Distribution type laser spot alloying method

A laser alloying and alloying technology, used in laser welding equipment, metal processing equipment, metal material coating technology and other directions, can solve serious problems such as tempering and softening crack tendency, improve the distribution shape and reduce stress accumulation , the effect of increasing the depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] A. The workpiece is controlled by the worktable and can move two-dimensionally along two mutually perpendicular directions in the horizontal plane. The laser beam is fixed and incident on the workpiece vertically from above the horizontal plane.

[0032] B. The workpiece is a cylinder. When it is placed on the worktable, its axis is in the horizontal direction and can rotate around its axis. The laser beam is fixed and incident on the surface of the workpiece vertically. After a circle around the axis is processed, the laser beam moves along The workpiece moves a certain distance in the direction of the axis to carry out the next round of machining around the axis.

[0033] C. The workpiece is a cylinder. When placed on the worktable, its axis is in the horizontal direction and can rotate continuously around its axis. The laser beam is incident on the surface of the workpiece vertically and moves at a uniform speed along the axis of the workpiece. Under the control of th...

Embodiment 1

[0035] Embodiment 1: the present invention is used for the method for strengthening grooved roll as follows:

[0036] 1) Clean the surface of the roll with gasoline, alcohol and other organic solvents until the surface is bright and free of rust;

[0037] 2) Prepare alloy powder according to the weight ratio of Fe:C:Si:B=(40~60):(5~10):(5~10):(1~3), put the prepared alloy powder into the delivery Powder device;

[0038] 3) Put the roll on the workbench, its axis is along the horizontal direction, and it can rotate around the axis;

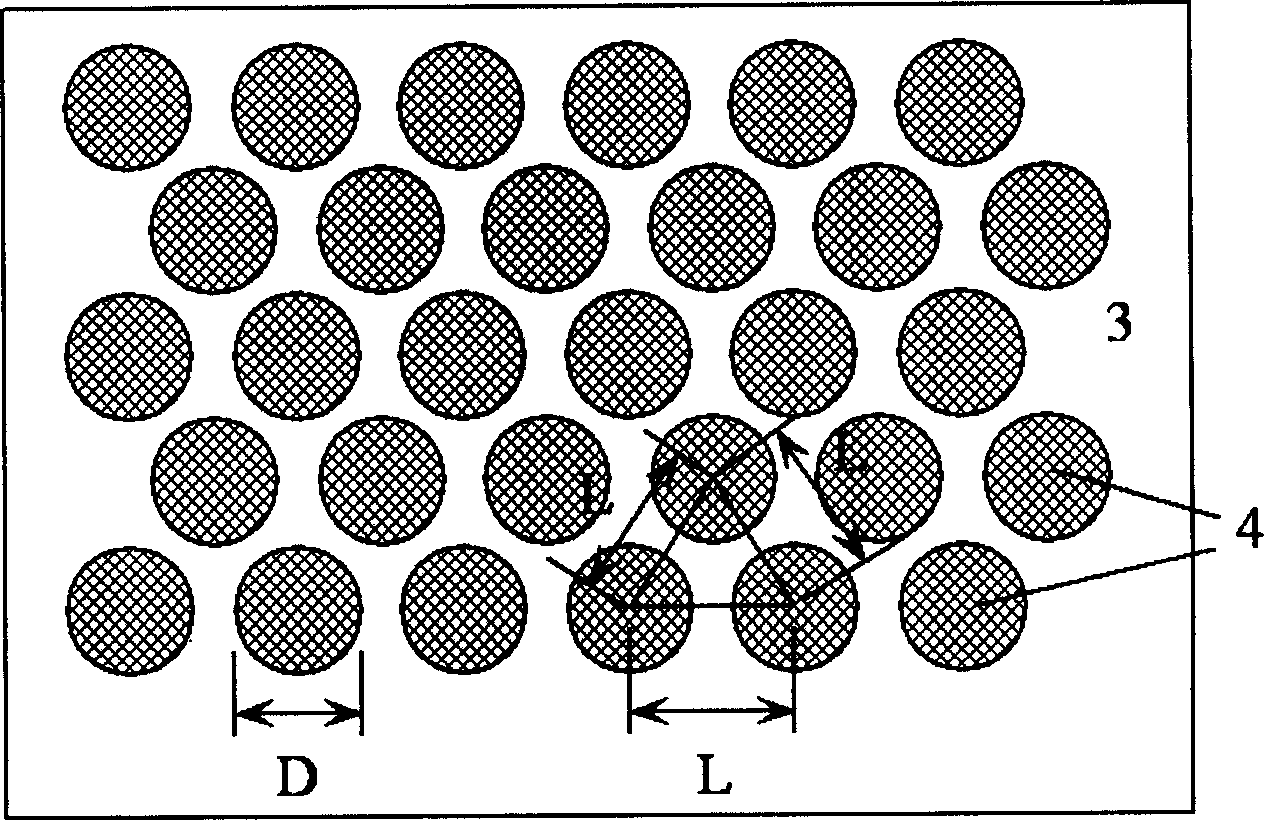

[0039] 4) Turn on the control system of the YAG laser and the powder feeder, adjust the direction of the laser beam so that the laser is vertically incident on the roll surface of the grooved roll, and use a pulse width τ of 0.1s and a power density of 10 7 W / cm 2 The laser processes the surface of the workpiece point by point, so that the laser action point produces a small hole effect, and the metal matrix and the powder fed in form a mixed mo...

Embodiment 2

[0042] Embodiment 2: the present invention is used for strengthening the method for nodular cast iron roll as follows:

[0043] 1) Clean the surface of the roll with gasoline, alcohol and other organic solvents until the surface is bright and free of rust;

[0044] 2) Prepare alloy powder according to the weight ratio of Fe:C:Si:B=(40~60):(5~10):(5~10):(1~3), and combine the prepared alloy powder with bonding After the agent is mixed, it is coated on the surface of the roll;

[0045] 3) After the coating is dry, place the roll on the workbench with its axis in the horizontal direction and rotate around the axis;

[0046] 4) Turn on the CO 2 The laser and its control system adjust the laser beam so that it is vertically incident on the surface of the roll, with a pulse width τ of 1.0s and a power density of 10 5 W / cm 2 The laser processes the surface of the workpiece point by point, so that the laser action point produces a small hole effect. The metal substrate and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com