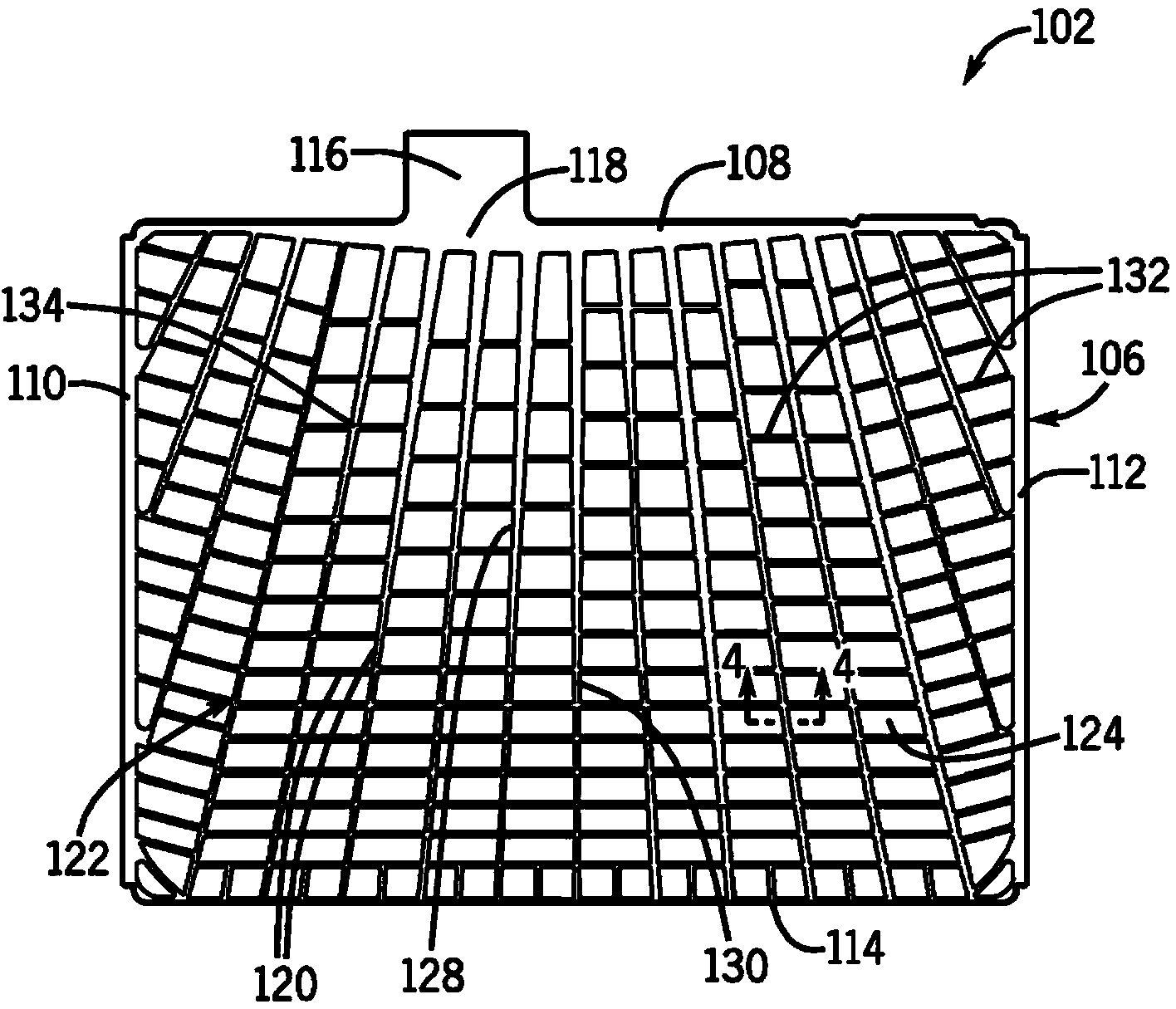

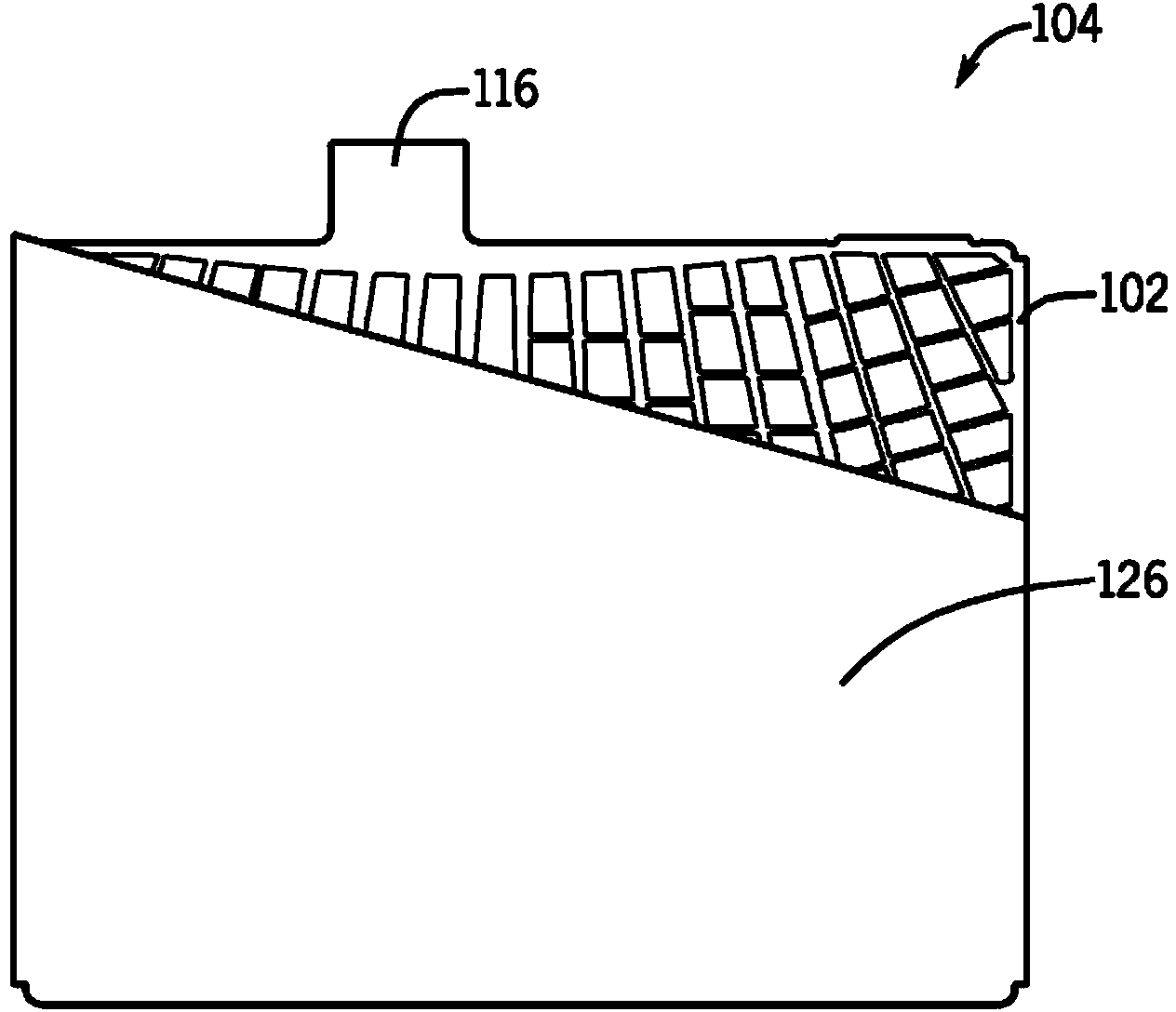

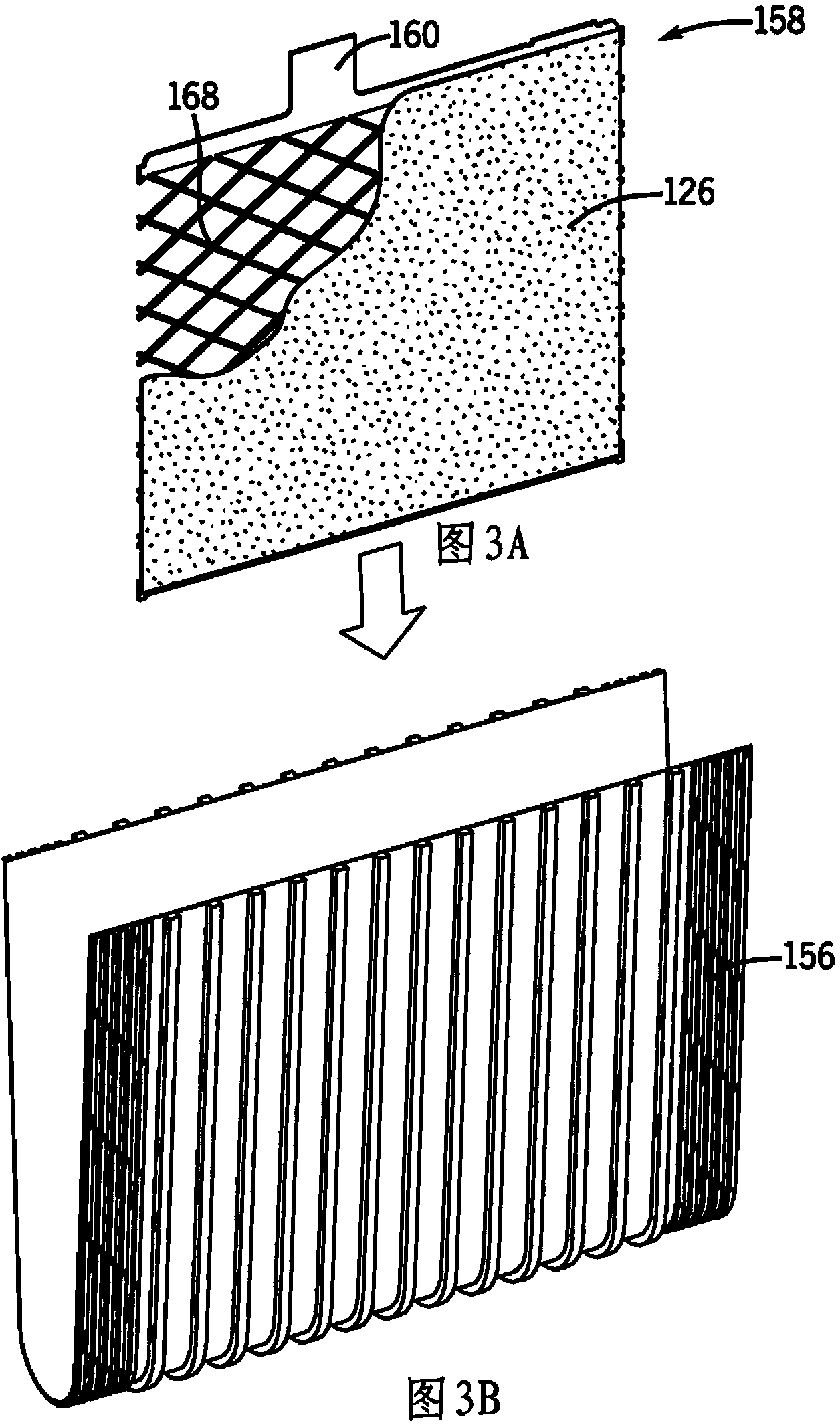

[0112] Exemplary examples of the degree of secondary deformation or corrosion resistance and their effects are given below.

[0113] Bare (uncoated) stamped battery grids formed from wrought lead are available. Fifty percent (50%) secondary deformation of the grid wires is provided on the stamped battery grid. That is, the deformation of the grid wire causes it to change fifty percent (50%) from its original stamped shape. Deformation is done by presses that change the shape and thickness of the segments of the grid wire. A secondary deformation of fifty percent corresponds to the resulting first accelerated corrosion rate or corrosion resistance. Note that the acceleration of the corrosion rate is relative to grid wires that do not undergo secondary deformation. A secondary deformation of thirty-five percent (35%) was also set and done according to the same general process. A secondary deformation of thirty-five percent corresponds to a resulting secondary corrosion resis...

Embodiment 2

[0127] The following examples illustrate hypothetical relationships between grid thickness and percent deformation or corrosion resistance. The percent deformation and the amount of corrosion resistance depend on the initial thickness of the grid.

[0128] In one embodiment, a grid having an initial grid wire thickness of 0.050 inches is subjected to 50% deformation of the grid wires resulting in a final thickness of the grid wires of 0.025 inches. A grid with an initial grid wire thickness of 0.075 inches was subjected to 50% deformation of the grid wires, resulting in a final thickness of the grid wires of approximately 0.038 inches. Likewise, a grid with an initial grid wire thickness of 0.050 inches is subjected to a 30% deformation of the grid wires to provide a final thickness of the grid wires of 0.035 inches, or to an 80% deformation of the grid wires to provide a final thickness of is 0.010 inches. A grid with an initial grid wire thickness of 0.075 inches was subje...

Embodiment 3

[0130] In one example of an embodiment, one or more of the battery grids has x voids. Each void is bounded by a continuous length of grid wire. In this example, the number of voids is less than x after the positive grid plate is expected to grow within the battery case.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com